In precision CNC machining services, micrometer level precision is the core pursuit, and hole quality is often the definitive factor determining the end use performance of the finished product. The critical process step in this area of work, rather than drilling, is high-precision reaming.

It will be detrimental to your projects to choose the wrong reamer and/or company.

This article will discuss how precision reamers can help you improve the quality of your custom CNC machining services and provide a systematic analysis framework that teaches you how to choose CNC machining manufacturers with the necessary specifications for high precision CNC machining.

In addition, we will let you know how JS Precision, with excellent skills in application using a world-class CNC machining tools, advanced CNC machining cost controls, as well as in-depth CNC machining cooperation, can become a trusted CNC machining supplier for your globally daunting tasks.

Key Answer Summary

| Decision-Making Core | Decision-Making Core | JS Precision's Solutions |

| Tool and Process Matching | Believing that "reamers are only for finishing drills," ignoring the decisive influence of their materials, coatings, and geometry on final accuracy and surface finish. | We offer reamer selection and process parameter optimization based on workpiece material, hole diameter tolerances, and surface requirements to ensure optimal hole quality. |

| Manufacturer Evaluation Criteri | Judging capabilities solely by equipment lists or quotations ignores the actual depth of their quality system, engineering support, and process control. | We demonstrate a complete AS9100/IATF 16949 quality process and provide a full data chain from DFM to FAIR, proving their systematic capabilities in high precision CNC machining. |

| Comprehensive Value Acquisition | We address the difficult trade-offs between CNC machining costs for prototype parts and mass production, and between local and overseas suppliers. | Leveraging the agile supply chain and economies of scale of Chinese manufacturing, we provide a one-stop precision CNC machining services, from rapid prototyping to stable batch production, offering top-tier precision and competitive CNC machining cost. |

Key Takeaways:

- Precision reamers are the "finishing touch" in CNC machining, directly influencing hole dimensional accuracy, cylindricity, and surface integrity.

- While assessing any CNC machining manufacturer, we need to focus on hardware aspects along with a look into the quality management system and how engineering collaboration is performed.

- Difficult-to-machine materials, like high-temperature alloys, require CNC machining tools and process strategies that are specifically designed for them, conventional methods can only result in rapid tool failure.

- The effectiveness of cost control in prototyping is contributed by design optimization, process simulation, and involvement of suppliers at an early stage.

- This means that the biggest Chinese makers, such as JS Precision, can deliver small batches of complicated parts seamlessly, they are able to serve customers locally while being cost-competitive globally.

Why Choose JS Precision? To Achieve High Tolerances In Precision CNC Machining

Excellence is the only option when it comes to the field of high-tolerance precision CNC machining. As clarified by the very core requirements of the ISO 9001:2015 quality management system, stable high-precision output depends on end-to-end process control.

Among customers in aerospace, medicine, and industry, JS Precision enjoys their trust because we meet the tolerance requirements but also set a different standard for them.

Our performance speaks for itself: with a consistent delivery of parts having linear tolerances given correctly as ±0.0125mm and critical feature geometric tolerances less than 0.01mm, we always strive to exceed industry standards.

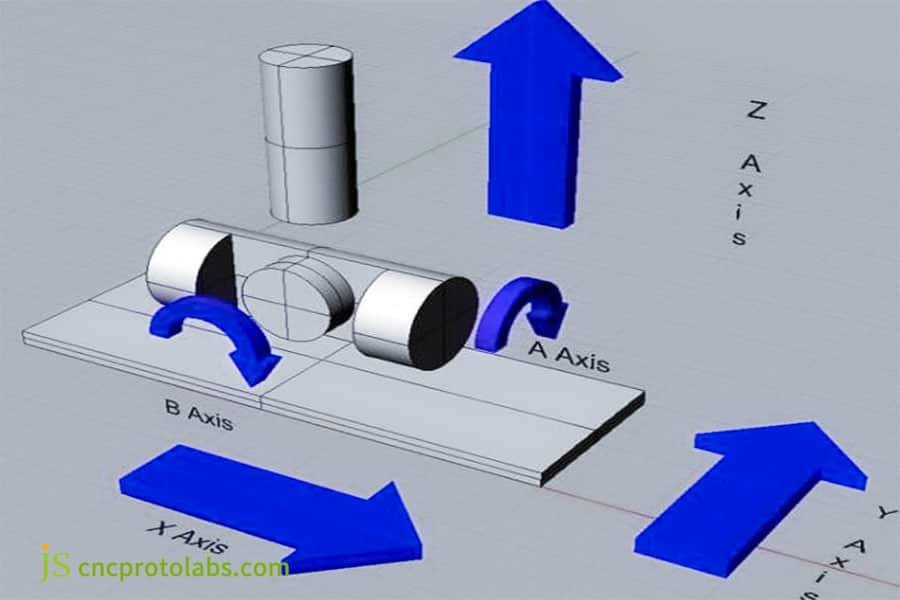

The core value added is delivered by offering comprehensive high-precision CNC machining solutions. We combine state-of-the-art five-axis CNC machining centers with tight process control, including in-machine probe inspection and real-time data monitoring, to completely eliminate machining deviations.

Our engineering team will execute designs, but also work with you to optimize the manufacturability of those designs, ensuring that even the most complex geometries are produced efficiently and accurately.

While some competitors brag solely about the quality of their equipment, we prefer to use results to tell the story of our strengths-for example, shaving 70% off of an aerospace customer's machining cycle times while tripling its accuracy.

When extreme accuracy and reliability are demanded by your project, JS Precision will not be an option but a guarantee of success.

Interested in how JS Precision provides the high tolerance for your parts? Upload your part drawings now for a free DFM analysis and an accurate quote, so we can take your design and turn it into a precision manufacturing reality.

Beyond The Drill: How Precision Reamers Elevate Your Custom CNC Machining Services

In CNC machining, the reamers available are the major tools for enhancing hole quality. Drilling acts as the first step in creating the hole, but reamers determine the size of the hole in terms of dimensions, surface quality, and geometric parameters.

Full Analysis of Reamer Types: Reamers

- Solid Carbide: Very rigid with high accuracy, ideal for precision CNC machining services.

- Indexable Insert Reamers: High cost-effective ratio for heavy-duty machining in large diameters.

- Special Purpose Reamers: For hard-to-machine materials, which demand certain specialty coating or shapes, represent core CNC machining tools.

| Application Scenarios | Recommended Reamer Types | Core Advantages |

| High-Tolerance Precision Machining | Solid Carbide Reamers | High rigidity, high precision |

| Large-Diameter Batch Machining | Indexable Insert Reamers | High cost-performance ratio, convenient tool changing |

| Machining of Difficult-to-Cut Materials | Specially Coated Reamers | Good wear resistance, strong adaptability |

Subtle Influence of Geometric Parameters: Inclination Angle, Chamfer Angle, and Chip Grooves

Reamer geometric parameters have a prominent effect: Inclination angle has a pronounced effect on the quality of the surface produced, chamfer angle is closely related to the centralization effect as well as the axial force component, and the design of the groove and the quality of the polish are crucial in preventing scratch defects on the sidewall in the machining of deep holes in hard materials.

Process Strategy: Synergy of Speed, Feed, and Coolant

Unlike drilling, reaming requires lower cutting speeds and feed rates to ensure accuracy. The high-pressure precision internal cooling system is indispensable, which can cool cutting edges, flush chips, ensure consistent dimensions and excellent smoothness, and is a key process guarantee for precision CNC machining services.

Figure 1 Reamer brings together the best of precision, efficiency, and cost-effectiveness, making it an indispensable asset for any serious CNC machining operation.

How To Determine The CNC Machining Manufacturer For High Tolerance Projects?

While selecting a CNC machining manufacturer for tolerance-intensive projects, it is important to move ahead of the marketing material and evaluate the ability and quality that the company provides. A high precision CNC machining company does not only provide high technology but a quality mindset.

Capability Audit: From Machine List to Process Control Documents

The equipment list may be quite impressive, and it can be verified by examining First Articles Inspections and Cpk/PPK histories of similar tolerance jobs, which are fundamental proof of their capabilities on this level of compliance, and this information can be expected from a reliable supplier.

In-Depth Engineering Dialogue: DFM as a Touchstone

Design for Manufacturability (DFM) is essential in assessing the competence of the manufacturer. A superior CNC machining manufacturer will be able to offer optimization solutions in terms of data analysis for the design details, not supporting the design without conditions can be perceived as lacking the ability to identify problems.

True Penetration of the Quality System

Comprehend a deep level of information regarding the quality management system of the manufacturer. Ask them about how they manage the lifetime of tools, the regular accuracy compensation of machine tools, and how they tackle the uncertainty of measurement equipment calibration.

This information is a direct reflection of the extent of quality culture and is the only assurance of quality product supply.

Figure 2 Implement comprehensive quality control measures throughout the entire manufacturing process.

Material Selection For High-Temperature Precision CNC Machining Services

The selection of materials and machining strategies should be synergistically matched in high-temperature, high-strength environments. Due to the different machining challenges with each high-temperature material, precision CNC machining services require experience.

High-Temperature Alloy Challenges and Solutions: Inconel, Hastelloy

The machining of Inconel and Hastelloy-high-temperature alloys with tendencies to harden and poor thermal conductivity-is very tough. Machining should be done with sharp cutting edges, rigid clamping, low speeds, high-pressure cooling, and a specialized CNC machining tool like AlTiN-based coatings.

Balancing the Art of High-Performance Aluminum and Titanium Alloys

For 7075-T6 aluminum alloy materials, eliminate the built-up edge, for TC4 titanium alloys, prevent the high-temperature phase transformation. Optimization of cutting parameters and cooling methods is adopted in order to realize a balance between quality and efficiency during precision CNC machining services.

Advanced Composite Materials: Delamination, Burr Formation to be Avoided

Carbon fiber reinforced polymer (CFRP) is prone to delamination and pilling during processing, requiring the use of a multi blade diamond coated specialized reamer to ensure smooth fiber cutting and guarantee hole wall quality.

Do you have high-temperature materials or materials which are difficult to machine? We can discuss your material specifications and applications, then customize a precision CNC machining services which will guarantee efficiency and quality.

Effective Strategies To Optimize CNC Machining Cost For Prototype Parts

The main purpose of the prototyping phase is to check the design as quickly as possible. Specific approaches may cut down on the CNC machining cost and at the same time focus on functionality to avoid unnecessary spending.

Design Simplification and Feature De-positioning

Simplifying non-critical features such as chamfers and very low-dimensional tolerance features by de-positioning or splitting hard-to-machine features such as small internal threads directly improves machinability and reduces the cost of CNC machining without influencing the process of design verification.

Material & Process "Downgrade" Selection

The functional testing prototypes can make use of machinable alternative materials like 6061 Aluminum Alloy in place of 7075 Aluminum Alloy, relax the requirements on the surfaces that do not interface, eliminate polishing activities which consume a lot of time, etc.

Standardization and Modularization Used

Giving priority to the utilization of manufacturer-standard blanks and tooling helps the manufacturer avoid totally customized solutions. It allows them to spread fixed costs, thereby reducing prototype CNC machining cost substantially.

Need to save money on prototypes without giving up performance? Have your prototype design reviewed by our team free of charge, and we'll help you optimize its cost to lower the CNC machining cost without compromising testing objectives.

The Viability Of Custom CNC Machining Services For Small-Batch Complex Parts

"Small batches, multiple varieties, and high complexity" is the core scenario of custom CNC machining services. Driven by FMS and advanced programming technologies, JS Precision and many other manufacturers have reached a high level of efficiency at a reasonable cost in small-batch production.

Batch flexibility of five-axis machining

Five-axis CNC machining centers can complete multi-faceted machining in one setup without the need for many setups and specialized fixtures. Even for small orders, between 1-10 pieces, they offer both precision and cost advantages in the machining of complex geometries.

Automation and rapid changeover

The tool magazine and automated worktable exchange make rapid changeovers and continuous machining possible. This helps in reducing non-cutting downtime in small batch production and ensures timely delivery and effective cost management in custom CNC machining services.

Digital procedures provide quality consistency

Digital twin simulation and CAM templates from digital procedures comply with ISO 230-4:2022 standards and provide process consistency for small-batch orders with no human error and process stability similar to large-batch production.

Require reliable quality and short leads in short runs of difficult-to-manufacture components? Get in touch with us and explore how flexible manufacturing options can deliver cost-efficient outcomes for custom CNC machining services.

Figure 3 Five axis CNC machining can process extremely complex parts from almost any angle, especially suitable for precision molds produced in small batches.

Case Study: A 70% Cycle Time Reduction In Aerospace Actuator Housing

Challenge

There was a demand from an aerospace firm for five sets of high precision bearing holes in an aluminum alloy actuator housing with an accuracy requirement of ±0.008mm with a coaxiality specification of 0.015mm.

However, due to the machining sequence carried out by the existing supplier, the datum error was further added, thereby increasing the specification for coaxiality to 0.02mm, along with the pass percentage being less than 85%, with the processing time being 35 hours for individual processing.

JS Precision’s Solution

Process Restructuring: While rejecting the five-axis machining sequence process, we switched to five-axis simultaneous machining. Using this process, all structural machining and hole systems machining could be accomplished in one setup without any errors related to conversion of datum.

Tool Optimization: We developed micron-level precision solid carbide reamer tools for the critical hole machining process and optimized cutting parameters and cooling systems to extend tool life and improve machining accuracy.

Online Monitoring: The in-machine inspection is done using an in-machine probe to carry out the reference inspection and compensation on the machine. This will help it compensate even minute changes on the fly.

Result:

The coaxiality level for critical hole systems improved from an accuracy of 0.02 mm to 0.006 mm, with the yield rate rising to 99.8%, while the machining time of one-off machining was reduced from 35 hours to 10 hours, improving the efficiency level by 70%. This not only ensured the reliability requirements but reduced the cost for customers by several thousand dollars.

Do your complex components have the same machining challenges? Get in touch to book a free consultation with our engineers. We're happy to show you where we can improve your process, accuracy, and cycle time—just like we did for this aerospace company.

Figure 4 detail overview actuator housing

What To Expect For Prototype And Production Lead Times From a Professional CNC Machining Manufacturer?

Accurate delivery schedules are part of project planning. A good CNC machining supplier should offer accurate delivery schedules that help to counteract the chances of delay.

Rapid Prototyping Process (Normally 5-10 days)

The prototype delivery time is 5-10 working days, including engineering review, programming, processing, and testing. A dedicated "fast track" and standardized process are key to rapid delivery.

Small Batch Production Lead Time (Normally 2-5 Weeks)

Small batch production lead time is within 2 to 5 weeks. This will involve preparation of tools, machining, complete inspection, and surface treatment. The higher the part complexity and volume, the higher the lead time.

Variables Affecting Lead Time: Communication and Complexity

Lead time will be dominated by two factors: the quality of design documentation and the feedback rate (reduction of internal communication overhead), and geometric and tolerance complexity of components - complex components take more time to machine.

Your Project, Our Promise: A Partnership Built On Precision And Reliability

Choosing JS Precision means embarking on a collaborative journey centered around your success. We offer a full process service system that covers prototyping, small batch, and high tolerance machining, catering to various needs of custom CNC machining services.

Total Ownership from Consultation through Delivery

There is a project manager and engineering staff responsible for the total process, from quote through delivery. There is a one-contact-person system for efficient communication.

Data-Driven Quality Commitment

Quality information package with all relevant documents (inspection documents, material certificates, process documents) is supplied along with the supplied parts to enable traceability regarding quality parameters.

Continuing Improvement Partnership Model

Based on projects which form the foundation for long-term partnership, we have deduced learnings post-project delivery and recommended improvements in design for ease of production in the finished product.

FAQs

Q1: What is the primary difference between reaming and boring?

Reamer is a size forming tool specifically designed to improve the dimensional accuracy and surface smoothness of existing holes. It has high machining accuracy but low adjustment flexibility. Boring tools are size correction tools that can adjust the position and size of offset correction holes, providing greater flexibility and a wider range of applications.

Q2: How to choose a reamer for stainless steel parts?

The carbide reamers to be selected should have sharp cutting edges and large rake angles. The coating of TiAlN or diamond is preferred to enhance the improvement of wear resistance. Due care should be taken to ensure adequate coolant supply to overcome the sticking characteristic and work hardening of stainless steel to ensure quality machining.

Q3: What can tolerances be with high-precision CNC machining?

When it comes to medium-sized metal components, the best CNC machining companies are capable of providing linear tolerance within ±0.0125mm to ±0.025mm. Geometric tolerance of the critical features can be held to a value of 0.01mm, which can satisfy the precise requirements of high-end sectors.

Q4: What’s the largest cost driver in CNC machining of high-temperature alloys?

The chief cause here is the cost of tooling. The high-temperature alloys used result in very rapid wear of the tools. In addition to this, higher speed of machining will result in poor machining quality. This leads to the need for lower cutting parameters, resulting in higher machining time. As a result, the total costs are increased.

Q5: What would be the most effective design recommendation to minimize cost in the prototyping phase?

Avoid the presence of deep cavities, small internal corner radii, or ribs that have very high aspect ratios as much as possible. These increase machining difficulties, enhance machining times, contribute to high tool wear rates, and are the major factors that contribute to increased costs regarding prototyping. Just by avoiding these factors, costs can be significantly reduced.

Q6: What are the main advantages of machining small batches (e.g., 10-100 pieces) of complex parts in China?

The core advantage is the best cost-effectiveness. We can achieve flexible small-batch production, with near-mass production precision, relying on extensive machining experience, and enjoy highly competitive unit prices that balance the requirements of quality and cost.

Q7: Do you provide material certification and traceability documentation?

Yes. We give complete MTCs and traceable batch numbers for all aerospace, medical, and critical industrial components. Every lot of parts is fully traceable, assuring compliance and quality reliability.

Q8: What is the basic process from inquiry to delivery when working with JS Precision?

Clearly and efficiently four-step process: submitting drawings online for quote and DFM feedback, confirming the order and locking in production scheduling, full-process visual tracking of production and quality inspection progress, secure packaging, and delivery with complete quality documentation.

Summary

In precision manufacturing, the devil is always in the details, where the difference between success or failure rests on the subtlety of selecting reamers or understanding the quality system implemented by the manufacturer.

Within the international manufacturing arena, China's premier precision CNC machining services company has a profound integration of technology depth, cost competitiveness, and collaborative technology capabilities that enable the company to offer you unparalleled options that go beyond territorial constraints.

JS Precision represents the ideal fulfillment of this tenet. On one hand, we not only have the technical capabilities to accomplish the aim of high precision CNC machining by utilizing various CNC machining tools effectively, but we have developed a dependable collaboration system focused on customer success.

It's time to bring your blueprints to life.

Now is the time for you to upload your part drawings to the JS Precision website. Not only will you receive a highly competitive CNC machining cost estimate, but you will also receive a free "Manufacturability and Process Optimization Proposal Report" tailored by our engineering team for you.

Let us collaborate to infuse your innovations with exemplary reliability through our precision processes.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com