CNC machine tools are changing the implementation of complex designs. If you have to mass produce 1000 gears with a tolerance of ±0.005mm or simply turn cylindrical shafts, you might encounter some level of difficulty in choosing between CNC machine tools and Lathes. Sometimes, poor choices can result in increasing expenditure and time wastage.

This guide will define the differences between the key characteristics of CNC machining and lathe tool characteristics and discusses how CNC machining China is the best choice for economical precision machining based on these differences.

When you finish reading the article, you will know which technology is needed for the geometry, tolerance level, and budget in your components and the way of smooth cooperation with professional partners to turn drawings into qualified products.

Key Answers Summary

| Key Questions | Key Answers | Value for You |

| Essential Differences? | CNC machining tools handle complex geometry, lathes machine simple rotating bodies. | Do not get confused and make it clear in which direction you should go with your project. |

| How to Choose? | For complex, multi-process, high-precision parts, choose CNC, for simple parts and small batches, choose lathes. | Get a decision-making framework for the optimization of investment and processes. |

| Why choose CNC Machining China? | With advanced equipment integrated and economy of scale, it reduces CNC machining center price by 20%-40%. | Balanced quality and price, it is suitable for projects like CNC machine for automotive parts. |

| Key conclusions? | Selection should consider part characteristics. CNC technology dominates modern manufacturing, and China's supply chain has significant advantages. | It establishes a holistic understanding to support strategic decision-making. |

Key Takeaways:

- Technological Determinism: The choice depends on the geometric shape of the part (complex vs. rotating body), tolerance requirements (± 0.005mm vs. ± 0.05mm), and production volume.

- CNC Dominates Modern Manufacturing: In the CNC machining and manufacturing paradigm, CNC provides unparalleled repeatability, flexibility, and integration.

- Dynamic Cost Assessment: For complicated components, the overall cost per unit could be less for the CNC system, the cost barrier for lathes is lower.

- Strategic Value of the China Supply Chain: For projects seeking both top-tier equipment and cost advantages, CNC machining China is a mature choice.

Why Refer To This Guide? Because Of JS Precision's CNC Machining Services

This guide is not merely conceptual, rather, it has over 15+ years of business experiences of JS Precision in catering to the CNC machining needs of customers in the automotive, aerospace, and medical industries.

We accomplished over 10,000 precision engineering projects. An example project is the optimization project for the production line of turbocharger housings for an automotive parts supplier with 5-axis CNC machines.

The completion time for single-part machinings was reduced from 45 minutes to 16 minutes, the efficiency gain was 65% with a boost in the yield rate from 85% to 99.5%, thus benefiting our client with over $2 million per year savings.

Our range of services fully satisfies the standards of ISO 9001:2015 and IATF 16949. In addition, every machine is equipped with Hexagonal Coordinate Measuring Machine to provide accuracy in processes to international standards.

We have expertise in CNC machining and manufacturing. We have provided customized machining solutions for aerospace clients, with machining precision of ±0.002mm, and injection mold component manufacturing for medical clients, with cost reduction of 30%-50%.

JS Precision possesses more than 20 imported 5-axis CNC machining centers and is staffed by a professional team of programming and process engineers.

What distinguishes us is the combination of depth of technical capabilities with practical experience: we offer not only the service of machining itself but take active efforts in design optimization, production risk mitigation, and accurate addressing of your manufacturing pains.

If you are looking for a reliable partner to validate processes and optimize costs, contact JS Precision. Provide your part drawings and requirements, and our engineers will offer a free feasibility analysis to help you avoid potential losses.

What Does CNC Machining Stand For?

CNC machining is the heart of modern precision manufacturing. Many people wonder, "What does CNC machining stand for?" Mastering its principles is the foundation of using CNC machining tools effectively.

Full Name and Core of CNC

CNC means Computer Numerical Control. It is the controller of machine tools with pre-programmed G-code and converts digital drawing into solid parts. Its automation completely eliminates human error, so batch precision will be consistent.

From Digital to Solid: The CNC Workflow

- CAD Design: Creation of 3D models with tolerance using SolidWorks.

- CAM Programming: Conversion to machine tool code and optimal tool path generation.

- Post-processing: Accommodation to CNC machining centers and modification.

- Machine Tool Execution: Machining in accordance with the program to create the final product.

The Fundamental Difference Between CNC Machining and Traditional Machining

CNC machining has significant advantages: it can be automatically monitored 24 hours a day, while traditional methods require full manual labor. Consistency reaches CPK>1.33, traditionally relying on operator skills; Support five axis linkage, traditional difficult to handle complex parts.

Want to discover how the process of CNC machining could radically change the face of production in your business? Would you like to get a copy of our free white paper entitled "CNC Machining and Manufacturing Best Practices"?

How To Compare CNC Machining Tools And Lathe Tools?

As a summary, the choice between the CNC machining tools and lathes is all about knowing the requirements for the parts. For you to make a rapid decision, I will give you a comparison using the dimensions below.

CNC Machining Tool Family: Milling Machines, Machining Centers, and Multi-Function Integrated Machines

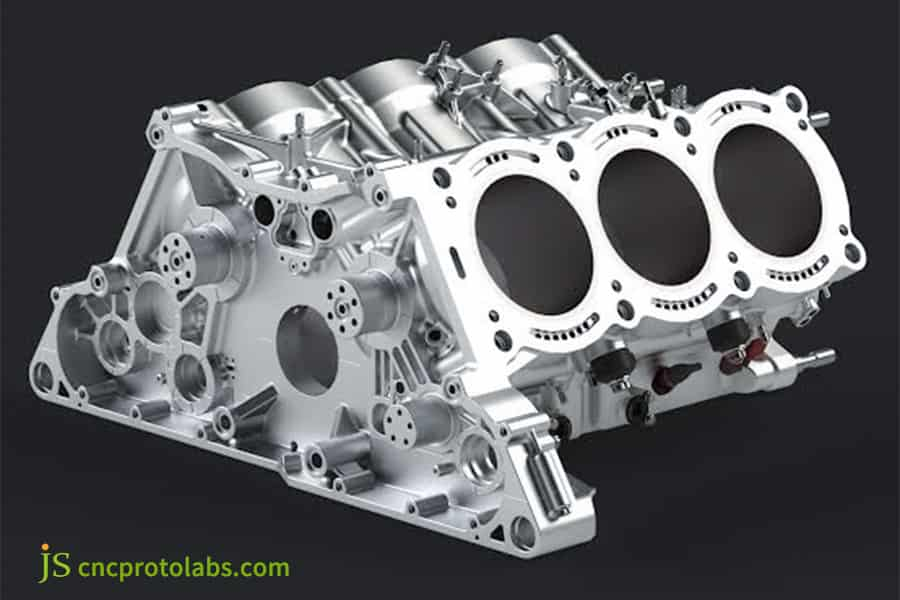

These include milling machines and machining centers, in which rotary cutting tools and multi-axis movement of the object to be machined enable multi-facetted machining.

Lathe Core Tools: The King of Rotary Body Machining

Workpiece rotation, tool fixed cutting, proficient in rotating parts such as shafts, manual, semi-automatic, CNC type, with initial investment much lower than CNC machining centers.

Key Performance Comparison Table (4D)

| Performance Indicators | CNC Machining Tools | Lathe Tools | Applicable Scenarios (Supplementary) |

| Automation Level | Fully Automatic (24-hour continuous operation) | Semi-automatic/Manual | CNC is preferred for mass production. |

| Precision Tolerance | ±0.005 mm | ±0.02-0.05 mm | CNC is essential for precision parts. |

| Flexibility | High (quick changeover for different parts) | Low (only suitable for rotating parts) | CNC is preferred for multi-variety, small-batch production. |

| Initial Investment | $50,000-$500,000+ | $50,000-$500,000+ | Lathes are preferred for limited budgets and simple parts. |

| Material Compatibility | Wide (titanium alloys, aluminum alloys, steel, plastics) | Relatively Limited (more suitable for soft metals). | CNC Machining Tools for Cycle-Sensitive Projects |

| Complex Part Turnaround Time | 20-60 minutes/piece | 60-180 minutes/piece | CNC Machining Tools for Cycle-Sensitive Projects |

Selection Guide: Project Needs Driven Decisions

Choose CNC machining tools for complex 3D parts, multiple processes, and ± 0.005mm tolerances. Simple rotary body, small batch, budget priority lathe.

- If the part has a complex three-dimensional contour, requires multi process integrated machining, or has a tolerance requirement of ± 0.005 millimeters, CNC machining tools are preferred.

- If the part is a simple rotating body, only requires prototyping or small batch production, or budget is the core constraint, choosing lathe tools is more cost-effective.

Why Are CNC Machining Centers The Backbone Of Complex Projects?

These projects look at CNC machining centers as a central part of their operation and have made machine centers indispensable within high-end manufacturing as a result of developments and improvements.

Machining Center Definition

It is capable of milling, drilling, and tapping with its Automatic Tool Change function, allowing multiple processes to be completed simultaneously with just one clamping position.

Comparison with Traditional Machines

Single clamping helps in eliminating errors in cumulative positioning and provides positioning accuracy of ±0.003mm. Changing tools through ATC takes only 0.5 – 2 seconds, and non-cutting time reduces by 40%.

- Less clamping time: Finishes all Machining in a single clamping position in less time compared to other machines.

- Enhanced accuracy: The positioning accuracy is given as ±0.003 mm, while the repeatability is stated as ±0.001 mm.

- Increased production efficiency: Automatic tool changer system tool changing time is only 0.5-2 seconds, reducing non-cutting time by 40%.

Practical Case: CNC Manufacturing of Automotive Turbocharger Housings

Challenge: A leading automotive supplier needs to produce turbocharger housings. Turbulence passages of the components involve complex curves with a tolerance of ±0.03 mm. Conventional methods involve 4 machines and 3 clamping points with a scrap rate of 15% and a single piece production time of 45 minutes, which is not sufficient for mass production.

Solution: JS Precision uses a 5-axis CNC machining center with a high-pressure cooling system. Complete the machining of all shapes, hole systems, and flow channels in one clamping operation.

Results: The scraps percentage reduced to 0.5%, the time reduced to 16 minutes, productivity increased by 181% primarily, and the accuracy of the flow channel fully complied with the standards of ISO 13485 to facilitate successful entry into the international market by the customers.

Who Should Consider CNC Machines For Automotive Parts Manufacturing?

There is a high precision requirement in the automotive industry, leading to CNC machine for automotive parts becoming the preferred selection for the manufacturer.

The tough demands of the automobile production industry: The key component tolerance is required to be ±0.01 mm, stable at high and low temperatures, with a production capability of over 100,000 units per year for each production model.

Typical automotive parts machined by CNC: Including basic auto parts like cylinder heads of auto engines, brake calipers, and gears.

Role of Lathes in the Automotive Supply Chain: Lathes have remained an essential part of the automotive supply chain, mainly for machining simple rotary components such as bolts, nuts, and drive shafts. Lathes can be coupled with CNC machining because of their lower capital costs and ability to mass-produce simple components efficiently.

IATF 16949 certification is an essential qualification for automotive parts manufacturing, and JS Precision's CNC machining centers fully comply with this standard.If you are involved in automotive parts production, consider obtaining a free cost quote from JS Precision to explore potential cost reductions of 20%-30%.

What Role Does CNC Play In Modern Manufacturing Ecosystems?

Industry 4.0 technology, CNC machining and manufacturing constitute the nucleus of smart factories, thus establishing the connection between the digital world and the physical world.

The Central Hub of Smart Manufacturing

The integration of CNC systems with MES or ERP functionality allows for data tracking and intelligent quality control. This results in 30% less downtime. Below is a comparison of equipment intelligent integration efficiency:

| Equipment Type | MES System Integration | Data Traceability Accuracy | Overall Equipment Effectiveness (OEE) | Fault Response Time | Batch Production Consistency (CPK Value) |

| 5-Axis CNC Machining Centers | 95%+ | Single Operation/Single Piece | 82%-88% | ≤5 minutes | ≥1.67 |

| 3-Axis CNC Milling Machine | 85%-90% | Single Operation | 75%-80% | ≤8 minutes | 1.33-1.67 |

| CNC Lathe | 80%-85% | Single Piece | 78%-83% | ≤6 minutes | 1.50-1.80 |

| Conventional Lathe | ≤30% | No Precise Traceability | 55%-65% | ≥20 minutes | 0.80-1.00 |

| Traditional Milling Machine | ≤20% | No Precise Traceability | 50%-60% | ≥15 minutes | 0.70-0.90 |

As is clear from the data, the intelligent integration of CNC machines is far superior to conventional machines in terms of production stability, which has made it the heart of the current production trend in the industry.

The CNC machining can reach the ppm-level defect rate control by program control and real-time detection.

Evolution of Traditional Tools

Contemporary CNC lathes and milling machines have been combined with auto configurations, like robotic loading and unloading devices, and are now an integral part of flexible manufacturing systems. Not only this, but this development will also ensure that traditional tools are no longer restricted to a single process. They will now better meet the requirements of intelligent production lines.

Want to know how to integrate CNC machining into your smart factory? Contact JS Precision with the note "Intelligent Integration" to receive a personalized "CNC Machining and Manufacturing Integration Guide" and master step-by-step implementation techniques.

How To Evaluate CNC Machining Center Price And Value In China?

CNC machining China are very cost-effective. They also represent an ideal global supply chain. We will now help you scientifically evaluate their cost effectiveness.

Industry Clustering Benefits: As the supply chain in Shenzhen, Suzhou, and other regions of China has developed considerably, economies of scale have led to lower production costs.

Price Composition Analysis: The CNC machining center price is up to 40% less expensive compared to the West due to advantages in terms of cost of labor, equipment, and logistics.

Key to Quality Assurance: In procurement, check the ISO 9001/IATF 16949 qualifications and the configuration of imported five-axis machines and coordinate measuring machines.

Maximizing ROI: Collaborating with CNC machining China suppliers such as JS Precision can achieve multiple values: compressing production costs without compromising quality. Relying on advanced equipment to handle complex processing projects; Using mature supply chain management to shorten delivery cycles.

Case Study: JS Precision Uses Five Axis CNC To Save The Crisis Of Racing Parts Suppliers

A top-class racing wheel manufacturer was facing production challenges. The two-stage process of "CNC lathe + 3-axis milling machine" had a scrap rate of up to 5%, a unit production time of 47 minutes, and could not fulfill order requirements during the prime seasons of the racing competition.

Core Challenge

There are three major bottlenecks in this process:

- Two clamping leads to a cumulative positional error of ±0.1 mm, which is incapable of satisfying the standard of parts for racing.

- The turnaround time from process to process and clamping/positioning takes up 30% of the total time.

- The production capability per month is just 450 pieces, which makes it difficult to cope with the rush order of 1000 pieces a month.

- The total cost of scrap + rework makes the single piece cost reach $45.

JS Precision's Solution

JS Precision didn't just replace the equipment but rebuilt the complete process. Solution details and data are as under:

1. Equipment Upgrade and Fixture Customization:

A German DMG MORI 50 5-axis vertical CNC machining center was adopted, and self-developed pneumatic precision fixture was utilized. Repeatability is ±0.003 mm, which can complete the whole process without second accession and avoid the error that may happen during secondary accession.

2. Optimization of Tool and Cutting Parameter:

In the case of 6061 aluminum alloy, 12 mm PCD inserts were used to conduct face turning at a linear speed of 800 m/min with feed rate 0.2 mm/rpm. For side milling and drilling, carbide coating tools are used. Dynamic milling strategy allows up to 3.5 mm depth of cut and results in efficiency enhancement by 60%.

3. Programming and Cooling Optimization:

Five-axis linkage optimizes the toolpath to make the tool side edge tangent to the curved surface while side milling, reducing the cutting force by 40%. Meanwhile, the 70-bar high-pressure internal cooling system cools at 25 liters/minute flow rate, keeping the aluminum alloy from sticking or generating a built-up edge, thereby increasing tool life 2.5 times.

Quantitative Results:

Significantly positive results were observed after the implementation of the new solution:

- Single-piece cycle time reduced from 47 to 22 minutes, an increase in machining efficiency by 113%.

- Monthly production capacity grew from 450 pieces to 1440 pieces, output increased by 220%.

- Scrap rate reduced from 5% to 0.2%, with almost zero reworks.

- Single-piece cost reduced to $29, which came out to be a 35% cost-saving, and the new investment is recoverable within 4 months.

If you are facing efficiency or quality bottlenecks, schedule a free consultation with a JS Precision engineer. We will customize a CNC machining solution specifically for you.

How To Make The Final Decision: Choosing The Right Machining Solution For Your Project

Still, the choice of CNC machining tools/lathes involves the integration of technological and business considerations. To make the best decisions, follow these three steps:

Step 1: Define Project Success Criteria

The important aspects to be defined: Is precision more important than price? Is the number of pieces being manufactured 100 units, or is it 100,000 units? Is it a complex shape in 3D space or simply a rotary shape?

Step 2: Assess Supplier Capabilities

The next The key risk associated with supplier selection is competency. The criteria emphasize on: Engineering support, quality control, project management competencies, which align with cost reduction, quality control, and stable delivery time, respectively.

Step 3: Initiate a Professional Inquiry

During inquiries with suppliers, one should be ready with required documents like 3D CAD drawings with tolerance marks, material details (like 6061 Aluminum alloy & Titanium alloy Ti6-Al4V), requirement for capacity for manufacture, and cycle time for delivery.

JS Precision engineers will provide a comprehensive solution covering process optimization, cost analysis, and risk assessment based on this information.

FAQs

Q1: For a simple shaft part, should I choose a CNC lathe or a conventional lathe?

For IT7 and above or for production work where a high degree of accuracy is required, a CNC lathe ensures reproducibility of parts produced. When only one unit is to be manufactured with a lesser degree of accuracy required, a conventional lathe would be more economical.

Q2: Are the startup costs (programming, fixtures) for CNC machining high?

There are costs involved in setting up, but the cost is evened out in the production of each item. When it comes to complicated parts, the advantage of not having to rework the material later on is way beyond the setup cost.

Q3: Can CNC machine all the materials that a lathe can machine?

Yes, CNC can process all such materials that are processed by lathes, and even difficult-to-cut materials like titanium alloys also can have better handling in the CNC process owing to its controllable parameters and sophisticated cooling system.

Q4: Which is more suitable for small-batch production (e.g., 50 pieces)?

Where simpler components are concerned, the lathe machine takes less time and costs less, for complex components, even for small batch production, the advantage of precision of CNC machine outshines rework loss.

Q5: How do I determine if my design requires 5-axis CNC machining?

For situations where there may be multiple surfaces to be machined that are not orthogonal, or situations where multi-face machining needs to be done in one setup to prevent the addition of errors, 5-axis CNC machining must be done.

Q6: Is the delivery time reliable when choosing a Chinese CNC supplier?

The availability of genuine Chinese Suppliers, transparent about their delivery schedules, is taken care of by JS Precision, which delivers 98% of the orders on time and manages their projects effectively.

Q7: What exactly does "precision" in CNC machining centers refer to?

Positional accuracy (for example, ±0.003 mm), repeatability (for example, ±0.001 mm), and contour accuracy would be considered. The assembly function and longevity of the components would be established by this.

Q8: Can the quality of CNC machining China truly rival that of local suppliers?

Chinese industry leaders employ globally harmonized equipment and quality management processes (e.g., IATF16949). JS Precision's products are of equal quality to local manufacturers, and much lower in price.

Summary

Decisions on choosing between CNC machining tools and lathes depend on project parameters and business requirements. When it comes to complex batch production, CNC machining centers promote effective and efficient results, while CNC machining China provides a viable economical solution.

No need to agonize about your next project. Just get in touch with JS Precision for your free DFM analysis and tailored optimal solutions and quotes, which will definitely give you that edge that you need.

There is no need for agonization over the costs of technology during the next project.

Contact JS Precision now! Your free DFM assessment can be provided by our partners in terms of drawings and requirements for material and production capacity and will specifically tailor a hybrid solution using the combination of CNC machining and the processes of the lathe machine.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com