3D printing vs CNC machining are two primary manufacturing processes that can turn product ideas into real objects. Selecting the incorrect method might not only cause budget excess but also parts that do not fulfill the performance standards.

This guide aims to unveil in detail the major differences along with the situations and selection logic between these two technologies with the help of references to relevant data and case studies to assist you in making an informed choice and at the same time showing how JS Precision through its professional CNC machining solutions and engineering experience can be your manufacturing partner.

Key Answer Summary

| Core Questions | Key Answers | Value for You |

| How to select a process depending on the project? | Segment the differences in materials, precision, and cost between the two technologies to deliver a clear choice framework. | Prevent wrong selection and save on R&D costs and time. |

| When is it necessary to decide on CNC, particularly 5 axis? | 5 axis CNC is a dependable answer if the requirements are strength, precision, or surface finish of high quality. | Have top performance parts and guarantee product reliability and lifespan. |

| How does JS Precision come up with the best solution? | Provide services from prototype to mass production, optimize manufacturing processes. | Obtain professional partners to ensure consistent quality and implementation of requirements. |

Key Takeaways

- The nature of the process determines the application:

3D printing is the best option for complicated geometric prototyping and small, batch production, whereas CNC machining is the most suitable for the final production of high precision, high strength metal parts.

- Precision and strength are the dividing line:

If the requirements for precision are beyond 0.1mm or if there is a need for the mechanical properties of a dense material, CNC (especially 5 axis) is a more preferable option.

- There is no better, only more suitable:

The best choice is the result of a thorough consideration of all the aspects such as materials, batch size, cost, delivery time, and performance requirements.

- Professional collaboration is key:

A partnership with the professionals such as JS Precision not only helps in optimization but also in process planning through CNC machining programs, thus, achieving the highest project success rates and benefits.

Why Trust The Comparison Of The Two Machining Processes From JS Precision?

CNC machining remains the core of our operations at JS Precision.We've dedicated ourselves to the precision manufacturing industry over the years and are recognized by ISO 9001:2015 for our rigorous quality management system.

This standard applies to our entire workflow: from CNC machining to prototyping and quality inspection. We even do comparative tests adhering to the ASTM F2924, 20 additivemanufacturing standard.

We have more than 45 CNC machine tools with extremely fine precision, covering the range of 3 axis, 4 axis, and 5 axis models, all of which have undergone an SGS precision calibration certification. In particular, 12 of the 5 axis CNC machining centers are equipped with German imported control systems, allowing them to work with ultra, high tolerance machining of 0.003mm.

Our engineering team members have an average of more than 10 years of experience in the industry and have been deeply involved with clients in such high-end industries as aerospace, medical equipment, and automotive. Together, they have produced more than 500, 000 precision parts.

The comparative analysis we do is grounded in actual production data and client case studies rather than being purely hypothetical. One such case is the landing gear project for a drone customer who is also one of the top 3 global drone manufacturers.

By examining the performance variations between 3D printing and 5 axis CNC machining, we came up with a solution that reduced the costs by 15%, satisfied the strength requirements, and shortened the R&D cycle by 20%.

We have established a comprehensive quality control system. Every batch of parts undergoes inspection by a coordinate measuring machine to ensure the data is accurate and reliable.

Want to verify the feasibility of your part's manufacturing process? Submit your part drawings. JS Precision provides a free comparative analysis of 3D printing vs CNC machining processes to help you avoid selection risks.

3D Printing Vs CNC Machining: What Are The Core Differences?

Understanding the inherent differences is an essential factor in determining the right process. This article section will explain the capabilities of each process along three key aspects: principles, materials and precision.

Working Principles and Technology Comparison

- 3D printing is a type of additive manufacturing, in which complex internal structures are built layer by layer with materials.

- CNC machining is a type of subtractive manufacturing, in which solid raw materials are formed by tool cutting.Factors such as precision and strength depend largely on whether the material is good and on the cutting process.

These two characteristics set the range of their applications.

Material Properties and Scope Comparison

Traditionally 3D printing has catered to photosensitive resins, nylon powder and a limited range of metallic powders. The presence of interlayer bonding issues and subsequently anisotropic mechanical properties characterizes parts manufactured by 3D printing.

CNC machining is capable of handling practically any solid engineering material such as 6061-T6 aluminum alloy and 316L stainless steel. After the machining process, parts have the same fully dense and isotropic properties as the original material, thus making them more dependable under high, load conditions.

Accuracy and Surface Quality Analysis

The accuracy and surface quality differences between the two are significant, meeting the requirements of ISO 286-1 standard. Specific data are shown in the table below:

| Process Type | Typical Tolerance | Surface Roughness Ra | Applicable Scenarios |

| FDM 3D Printing | ±0.3mm | 12μm | Conceptual models, non-functional parts |

| SLS 3D Printing | ±0.1mm | 3.2μm | Medium-precision functional prototypes |

| 3-Axis CNC Machining | ±0.05mm | 1.6μm | Simple structural metal parts |

| 5-Axis CNC Machining | ±0.01mm | 0.4μm | High-precision assembly, fluid sealing parts |

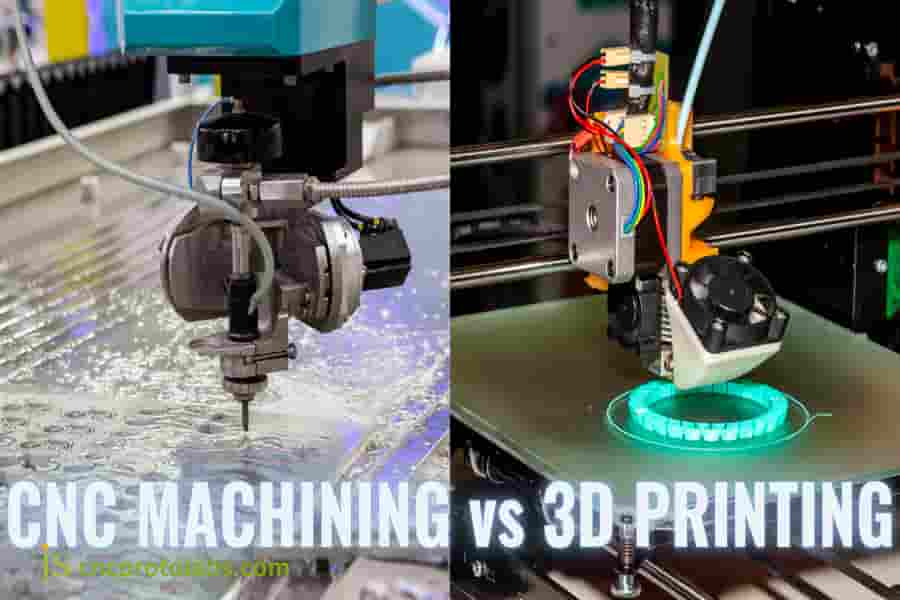

Figure 1: A split-screen image. The left side shows a blue CNC machine cutting metal, while the right side shows a yellow 3D printer creating a blue-green ring, with the title “CNC MACHINING VS 3D PRINTING”.

CNC Machining Vs 3D Printing: How To Choose Based On Your Project Needs?

Once you get to grips with what fundamentally sets the two apart, it is quite logical and very helpful to pick the course of action tailor, made for your project needs. Here, a decision-making framework is drawn up from cost, speed, and design freedom aspects, spotlighting the fact that 5 axis cnc machining services cannot be substituted.

Cost-Benefit Analysis: Relationship between Prototype, Batch Size, and Complexity

The cost differences between the two processes are significant at different production batch sizes, as detailed in the table below:

| Production Batch | 3D Printed Unit Cost (USD) | CNC Machining Unit Cost (USD) | Advantageous Process |

| 1-10 pieces | 45 | 380 | 3D Printing |

| 11-50 pieces | 45 | 120 | CNC Machining |

| 51-200 pieces | 45 | 40 | CNC Machining |

| 200+ pieces | 45 | 22 | CNC Machining |

- 1-10 complex prototypes: 3D printing requires no tooling, resulting in a significant cost advantage.

- 10-500 metal parts: CNC machining prototyping and small batch processing are more economical.

- Highly Complex Multi-Axis Parts: Requires specific evaluation based on process difficulty.

Production Speed vs. Delivery Time Comparison

- 3D Printing: The preparation time is only 15-30 minutes, which is very fast when printing a single piece, but post, processing is quite a hassle.

- CNC Machining: Programming and clamping require 2-8 hours, single piece time can be drastically reduced in mass production, thus it is capable of rapid mass production.

Design Freedom vs. Structural Strength Considerations

- 3D Printing Benefits: These technologies are better suited than CNC machining to producing complex internal flow channels and topology optimized structures.

- CNC Machining Benefits: The parts will be able to withstand heavy loads and have high fatigue strength, and the absence of interlayer bonding will eliminate weaknesses.

When is 5-Axis CNC Machining the Unbeatable Solution?

5 axis cnc machining services add two rotary axes to the X/Y/Z three-axis setup, thus enabling the machining of complex curved surfaces in one single setup. Some of the typical uses might be engine impellers, titanium alloy knee joints, and parts with form and position tolerances <0.02mm.

In comparison to 3D printed metal parts, it excels in all aspects like precision, surface finish, and material density, thus being the only option for high performance final parts.

CNC Machining Prototyping Or 3D Printing: Which Path To First Article?

Prototyping is a vital stage in the development of the product. The selection of the proper prototyping method can speed up your verification cycle, help you to avoid rework, and have a direct influence on your R&D efficiency and cost control.

Many customers are easily tricked into "speed-seeking" or "cost-saving" at the prototyping stage. The point is to align your verification objectives, which is also a problem JS Precision solves at its CNC machining prototyping services.

Select 3D Printed Prototyping

- When your objective is to quickly clarify the conceptual shapes, assembly relationships, or market demonstrations; material mechanical properties are secondary.

- When the structure is so complex (e.g., dense internal channels, hollow topologies) that CNC machining would be impossible, and no load testing is needed, then 3D printed prototyping is perfect for you to rapidly iterate at the very beginning of new product development.

Select CNC machining prototyping

- Need to test the true function, durability or fatigue strength of the parts.

- The prototype material must be consistent with the mass-produced parts to ensure that the test data can be directly used as a reference for mass production.

- Hope the prototype can be directly used for small-scale trial production, achieving a seamless transition from prototype to mass production.

A comparison of the core performance and applicable batch sizes of different prototyping processes can intuitively assist in prototyping process selection decisions:

| Prototyping Process Type | Prototyping Material Compatibility | Typical Tolerances | Single-Piece Delivery Time | Applicable Batch Size Range | Unit Cost (USD) |

| FDM 3D Printed Prototype | PLA, ABS, PETG | ±0.2-0.3mm | 4-8 hours | 1-5 pieces | 25-50 |

| SLS 3D Printed Prototype | Nylon 12, Nylon 66 | ±0.1-0.15mm | 8-12 hours | 1-10 pieces | 80-150 |

| 3-Axis CNC Machining Prototype | 6061 Aluminum Alloy, 304 Stainless Steel | ±0.05-0.1mm | 12-24 hours | 5-30 pieces | 120-200 |

| 5-Axis CNC Machining Prototype | 7075 Aluminum Alloy, Titanium Alloy | ±0.01-0.03mm | 24-48 hours | 3-20 pieces | 300-500 |

| CNC+3D Hybrid Prototype | Metal + Resin Combination | ±0.05-0.1mm | 16-32 hours | 2-15 pieces | 180-300 |

Looking to do CNC machining prototyping? Note "Rush Prototype," and JS Precision offers cost-effective prototyping solutions with delivery as fast as 3 days. We also provide free DFM advice to ensure the prototype design aligns with subsequent mass production processes.

How Does Optimizing The CNC Machining Program Boost Efficiency?

A professional CNC machining program is crucial for raising the level of CNC machining efficiency, decreasing costs, and maintaining quality. Several customers are unaware of program optimization, which results in longer machining cycles, more tool wear, and higher part scrap rates, thus increasing manufacturing costs.

We have a professional programming engineer team that not only has deep knowledge and experience in CNC machining program optimization but also through various projects they have developed standardized optimization procedures.

Reducing Idle Time and Improving Cutting Stability

Optimization of tool travel path helps to reduce non-cutting time. At the same time, cutting parameters are changed in accordance with the material properties to keep the cutting load constant, thus efficiency is increased by more than 30%, tools last longer, and consumable costs are lower.

Simulation and Collision Detection

Before processing complex parts, a full process simulation is conducted using professional software to simulate the cutting path and clamping position. Interference and collision problems are detected in advance to avoid damaging the workpiece, tools, and equipment, and to prevent rework losses caused by programming errors.

Want to improve the efficiency of your CNC machining program? Submit your machining path file, and our engineers will optimize it for free, reducing machining costs and providing optimization explanations to help you clearly understand the value of the improvements.

Figure 2: Close-up of a CNC lathe's control panel displaying G-code, coordinates (e.g., X104.210, Z-81.136), spindle speed, and a red emergency stop button.

Can Automated CNC Machining Solutions Handle Your Complex Parts?

What is Automated CNC Machining?

Auto CNC machining is a smart manufacturing mode that combines automatic tool changers and robotic material handling, thus enabling 24 hour unattended production. It basically gives a perfect answer to the main issues of low manual efficiency, unstable quality, and difficulty in guaranteeing delivery time in the batch processing of complicated parts.

JS Precision is a professional auto CNC machining company deeply familiar with the field, advanced automated equipment at the disposal of the company, and able to stabilize the production of multi variety, small batch complex parts.

One, Stop Solution for Complex Part Machining

Through process design, specialized tooling, automated workflows, and end-to-end quality control, JS Precision's CNC machining solutions are a one-stop service for your needs.

This is not just about automated machining, it is about designing solutions that fit the exact customer part requirements, thereby providing excellent quality from the first to the thousandth piece, while at the same time lowering labor costs and waste rates.

Figure 3: A yellow robotic arm handles small components in a bright, automated factory with conveyor belts and workstations.

A UAV Landing Gear Case Study: From 3D Printing To 5-Axis CNC

Customer Challenge

UAV company attempted to prototype a landing gear using metal 3D printing.

However, the prototype fractured at the interlayer joint causing its failure during a drop test. The manufacturing of this component was complicated by the requirement of an internal damping cavity, irregular structure, a yield strength of more than 450MPa, and a surface roughness of Ra1.6m.

The 3D printing process was optimized several times but it never reached the set requirements, therefore the company decided to contact JS Precision for our 5 axis cnc machining services.

JS Precision Solution

Program and Quality Control:

The team developed an optimized CNC machining program that considered the characteristics of 7075-T6 aluminum alloy, changed the cutting speed and feed rate to prevent the occurrence of vibrations during machining and avoid damage to the material.

An online probe was used during machining for the real, time dimension compensation whereby the accuracy was constantly checked to ensure the part was within the required tolerances.

Process Planning:

Through 5 axis cnc machining services, 7075-T6 aerospace grade aluminum alloy blanks (the same as the customer's mass production materials) were used and cutting tools were custom-designed with carbide and long-neck features for machining complex internal and external surfaces in one single setup, thus, getting rid of secondary clamping errors and ensuring dimensional and positional tolerances of the part are adequate and meet the standards.

DFM Optimization:

The engineers refined the internal cavity structure of the landing gear by slightly changing the fillet radius and adjusting the wall thickness distribution. We did not change the original shock absorption feature and design idea but instead, we fitted it with 5 axis tooling intervention path, thus, dodging machining interference and enhancing the overall strength of the component.

Quantitative Results

Yield strength was measured to be 480MPa in the landing gear post the JS Precision machining optimization, a figure which is significantly higher than the 450MPa marking set by the customer. The weight had been lowered by 15% of that of the original 3D printed prototype, thus the entire aircraft load got lighter.

The surface roughness was at Ra1.2m which was a step up from the Ra1.6m standard, thus, the part scrap rate was almost at zero. The delivery time was reduced by 20% from the customer's anticipated cycle, thus, the mass production of the customer's model was sufficiently backed. The customer will later give us the machining of this series of landing gears as the next task.

Want to replicate a similar success story? Submit your part's technical challenges (drawings, tolerances, material requirements), and JS Precision will customize a manufacturing solution for you, breaking through process bottlenecks and achieving efficient implementation from prototype to mass production.

Figure 4: A black drone landing gear with two extended struts, metal connecting joints, and a large central wheel, isolated on a white background.

Why Choose JS Precision For Your Custom Precision Part Manufacturing?

In the sphere of precision manufacturing, it is much more critical to locate a reliable partner than merely to decide on a process. JS Precision is a company that has been deeply engaged in CNC machining vs 3D printing over numerous years.

By means of its professional technology, comprehensive services, and rich experience,we company has become a long-term manufacturing partner for many high-end clients worldwide. Its core advantage is delivering CNC machining solutions perfectly matching the client's requirements, thus effectively addressing their pain points and generating value.

Planning the Optimal Manufacturing Path for You

JS Precision performs an unbiased analysis of the pros and cons of 3D printing vs CNC machining based on the entire project (budget, performance, time, batch size) and henceforth draws up the best route from prototype to mass production which helps you to cut R&D costs and shorten delivery times.

End-to-End Quality Assurance: From Drawings to Finished Products

Our equipment is a 5 axis CNC machining center, and we have a professional CNC machining program team, a three- coordinate quality inspection system, and auto CNC machining capabilities. A dedicated team member constantly interacts with the process ensuring quality and delivery time are kept under control.

A Reliable Partner Rooted in China, Serving the World

We are rooted in China's high-end manufacturing cluster, providing cost-effective and fast response services, equipped with a multilingual team, and serving customers in over 50 countries and regions worldwide.

Need Customized CNC Machining Solutions? Tell us your part requirements to receive a complete solution including process, cost, and delivery time, and enjoy free DFM optimization services.

FAQs

Q1: Which is cheaper, 3D printing or CNC machining?

It varies based on quantity, material, and complexity. For single or low, volume complex plastic prototypes, 3D printing is cheaper, while for metal parts or high, precision and high, strength pieces, CNC machining will give you a lower total cost.

Q2: What level of precision can CNC machining achieve?

Our standard CNC machining product accuracy is 0.025mm. By optimizing the processes, we can reach 0.01mm or even higher for critical features.

Q3: Can I use 3D printing to produce end-use metal parts?

Yes, but you have to compromise on the surface finish, internal porosity, and mechanical properties of the metal parts, which are anisotropic. CNC machining is a better choice for load-bearing components.

Q4: Why is 5-axis CNC machining more expensive than 3-axis?

Due to its higher equipment cost and more complicated programming, but it can perform multi, face machining in one setup only, thus reducing error accumulation and secondary setup time. For complex parts, it actually translates into overall cost savings.

Q5: How can I reduce my CNC machining costs?

Among the ways to keep your machining costs under control are: redesigning to avoid very deep pockets, using the same corner radii, choosing proper materials and tolerances, and wisely increasing the batch size.

Q6: Is the transition from prototyping to mass production smooth?

Extremely smooth. CNC machining prototyping involves the same methods and quality control systems as mass production. Performance data of prototypes can be directly applied for mass production, thus the transition can be seamless.

Q7: What benefits can "automated CNC machining" bring me?

It allows for higher-quality consistency, faster delivery times, and the ability to handle multi, variety, small, batch orders, which, in turn, lowers your management and time costs.

Q8: What is the minimum order quantity (MOQ)?

For CNC machining, we can support your needs from single-piece prototyping all the way to mass production. There are no strict MOQ limits, and we are fully committed to meeting your R&D and production requirements.

Summary

3D printing and CNC machining cannot be weighed against each other in terms of absolute superiority or inferiority, the deciding factor is whether they fit your project requirements. Leveraging our specialized process knowledge, complete equipment system, and abundant project experience, JS Precision will efficiently assist you in selecting the right process.

Seize the opportunity to make your design a precision product that is competitive in the market.

Click to contact us, send your parts drawings and technical requirements, and the expert team of JS Precision will offer you customized CNC machining solutions that are exactly what you need to bring your ideas to life.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com