CNC machining service often face such scenarios: medical device manufacturers who have precision component drawings with tolerances of ±0.005mm and control unit cost need, some aerospace companies have complex designs that cannot be implemented in multiple factories due to process limitations.

Whether you require one prototype or volume production, a thorough understanding of each step, from CNC machining process optimization through to CNC machine price, will ultimately assist in making better purchasing decisions.

This guide will present the complete picture about precision parts manufacturing and point out the ways JS Precision can be your trustful manufacturing partner.

Figure 1:The working process of a CNC lathe: the chuck is driven by a motor to rotate the workpiece at high speed, while the cutting tool performs precision machining on the material.

Core Answer Summary

| Procurement Dimensions | Key Considerations | JS Precision Value |

| Services and Processes | Machining Capacity, Quality Control, Delivery Reliability. | Optimized CNC machining process ensures high-quality delivery and rapid response. |

| Technology and Tools | Tool Selection, Parameter Optimization, Process Stability. | Professional CNC machining tool selection and cutting parameter database. |

| Cost and Location | Price Competitiveness, Supply Chain Efficiency, Quality Control. | Combining CNC machining USA quality standards with CNC machining China cost advantages. |

| Parts and Quality | Material Properties, Tolerance Requirements, Surface Finish. | Ensure that every CNC machining part meets strict technical requirements. |

Why Choose Us? JS Precision offers dependable CNC Machining Service

By choosing JS Precision as your CNC machining service partner, you are not merely outsourcing a task, you will be acquiring a strategic ally who is committed to making your project successful.

Our commitment to excellence is rooted in advanced technology, strict quality control, and deep industry expertise. Our quality management system follows the core principles of ISO 9001 quality management system defined by the International Organization for Standardization (ISO).

We know that parts we produce are usually critical to the performance, safety, and reliability of your final product. Therefore, we have built our processes around precision, efficiency, and unwavering quality principles.

This is reflected in our capabilities. We have top-of-the-line CNC machine tools, including multi-axis milling and turning centers that can handle complex geometries and extremely tight tolerances up to ±0.005mm.

From common aluminum alloys to high-performance engineering plastics such as PEEK and titanium alloys, we machine more than 100 materials to make sure that we can meet the particular mechanical and environmental specifications your application requires.

This guide is the culmination of extensive experiences in this field. The insights contained herein are based on real-world applications and problems we have successfully overcome for various clients from the aerospace, medical, automotive, and consumer electronics fields.

Trust the information that will be provided in this article, as it has a proven track record for delivering high-quality and reliable CNC machining parts.

Do you want to know how we can customize CNC machining services for your industry? You can submit a summary of your parts requirements and immediately receive a free exclusive cooperation plan to avoid selection risks.

How Does A Professional CNC Machining Service Transform Your Design Into Reality?

From digital concept to physical part, the core is an optimized CNC machining process. JS Precision breaks it down into three key stages:

Digital Manufacturing Process:

Upon receipt of your CAD model, we conduct the necessary design optimization and cost reduction in DFM review, generate G-code by using CAM software (which includes virtual simulation to prevent any errors), and import it into the CNC machining tools to finish subtractive machining.

Quality Control System:

- First-piece inspection: Full inspection of the first piece using equipment like CMM to confirm that it is within tolerance before going into mass production.

- Process control: sampling regularly from key dimensions, monitoring tool wear.

- Final Inspection: Complete inspection to customer specification before delivery to ensure no defective products leave the facility.

Standard Operating Procedures:

It logs the entire process from the program sheets right through to inspection reports, providing full lot traceability and guaranteeing the same quality standard, whatever the size of order.

Do you want your design to land smoothly? Upload CAD drawings immediately and note 'Process Optimization' to receive a free DFM analysis report, which helps optimize the CNC machining process.

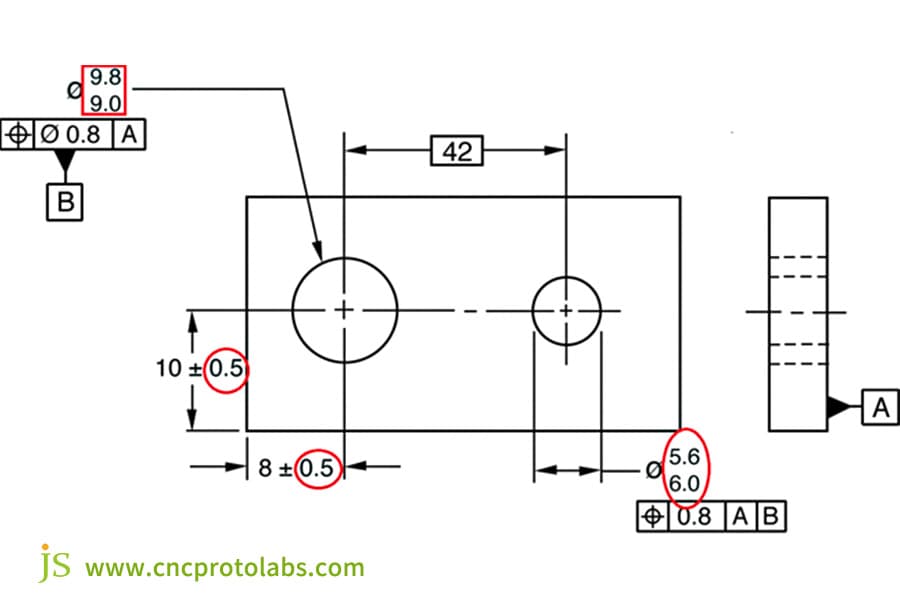

Figure 2: Tolerances on a design. It is crucial to conduct comprehensive and meticulous inspections on components with strict tolerance requirements.

What Level Of Precision Can You Expect From Modern CNC Machining Services?

Precision Grade Range: A Capability Range from Standard to Ultra-High Precision

Non-critical components can be produced with standard precision (±0.025mm), whereas high precision-±0.005mm-is the standard at JS Precision, suitable for parts in aerospace and medical, ultra-high precision, ±0.0025mm+, calls for special equipment and environmental controls, used for optical components among others.

Influencing Factors Analysis: Three Core Elements

- Machine Tool Precision: Structural rigidity and guideway quality constitute basic precision.

- Thermal Compensation: Eliminating thermal growth during machining by system adjustments.

- Tool Wear: Regularly inspect and replace the tools. Apply wear-resistant coating.

Precision vs. Cost Balancing: Scientifically Selecting Precision Grades

Specifying tolerances that are too high increases the costs for CNC machining parts. Focus on the "minimum tolerance required for function," and relax tolerances in non-critical areas.

CNC Machining Accuracy Grade and Cost Matching Table

| Accuracy Grade | Tolerance Range | Applicable Part Type | Required Machining Equipment | Surface Roughness (Ra) | Cost Impact Ratio (Relative to Conventional) | Typical Industry Cases |

| Conventional Accuracy | ±0.025mm | Consumer Electronics Housings, General Brackets | 3-Axis CNC Milling Machine- Entry Level | 1.6-3.2μm | 1.0 (Base) | Home Appliance Parts, Toy Structural Parts. |

| Medium Accuracy | ±0.01-0.005mm | Automotive Bearing Seats, Sensor Housings | 3-Axis / 4-Axis CNC (High-Precision) | 0.8-1.6μm | 1.5-2.0 | Automotive Parts, Industrial Sensors. |

| Ultra-High Accuracy | ±0.0025-0.001mm | Medical Implants, Aero-engine Blades | 5-axis CNC+constant temperature workshop+CMM measuring instrument | 0.2-0.8μm | 2.5-4.0 | Heart stents, satellite components. |

Figure 3: Strict tolerances refer to the small deviations allowed in part dimensions - typically with an accuracy of ± 0.001 inches.

How To Optimize Your CNC Machining Process For Maximum Cost Efficiency?

Optimizing the CNC machining process means reducing costs and increasing efficiency, other than controlling CNC machine price amortization.

Design Optimization Strategies:

The design phase has the most influence on cost. In conjunction with our engineering group, working on DFM can greatly reduce your cost:

- Standardized features: Employ holes with standard drill bit sizes, internal fillets that can be machined with standard tools, and avoid deep cavities or holes with large length-to-diameter ratios.

- Reduce complex surfaces: Simple geometry is easier and quicker to machine. When possible, replace complex 3D surfaces with stepped features.

- Reasonable tolerance allocation: As explained earlier, assign tight tolerances only when strictly needed.

Process Parameter Optimization:

Our CNC machining process employs a validated database of cutting parameters, optimized for each material. These include:

- Cutting speed-feed rate-depth of cut: The optimal combination among these factors maximizes material removal with minimum tool wear and machining time.

- Tool life management: We monitor the use of tools and proactively replace them before degradation in order to prevent part scrap and machine damage.

Improvement in Production Cycle Time:

Another key to cost-effectiveness is increasing throughput:

- Tooling optimization: Employing efficient fixtures and jigs reduces setup time and allows multiple parts or features to be machined in one setup.

- Improvement of toolpaths: Cutting time and idle travel time are reduced by utilizing HSM strategies and optimizing toolpaths.

- Batch production: Where possible, manufacturing several parts in one production batch spreads the initial set-up time and cost.

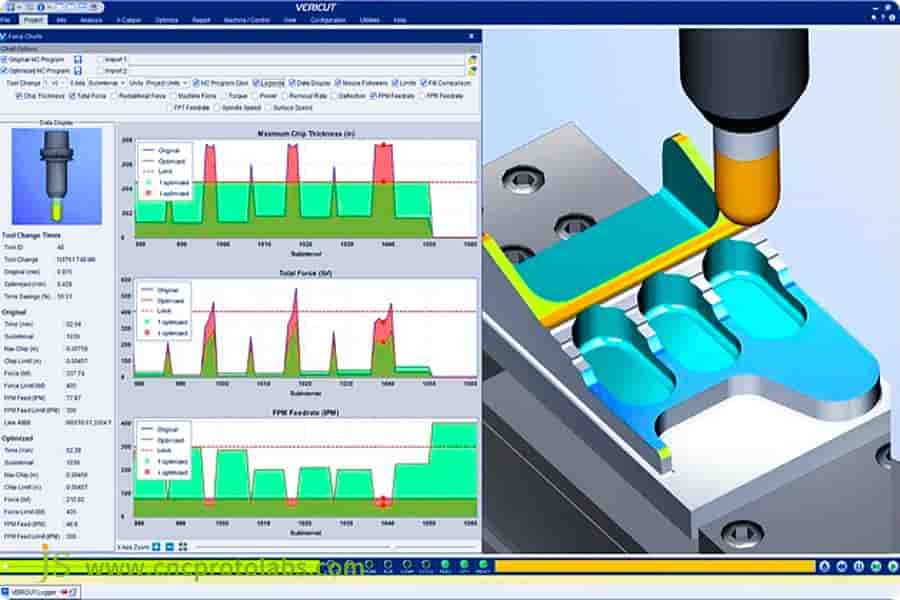

Figure 4: Use optimization software to simulate the entire machining process and find methods to optimize feed rate and tool path.

Which CNC Machining Tools Deliver The Best Results For Aluminum Parts?

The core of aluminum alloy processing is to choose the right CNC machining tools, with attention to tool material, geometry, and coating.

Tool Material Selection: Matching to Needs

- Carbide Tools: General-purpose choice, fine-grained and wear-resistant, suitable for common aluminum alloys (e.g., 6061),

- PCD Tools: Suitable for high-silicon aluminum alloys, such as ADC12, or for mass production, long lifetime, and high initial investment.

Geometric Parameter Optimization: Affecting Chip Removal and Smoothness

- Rake Angle: A large positive rake angle (12°-15°) reduces the cutting force and favors chip removal.

- Helix Angle: The 45° high helix angle is favorable for chip removal in cavity machining.

- Number of cutting edges: 2-3 cutting edges balance chip space and strength.

Coating Technology Applications: Targeted Selection

- Uncoated: For machining ordinary aluminum alloys.

- Diamond Coating: reduces friction, eliminates built-up edge, used for high speed machining.

- TiAlN Coating: Good for machining steel, with only limited applications on aluminum alloys.

Do you want to choose the right CNC machining tools for aluminum alloy processing? By informing you of the aluminum alloy model and processing requirements, you can obtain a free tool selection list to improve processing efficiency.

What Materials Are Ideal For Manufacturing Precision CNC Machining Parts?

Classification of Metallic Material: Core Characteristics Comparison

- Aluminum Alloys (6061/7075): Lightweight, easy to machine, for aerospace/consumer electronics.

- Stainless Steel-303/304/316: Strong, corrosion-resistant, suitable for medical/marine equipment.

- Titanium Alloys Grade 2/5: high strength-to-weight ratio, biocompatible, used in medical implants/aerospace.

- Copper alloys: electrically and thermally conductive and serve for electrical connectors.

Engineering Plastics Selection: Focusing on High-Performance Applications

- PEEK: high temperature and chemical resistance, for aerospace/medical applications.

- ULTEM: high strength, flame-retardant, for electrical insulation.

- Nylon: abrasion resistant, tough, glass fiber reinforcement is possible.

Detailed performance and applications for materials of CNC machining

| Material Type | Specific Model | Density (g/cm³) | Tensile Strength (MPa) | Applicable Temperature Range (°C) | Corrosion Resistance | Typical Application | Price per Kilogram (USD) |

| Aluminum Alloy | 6061-T6 | 2.7 | 310 | -55~120 | Good | Electronics casings, drone frames. | -5-8 |

| Stainless Steel | 316L | 8.0 | 515 | -270~450 | Excellent | Medical instruments, marine sensors. | 8-12 |

| Titanium alloy | Grade 5 | 4.5 | 860 | -250~300 | Excellent | Artificial joints, aerospace structural components. | 35-50 |

| Engineering Plastics | PEEK | 1.32 | 90 | -200~260 | Excellent | Medical implants, high-temperature seals. | 80-100 |

| Copper Alloy | BrassH62 | 8.5 | 330 | -200~200 | General | Electrical plugs, heat sinks. | 10-15 |

CNC Machining China Vs. USA: Where Does The Real Value Lie In Price Competitiveness?

The choice between CNC machining China and CNC machining USA depends upon the balance of cost, quality, and timely completion.

Cost Structure Analysis: Major Differences

- CNC Machining China: Cheaper labor/raw material costs, 30-50% less than in the US, but consider the tariffs, shipping costs, and delivery time.

- CNC Machining USA: higher labor/management costs, higher amortization of CNC machine price but lower shipping cost and faster delivery times in the North American market.

Quality Standard Comparison: Depth of Implementation is Key

- CNC Machining USA: More AS9100/ISO13485 certifications, more strict regulations.

- CNC machining China: Most companies are passing ISO9001, and leading ones like JS Precision already passed such rigid certifications, quality nearing US levels.

Comprehensive Value Assessment: Choose as per Your Needs

- CNC Machining China: cost-driven, large-volume, long lead times acceptable.

- CNC Machining USA: Prototype/Intellectual Property sensitive/critical components, fast lead times required.

JS Precision prides itself on "Chinese prices + international quality," a balance of cost and quality.

Want to weigh the optimal solution between CNC machining China and CNC machining USA? Inform your target market and order requirements, and obtain free regional selection analysis, balancing cost and timeliness.

Case Study: Achieving 40% Cost Reduction While Improving Precision By 30%

Client Challenge

A medical device manufacturer had to face and find a solution to a twofold problem:

It needed to drastically reduce the cost of manufacturing a critical valve component for one of its diagnostic devices, while increasing the accuracy of the mating dimensions from ±0.025mm to ±0.015mm to raise the reliability and service life of the equipment.

None of the designs or processes of the day could meet both requirements simultaneously.

Our Solution

After JS Precision team intervened, we did not simply accept the original design for processing. We launched an extensive VA/VE project:

1. Redesigned Part Structure:

Closely working with the customer, our engineers redesigned the component. A complex structure, originally assembled from a number of parts, was optimized into a single part integrally formable through a 5-axis CNC machining process. This eliminated the cost of assembly and attendant errors while improving structural rigidity.

2. Optimized CNC Machining Process:

In the new design, we chose a more appropriate aluminum alloy material by changing it from 6061 to 7075, thus maintaining the strength with thinner wall thicknesses. We used specialized CNC machining tools (high helix angle hard alloy end mills) and optimized cutting parameters to achieve high-speed milling and reduce processing time.

3. Dedicated Processing Strategy:

Special boring tools are adopted in the processing of critical holes, and online measuring probes are integrated into the machine tool to realize real-time dimension compensation during processing that can guarantee stability in precision.

Measurable Outcomes

Through our professional CNC machining service and optimized CNC machining process, our clients have reaped the following benefits:

- 40% unit cost reduction: The main contributors are material optimization, part count reduction, and improved machining efficiency.

- 30% improvement in critical dimensional accuracy: Accuracy has increased gradually from ±0.025mm to ±0.015mm, thus enhancing the performance of the overall equipment.

- Delivery time cut by 50%: Time from placing an order up to delivery has reduced considerably due to process simplification and our efficient production scheduling.

This case study illustrates how JS Precision applies its engineering acumen to transform challenges into major performance improvements and cost savings.

Do you want to replicate similar cost reduction and efficiency improvement achievements? Immediately call the hotline and leave a note with "Case Study" to obtain free CNC machining service solutions in the same industry and avoid processing risks.

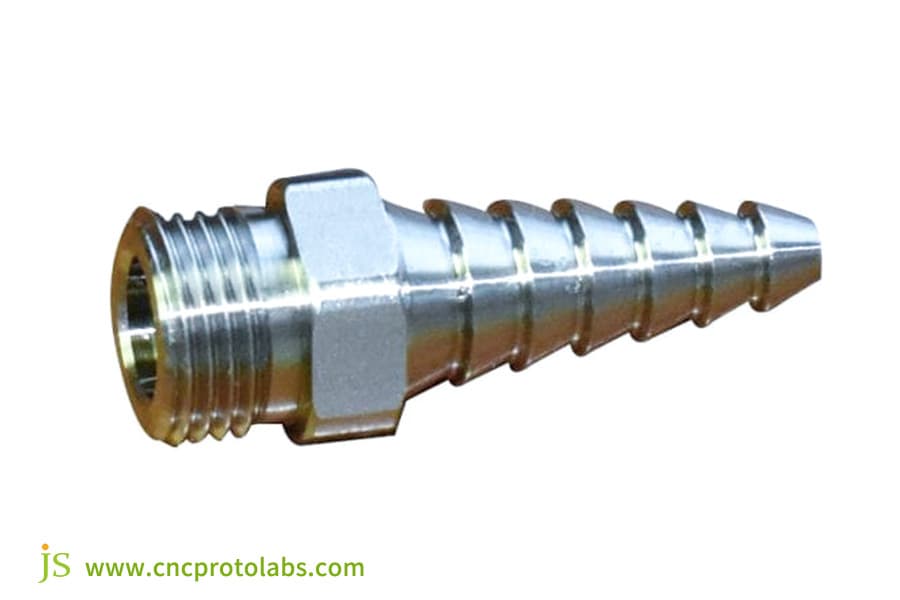

Figure 5: High precision CNC valve components

How To Navigate The Complex Landscape Of Global CNC Machining Services?

Supplier Evaluation Framework: Four Core Dimensions

- Technical Capabilities: Type of equipment (3-axis/5-axis), material/tolerance handling capabilities.

- Quality System: Certifications, quality inspection processes - ISO9001/AS9100.

- Response Speed: Timeliness of quotation/technical response.

- Price Competitiveness: Reasonable quotation after consideration of first three aspects.

Risk Management Strategy: Three Major Measures

- Multi-source supply: two qualified suppliers for key components.

- Quality Audit: Onsite/remote audits for batch projects.

- Progress Monitoring: Regular production reports - pictures/inspection data.

Partner Selection: From Transaction to Strategy

Choose partners like JS Precision who are willing to understand your business, provide improvement suggestions, and grow together, with value exceeding a single CNC machine price.

How To Start Your Project With Our CNC Machining Services Today?

Getting started on your project and working with our CNC machining service at JS Precision is easy and straightforward. We are committed to making this process as smooth and efficient as possible.

Requirements Clarification

Please provide complete technical specifications, quality requirements, budget, and timeline.The more detailed your information, the faster and more accurate our response will be. If possible, please prepare:

- 3D CAD models in STEP or IGES format, and/or 2D engineering drawings in PDF or DWG format.

- Material specifications.

- Quantity required: prototype, small batch, large batch.

- Specific demands on surface treatment.

- Target timeline and approximate budget range.

Design Review Process

Once we receive your documents, our engineering group will conduct a free Manufacturing Feasibility Analysis (DFM).

A detailed quotation and written report will be presented to you within 24 hours, this often includes recommendations for design optimization that could lower your cost, improve manufacturability, or enhance performance. This is a value-added service and is free of charge.

Project Execution Guarantee

Once you confirm your order, a dedicated project manager will be assigned as your single point of contact.

You will get a clear production plan and updates at each milestone, including material arrival, production commencement, and completion of final inspection. We ensure that every project is executed under rigid schedule and quality control until the product is delivered on time.

FAQs

Q1: What is the typical lead time for CNC machining prototypes?

For simple prototypes, this would take about 3-5 days, while complex parts take up to 1-2 weeks. This depends highly upon the complexity of the design, but also upon the current factory production schedule.

Q2: How do you ensure quality consistency in mass production?

We follow statistical process control to monitor production data, regularly calibrate equipment, employ standard operation procedures, and integrate total quality control into our process. All of these together guarantee consistent quality in mass production.

Q3: Can you handle both metal and plastic materials?

Yes, we can process different metals and engineering plastics. The metals include aluminum alloy, stainless steel, titanium alloy, etc., common plastics include PEEK, ULTEM, nylon, etc.

Q4: What is your minimum order quantity policy?

We don't have an MOQ, and we support everything from single-piece prototyping to large-scale mass production. This way, quality standards are assured to be the same for any order quantity.

Q5: How do you handle design confidentiality?

We will sign the confidentiality agreement with you, using encrypted methods to send design files. When the project is completed, we will process the design data according to your requirements so that your design information will not be leaked.

Q6: What surface finishing options do you offer?

The products are available with various finishes, such as sandblasting, anodizing, electroplating, powder coating, passivation, etc., for different appearance and performance requirements.

Q7: How do you manage tight tolerance requirements?

We use high-precision CNC equipment with professional tooling and fixtures, control the temperature in the workshop, and perform online measurement to ensure conformance to tight tolerance requirements.

Q8: Can you assist with design optimization for manufacturing?

Yes, we provide manufacturing design optimization as a service from our engineering team. Structural optimization in concert with tolerance and process optimization allows us to help you lower machining costs while improving quality.

Summary

Accordingly, in today's globalized manufacturing landscape, a wise choice of CNC machining service will assure not only part quality but will also directly influence the market competitiveness and profitability of any given product.

Equipped with sophisticated CNC machining process technology, rigorous quality control, and competitive CNC machine price, JS Precision has become the strategic partner for many global companies across a wide span of industries.

Start your precision manufacturing project today!

→ Click to upload your design files for a professional quote and manufacturing analysis

→ Contact our technical experts for personalized machining solutions

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com