Large part CNC milling services are the core support for high-end manufacturing. As the trend shifts towards lighter products, the need for large custom aluminum parts has increased significantly. But during CNC milling for large parts, thin, wall deflection is one of the major issues that result in part scrap, project delays, and budget overruns.

This article analyzes the root causes of deformation in large thin-walled parts and reveals how professional large part CNC milling services can transform challenges into precision advantages through the integration of processes, equipment, and materials. Choosing the right partner is the key to achieving design intent.

Core Answer Summary

| Core Questions | Key Answers | Value Brought to You |

| Why do large thin-wall parts tend to easily deform and be scrapped during machining? | The three major causes, thus leading to deviations from the original dimensions and increased costs, are cutting force, the release of residual stress, and cutting heat. | The identification of the fundamental reasons for these problems cuts down on the ineffective guesswork and demonstrates the need for expert thin-wall machining services. |

| How do professional service providers prevent deformation in a methodical way? | They achieve this with the help of personalized programming, stress management from start to finish, and 3D deformation control together with the use of high rigidity equipment. | This cuts down on the number of scrapped parts and projects are finally delivered on time and within budget. |

| How can one find a trustworthy partner for large CNC milling services? | Comprehensive evaluation of processing cases, equipment capabilities, aviation certification, and engineering support level. | Select partners who can solve design challenges and provide complete solutions. |

Key Takeaways

- Controllable Deformation:

By working through the steps methodically, the machining deformation of large thin-wall parts can be consistently controlled within the 0.1mm or even tighter tolerance limit.

- Process Priority:

More than half of the deformation risks can be removed before the machining stage through early DFM (Design for Manufacturing) and cutting simulation.

- Equipment is the Foundation:

Reliable CNC milling for large parts is impossible without using machine tools that are not only highly rigid (e.g., gantry structures) but also thermally stable.

- Partners are an Extended Team:

By selecting a service provider such as JS Precision that has aerospace CNC machining experience, you can instantly lower your technical risks and thus, your overall costs.

Why Trust This Guide? JS Precision Has Extensive Experience In Large CNC Milling Services

JS Precision has primarily concentrated on large part CNC milling services for more than ten years, thus gaining considerable experience and a deep understanding of the needs of aerospace and high end equipment manufacturing clients.

We have manufactured upwards of 10, 000 complex large thin-wall parts, and our customers' repurchase rate has been more than 85%. Our knowledge of CNC milling processes comes from a combination of large, scale hands, on experience and constant technological innovation.

On the material side, JS Precision controls the quality of materials by using only aluminum sheets that have been pre-stretched and come from aerospace, certified suppliers. Each material batch is accompanied by a full melting report as well as an ultrasonic flaw detection report, thus totally eliminating the risk of warping caused by defects in materials at the very source.

In terms of equipment configuration, we are equipped with multiple large gantry milling machines with a stroke of over 3 meters. The machine tool has a static stiffness of 120N/µm and is paired with a fully closed-loop grating ruler feedback system, ensuring a stable positioning accuracy of ± 0.005mm.

Our technical solutions are in very strict alignment with the AS9100D aerospace quality management system standards, and all major operations are NADCAP-certified (certification number: NADCAP-2025-TS-0012).

In terms of process improvements, JS Precision's exclusive "seven-step sequential stress relief process" has enabled customers to bring down the failure rate of large thin-wall parts drastically, from over 30% to less than 2%.

For those facing challenges in machining large thin-walled parts, choosing an experienced partner can directly avoid trial-and-error costs. Want to verify our technical capabilities? Submit your part drawings now, and JS Precision's engineering team will provide you with a free, customized DFM manufacturability analysis report, allowing you to anticipate machining risks in advance.

Why Are Thin Walls So Prone To Deformation In Large Part CNC Milling?

During CNC milling, the risk of deformation of large thin-walled parts is significantly higher than that of ordinary parts. This problem is especially noticeable in large part CNC milling services. Here we are going to look at the main reasons for the deformation of the parts physically and from the cost viewpoint.

Physical Causes of Deformation: 3 Major Ones

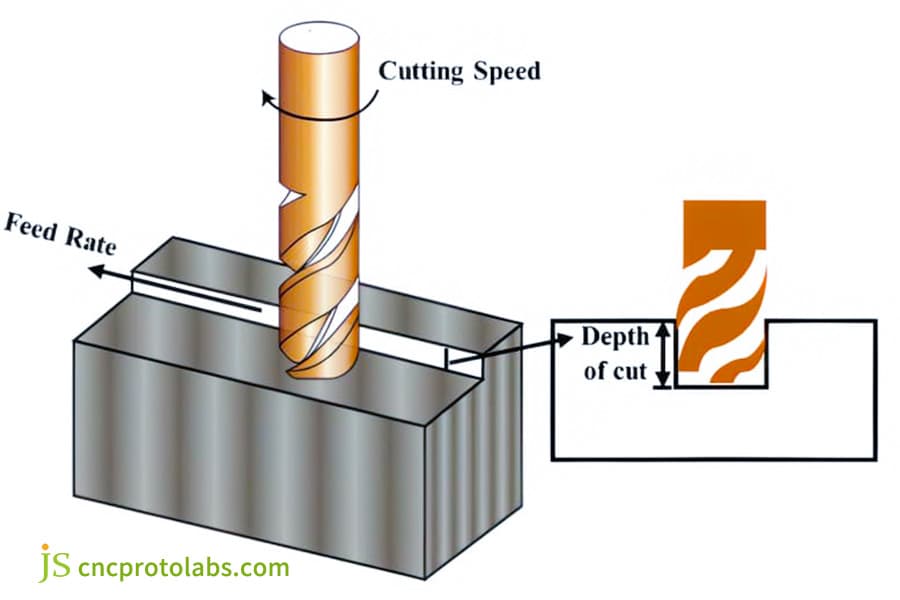

1. Tool Deflection Due to Cutting Force:

If the tool side edge is cutting thin walls with a thickness less than 3mm, the radial cutting force which can be beyond 100N will act on the wall surface and push it, the wall being elastically deformed leading to overcutting or the formation of chatter marks by tooling. In large part CNC milling services, this is even more evident as the workpiece size goes up.

2. Subtle Residual Stress Release:

The combination of residual stress from rolling and quenching of aluminum alloy blanks and the unbalanced state caused by the removal of a large portion of material results in warping. Stress release after the cutting process may cause deformation to go over 2mm, thus representing the major difficulty in thin-wall machining services.

3. Heat Generated by Cutting Causing Uneven Local Expansion:

The heat beyond 200C produced by high, speed cutting together with the coolant's rapid cooling leads to the creation of thermal stress, which results in uneven shrinkage and thus the loss of dimensional stability. The thermal deformation keeps accumulating during extended CNC milling for large parts.

From Precision Failure to Cost Disaster

Deformation may even cause problems like direct physical interference during the assembly of an aircraft wing rib lack of rigidity of satellite supports, or failure of the airtightness of a radiator.

Discarding a high value aluminum part worth tens of thousands of dollars only due to deformation, of course, means material loss but can also cause project delays for a number of weeks and design modification costs several times the machining fee.

How Do Thin-Wall Machining Services Strategically Prevent Warping?

The main point of deformation prevention during thin-wall machining services is "uniform force distribution, step-by-step pressure release, and precise temperature control." JS Precision achieves systematic control of deformation through intelligent programming and full process stress management.

Intelligent Programming and Toolpaths Cutting the Whole into Pieces

1.Layered Milling and Multi Axis Linkage:

Employing axial layered cutting (for example, 0.5mm depth of cut per layer) and five axis linkage side milling together, it is possible to generate a continuous and uniform cutting force that prevents localized overheating and stress concentration. This programming strategy can effectively reduce the yield of thin-walled workpieces in large part CNC milling services.

2. Scientific Combination of Parameters:

Carry out the strategy of "high speed, small depth of cut, and fast feed" (e.g., S12000, ap0.3mm, F3000mm/min) in order to both maximize the removal efficiency and minimize single, point cutting force.

Custom large aluminum parts with varied thicknesses need totally different process parameters.The following is a standard parameter table from JS Precision, validated through thousands of practical tests:

| Wall Thickness (mm) | Spindle Speed (S, r/min) | Depth of Cut (ap, mm) | Feed Rate (F, mm/min) | Tool Diameter (mm) | Coolant Pressure (MPa) | Applicable Material Grade |

| 1.0-1.5 | 15000-18000 | 0.15-0.25 | 3500-4500 | 6-8 | 0.8-1.2 | 6061-T651/7075-T7351 |

| 1.6-2.5 | 12000-15000 | 0.25-0.4 | 3000-4000 | 8-12 | 0.6-0.9 | 6061-T651/5083-H116 |

| 2.6-3.5 | 8000-12000 | 0.4-0.6 | 2500-3500 | 12-16 | 0.5-0.8 | 6061-T651/2024-T351 |

| 3.6-5.0 | 6000-8000 | 0.6-1.0 | 2000-3000 | 16-20 | 0.4-0.6 | 5083-H116/2024-T351 |

| 5.1-8.0 | 4000-6000 | 1.0-1.5 | 1500-2500 | 20-25 | 20-25 | 6061-T651/5083-H116 |

Full-Process Stress Engineering Management

1. Material pretreatment is a key factor

It is necessary to focus on the use of pre-stretched aluminum plates treated by vibration aging method or under T74/T7351 conditions which can help to a reduction of internal initial stress from the source by more than 60%.

2. "Step, by, step" way of machining

Here the author has given the details of the process used and it also has been used to follow the process of (3mm allowance) roughing stress relaxation (natural or artificial aging) (0.8mm allowance) semi finishing final finishing, gradually releasing the stress at each stage.

Figure 1 Use lower feed rates, smaller cutting depths, and sharp tools with larger rake angles to reduce workpiece stress.

Figure 1 Use lower feed rates, smaller cutting depths, and sharp tools with larger rake angles to reduce workpiece stress.

What Parts Of a CNC Milling Machine Are Non-Negotiable For Stability?

The capability of the parts of CNC milling machine to perform operations is what ultimately determines the upper limit of precision in large CNC milling services, especially when manufacturing large thin-wall parts. Hence, machine tool rigidity, thermal stability, and drive precision are all essential factors.

Ultimate Rigidity, Thermal Stability, and Geometric Accuracy

1. Machine Tool Rigidity Determines the Upper Limit:

The integral mineral casting or cast iron bed of a large gantry milling machine requires a static stiffness greater than 100 N/m (road with ISO 230-2 standard) to effectively dampen cutting vibrations and prevent chatter. JS Precision's gantry milling machines get a static stiffness of 120 N/m, way above the industry standards.

2. Thermal Stability Ensures Consistency:

A constant temperature workshop (201C), a spindle and leadscrew liquid cooling system, and a thermally symmetrical design keep thermal errors below 0.01mm for a long period. This is the basis for obtaining high precision in CNC milling for large parts.

High-Precision Drive and Real-Time Feedback

1.High, Performance Electric Spindle: Features a low vibration, high dynamic response electric spindle (torque up to 100Nm) for smooth operation even at low cutting force conditions.

2.Full Closed Loop Position Control: Equipped with a linear encoder to achieve full closed, loop feedback, the system can compensate for lead screw thermal expansion and backlash, thus, ensure a positioning accuracy of 0.005mm.

| Machine Tool Components | Performance Parameter Requirements | JS Precision Configuration | Accuracy Contribution |

| Bed Material | Mineral Casting/Cast Iron | Mineral Casting | Increases static stiffness by 15% |

| Spindle Torque | ≥80Nm | 100Nm | Ensures stability in low depth-of-cut cutting |

| Cellulator Resolution | ≤0.001mm | 0.0005mm | Compensates for positioning errors |

| Cooling Method | Dual Cooling Spindle + Lead Screw | Triple Cooling Spindle + Lead Screw + Bed | Thermal error controlled within 0.01mm |

Want to know how high-rigidity machine tools improve machining stability? View JS Precision's list of parts of CNC milling machine configurations now to get detailed parameters for large gantry milling machines.

Why Is Aluminum The Premier Choice For Custom Large Aluminum Parts?

Custom large aluminum parts are identified as the perfect option for lightweight, luxury equipment. The intrinsic features of the material and the process benefits of aluminum alloys have made them the leading choice in large part CNC milling services.

Aluminum Alloys: Light, weight, Machinability, and Performance

In comparison to steel and titanium alloys, aluminum alloys (like 7075-T6) provide better specific strength, thus they become the primary option for achieving lightweighting.

Their excellent machinability results in higher material removal rates and less machining stress. Various grades of aluminum alloys differ vastly in their respective usage scenarios:

- 6061-T651 is ideal for the manufacture of general structural parts.

- 7075-T7351 is the grade for high strength, high toughness, and stress corrosion resistant aerospace critical components.

- 5083 is typically utilized where corrosion resistance is necessary such as in marine engineering.

Quality Control at the Ground Level

By strongly emphasizing that the material should be pre-stretched sheet metal from aerospace, grade suppliers with full melting batch reports, one can be sure of obtaining stable material properties.

Service providers of the highest standards perform ultrasonic testing as well as other tests on the materials being delivered to them to ensure that there are no internal defects.It is the initial stage of guaranteeing the dependability of custom large aluminum parts.

| Aluminum Alloy Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Applicable Scenarios | Processing Difficulty |

| 6061-T651 | 310 | 276 | General Structural Components | ★★☆☆☆ |

| 7075-T7351 | 510 | 480 | Aerospace Critical Components | ★★★★☆ |

| 5083-H116 | 270 | 145 | Marine Corrosion-Resistant Components | ★★★☆☆ |

| 2024-T351 | 480 | 325 | High Fatigue Strength Components | ★★★★★ |

Want to choose the optimal grade for your custom large aluminum parts? Contact JS Precision, our material engineers will provide you with free material selection advice.

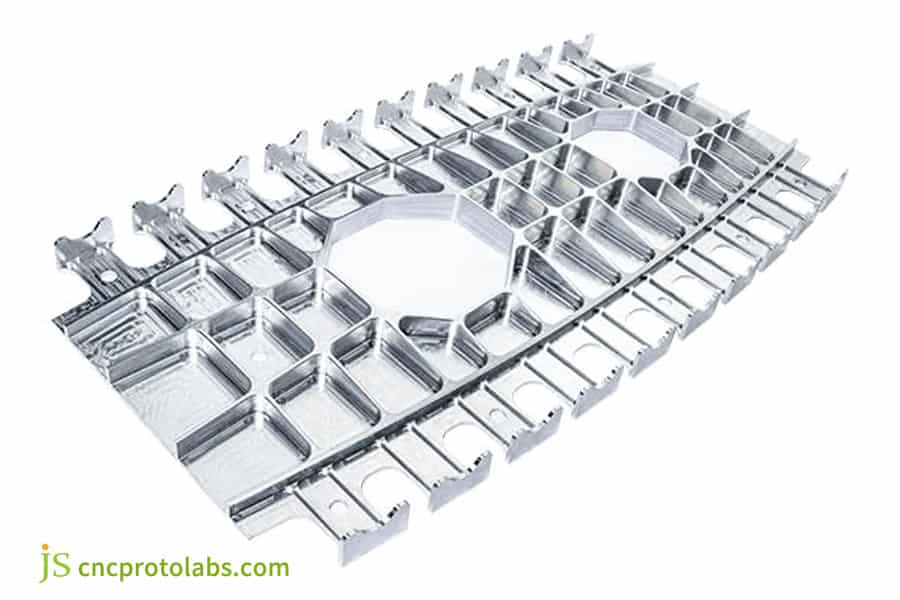

Figure 2 A silver thin-walled aluminum part with complex geometry and a central circular aperture.

Figure 2 A silver thin-walled aluminum part with complex geometry and a central circular aperture.

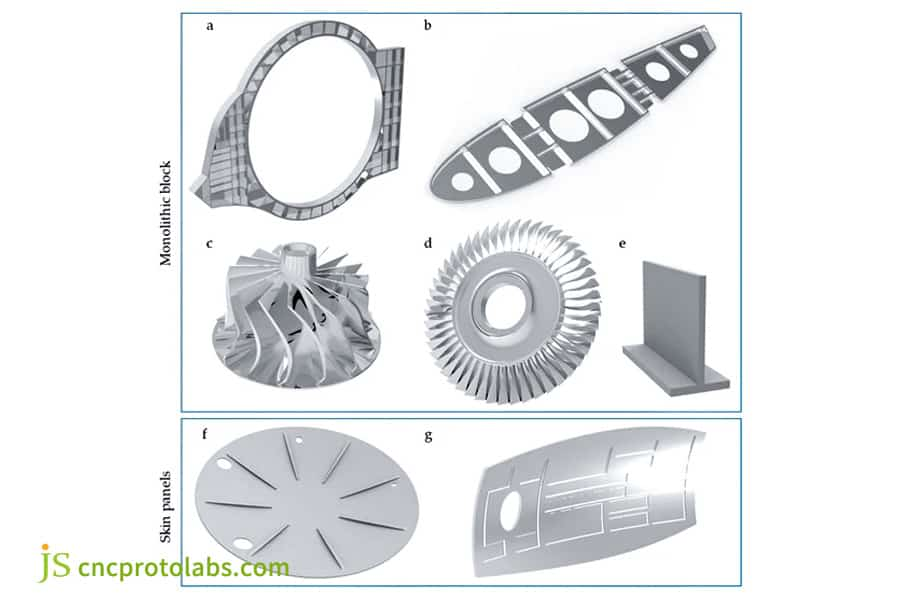

How Does Aerospace CNC Machining Push The Limits Of Precision?

Aerospace CNC machining is the epitome of precision in the industry and its machining standards as well as its processes are used as a reference level for large part CNC milling services.

Highly Demanding Aerospace Code Components

Consider the aircraft bulkheads (1.5mm thick, 0.2mm profile requirement) or the satellite antenna supports (thin-wall mesh structures) for instance, these components require the ultimate properties of rigidity, dimensional stability, and reliability at the same time very light weight. The manufacturing of these parts is the peak of the testing of thin wall machining services.

Collaboration for Better Engineering Solutions

Expert service providers get involved at an early stage, they offer DFM (Design for Manufacturing) consultation (such as simplifying fillet radius and adding process reinforcement ribs), they also utilize cutting force and deformation simulation software for risk prediction, and in the end, they deploy laser trackers or CMMs for the full, area inspection.

JS Precision's aerospace CNC machining team has done more than 500 thin-wall satellite and aircraft parts successfully, with all their tolerances controlled within 0.05mm.

Figure 3 Thin walled aerospace components machined by CNC

Figure 3 Thin walled aerospace components machined by CNC

What Should You Look For In a Partner For CNC Milling For Large Parts?

When you search for a partner to help you with CNC milling for large parts, apart from just considering the price, you also need to weigh the technical force and service capabilities of the potential partner. JS Precision has thus enumerated five core evaluation criteria to assist in your selection of a trustworthy service provider.

Five Point Question List to Evaluate Technical Competences

- Are you able to produce for us a portfolio of successful case studies and demonstrate the measured deformation data (e.g., CMM reports) for similar complex thin-wall parts?

- What are the specifications (stroke, rigidity) and accuracy (positioning/repeatability) of your large gantry milling machine?

- Have you got the process simulation capability? How do you handle your raw materials supply, and who are your heat treatment partners?

- Do you have any aerospace certifications like AS9100/NADCAP?

- Would you be able to provide DFM optimization guidance during the design phase?

Assessing Overall Value

An examination of their quality control system and testing instruments (a laser interferometer, a coordinate measuring machine) is necessary. Evaluating the competence of the engineering team to deliver effective DFM optimization suggestions during the design phase can help you save significantly on later costs, which would be well beyond the service fee.

Want to quickly screen qualified large CNC milling services suppliers? Download JS Precision's supplier evaluation checklist now and check each item to avoid pitfalls.

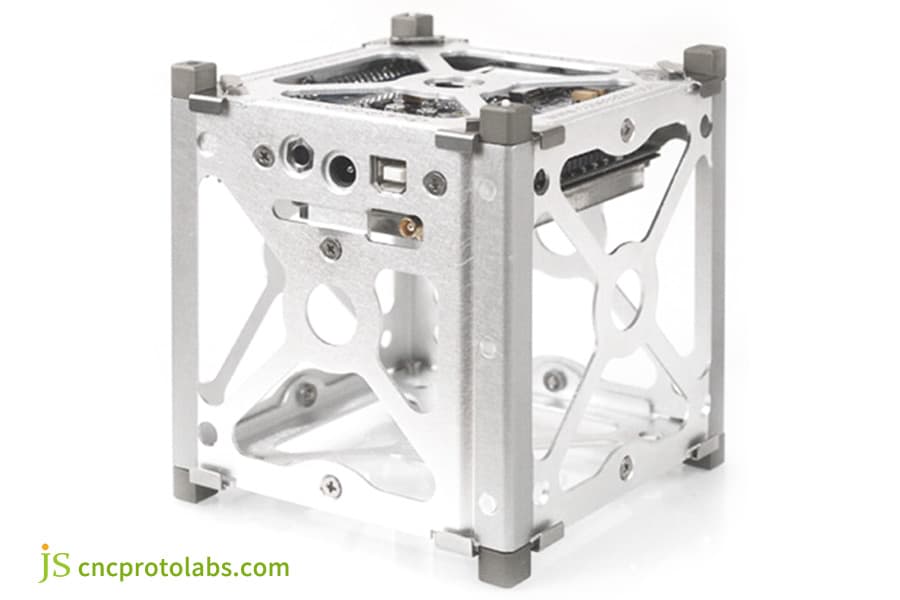

Case Study: Overcoming The 0.8-Meter Satellite Frame And Increasing The Flatness From 1.2mm To 0.15mm

Challenge

An aerospace client needed to machine an 800mm x 600mm aluminum alloy satellite frame with an overall wall thickness of 2.5mm, internal honeycomb reinforcement, and material 7075-T7351. The required flatness was 0.2mm.

The overall flatness of the frame after the first machining operation was beyond the tolerance by 1.2mm and also there was a local warping. These repair operations did not meet the assembly requirements and consequently the customer was at risk of the losing the time of the project.

JS Precision Solutions

1.DFM Optimization and Simulation:

Three 8mm temporary process bosses are added in non critical areas based on the prediction of stress distribution using Deform software. The layout is optimized through finite element analysis which results in an increase in rigidity without interfering with the assembly.

Simulated clamping forces are used to select a six point positioning scheme that is capable of controlling the clamping deformation to within 0.03mm. This method is aimed at increasing the machining stability of thin-wall parts in large CNC milling services.

2.Customized Process Package:

A tailor made seven-step process is used: rough milling, artificial aging, semi-finish milling, secondary artificial aging, finish milling.

Rough milling leaves a 3mm allowance to remove 80% of the redundant material, then the alloy is aged at 120 for 4h to release the internal stress. Semi finish milling leaves a 0.8mm calibration allowance, and finish milling uses an S12000 speed and 0.3mm depth of cut for staged stress relief. This is the core technology of JS Precision thin-wall machining services.

3. Dedicated Tooling and Real Time Monitoring:

A vacuum adsorption and multi, point flexible support fixture was created, which included a vacuum pressure of 0.6, 0.8 MPa, and four adjustable support blocks to prevent warping.

With the machine tool's on board probe, the five key features of each stage were inspected with an accuracy of 0.002 mm.Data was returned in real, time, thus ensuring controllability of the entire machining process.

Results:

The flatness of the final part was always kept within 0.15 mm, and the weight completely satisfied the design criteria.It was able to pass the full, scale inspection and acceptance by a laser tracker.

In comparison to the customer's repeated mold modifications and adjustments, lead time and cost were more than 40% optimized, hence saving over $20, 000 USD directly, and at the same time, assembly risks were lessened.

Do you also face similar challenges in machining large thin-walled parts? Submit your part drawings now, and JS Precision's engineering team will customize a solution for you, replicating the success of the satellite frame case.

Figure 4 Satellite frame milled by CNC milling

Figure 4 Satellite frame milled by CNC milling

FAQs

Q1: What is the minimum wall thickness that can be achieved for machining large thin-walled parts?

For aluminum alloys, process optimization and proper support allow stable machining of wall thickness down to 0.8-1.0mm in general, with some local details possibly being even thinner.

Q2: How much does controlling deformation typically increase cost and lead time?

Systematic process implementation raises the machining time by around 20% to 30%. Yet, when compared to scrapping and reworking or making adjustments at a later stage, the total cost and time are greatly saved.

Q3: What size parts can you machine?

JS Precision is equipped with multiple large gantry milling machines with travel over 2 meters, thus are capable of processing workpieces up to 3000mm×1500mm×1000mm.

Q4: Besides aluminum alloys, can you machine thin-walled parts made of stainless steel or titanium alloys?

Sure. But the approaches differ depending on the material. To avoid thermal stress, low cutting speeds are used for titanium alloy, while for stainless steel, the focus is on the tool wear and work hardening.

Q5: How do you ensure the long-term dimensional stability of machined parts?

This is ensured through material pre stabilization treatment, multiple stress relief aging processes during processing, and final heat treatment (such as T6 tempering).

Q6: If my design may have manufacturing risks, can you review it in advance?

Exactly this is the core value of our company. We give free DFM (design for manufacturability) analysis reports and before production, we also advise on the best optimization ways.

Q7: Are these processes also suitable for small-batch trial production (5-50 pieces)?

Fully applicable. Small batches require strict processes to ensure consistency. We optimize CAM and tooling to achieve efficient and repetitive production.

Q8: What is the typical lead time?

For the complex, large, and thin-wall parts, the usual lead time from drawing to delivery is 3-6 weeks, this, however, depends on the complexity of the process and the current production schedule.

Summary

To overcome the deformation caused by processing large thin-walled parts, a systematic engineering approach that integrates precision programming, high rigidity equipment, materials science, and quality management is required. Service providers should not only be operators, but also engineers who understand manufacturing principles.

JS Precision, leveraging its experience in aerospace CNC machining, has developed a thin, wall machining service system that can be tested from design collaboration to final inspection, thus ensuring the realization of your design blueprints.

If you are troubled by large and complex parts, thin-walled deformations, or high-precision requirements, please contact us immediately. Submit your drawings to obtain a feasibility analysis and process plan exclusive to the JS Precision engineering team. Let us use professional skills to transform your challenges into reliable product advantages.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com