CNC milling & machining services are central solutions in the manufacturing of complicated assemblages in assembly manufacturing. While designing an industrial robotic wrist module, a crucial part of a medical device, and aerospace components, complicated assemblages often become a constraint in the entire process of the manufacturing system.

In the traditional model for component procurement, to assemble the 12 pieces would require 4 hours, and through the accumulated tolerances, there would be misalignment in the bearing housings, incurring hidden costs in excess of 30 percent.

As will be shown in this article, the way in which the integration of high-tech CNC milling and machining solutions—a particularly comprehensive approach to manufacturing complex assemblies—can systematically address these issues and turn assemblies from “cost centers” into “competitive advantages.”

We will examine how JS Precision, based in China, uses its strong engineering partners capabilities and large precision manufacturing capacity to offer savings-oriented solutions to international customers, which go much beyond the capabilities of generic machining in their region.

Key Answer Summary

| Decision Core | The Pitfalls of Generic Solutions | The Integration Value of JS Precision |

| Cost Control | Whereas others are only comparing prices for single-piece CNC milling products without considering the dramatic increase in total costs required for assembly debugging, scrap, and chain supply management. | Our solutions cover DFA/DFM analysis to integrated manufacturing of workpieces, thus minimizing components and assembly sequences to optimize total costs. |

| Precision and Consistency | Having several suppliers handle processing coupled with uncontrolled cumulative tolerances leads to an inconsistent benchmark, thus an uncontrolled cumulative tolerance, which affects assembly precision. | In a fragmented supply chain, there is less ability to coordinate delivery dates, a delay in any process stops every project altogether. |

| Supply Chain Resilience | In a fragmented supply chain, there is less ability to coordinate delivery dates, a delay in any process stops every project altogether. | As a one-stop CNC milling & machining services provider, we coordinate all processes internally, provide unified delivery commitments and quality responsibilities, greatly simplify management, and reduce risks. |

| Technology Adaptability | The general purpose machine fails to fulfill the requirement for the coordination of processing for various materials and complex shapes, and there are great differences in quality during mass production. | Integrating multiple processes such as milling, turning, and additive manufacturing, suitable for processing multiple materials such as aluminum, steel, and engineering plastics, ensuring stable quality throughout the entire process from prototype to mass production. |

Key Takeaways:

1. The true cost is in assembly: Minimizing components and assembly steps is more efficient to cut complex system costs.

2. Integrated manufacturing is superior to subcontracting because machining critical mating components on the same high-quality machine tool in the same coordinate system represents the only viable course to ensure assembly accuracy.

3. ROI is highest in early collaboration: The cost savings potential, through DFM/A analysis, in the design phase intervention, typically, exceed 20%.

4. A technology-cost two-fold solution for Chinese manufacturing: Leading Chinese manufacturers, JS Precision for example, are capable of offering CNC milling service with the technology level of the best global corporations from Europe and the US but with more competitive prices and response time.

JS Precision CNC Milling Solutions: Reducing The Burden Of Complex Manufacturing

To solve the manufacturing pain points of complex assembly, choosing a partner with E-E-A-T capabilities is key.

JS Precision has been actively associated with the CNC milling sector for the last 20 years, having dealt with more than 500 clients across the globe in high-end sectors like autos, aeronautic, and bio-medical, thus experiencing its importance in combined manufacturing and related know-how with its technological prowess and experience.

JS Precision has more than 30 high-end machining centers, including 5-axis gantry-type machining centers and mill turning machines, with a maximum processing ability of 2000mm × 800mm × 700mm and a high precision positioning requirement within ±0.005mm, enriching the processing capabilities for large and complex parts.

Our engineering team consists of more than 15 senior DFM engineers, averaging 8 years of industry experience, which allows them to identify possible manufacturing and assembly problems in the design phase.

As of now, JS Precision has reduced the average number of parts for customers by 75%, reduced total costs by 30% -57%, and maintained a delivery on-time rate of 99.5%. Our company has obtained ISO 9001:2015 and AS9100D aerospace certifications, and our quality system covers the entire process from raw material procurement to final assembly verification.

Want to verify if your complex assembly can achieve cost reductions of over 50%? Contact a JS Precision engineer now, provide assembly information, and receive a free customized CNC milling & machining services solution to clearly understand the potential for space savings and precision improvements.

How Can Integrated CNC Milling & Machining Services Slash Your Assembly Costs?

After knowing the capabilities of JS Precision, you might wonder how exactly the integrated CNC milling and machining service can decrease the assembly costs. The solution involves a comprehensive analysis of the overall cost structure. The CNC milling & machining services can eliminate the invisible or hidden costs at a system level.

The Cost Iceberg: Invisible Assembly and Debugging Costs

In many organizations, the price of individual components is evaluated, ignoring the significant effects of the hidden costs associated with a component model.

In a traditional component model, the costs associated with assembly time, rework in debug, additional fixtures, and management coordination comprise over 30% of the total costs involved in such a model.

For instance, components sourced from different suppliers might need yet another 2-3 days of debugging on account of incompatibility of interfaces. Such a cost of effort can often be easily underestimated.

Subtraction in Integrated Manufacturing: From Multiple Parts to One Workpiece

JS Precision uses CNC milling & machining in performing part integration and functional integration, thus eliminating directly the cost associated with the assembly process and connectors.

For example, integrating 12 independent aluminum and steel parts into 3 core components through five-axis milling not only reduces the processing cost of 9 parts but also completely eliminates assembly steps such as screw fixing and pin positioning.

| Cost Type | Traditional Component Model Percentage | JS Precision Integrated Model Percentage | Savings Percentage | Average Annual Savings (100,000 units mass production) |

| Parts Processing Cost | 25% | 30% | -20% | -$50,000 |

| Assembly and Debugging Cost | 35% | 5% | 85.7% | $300,000 |

| Management and Coordination Cost | 20% | 3% | 85% | $170,000 |

| Scrap Loss Cost | 10% | 1% | 90% | $90,000 |

| Other Hidden Costs | 10% | 1% | 90% | $90,000 |

| Total Cost | 100% | 40% | 60% | $600,000 |

Want to accurately calculate your assembly's total cost? Submit your part drawings and assembly requirements, and JS Precision will provide you with a free comparison of the cost differences between traditional methods and integrated CNC milling & machining services, allowing you to see hidden expenses and find the optimal cost reduction path.

Why General-Purpose Machining Fails Complex Assemblies: The Triad Of Challenges

These assemblies require very high standards of manufacturing precision, coordination, and scalability. General and decentralized machining methods cannot adequately address these requirements, CNC milling services need to be integrated to meet such challenges.

Accumulated tolerances and interface matching problems

When multiple parts come from different suppliers, each supplier has different machining benchmarks. Even if the individual parts meet the drawing requirements, the tolerances will accumulate and amplify.

For example, for an assembly consisting of 5 parts, although the tolerance is given as ±0.02mm, the final accumulated tolerance may reach ±0.1mm or above, leading to bearing misalignment, assembly interference, or functional failure.

Multi-material and process collaboration

Assemblies often include multi-material participation, including aluminum, steel, and engineering plastics. With this comes a number of processes, such as milling, turning, and additive manufacturing. Dispersed suppliers cannot optimize process sequences.

For instance, the distortion of parts after heat treatment can't be compensated precisely in subsequent milling, and compatibility issues with surface treatment may not fit, making a collaboration failure rate greater than 30% or so.

Scaling and Supply Chain Fragility

Disadvantages of a supply chain in a dispersed area are aggravated from prototype development to mass production. Different suppliers will have varied production cycles, and it will be challenging to align the delivery dates. Failure of any part will be a project stopper. Adding, modifying, or extending suppliers will take a recertification time of 1-2 months.

The Technical Pillars Of Cost Savings: A Deep Dive Into Advanced CNC Machining

Technical support pillars of cost effectiveness are four in number. They make it possible to attain greater precision and efficiency in CNC milling services as well as CNC milling for large parts.

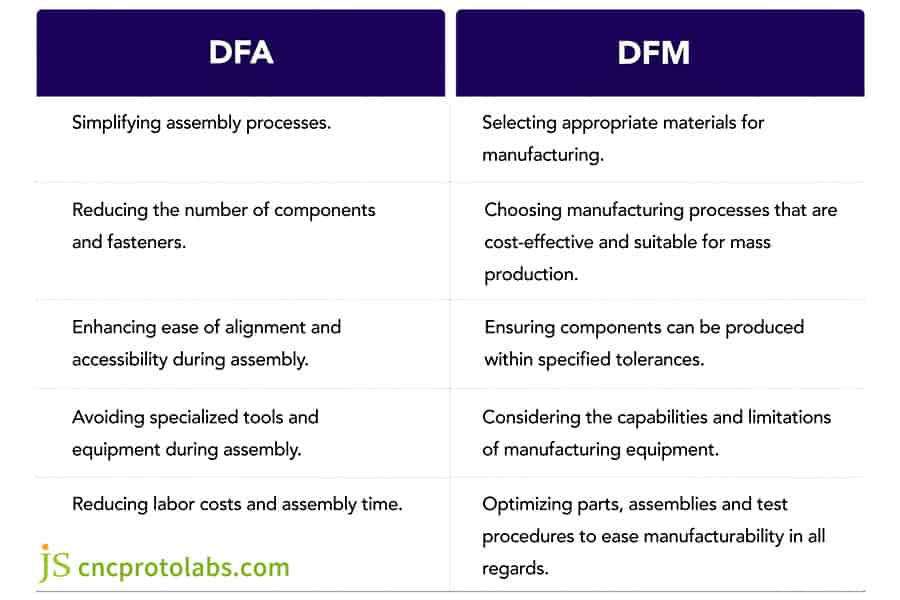

DFA/DFM: Your Blueprint for Savings

JS Precision engineers are involved in the design phase, analyzing and optimizing part layouts through assembly oriented design (DFA) to reduce the use of fasteners. Reduce processing difficulty through Design for Manufacturability (DFM) feedback.

For instance, when deep holes are modified to stepped holes, tooling cost savings can amount to 30%, and there are also fewer chances of tool breakage. A sharpened corner can be modified to a rounded corner to enhance milling times by 25%. Such DFA/DFM analysis normally generates an average savings range between 20% to 35%.

High Level Programming & Toolpath Intelligence

We have been applying the most advanced machining strategies like five-axis simultaneous programming with the result of more than 40% increased machining efficiency and tool life when processing deep cavities and hard materials.

While CNC milling for large parts, the programming staff precisely control the deformation and stress during machining and the machining accuracy for the components of the large frame machine.

Specialized Processes for Monumental Tasks

JS Precision also has a large parts machining workshop. The gantry milling machines in JS Precision have machining strokes of 2000mm x 800mm x 700mm.

Moreover, after adopting custom-designed chemical joints, it is ensured that large parts remain stable during machining. In addition, large-scale measuring equipment like laser trackers are used in gantry milling machines to track machining accuracy.

Quality as a System, Not a Checkpoint

Our company has developed a closed-loop quality system, fully compliant with ISO 9001:2015. All procedures, starting from the First Article Dimension Report (FAIR) and Statistical Process Control (SPC) through final assembly verification, are data-driven.

Through supply chain integration, ensure batch consistency of raw materials, guarantee quality from the source, and control the consistency error of mass-produced parts within ± 0.008mm.

Want a cost-competitive design right from the beginning? Get in touch with the JS Precision engineering team, share the requirements of your cnc milling products, and you will have free DFA/DFM analysis. This will make our CNC milling services accommodating to your design prior.

Figure 1 The main objectives of DFA and DFM

Consistency At Scale: How To Ensure Every CNC Milled Part Fits Perfectly?

In mass production, thousands of CNC milling products must maintain consistent accuracy in order to achieve instant assembly without the need for optional parts. This requires a joint guarantee from three aspects: equipment, benchmarks, and processes.

Machine Tool Precision is Just the Beginning: Thermal Compensation and Process Monitoring

JS Precision uses high-end machine tools that incorporate linear encoder feedback and software controls for thermal expansion error correction.

This allows it to fully compensate for errors that may arise from temperature changes in its environment, ensuring precision to within ±0.003mm. It also has an online probe system that allows it to automatically detect and correct errors that may arise from tool wear.

Unified Reference System: Absolute Coordinate System from Machining to Inspection

Completing critical mating characteristics on one machine in one clamping is of fundamental importance to ensure accuracy. JS Precision employs an absolute coordinate system for programming and machining.

The measurement coordinate system of JS Precision's coordinate measuring machine (CMM) is ideally aligned to the machining coordinate system to ensure that direct measurements are made in production for achieving repeatability accuracy of ±0.002mm.

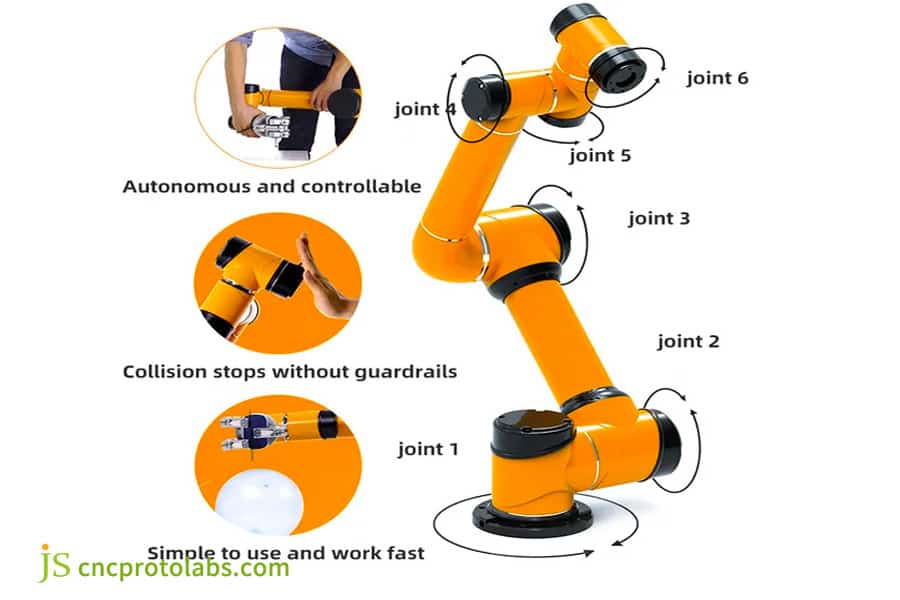

Case Study: 57% Cost Reduction – Transforming An Industrial Robotor Arm Assembly

An automation equipment manufacturer faced the challenge of manufacturing a six-axis robot wrist module. The original design consisted of 12 separate aluminum and steel parts assembled with screws and pins. This not only resulted in high CNC milling service prices but also presented serious precision and efficiency issues.

Challenges

Inability to allow a bearing housing coaxial error of 0.08mm, which made the robot malfunction, and on-site debugging averaged a successful rate of only 85% in an average of 4 hours per unit, there were 12 parts sourced from only 3 suppliers, which made coordinating delivery difficult and caused delays of up to 15 days, and the total cost of mass production was $120 per unit.

JS Precision Solution

1. DFA/DFM Reconfiguration: Subdivision of the 12 components into 3, which involve incorporating an aluminum main frame and two components of transmission related to steel, into which all bearing housings are integrated.

2. Process Integration: The integrated aluminum frame is processed on a single setup via a 5-axis gantry machining center so that the coaxiality of the holes in the bearing housing has a tolerance of φ0.03mm. The steel parts are processed on a milling and turning machine in the same factory with the same objective of process integration.

3. Quality Control: The whole frame is measured for precision using a CMM, thereby providing a 3D deviation chromatogram that is accurate. The whole process in production is controlled using the SPC system, which helps in adjusting parameters.

Results

The number of parts is down by 75%, assembly time is now 30 minutes versus 4 hours, commissioning pass is now 99.9% versus previous levels, and manufacturing costs per unit are down to $51.6, which is a reduction of 57%.

Lead times are down from 45 to 25 days, yet on-time delivery is now 99.5% versus previous ratios. Rigid module design is now up by 30%, and service life is longer by 2 years.

Customer Feedback: “JS Precision's combined CNC milling and machining process eliminated our entire assembly problem, which gave us a huge cost benefit and helped us gain a competitive advantage in the marketplace.”

Do you have similar complex assembly manufacturing challenges? Contact JS Precision engineers to provide a detailed explanation of your product pain points, and you will receive one-on-one solution consultation, allowing a professional team to tailor an integrated manufacturing solution for you.

Figure 2 Six-axis articulated-arm robots get their name from the six distinct rotations that allow them to grip an object at almost any angle and at almost any point within their reach.

What Factors Truly Drive CNC Milling Machine Cost And Your Project Quote?

There are lots of customers that ask about the CNC milling machine cost. In reality, the price breakdown basically depends on several factors like the capability of the machine and the part design itself. This will help you in making the best decision possible.

Capability Premium: Five-Axis, Multi-Channel, and Large Machine Tools

Five-axis linked, milling and turning composite, and large stroke motion machine tools entail higher capital and operational expenses.

For instance, the capital cost of a five-axis gantry machining center is 3-5 times higher than that of the typical three-axis machine tool. However, the five-axis machine center can perform the machining of complex parts in a single pass, thus incurring lower costs per unit.

| Machine Tool Type | Purchase Cost Coefficient | Operating Cost Coefficient | Machining Accuracy | Applicable Part Type | Unit Cost Coefficient (Complex Parts) |

| Ordinary Three-Axis Milling Machine | 1 | 1 | ±0.01mm | Simple structure, single-plane parts | 1 |

| Five-Axis Linkage Milling Machine | 3.5 | 1.8 | ±0.005mm | Complex curved surfaces, multi-faceted machining parts | 0.6 |

| Mill-Turn Turning Center | 4 | 2 | ±0.003mm | Shaft-type, multi-functional parts | 0.5 |

| Large Gantry Milling Machine | 5 | 2.5 | ±0.01mm | Large frame parts over 2000mm | 0.7 |

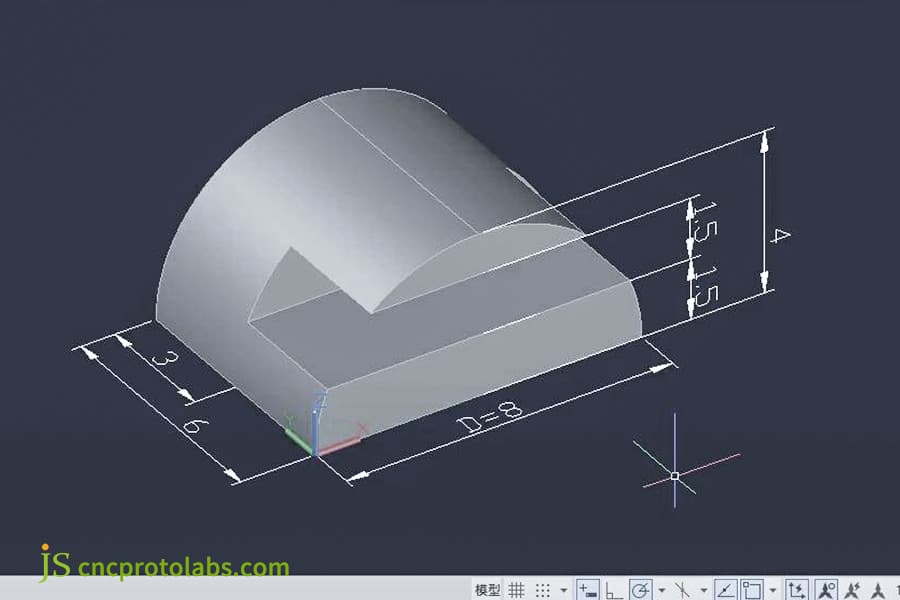

Your Geometry: Programming Time and Material Usage

The presence of complex surfaces, detailed features, and thin-walled components will exponentially add to programming and machining time. For instance, components with complex surfaces will take 2-3 times the programming time of other components, while thin-walled components will reduce machining efficiency by 50%.

Layout optimization ensured that material utilization rose from 60% to 85%, and as a result, the cost of CNC milling for large parts decreased by 15%-20%.

Need a pricing breakdown? Simply send JS Precision the 3D model of your part, and a free CNC milling machine cost breakdown will be provided, indicating the percentage of cost for each step involved in the process.

Figure 3 Simple shapes like rectangles or cylinders can be processed faster and cheaper.

Your Roadmap To Savings: How To Start With a Customized CNC Machining Solution?

There is a better way of working together. JS Precision presents a three-step way of collaboration that can easily adjust CNC milling service in accordance with your requirements.

Step 1: Turn in Your “Challenge,” Not Just Drawings

We would like to encourage you to contribute assembly models, performance needs, and pain point descriptions, not only diagrams for parts in random spots. In turn, JS Precision engineers can gain a complete understanding of requirements and start systematic DFA analysis to pinpoint key regions for optimization.

Step 2: Engagement in In-depth Engineering Review Meeting

JS Precision will establish an inter-departmental team of engineers who will communicate directly with your design team via video conferencing. Engineers will offer solutions for parts integration and process optimization, as well as the most optimal process route and answer any technical inquiries you have.

Step 3: Get a Transparent Quote & Prototype Plan

A transparent quote and plan will This quote will specifically identify the overall cost saving of the integrated manufacturing solution over traditional piecework, including parts reduction and assembly reduction. There will be a plan for rapid prototyping, usually accomplished in 2-3 weeks, for checking the viability of the design.

FAQs

Q1: In integrated design, the individual workpieces are bigger, more complicated, wouldn't this push up the costs of CNC milling?

While a single part machining cost may be higher, JS Precision eliminates the cost of multiple parts machining, handling, assembling, and quality inspection, thus drastically reducing the total cost while ensuring more consistent quality. This advantage is further dramatized when it comes to mass production.

Q2: What size of integrated parts can you process?

The big gantry milling center of JS Precision can process an aluminum alloy workpiece as large as 2000mm × 800mm × 700mm, which can meet the machining requirements of the big frame and structure in most industries.

Q3: Can you handle all multi-material assemblies?

Yes, JS Precision provides precision milling and turning of materials such as aluminum, steel, stainless steel, brass, and engineering plastics. It is possible to coordinate the process sequence and surface treatment for each part to ensure compatibility.

Q4: How to ensure the machining accuracy of integrated large parts? For example, the flatness of the entire length?

In the case of JS Precision, it adopts a high-speed light-cutting strategy in order to control the stress deformation. A temperature-controlled workshop is adopted for machining and inspection. For an aluminum part of length 1m, its flatness is controllable to within ±0.1mm/m.

Q5: Is it difficult to communicate and manage projects with overseas suppliers?

Not at all. JS Precision uses English-speaking project managers and engineering teams, and the company utilizes an online collaboration platform, where updates and data are given in real-time online, and so on.

Q6: Is surface treatment and heat treatment a part of the services offered?

Yes. It also provides one-stop post-processing solutions like anodizing, sandblasting, painting, and heat treatment processes like solution aging, ensuring control and minimizing risks in integrating with other suppliers.

Q7: How long does delivery normally take?

For the assemblies involving standard levels of complexity, prototype development takes 2-3 weeks. Large-scale production, depending upon the volume, takes 4-8 weeks. For meeting delivery requirements, JS Precision has expedited processes for handling urgent demands.

Q8: How about JS Precision in China compared with a Chinese source?

JS Precision, while providing equal or even higher technological capabilities (especially in complex and large part processing), can offer more competitive total costs and faster response times through its supply chain and manufacturing ecosystem advantages.

Summary

The issue related to complex assembly and manufacturing would never be about individual machining, but would instead involve a collaborative issue within the overall system. The overall capabilities related to CNC milling & machining services would, therefore, help to address any related welding, precision, and supply-related concerns.

JS Precision would eliminate all limitations with the help of proper integration and accumulated experience, turning complex assembly into a competitive advantage.

It’s time to think again about your manufacturing plan.

Please send us your assembly model or the most challenging component. Our engineers can offer you a "Free Integrated Manufacturing and Cost Saving Potential Analysis Report" to clearly illustrate the potential savings and performance gain you can enjoy through deep collaboration.

Let's work together to transform your assembly from a cost burden to a market edge.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com