Iron milling is the core process for industrial parts processing, but have you been troubled by high product defect rates caused by precision fluctuations when searching for iron milling services for cast iron joints in industrial robots? When budgeting for milling angle iron, are you confused about all the different costs on a quotation?

Alternatively, do you have doubts when looking for a precision CNC milling supplier about whether the "CNC milling services near me" options really fit your needs?

The following guide will delve deep into the world of precision iron milling and show how to attain the best machining quality with superior cost-effectiveness, while explaining why leading manufacturers around the world prefer Chinese companies as partners in business.

Key Answers Summary

| Comparison Dimensions | Traditional Local Machining Services | JS Precision Precision Milling Services |

| Core Technology and Precision | Focus on general machining capabilities. | Specializing in precision milling, with exclusive parameter libraries for cast iron and steel, achieving micrometer level tolerances. |

| Tooling and Cost Optimization | The wear costs of standard tools are not transparent. | Use iron milling cutters designed for specific materials, thus optimizing tool life and machining parameters to reduce unit costs. |

| Complex parts processing | May refuse or offer high prices for handling miscellaneous items. | We specialize in the milling angle iron, or other hard-to-machine profile shapes, and multi-axis linkages which can handle challenging geometries. |

| Overall Cost-Effectiveness | Initial quotations may be lower. | Due to process optimisation, cost-effective milling bits for steel, and large-scale production, the overall cost of ownership is lower. |

Iron Milling Core Points: JS Precision Helps You Lower Costs And Enhance Precision

JS Precision boasts over 15 years of experience in iron milling, and our quality control system strictly follows the ISO 9001:2015 quality management standard of the International Organization for Standardization (ISO), ensuring consistency from process to output.

We've served 12 industries, including automotive, aerospace, and industrial robotics, and have processed over 500,000 iron-based parts.

For example, we've optimized the processing procedure of ductile iron joints for a US industrial robot customer. We improved the critical flatness accuracy from ±0.05mm to ±0.035mm and reduced the overall cost per part by 25%. We solved the problem of difficult clamping of milling angle iron for an automotive parts customer to increase machining efficiency by 20%.

We are familiar with the selection of various iron milling cutters and proficient in parameter optimization for precision CNC milling.

This guide sums up years of our practical experience.Every suggestion has been verified through actual projects, so you can completely trust its professionalism because this content comes from our experience in helping clients solve real-world problems.

Would you like to achieve mastery of core iron milling strategies that can work for your project as soon as possible? Please provide us with your part drawing and machining requirements, and we will create a preliminary cost optimization and precision assurance plan absolutely free of charge to help you avoid detours.

What Is True Precision Iron Milling?

Having understood JS Precision's experience, let me explain first the basic question of what true precision iron milling is.

Material removal is by no means an easy process, instead, it's a systematic engineering process incorporating precision machinery and specialized knowledge. Its foundation is based on a profound understanding of the material itself, for example, commonly used gray cast iron grades and their properties can be found with authoritative definitions in standards such as ASTM A48.

It can rework cast iron, steel, and other iron-based materials into high-value precision parts, thus playing an irreplaceable role in the machining of high-rigidity, wear-resistant components.

From Raw Material to Finished Product: The Definition of Iron Milling

Modern iron milling, in conjunction with precision CNC milling technology, has made the processing of complex cavities, curved surfaces, and ultra-high-precision mating surfaces possible. As an example, straightness of machine tool guideways can be as high as ±0.01mm, thus far outstripping traditional processes to meet high demands.

Why are iron-based materials still the backbone of industry?

Iron-based materials are central to industry due to performance and cost advantages.

- Gray cast iron: Good vibration damping, low cost, used for machine tool bases and engine blocks.

- Ductile iron: high strength, good toughness, used in gearboxes and joints of industrial robots.

- Steel (A36 steel, 4140 pre-hardened steel): High wear resistance, application in transmission pieces in automated machinery, 4140 steel drive shafts are at a hardness of HRC 30-35.

Machining Cast Iron versus Steel: What's The Difference In Precision CNC Milling?

Having defined precision iron milling and the significance of iron-based materials, it becomes vital to understand how cast iron and steel are machined differently with precision CNC milling. JS Precision has summarized targeted solutions to avoid machining defects.

Handling Graphite: Chip Breaking and Dust Control in Cast Iron Machining

The challenge of machining cast iron is caused by short graphite chips and dust.

Solution: Choose an iron milling cutter with a rake angle of 15° and a clearance angle of 10°. Gray cast iron machining should be performed with a cutting speed of 80-120 m/min and feed rate of 0.1 - 0.2 mm/r. It shall be equipped with a dust extraction system specifically dedicated to this operation.

Conquering Hardness: Heat and Hardness Management in Steel Machining

Steel machining is prone to generate heat. Measures include: adopting TiAlN coating milling bits for steel machining, life increased by 30%+, use high pressure emulsion cooling, while machining 4140 pre-hardened steel with HRC28-32, speed of 60-100 m/min and feed rate of 0.08-0.15 mm/r.

Comparison of Precision CNC Milling Process Parameters for Cast Iron and Steel

| Material Type | Recommended Tool Type | Cutting Speed (m/min) | Feed Rate (mm/r) | Cooling Method | Main Problems Solved |

| Gray Cast Iron | Carbide Iron Milling Cutter | 80-120 | 0.1-0.2 | Dry / Dust Collection | Chip breaking, dust control |

| Ductile Cast Iron | Coated Carbide Iron Milling Cutter | 70-100 | 0.09-0.18 | Dry / Dust Collection | Chip adhesion, precision fluctuation |

| A36 Steel | TiAlN Coated Milling Bits for Steel | 100-150 | 0.12-0.22 | Emulsion Cooling | Cutting heat, tool wear |

| 4140 Pre-hardened Steel | TiAlN Coated Milling Bits for Steel | 60-100 | 0.08-0.15 | Emulsion Cooling | High Hardness Machining and Deformation |

Figure 1: Cast Iron vs. Steel.By understanding the differences between the two, manufacturers and engineers can make informed decisions and effectively meet project requirements.

Limits Of Precision: What Great Tolerances Are Achievable With Precision CNC Milling?

Precision is a top concern for many customers in iron milling, especially for industrial robots and aerospace parts, since even a small deviation in tolerance can lead to equipment failure.

Precision CNC milling by JS Precision provides extremely high tolerance control. We also know what the variables are that affect precision and can specifically protect every micron.

Five Key Factors Affecting Final Precision

Five factors have to be controlled to realize the precision of ±0.01mm or even more:

1. Rigidity of Machine Tool: The precision milling machine consists of a one-piece cast bed that is rather rigid. It can ensure the amplitude of vibration during machining within 0.002mm, thus avoiding the influence of vibration on precision.

2. Thermal Stability: The workshop is fitted with a constant temperature system maintaining the temperature at 20±2℃. A 1℃ temperature change will cause a dimensional change of about 0.012mm in steel parts, constant temperature reduces thermal deformation.

3. Tool Runout: The iron milling cutter's runout should be controlled below 0.003mm using a dedicated tool calibrator. Excessive runout leads to poor surface roughness and decreased precision.

4. CNC System: Equipped with a Siemens 828D CNC system, high positioning accuracy enables the use of complicated machining paths with reduced path deviations.

5. Measurement Feedback: During the machining process, an online probe is used to monitor part dimensions. Any deviation is then automatically compensated for to ensure final accuracy according to standards.

How do we protect every micrometer for you?

For it to maintain its precision continuously, JS Precision has invested in multiple aspects: In the process of budgeting for milling angle iron, JS Precision breaks down the cost structure, adding a new batch quotation table to help you clearly understand the value of fees and transaction costs.

Want to know the maximum precision your precision milling parts can achieve? Upload your part drawings and specify your precision requirements. We will use professional equipment to conduct a simulation analysis and provide you with a free precision achievability report.

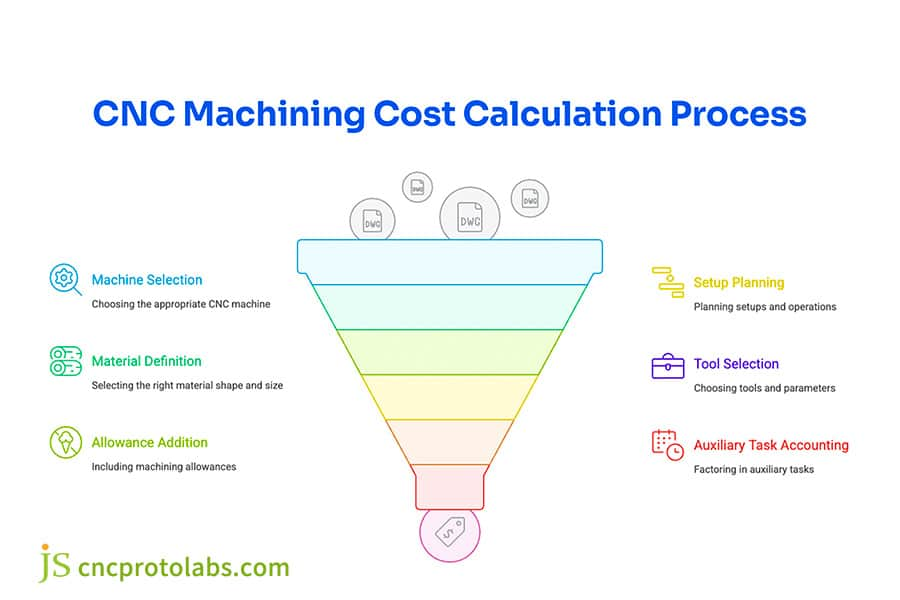

Cost Decryption: How To Estimate Your Milling Angle Iron Machining Project Budget?

Many clients are confused about budget estimation when undertaking iron machining projects such as milling angle iron. They don't know where the money in the quotation is going, nor do they understand why the milling machine cost affects the final cost.

In fact, the cost of iron milling projects has a clear structure. JS Precision will help you break down the cost, allowing you to understand the value of each expense.

Price Quote Analysis: Where Did Your Money Go?

Iron Milling Project Cost Breakdown

| Cost Item | Percentage (%) | Explanation |

| Material Cost | 30-35 | Because of the special profile of milling angle iron, its material cost is higher than that of ordinary sheet metal by 5-8%. |

| Programming Cost | 8-12 | For more complicated parts, multi-axis programming may increase the cost by 3-5%. |

| Machining Time Cost | 35-40 | Precision CNC milling is 20% more efficient than traditional machine tools, reducing time costs. |

| Tool Wear Cost | 10-15 | Opting for the appropriate iron milling cutter may lower the tool wear cost by about 30%. |

| Surface Treatment Cost | 5-8 | Mirror polishing (Ra 0.4 μ m) costs more than ordinary deburring. |

Price List of Milling Angle Iron (Q235, 1000mm×50mm) in Various Quantities

| Machining Batch (pieces) | Unit Price (USD) | Total Price (USD) | Delivery Time (days) | Discount Policy |

| 10-50 | 18.5 | 185-925 | 7-10 | No Discount |

| 51-200 | 15.2 | 775.2-3040 | 10-15 | 8% Bulk Discount |

| 201-500 | 12.8 | 2572.8-6400 | 15-20 | 16% Bulk Discount + Free Inspection |

| 500+ | 10.5 | 5250+ | 20-25 | 22% Bulk Discount + Free Packaging |

For instance, taking a 1000mm long milling angle iron made from Q235 material, the cost range is around $150, inclusive of material costs amounting to $45, programming costs at $15, labor costs at $60, cutting tool costs at $18, and surface treatment at $12.

Milling angle irons have more laborious clamping work, where the processing time is 15-20% higher than that of ordinary sheet metal, making the cost of labor a bit higher.

Investing in Efficiency: How to Understand the Value of Milling Machine Cost?

High-end precision CNC milling machines cost $150,000 to $300,000. Again, while expensive, they offer the added value of 20% faster processing speeds, 30% tool life extension, and lower defect rates. Example: The machine helped a client reduce unit costs by up to 18%.

If you need an accurate budget evaluation for your milling angle iron, please inform us about the dimensions of a part, material, and machining requirements. We will provide you with a detailed cost breakdown to help you find areas for cost reduction.

Figure 2: CNC machining cost calculation process.Pricing CNC machined parts may seem like a puzzle, but as long as you follow the steps, you will find that it is actually very simple.

How To Determine The Cost Effectiveness Of An Iron Milling Cutter?

The selection of the correct iron milling cutter is of utmost importance. JS Precision's tool cost comparison table enables you to pick an appropriate tool with the lowest total cost of ownership.

More Than Just Price: Balancing Tool Life and Machining Efficiency

The basic rule of thumb is "Cost per piece = Tool Price ÷ Number of parts that can be machined". Example: tool A, $50 to machine 100 pieces, $0.50 per piece, tool B, $80 to machine 200 pieces, $0.40 per piece. Thus, tool B is more economical.

Iron Milling Cutter Procurement and Usage Cost Comparison

| Cutter Model | Material | Coating | Unit Price (USD) | Number of Machinable Parts | Cost per Cutter (USD) | Applicable Materials |

| TC-01 | Ordinary Carbide | None | 45 | 80 | 0.56 | Grey Cast Iron |

| TC-01 | Ultrafine Carbide | TiCN | 85 | 200 | 0.43 | Ductile Cast Iron |

| TC-01 | Ultrafine Carbide | TiAlN | 130 | 180 | 0.72 | 4140 Pre-hardened Steel |

Tailored to Your Materials: JS Precision's Cutter Selection Strategy

Choose material according to the hardness, coating depending on the machining method, and flute type according to the chip type. For instance, TC-02 is recommended for ductile cast iron and TC-03 for hardened steel due to compatibility in tool requirements.

Not sure which iron milling cutter is right for your job? Upload your material sample or provide the material model number and our tooling experts will recommend the most cost-effective cutter and provide a trial program.

Figure 3: When purchasing tools, consider whether they can maximize performance, meet technical requirements, and also have economic advantages.

Overcoming Geographic Boundaries: Why CNC Milling Services Near Me Isn't The Best Option?

Most customers, when searching for precision milling, make "CNC milling services near me" their priority, thinking that will be more convenient. In today's global world, such geographical limitations could result in higher prices, limited technology, or longer delivery times. We at JS Precision can offer better value with our efficient global logistics and management.

The Hidden Ceiling of Local Services: Limitations in Technology and Capacity

"CNC milling services near me" is usually provided by small-scale suppliers, whose ability in technology and capacity is quite limited: they only have 3-axis precision CNC milling machines, which can't process complex multi-axis linkage parts, meanwhile, they lack experience in processing special materials.

In terms of capacity, the local suppliers usually have just 5-10 machines and need 2-3 months for orders over 1000 pieces, while JS Precision can deliver in one month, having more than 50 machines.

Moreover, the CMMs are lacking in local suppliers. In this situation, full-dimensional inspection is difficult to carry out and will have to compromise on accuracy. For example, one customer had to return us for rework because his local supplier lacked necessary fixtures for milling angle iron, resulting in substandard machining accuracy.

Seamless Collaboration: How Do Global Clients of JS Precision Manage Projects Thousands of Miles Away?

Our remote collaboration is more effective and transparent than local communication:

We have a client portal system for real-time project progress tracking, regular online meetings and weekly progress reports, DDP service with DHL and FedEx, providing end-to-end cargo tracking with 7-10 day delivery for US customers, and a professional after-sales team available 24/7.

One US customer who employed our system to track industrial robot joint parts in real time while machining was able to deliver the project 3 days in advance.

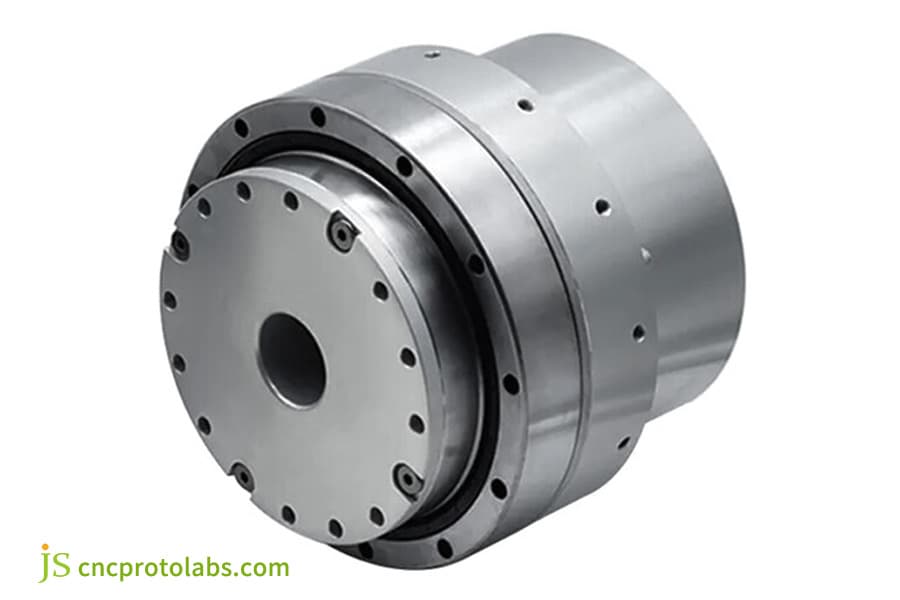

Case Study: JS Precision Helps A US Industrial Robot Manufacturer Overcome Bottlenecks By Reducing Costs By 25%

The major US manufacturer of industrial robots produces mainly 50kg payload industrial robots. Its core component is ductile iron joints, and its quality decides directly the operational accuracy and working life of robots.

Previously, they chose a local supplier for iron milling but faced two serious problems that resulted in bottlenecks. These difficulties were successfully overcome when partnering with JS Precision.

Customer Dilemma: Precision Fluctuations and High Local Costs

The joint bearing mounting plane requires ±0.05mm and Ra 1.6μm, but local machining resulted in fluctuations of ±0.08mm, causing abnormal robot noise and a 15% defect rate.

The procedure required one hour of man-hours due to manual grinding. Tool life was only 50 pieces/tool, and the cost per piece was $200-a 30% increase in cost over budget. Communication between the customer and this local supplier failed, and the only alternative left was to seek a new partner.

Solution by JS Precision: Process Optimization & Custom Tooling

From the analysis of the local defective parts, the main reasons were identified by JS Precision: inappropriate clamping (two-point support and deformation) and excessively high cutting parameter (120m /min-heat deformation). After that, the following solutions were developed:

1. Redesign Clamping Scheme: Adopt multi-point flexible support clamping, adding three auxiliary supporting spots at the weakest position of the workpiece to minimize distortion in machining. At the same time, positioning should be done with a special fixture to ensure that when clamping many times, the repeatability is within ±0.005mm.

2. Optimize Cutting Parameters: The cutting speed should be adjusted from 120m/min to 90m/min, and the feed rate shall be from 0.15mm/r to 0.12mm/r. Use a small depth of cut, 0.5mm, with multiple tool paths to decrease cutting heat, preventing part deformation.

3. Special Iron Milling Cutter: This ductile iron part adopts a special iron milling cutter design in cooperation with the tool supplier. It employs ultra-fine grain cemented carbide with TiCN coating and shallow groove design for improvement of wear resistance and chip breaking ability.

Data Speaks: Outstanding Achievements

After optimization, flatness stabilized at ±0.035mm, the accuracy increased by 30%, defect rate to 0, tool life increased to 150 pieces/cutter, processing time to 2.5 hours, and unit cost was reduced by $150 (25%).JS Precision became its strategic partner in Asia, and over 5000 parts have been processed for it, with a record on-time delivery rate of 100% to date.

If you too face similar bottlenecks in processing, please send us your part issues and requirements, and we will develop a custom breakthrough solution for you, drawing on our successful case experience.

Figure 4: Iron robot joint

FAQs

Q1: What are some common iron-based materials you use?

Our commonly used iron-based materials are A36 steel, 4140 pre-hardened steel, 304/316 stainless steel, gray cast iron, and ductile iron that meet performance requirements for parts in several industries, such as gray cast iron being used for machine tool bases.

Q2: What is the highest surface roughness you can achieve?

The surface roughness of our machined iron-based material varies from material to material and the processing method. After precision milling and polishing, we can achieve a mirror finish with a maximum Ra of 0.4μm that meets the requirements of high-end parts.

Q3: What is the lead time for prototyping new projects?

We will deliver the first piece in about 5-7 working days after receiving part drawings from customers and confirmation of the order. If parts are complicated and special tools are required, we may need 1 or 2 more days, but we will let you know in advance.

Q4: How do you manage the international freight and customs clearance?

We cooperate with international logistics such as DHL and FedEx for DDP service. We track the goods throughout the process and we will go through customs clearance to ensure safe and punctual delivery.

Q5: What should be in my design files?

Provide a STEP/IGES 3D model and PDF/DWG 2D engineering drawings of the components, and clearly state part dimensions, tolerances, materials, surface requirements, and assembly relationships.

Q6: Are there any special strategies you have for deep cavity milling?

Deep cavity milling applies a dynamic milling strategy for the purpose of optimizing toolpaths with reduced cutting forces. It makes use of long-neck tools and equips internal cooling equipment for smooth chip removal.

Q7: Does the quotation include all costs?

We provide quotations based on complete sets of goods, and the quotation includes the processing cost, standard packing, and factory inspection fee. Special packing or extra test will be announced with quotation separately in advance.

Q8: What is the biggest advantage you have compared to local suppliers?

Our core advantage with respect to local suppliers is that we can offer, at the same or higher quality, competitive prices and complete solutions to deliver our promise thanks to technological optimization such as multi-axis machining and economy of scale.

Summary

Where precision manufacturing is concerned, decisions are deterministic. Whether budgeting for milling angle iron or high precision CNC milling services, JS Precision puts years of experience and expertise to work assisting you in reducing costs, improving accuracy, and overcoming geographical constraints to make your iron milling projects run more smoothly.

Let distance not be a barrier to accessing world-class manufacturing capabilities. Get the tailored precision milling solution for your needs. Upload your part drawings now and get an instant quote based on expert analysis. Find out yourself how precision manufacturing from China can empower your business!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com