Precision CNC milling services are facing a surface defect pain point in the high-end precision parts manufacturing field that is easily overlooked but has a significant impact - Quadrant Protrusion.

This tiny defect at the micron level is like an "invisible enemy" in the quest for perfect surfaces. It affects the look of parts and can lead to functionality, sealing, or assembly precision problems, thus resulting in higher post, processing costs and project risks. Professional precision CNC milling services play a vital role in fixing this problem through systematic solutions.

Here is an article that discusses the cause and gives complete sets of strategies, including technical changes and choosing suppliers.

Core Answer Summary

| Your Core Concerns | JS Precision's Solutions | Core Value for You |

| Quadrant groove tool marks adversely affect part accuracy and appearance, and are almost impossible to remove. | For CNC milling metals, we deliver thorough diagnostics and tailor, made process packages for machine tools, control, and processes. | Get perfect surfaces, cut down on secondary polishing, and make sure that the part's functionality is as designed. |

| The standard suppliers are unable to solve deeply rooted problems because of the high internal debugging costs and the lack of experience. | By means of up, market CNC milling machine services and process knowledge, we supply basic solutions. | R&D debugging time and cost savings, stable machining results, and project progress acceleration. |

| How can one recognize the suppliers that have the capability of solving such precision problems in the CNC milling China market? | Use the machine tool and calibration report presentations and sample verification to show custom precision machining services professionalism. | Develop a long, term relationship of trust and ensure the constant production of high quality parts for complex aluminum CNC milling machining tasks. |

Key Takeaways

- Quadrant protrusions appearance can be explained by servo system lag, backlash, and path control effects together. A systematic solution is necessary.

- The way the problem manifests and the strategies for its optimization should be adjusted to the case of the different materials being machined (e.g. aluminum vs. steel). CNC milling for aluminum parts are very sensitive to parameters.

- Besides the price and the basic equipment, make the main emphasis while choosing a supplier on the dynamic performance of their machine tool, their ability of control system optimization, and their experience in the process.

- If you have early technical communication with experts like JS Precision, it is possible to apply their mature process packages directly to solve the problems in 1-2 iterations.

How To Eliminate Quadrant Protrusions? JS Precision CNC Milling Service Solutions

Quadrant protrusion is a typical problem in precision CNC milling services. Only a systematic solution that integrates machine tools, processes, and materials can solve such a problem. It is nowhere close to merely tweaking one single parameter.

JS Precision has been in the engineering team business for over 20 years. During this time, the company has developed a proprietary problem, solving system.

- A thorough diagnostic is carried out during which the machine tool servo system, guideway rigidity, and backlash are precisely tested to ensure that the backlash is controlled within 0.003mm.

- A process package is tailored by picking up the right tool coating, cutting parameters, and path strategy based on the features of CNC milling metals.

- Closed, loop verification, i.e., employing a coordinate measuring machine (CMM) and profilometer for a quantitative inspection to ascertain that the defect has been eliminated entirely.

The improvement of quadrant errors by means of precise compensation is one of the things illustrated in ISO 230-2:2018.

JS Precision has brought this technology into the optimization of machine tool transmission components, along with its self, served servo parameter calibration solution, which have together allowed it to reach an accuracy level of 0.005mm in over 95% of the projects.

We company also helps customers cut down their processing costs by an average of 20%, and 98% of the delivery orders are on time.For high-requirement scenarios such as aluminum CNC milling machining, we can also provide dedicated high-speed, shallow-depth-of-cut processes to avoid tool sticking and increased vibration.

Choosing a supplier that can fundamentally solve the problem is far more cost-effective than repeated rework. Want to verify the capabilities of our precision CNC milling services? Submit your part drawings now, and JS Precision will provide you with a free process feasibility analysis and cost calculation, allowing you to visually see the effect of quadrant protrusion resolution.

What Is a Raised Blade Pattern In The Quadrant And Why Does It Affect The Quality Of The Parts?

CNC milling quadrant protrusions and tool marks are usually the main culprits hurting the quality of precision parts, and precision CNC milling services are basically the lifeline in fixing this problem.

Visual Manifestations of the Problem

You may see protrusions, tool marks, or even overcutting on the surface of parts at the circular, curved contours, or corners. These faults are generally micron, level deviations, i.e., in the range of 0.005 to 0.02 mm. They are almost invisible to the naked eye but have a direct impact on the core performance of the part.

Multiple Harms to Parts

- The presence of protrusions and marks will drastically change the surface roughness to such an extent that the Ra value will increase and the overall appearance and functionality of the high, end product will be compromised.

- The accuracy of the assembly will get affected which will be demonstrated, for example, by the occurrence of jamming due to the mating of a bearing housing thus the overall stability of a machine operation will be impaired.

- The sealing performance of the parts will be compromised thus leakage risks in hydraulic and pneumatic components will be very easy to occur.

- The use of post-processing will be more required and thus the costs will rise, for example, a polishing process will be necessary to fix the defects.

Figure 1: Two cylindrical aluminum parts side-by-side; the right one shows visible scratch marks and surface defects, illustrating potential quadrant protrusion issues.

How Does Precision CNC Milling Services Define And Diagnose Quadrant Bulge Problems?

Accurate diagnosis is the first step for solving any problem. The strength of precision CNC milling services is that they can find out the main cause of the quadrant protrusion tool marks very fast.

The main point is system dynamic error

This defect is caused by the combined effects of delayed servo motor response, insufficient reverse clearance compensation, and rail friction during coordinate axis reversal of the machine tool.

When the machine tool performs arc interpolation, the motion speed of the two coordinate axes needs to be accurately matched, and any lag of either axis will lead to path deviation, ultimately forming a protrusion.

Fast Problem Diagnosis

- Inspect the 90-degree corners of the part for any small roundings or protrusions.

- Determine the diameter of the circle and verify whether the dimensions of the quadrant points are equal.

- Check the machine tool backlash, is the value higher than 0.003mm which is the critical value?

- During the cutting process, is there any tool chatter that can be seen?

CNC Milling Machine Services: Which Machine Tools And Servo System Factors Cause Protrusion?

The very heart of CNC milling machine services is how well the machine tool performance and servo system can interact, hence directly determining whether quadrant bulges or tool marks will be formed.

Core Mechanical and Electrical Reasons

- Servo gain is not properly set: If the gain is set too high, this will easily make the machine vibrate, however, if the gain is too low the machine response will be delayed.

- Excessive backlash: If the backlash is more than 0.003mm, the free travel during reversal will directly cause the deviation of the path.

- Problems in guideway rigidity or wear: During the movement, the deformation will affect the positioning accuracy of the coordinate axes.

- Ball screw friction is not stable: Friction suddenly changing during reversal will cause the motion trajectory to be disturbed.

What does the Control System play?

The compensation algorithm performance is very different among various control system brands.

As a matter of fact, there is a difference between Fanuc's AI contour control and Siemens' Advanced Surface system, in the sense that both systems have a better capability of pre-reading and smoothing, thus can significantly decrease quadrant errors. This kind of advanced feature is not available in low-end systems, so they have difficulties in meeting the needs of high precision machining.

Comparison of Quadrant Error Compensation Capabilities of Different Control Systems

| Control System Brand | Compensation Algorithm | Quadrant Error Control Accuracy | Applicable Scenarios | Supporting Services |

| Fanuc | AI Contour Control | ±0.004mm | High-precision molds, aerospace parts | Original factory parameter calibration |

| Siemens | Advanced Surface | ±0.003mm | Complex curved surfaces, medical parts | Real-time path optimization |

| Domestic Economical System | Basic clearance compensation | ±0.015mm | Ordinary structural parts, low-precision parts | Simple parameter adjustment |

| Heidenhain | TNC640 Dynamic Compensation | ±0.002mm | Ultra-precision optical parts, satellite components | Full-process adaptation |

| Mitsubishi | Intelligent Contour Control | ±0.006mm | Automotive parts, mass production parts | High-efficiency mass production solutions |

What Are The Differences In CNC Milling Protrusion Issues When Processing Different Metal Materials?

The different material properties of CNC milling metals cause the performance and effect of quadrant protrusion tool marks to differ drastically.

Challenges with Soft Metals (e.g., Aluminum Alloys)

The parameters for CNC milling for aluminum parts are particularly finite. Aluminum alloys with high surface finish requirements tend to highlight any tool marks.

On the other hand, the high viscosity of aluminum alloys makes it very easy for improper cutting parameters to cause tool sticking and chatter, which are main contributors of quadrant protrusion problems, thus impacting the appearance and assembly accuracy of parts.

Challenges with Hard Metals (e.g., Stainless Steel)

In the case of stainless steel and other hard metals, the cutting forces are so high that changes in the servo load occur, thus affecting the path tracking accuracy.

Quadrant protrusions in such materials are generally in the form of hidden dimensional deviations rather than surface tool marks, which makes them very difficult to locate and fix and thus requires high service level from CNC milling machines.

Figure 2: An assortment of metal stock including blocks and rods in silver and copper colors, showcasing material variety for precision machining.

What Are The Targeted Elimination Strategies For CNC Milling For Aluminum Parts?

The quadrant protrusion problem in CNC milling for aluminum parts needs focused process strategies to tackle it.

Precision Adjustment of Process Parameters

- Applying high, speed rotation, slowly varying the speed within 8000-12000 rpm to shorten the time of tool, material contact.

- Keeping a small depth of cut, limiting the finishing depth of cut at 0.1-0.2 mm to lowering the cutting force and vibration.

- Adjusting the feed rate, managing the feed speed at 0.05-0.1 mm/tooth to guarantee an uninterrupted cutting.

- Selecting sharp finishing tools with special coatings, e.g. diamond-coated tools, to the reduction of tool sticking.

Programming Path Optimization Technology

- Using the arc filtering function to make the corner movement path of the tool smoother.

- Adjusting corner deceleration to reduce the feed speed at corners so that the servo system can track accurately.

- Utilizing NURBS interpolation to enhance the machining accuracy of complex curved surfaces thus minimizing path deviation.

Want to overcome the quadrant protrusion problem in aluminum alloy parts? Tell JS Precision your aluminum part model and precision requirements to get a customized aluminum CNC milling machining process solution.

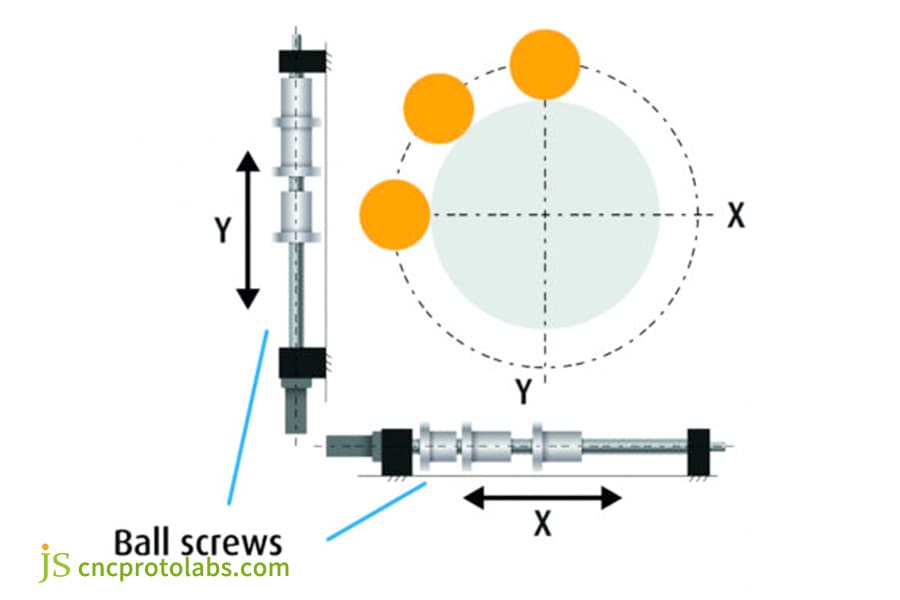

Figure 3: A technical diagram illustrating X and Y-axis ball screws for precise machine tool movement, with a circular workpiece boundary outlined.

Custom Precision Machining Services: What Exclusive Process Optimizations Do You Need For Your Customized Project?

Custom precision machining services are essentially about the art of tailoring. JS Precision is capable of developing personalized process optimization solutions for your initiatives.

Systems Engineering from Conception to Final Product

- ASME Y14.5-2009 requires giving feedback on Design for Manufacturability (DFM) to optimize part geometry and eliminate complex protrusion-prone corners.Work out a stepwise roughing and finishing scheme.

- Roughing gets rid of the major part of the waste material, whereas finishing guarantees accuracy.

- Integrate vibration analysis to determine the best clamping solution, e.g. to use hydraulic clamps or soft jaws, to prevent part deformation.

Measurement, Driven Iterative Closed, Loop

Employing a high, precision coordinate measuring machine (CMM) to carry out contour measurement of the workpiece, transferring the measurement result back to the programming end for parameter adjustment, thus creating a closed-loop optimization. This approach is a sure way to attaining continuous process improvement, eventually completely removing the quadrant protrusion tool marks.

JS Precision Custom Process Optimization Effect Data

| Project Type | Material | Original Defect Value | Optimized Precision | Shorter Delivery Time | Lower Cost |

| Drone Camera Bracket | 7075 Aluminum Alloy | 0.015mm | ±0.005mm | 30% | 25% |

| Aerospace Bearing Housing | Stainless Steel 316L | 0.012mm | ±0.004mm | 25% | 20% |

| Medical Surgical Instruments | Titanium Alloy TC4 | 0.008mm | ±0.002mm | 20% | 18% |

| Satellite Structural Components | Aluminum Alloy 6061 | 0.020mm | ±0.003mm | 35% | 22% |

| Automotive Sensor Housing | Zinc Alloy | 0.018mm | ±0.006mm | 28% | 21% |

Want a customized precision machining solution? Submit your part drawings to JS Precision, and we will provide you with a free DFM analysis report to improve the cost-effectiveness of your custom precision machining services.

How To Evaluate The Technical Strength Of Global Suppliers In Solving This Problem When Selecting Them?

In the process of picking suppliers from the CNC milling China market, one of the most important criteria to check their technical prowess because it is the main factor that decides if quadrant protrusion problems can be tackled or not.

Basic Technical Specifications

- What is the brand and model of the machine tool, does it have a top-level control system like Heidenhain or Fanuc?

- Backlash calibration data, is it possible to control the backlash stably within 0.003mm?

- Servo parameter tuning experience, have they done tuning for different types of materials?

- What testing equipment do they have, are they equipped with high-precision testing tools like coordinate measuring machines and profilometers?

Samples as a Proof of Capability

One should propose to the suppliers to experiment a free or paid run of machining of test pieces that include typical curved surfaces and corners, and then measure their contour accuracy and surface roughness, e.g. asking for Ra < 0.4m. Checking with samples is a way to get the suppliers technical capabilities verified directly.

Want to identify high-quality suppliers in the CNC milling China market? Contact JS Precision to obtain a free supplier evaluation list and avoid selection pitfalls.

Case Study: Overcoming The Problem Of Quadrant Protrusion Of Aluminum Alloy Parts For Drone Camera Bracket In 48 Hours

Challenge

A drone manufacturer needed a batch of high, precision 7075 aluminum alloy camera mounts. During the internal CNC milling for aluminum parts, the tiny protrusion about 0.01-0.015mm kept showing up at the quadrant transition point of the curved guide rail surface.

Because of this, the lens got jammed. Manual polishing would have compromised the precision of the part, which is why the project was stuck.

JS Precision Solution: Three, Step Systematic Eradication

1. Dynamic Diagnosis: After receiving the customer's parts and program, engineers studied the original toolpath and parameters. They concluded that the main problem was the incompatibility between servo response parameters and cutting conditions.

2. Customized Process Package: We used a high-dynamics five-axis milling machine equipped with a Heidenhain TNC640 system to

optimize servo feedforward gain and contour tolerance. Aluminum CNC milling machining was done using a single flute large helix angle precision milling cutter selected specifically, and reprogramming was done using NURBS interpolation.

3. Verification and Delivery: Once the first piece was manufactured, a contouring instrument was employed for the inspection, and protrusions were totally eliminated. The total contour accuracy was kept within 0.005mm, and the surface roughness Ra was 0.3m.

Results

JS Precision handed over a qualified sample within 48 hours, which entirely settled the assembly issue. The customer was so impressed that he gave JS Precision the next three batches, in total 500 pieces. This led to a 25% cut in per piece machining costs and a 30% cut in delivery time.

Facing similar precision parts machining challenges? Contact JS Precision now, submit your part requirements, and we'll provide you with fast prototyping services, proving the value of our custom precision machining services.

Figure 4: Two matte-black anodized aluminum scope rings with engraved “34mm” and torque specs, showcasing finished precision-milled components.

FAQs

Q1: When are quadrant tool marks most likely to appear?

The defect is most likely to occur during machining operations of full circles or rounded contours, and right angle 90-degree corners, as these instantaneous directional changes of the programmed path exceed the machine tool servo response speed.

Q2: Is it possible to get rid of the tool marks by reducing the feed rate?

Slightly lowering the feed rate at the corner should be able to help the defect to some extent. However, an excessive reduction will not only affect the efficiency of machining but may also cause other surface problems. It has to be adjusted comprehensively together with servo parameters.

Q3: Does it make a big difference between solving this problem with new and old machine tools?

Yes, there is a big difference. Particularly the new CNC machines within the last 5 years are more likely to be equipped with great technology of servo drives and control algorithms combined with better built, in anti, tool mark functions, thus, they can be solved quite easily.

Q5: How do you measure and verify if the protrusion has been eliminated?

We use high-precision profilometers or coordinate measuring machines to scan dense points of feature contours, generate contour curve graphs magnified hundreds of times, and quantitatively analyze whether defects have been eliminated.

Q6: Will solving this problem significantly increase processing costs?

Process optimization itself usually does not incur additional fees, as it falls within the professional scope of our precision CNC milling services. Choosing us can actually save on rework and scrap costs.

Q7: Are you also willing to conduct this kind of deep optimization for prototypes or small batch parts?

Of course we am willing. This is the value of custom precision machining services, as we apply best practices from the first piece to ensure the success of prototype functionality and appearance in one go.

Q8: Can China's CNC milling machine services achieve the required level of accuracy to avoid protrusions?

Absolutely possible. Taking JS Precision as an example, we invest in top-notch imported equipment and strictly maintain it, possessing in-depth process knowledge that can meet or even exceed the precision requirements of international customers.

Summary

Quadrant protrusion tool marks should not be seen as an unsolvable problem, instead, they are a way to check the technical abilities of a precision CNC milling services provider.

The real answers lie in knowing the machine tool performance very well, accurately understanding the material properties of CNC milling metals, and having a lot of experience in turning these two into stable processes. From all the CNC milling China market options available, the wise choice is to skip the price traps and directly talk to the technical experts.

Act now! Send to JS Precision the part drawings that are giving you this problem. Our engineering team will offer you a thorough diagnostic analysis and tailor-made process solutions that will enable you to get rid of the quadrant protrusions completely and reach the next level of zero-defect precision manufacturing.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com