Aluminum CNC milling service is the core support for solving the manufacturing problems of aerospace structural components.

Weight is one of the key parameters affecting fuel consumption and payload in the aviation industry, and at the same time, the lightweight and high strength character of the wing ribs and beams will ensure the aircraft's performance and safety.

The question is: how can aerospace aluminum ingots be turned into high precision reliable components? This, indeed, is the main challenge and the essence of aluminum CNC milling service.

In the article we will dive into how CNC milling aluminum is a shaping factor of modern wings and also discuss why working with experts such as JS Precision, who through their experience with aviation standards, know the industry inside out, is the key to success in a project.

Quick Overview of Core Answers

| Core Questions | Key Answers | Value Brought to You |

| Why is CNC milling aluminum for wing components the main method? | CNC milling aluminum takes advantage of the excellent strength-to-weight ratio of aerospace aluminum. It is through a highly precise forming process that lightweight and high performance key structural components can be made. | Knowing the technology advantages at the core makes it obvious that suitable projects should be selected. |

| How can one make sure the parts conform to tight aviation standards? | Using suppliers capable of aerospace CNC milling, their stringent processes are basically the foundation of flight safety. | Establish key evaluation dimensions for quality and compliance when selecting suppliers. |

| What additional benefit might come from opting for Chinese suppliers? | JS Precision, one of the leading Chinese aluminum CNC milling service providers, is at the forefront in adopting advanced technology and has cost advantages which they can pass on to their customers in the form of custom aluminum machining solutions. | Obtain a reliable partner perspective that balances top-notch quality, cost efficiency, and supply chain resilience. |

Key Takeaways:

- Precision means safety:

The structural components of aerospace usually require contour tolerances within ±0.05mm and hole position accuracy within ±0.025mm. Only high dynamic precision 5-axis CNC milling can meet these standards in a continuous manner.

- Material and process synergy:

Different aerospace aluminum materials e.g. 7075-T6 and 6061-T6, require customized cutting parameters and post-processing (e.g. T73 aging treatment) to achieve a balance between strength, stress corrosion resistance, and machinability.

- Light weighting is the direct creation of value:

Utilizing topology optimization and CNC milling integration of aircraft parts, a 15- 30% weight reduction of the components could be obtained, thus significantly increasing fuel efficiency and the load capacity.

- End-to-end traceability is the bare minimum:

The entire digital documentation (in line with AS9100) of the raw material melting to the final product is a compulsory condition for aerospace project entry.

Why Trust This Article? JS Precision’s Insight Into Aerospace CNC Milling Services

The professionalism regarding aluminum CNC milling services is what sets the safety standards for aerospace components, while the capability to implement CNC milling technology is mainly a matter of the supplier's qualifications and experience.

JS Precision, a leading company in the aerospace aluminum parts processing industry, holds with pride dual ISO 9001:2015 and AS9100D certifications, thus thoroughly meeting the global aerospace and defense industry's supply chain access requirements.

Our company is equipped with several German DMG MORI 5 axis high speed milling centers, with a capability range of 1200×800×600mm, allowing us to process structural components of an aircraft that are very critical such as wing ribs and beams.

Regarding project experience, JS Precision has been a supplier for over 50 global aerospace companies, spanning various fields such as commercial aircraft, drones, and eVTOL, and delivering over 100, 000 high precision aerospace aluminum parts while maintaining a flawless quality record.

One such example is that we extended our aluminum CNC milling services to a worldwide eVTOL manufacturer, where we precisely completed the machining of complex wing main spars, thus aiding them in the smooth progression of their flight test plans.

All of the core engineers at our company have more than 10 years of aerospace machining experience. They are familiar with the cutting parameters and post-processing techniques of the major aerospace aluminum materials 2024, 6061, and 7075, and can accurately address industry problems such as machining deformation of thin walled parts and chip removal from complex cavities.

All the technical viewpoints in this article are from JS Precision's practical project summaries and are in line with the AS9100D aerospace quality management system standard.

For top-tier aerospace clients, the major factor deciding a partner is their risk management capability. JS Precision starts with the design stage, offering DFM/A process optimization suggestions to reduce R&D risks, and allows clients to keep track of machining progress and quality in real time via a digital platform.

Want to verify JS Precision's aerospace machining capabilities? Contact our engineers now, submit your component drawings, and receive a free customized process feasibility analysis report.

What Unique Advantages Does CNC Milling Aluminum Offer For Wing Ribs And Spars?

The fusion of CNC milling technology and aerospace aluminum turns out to be the perfect choice for light yet sturdy wing components. Aluminum CNC milling are indeed the best fit for the process requirements of manufacturing wing ribs and spars.

Exceptional Strength-to-Weight Ratio and Material Properties

Aerospace aluminum alloy grades (e.g., 7075-T6, yield strength 503 MPa) have an exceptional strength-to-weight ratio. Aluminum CNC milling can make the most of topology optimization for the maximum removal of redundant material. 2024 aluminum alloy contains around 4.4% copper and has very high fatigue strength.

Accurate CNC milling enables the machining of weight, reduction cavities in non stressed areas of wing ribs, thus a weight reduction of 15-30% is achieved without the loss of structural integrity.

Unrivaled Geometric Freedom and Accuracy

Wing ribs need convoluted airfoil surfaces and reinforcements ribs to fit aerodynamic forms. CNC milling aluminum can hold the main contour tolerances within ±0.05mm and hole position accuracy to ±0.025mm. The features that are hard to realize with traditional processes, such as deep cavities and thin walls, can be produced in one shot through programming.

Scalable Economy from Prototype to Mass Production

CNC milling is a highly flexible technology. By using small-batch prototyping it is possible to avoid spending money on custom molds since the program is changed to adjust the dimensions and in this way R&D risks are kept at a minimum.

Medium and large-batch production can be optimized by tuned toolpaths and automated clamping, thus being more efficient and reducing unit costs.

Comparison of Machining Performance of Mainstream Aerospace Aluminum Materials

| Aluminum Alloy Grade | Yield Strength (MPa) | Machining Difficulty | Applicable Components | Weight Reduction Potential | Corrosion Resistance |

| 2024-T3 | 324 | Medium | Wing Ribs, Fuselage Skin | 20% | Medium |

| 6061-T6 | 276 | Low | Non-load-bearing Structural Components | 15% | High |

| 7075-T6 | 503 | High | Wing Spans, Landing Gear Components | 25% | Medium |

| 5083-H111 | 193 | Low | Aviation Fuel Tank Components | 18% | Extremely High |

Want to know which aluminum material offers the best cost-performance ratio for your wing components? Contact JS Precision now for a free aluminum material selection and machining cost calculation plan, and gain a deeper understanding of the cost reduction potential of CNC milling aluminum.

Figure 1: A collage showing an aircraft landing gear, a CNC tool in action cutting aluminum, and a stack of finished, complex-shaped aluminum aerospace parts.

Figure 1: A collage showing an aircraft landing gear, a CNC tool in action cutting aluminum, and a stack of finished, complex-shaped aluminum aerospace parts.

Why Is 5-Axis CNC Milling The Ideal Solution For Complex Aerospace Components?

Being able to make complex aerospace CNC milling parts is an essential skill, and 5-axis CNC milling is the right technology that can easily handle structural components with irregular shapes such as wing ribs and beams.

Single, Site Forming of Complex Geometry

Normally, 3 axis machining of wing ribs will have to be clamped several times, and this can lead to error accumulation pretty easily. 5-axis CNC milling can do all the surface machining in a singe clamping simply by rotating the workpiece or the tool, resulting in a positional accuracy of ±0.025mm, thus satisfying the very strict requirements of aerospace components.

Optimized Toolpath and Surface Quality

5-axis CNC milling always ensure the best cutting angle between the tool and the workpiece, thus chip removal is done efficiently, machining stress gets significantly reduced, a top-quality surface with Ra 0.4μm is produced, less polishing is required, and the delivery time is shortened.

Shorter Delivery Time and Improved Material Utilization

By 5-axis CNC milling parts with complex ribs, clamping and auxiliary times can be cut down by over 30%. Also, near-net-shape technology has taken the percentage of material utilization from 30% in the conventional processes up to more than 60%, which, besides, has resulted in a significant decrease in the cost of raw materials.

Comparison of 5-axis and 3-axis Machining Efficiency

| Machining Indicators | 3-axis CNC Milling | 5-axis CNC Milling | Improvement |

| Number of Clampings (Complex Ribs) | 5 | 1 | 80% |

| Machining Cycle Time (Single Piece) | 12 hours | 4 hours | 67% |

| Positioning Accuracy | ±0.1mm | ±0.025mm | 75% |

| Surface Roughness Ra | 1.6μm | 0.4μm | 75% |

| Material Utilization | 30% | 65% | 117% |

How Does Aerospace CNC Milling Ensure Parts Meet Stringent Flight Safety Standards?

The major idea of aerospace CNC milling is that a flight safety standard can be ensured for a molded part, by end-to-end control.

Full Chain Traceable Quality Control System

- Raw Material Certification: Aerospace aluminum compliant with AMS is used. Each batch is identified with a melting number and certificate of material.

- Process Monitoring: Online SPC statistical process control, real time monitoring of dimensional deviations and parameter adjustments.

- Finished Product Inspection: Full dimensional inspection using a coordinate measuring machine, generating reports to ensure parts meet drawing requirements.

Targeted Post-Processing and Non Destructive Testing

- Post-Processing: Depending on the requirement, treatment by shot peening, hard anodizing, etc., is done to enhance the fatigue life and corrosion resistance.

- Non Destructive Testing: Such techniques as FPI and UT are used for the detection of internal micro, cracks of the parts, thus, the hidden defects are totally excluded.

Simulation-Driven Process Verification

Simulate cutting force and deformation using CAM software before processing, predict problems, and adjust process parameters to avoid component deformation exceeding tolerance caused by processing stress.

Want to ensure your parts pass aerospace safety certification? Contact JS Precision immediately to obtain a complete aerospace CNC milling quality control checklist to mitigate certification risks.

Figure 2: A close-up view of a cylindrical metal aerospace component being inspected with a precision measuring tool for quality control.

Figure 2: A close-up view of a cylindrical metal aerospace component being inspected with a precision measuring tool for quality control.

What Is The Complete Process For CNC Milling Aircraft Parts From Design To Delivery?

The entire process for CNC milling aircraft parts is under standardization. For instance, wing ribs, the exact process is:

Design Collaboration and Process Planning

JS Precision engineers perform DFM/A design reviews with customers to help them optimize part features and thus, improve component manufacturability and reliability.

Precision Machining and Surface Treatment

- Rough Machining: Material is removed at a high rate, allowing finishing to be done on a smaller area.

- Semi-Finish Machining: Release stress so that there is no deformation later on.

- Finish Machining: Complete the work to the measure and surface finish requirement.

- Post-Processing: The steps include deburring, polishing, and anodizing to aerospace specifications.

Final Verification and Compliance Packaging

- Full Dimensional Inspection: Laser scan comparison is used to produce a first piece inspection report.

- Packaging and Delivery: Special moisture-proof and anti-static packaging to ensure the product does not get damaged during transportation.

Want to understand the detailed process from design to delivery for your parts? Tell JS Precision your project requirements to receive a free customized CNC milling aircraft parts process plan.

When Should You Consider Custom Aluminum Machining For Your Aerospace Project?

When regular items are not able to satisfy the requirements, custom aluminum machining is the best option. The customization potential of aluminum CNC milling service can help aerospace projects to overcome the problem of unique challenges.

Non Standard Design and Integration Problem Solving

In the case of non standard designs, e.g. integrated wing ribs and irregularly shaped connectors for new UAVs, custom aluminum machining is able to adjust the process in a flexible way so as to achieve integrated molding, thus lowering the need for assembly and improving the reliability.

Requirements for Special Material and Performance Combinations

With regard to special materials such as 2xxx series aluminum alloys, custom aluminum machining is capable of modifying cutting parameters and tools in such a way as to satisfy high strength, heat resistance, and other requirements, thereby e.g. solving the problem of adaptation of conventional machining.

Rapid Prototyping and Iteration Support

JS Precision guarantees to hand over working prototypes not later than 10 business days upon receipt of data, thus helping customers R&D verification and significantly shortening product launch cycles.

How To Choose a Reliable Partner For Your Aluminum CNC Milling Service?

Selecting a reliable aluminum CNC milling service provider is not a matter of a day. One needs to do a thorough evaluation of the potential provider going through the three dimensions of core capabilities, qualifications, and service.

Core Capability Assessment Checklist

- Equipment Capability: Will the service provider be able to operate a high speed 5 axis milling center? Is the travel of the machine sufficient to accommodate the part dimensions?

- Process Capability: Does the company have a record of aerospace aluminum processing parameters? Does it have on, machine measurement capability?

- Quality Capability: Are there advanced testing facilities in the company such as coordinate measuring machines (CMMs) and Flat Process Inspectors(FPI)?

Certifications and Quality Culture

One must have AS9100D certification if they want to be an aerospace supplier, while NADCAP special process certification indicates higher technical standards. However, it is equally important to address the supplier's awareness of quality control from start to finish.

Engineering Support and Supply Chain Resilience

Investigate how much aerospace project experience the engineering team of the supplier has along with the process optimization skills before also checking supply chain stability to be sure of a dependable long-term delivery.

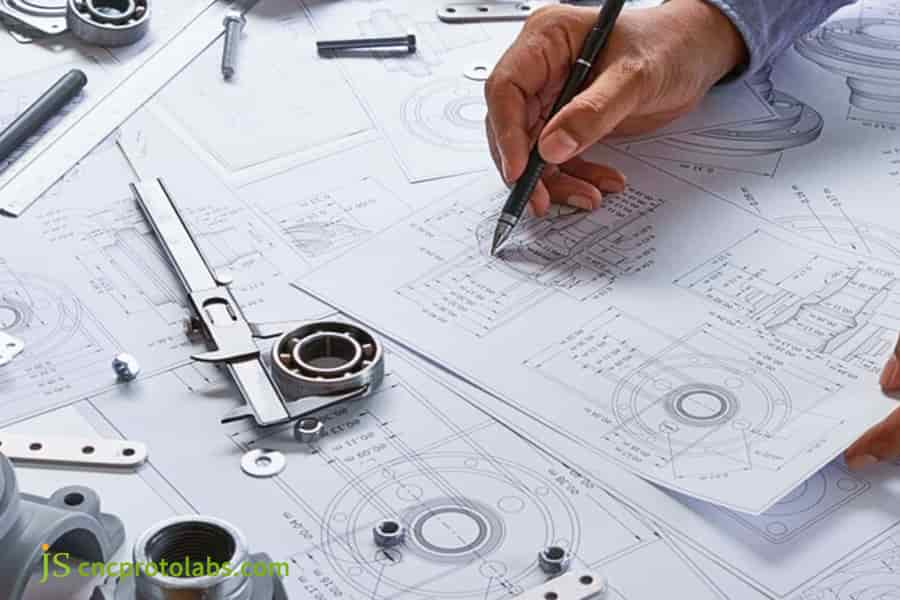

Figure 3: Hands reviewing a mechanical drawing surrounded by design blueprints and actual hardware parts, emphasizing detailed design and specification.

Figure 3: Hands reviewing a mechanical drawing surrounded by design blueprints and actual hardware parts, emphasizing detailed design and specification.

Case Study: Weight Reduction Of 15%, Breakthrough In 5-Axis Machining Of Wing Main Beam By a Certain eVTOL Manufacturer

Challenge

As a result of the complex multi-chamber internal structure of the wing spars (material 7075, T7351) of an electric vertical takeoff and landing (eVTOL) aircraft, the manufacturer was confronted with an extremely complicated design.

There were various manufacturing limitations in the shape and structure of the wing spar ribs that could not be satisfied by traditional 3 axis machining methods. Also, the original design weight of the component was 12% over the target. Meanwhile, the client needed a turnaround time that was less than 45 days, which is more than double the industry standard.

JS Precision Solution

1. Collaborative Design and Simulation Optimization:

Working hand in hand with the client's engineers, JS Precision brought about an optimized design of the internal rib layout through DFM, which also helped in identifying non load-bearing areas for material removal. Additionally, prediction of machining deformation through cutting simulation software and pre-compensation of the dimensions were done.

2. Five Axis Precision Machining Strategy:

A "layered and partitioned" cutting strategy was implemented by making use of a German DMG MORI 5 axis high speed milling machine and tailor-made forming tools to accomplish all surface and cavity machining in a single setup. This strategy helped in avoiding the buildup of errors due to multiple positioning.

3. Integrated Post-Processing:

After processing, the CNC shot peening process is directly carried out to improve the fatigue life of the components, followed by precision anodizing treatment in accordance with MIL-A-8625 standard.

Results

The wing main sparsity component was accomplished with 100% first pass yield, a 15.2% weight reduction, and static load test strength exceeding design requirements by 10%. The delivery cycle was reduced by 25% against the original plan, thus assisting the client in smoothly progressing the eVTOL flight test program.

This case fully demonstrates the technological advantages of 5-axis CNC milling. Want to achieve similar breakthroughs in your aerospace projects? Contact JS Precision now, submit your component requirements, and obtain a customized machining solution.

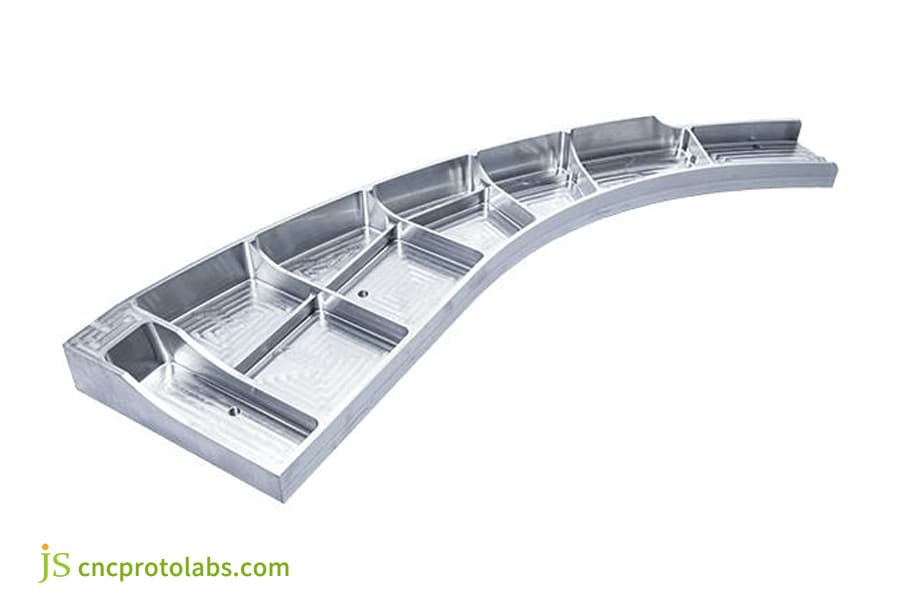

Figure 4: A smoothly finished, curved aluminum component with a complex structure, exemplifying advanced machining for aerospace applications.

Figure 4: A smoothly finished, curved aluminum component with a complex structure, exemplifying advanced machining for aerospace applications.

FAQs

Q1: What are the most common aluminum alloy grades used in the aerospace field?

The most common are 7075 (a high strength alloy that can be used for load-bearing components), 6061 (a versatile alloy that is good for non load-bearing components) and 2024 (this alloy is high in fatigue strength and thus can be used for wing ribs). With each of these alloys, the proper application is based on the stress conditions of the part.

Q2: What degree of accuracy can the machining of aluminum parts typically achieve?

For aerospace structural components, contour deviations can typically be stably controlled within ±0.05mm, and critical hole diameter and hole position deviations can reach ±0.025mm, thus meeting the strict requirements of aerospace assembly.

Q3: What is the reason that aerospace parts require special certifications (e.g., AS9100)?

The AS9100 system requires traceability, risk management, and continuous improvement to be carried out throughout the whole process from design to delivery and it is the basic access requirement for the safety and quality of the aerospace supply chain.

Q4: How can the corrosion resistance of machined aluminum parts be guaranteed?

Mainly through surface treatment processes, for example, in hard anodizing, a thick and hard oxide film is formed on the aluminum surface which results in greatly improved wear resistance and corrosion resistance of the parts and thus the parts are fit for the aerospace environment.

Q5: How long does it usually take to get a sample after providing drawings?

For typical wing rib parts, depending on the component's complexity, a professional aluminum CNC milling service company can have the first functional prototypes ready within 2-4 weeks, thus speeding up the R&D process.

Q6: What dimensions of aerospace aluminum parts can you manufacture?

JS Precision's five axis machining centers can move up to a maximum of 1200 x 800 x 600 mm, thus satisfying the dimensional machining requirements of most wing ribs, beams, and other components.

Q7: Does the price vary greatly between small-batch and large-batch production?

The difference is quite large as, in small-batch production, the one time costs of fixtures, programming, etc., cannot be spread out, thus resulting in a higher unit price, however, professional suppliers can still reduce this price gap efficiently through process optimization.

Q8: Would you be able to provide live updates of the machining process?

Yes, JS Precision routinely sends customers inspection results, photos of the machining, or videos of important processes via a digital management platform, thus making the project progress transparent and controllable.

Summary

In the aerospace industry, the aluminum CNC milling service is becoming more than just one of the manufacturing steps. Rather, it is now a key factor in the innovative design and flight safety.

With 5-axis CNC milling, the precision molding/machining capabilities are available while aerospace CNC milling provides the end-to-end quality control that ensures that each component of the aircraft such as wing ribs and beams supports not only the performance but also the safety.

Choosing a partner like JS Precision means choosing top-notch technology, reliable quality, and efficient supply chain.

Let's make the wings for your next aircraft innovation the strongest. Send us your drawings or let us know your requirements and we will provide you with a tailored technical feasibility study and a very competitive offer.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com