CNC milling metals is often the key to determining product performance, cost, and delivery time when you’re seeking manufacturing solutions for aerospace precision brackets, medical device core components, or consumer electronics casings.

Are you analyzing the CNC milling services near me or international suppliers with trepidation due to the intricacies involved in material choice? Various usage conditions pose highly differing requirements on the CNC milling metals.

This article will give you the clear road map for decision-making on materials and processing and will also expose the potential of JS Precision's profound knowledge of materials and transparent processing and pricing for you to choose the reliable China CNC metal machining supplier that will fit into your global manufacturing map.

Summary of Core Answers

| Decision Dimensions | Misconceptions | Solution by JS Precision |

| Material Selection | The decisions are made entirely on strength or expense, without considering the combination of machinability, heat treatability, and final properties. | From our database of application scenarios and simulations, we propose the material-process option bearing the best overall properties and incurring the lowest total expense. |

| Precision Achievement | Believing that accuracy depends solely on the machine tool, ignoring the systematic impact of material properties, process strategies, and thermal control on the accuracy of CNC milling components. | Use of a comprehensive precision-based production and quality control system for high demand requirements. |

| Supplier Evaluation | Overemphasizing "proximity" and "low unit price"—ignoring long-term strengths like technical skills, quality management systems, and engineering support. | International certifications, electronic collaboration, and in-depth DFM support allow us to offer more reliable and competitive CNC milling services than local companies, even based in China. |

Key Takeaways

1. System Engineering - Multi-Dimensional Balance: Material selection, for example, involves several aspects related to balance, such as mechanics, corrosion resistance, machinability, and post-processability, rather than making decisions based on a single indicator.

2. Cost Core - Machinability: Material hardness, workability, and thermal conductivity primarily define the machining time and tool wear and are the key factors leading to high titanium cnc machining cost.

3. Precision Assurance - Full-Process Control: CNC milling components depend on the accurate control of material stresses, thermal deformations generated by processing, and tool dynamics.

4. Made in China – Global-Class Capabilities: Being a premier China CNC metal machining supplier has competitive advantages in terms of technology, quality, and cost. The application of digitization enables China to overcome geographic distance.

5. Early Collaboration - Cost Reduction and Efficiency Improvement: The earliest point to communicate DFM is when quoting to maximize the benefits of collaboration in terms of cost reduction and efficiency improvement.

How To Choose Metal Materials For CNC Milling? JS Precision Practical Advice

Have you ever struggled with material choices, wanting strength but being apprehensive of sky-high prices, or seeking process flexibility but fearing it may come at the cost of performance? Trust me, you're not alone.

JS Precision has 15 years of experience in CNC milling solutions and has completed more than 2000 projects in the fields of aerospace, medical devices, and consumer electronics. We have worked on more than 100 types of metal materials such as aluminum alloys, stainless steel, and titanium alloys, and have completed ultra-precision machining with a precision level of ±0.005mm.

Compliant with the ISO 13485:2016 quality standard for the medical industry, our process compliance and reliability have been recognized by global customers.

We also solved problems involving titanium alloy components for an aerospace company and optimized the cost of processing and resistance to corrosion of stainless steel for a medical equipment firm.

This handbook distills our own years of practical experience. Whether logic related to materials or specifics of process, all recommendations here have been proven in practical work, so you can trust to our handbook completely.

Interested in finding the perfect CNC milling metals quickly? Just contact us at JS Precision and let us know what your intended use case, performance needs, and budget parameters are. Our experts will then offer you three personalized metal selection solutions for free.

How To Select The Best Material For CNC Milling Metals Based On The Application?

Material choice will never be a consideration based on comparisons between strength and price, instead, material choice will always involve the creation of a multi-criteria decision-making process.

Material choice for CNC milling metals depends on various factors that may include operational needs and work environment conditions to guarantee the required functionality of the produced parts.

Performance Pyramid - From Mechanical Properties to Environmental Adaptability

Mechanical properties are the core competitiveness of materials, strength determines load bearing capacity, hardness affects wear resistance, toughness can resist impact, and fatigue limit is related to service life. Corrosion resistance becomes a key selection indicator in humid, acidic and alkaline corrosive environments.

The Hidden Variables of Cost: Material “Machinability”

Machinability represents a significant pricing factor, and surprisingly, it is frequently underemphasized. Increased work hardening results in greater difficulty of cutting, low thermal conductivity materials such as titanium alloys readily concentrate machine tool-cutting heat, and materials with hard constituents expedite tool deterioration. These characteristics increase the total pricing.

Application Scenario-Driven Material Selection Method: A Quick Reference Checklist

| Requirement Type | Suggested Material | Key Benefits | General Use |

| High Strength and Light Weight | 7075 Aluminum / Titanium Alloy | High strength, light weight | Aerospace products, drone parts |

| Highly Corrosion Resistant | 316L Stainless Steel | Corrosive substance resistant, moisture resistant | Medical devices, marine parts |

| Comprehensive Performance and Machinability | 6061 Aluminum | Easy to process, moderate cost | Consumer electronics cases, general parts |

| High Wear Resistance | Tool Steel | High hardness and wear resistance | Molds and cutting tools |

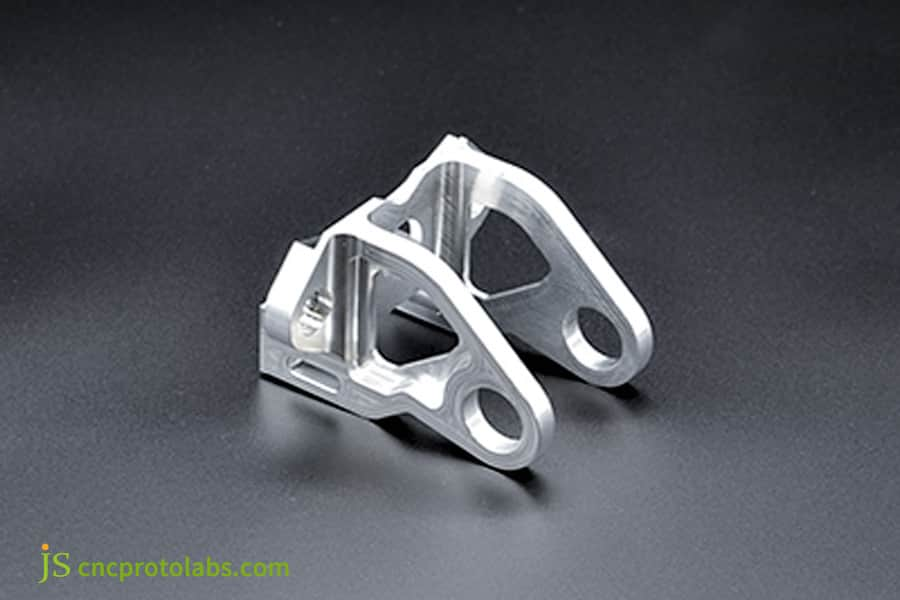

Figure 1: Metal is one of the most common types of materials in CNC milling, and there are many types of metals to choose from.

What Specialized Techniques Elevate CNC Milling Components To The Highest Standards?

The production of high-precision CNC milling components requires attention to detail. However, in order to meet the requirements for high tolerances, complex geometries, and high surface finishes, specialized processes and techniques are applied in the production of CNC milling components.

Taming The Thermal Deformation Process - Control and Cooling Techniques

Heating during processing is the nemesis of precision. It is required to optimize cutting conditions to minimize cutting speed and feed, increase the pressure of the coolant for materials like titanium alloys and stainless steel, and superimpose the process of layered cutting to prevent the buildup of heat in one pass.

The Micrometer-Level Challenge: Machining Solutions for Thin Walls and Micro-Features

Thin walls and micro-features deform easily. It is necessary to adopt a processing method that uses small-diameter and highly rigid milling cutters to alleviate the influence of cutter force, and flexible fixtures or vacuum adsorption fixturing can then be used.

Residual Stress Management, Material Pre-Treatment, and Machining Strategy

This residual stress might cause deformation of the part at a later time. Stress-relieving heat treatment of the part blanks is required, cutting paths must be symmetrical for stress balance, and roughing must proceed before the final cutting for excess material removal through finish cutting.

Do you want your CNC milling components to offer a precision capability down to micrometers? Engage JS Precision for a process diagnostic service. JS Precision's technical experts shall design a specific machining procedure in view of your component characteristics.

Local Or Global? How To Assess The Quality Of CNC Milling Services Near You

In my search for CNC milling services near me, I should not prioritize distance, but it is essential to focus on what matters most in determining a successful outcome – the competencies of the supplier. It is vital to learn scientific evaluation techniques.

Hard Indicators of Technical Capability: Equipment, Software, and Certifications

Technological strength depends on the configuration of machine tools, such as the number of five-axis machines and machine brands with multi-axis capabilities, CAM software supporting five-axis programming.

In terms of industry certifications, ISO 9001 is the starting point, followed by the necessity of AS9100 in the aerospace industry and ISO 13485 in the medical industry– these are the key service quality requirements.

Visibility of Quality System: From Report of Inspections to Process Control

An effective quality system gives assurance of part quality. The extent of quality control exercised by a supplier may be ascertained from the level of detail provided in the First Article Inspection Report (FAIR), Statistical Process Control Data, and inspection equipment capability in terms of Coordinate Measuring Machines (CMM).

Skills in Communication and Collaboration – Engineering Support and Transparency

Soft skills have a significant influence on collaboration efficiency. The most important points to check in this area include professionalism in the supplier’s DFM optimization proposals, communication in projects, and transparency in price information -- this is very important for avoiding any future misunderstandings.

Searching for CNC milling services near me? Request a copy of the supplier evaluation checklist from JS Precision to effectively evaluate suppliers. You can also visit our factory to learn more about how our equipment and processes work firsthand.

Figure 2: When choosing reliable CNC milling services, priority should be given to accuracy, material expertise, and mature quality control processes.

How Do Different Grades Shape The Outcome Of Your CNC Machining Aluminum Parts?

Aluminum alloy is the preferred material for CNC machining aluminum parts, with significant differences in performance, processing characteristics, and cost among different grades. Precise selection can result in better part performance and lower costs.

6061 vs 7075: The Battle of the Versatile King and the Strength Champion

| Comparison Dimension | 6061 Aluminum Alloy | 7075 Aluminum Alloy |

| Mechanical Properties | Moderate strength, high toughness. | Very high strength, similar to steel strength. |

| Machinability | Easy to machine, low tool wear. | Difficult to machine, requires special tools. |

| Weldability | High weldability | High welding difficulty and tendency to crack. |

| Anodizing effect | Even oxide layer, stable color. | Has a good anodizing effect, but requires process control. |

| Typical Applications | Consumer electronics casings and structural parts. | Aerospace parts and high-strength brackets. |

| Cost | Relatively low. | 30%-50% more expensive than 6061. |

Non-Standard Options: When to Consider 5052, 2024, or Other Aluminum Alloys?

There are also special situations requiring non-standard aluminum alloys:

- 5052, which has strong formability and corrosion resistance and is preferred in situations requiring bending and stretching.

- 2024, which has strong fatigue resistance and is preferred for aerospace applications.

- 1100, which can be selected on the basis of high electrical conductivity, and 6082 on the basis of high hardness.

T6, T651, T7351… What Role Do They Play in Machining?

The condition of the molybdenum alloys strongly depends on machining and properties, as follows:

- T6 condition has high strength but high deformation during machining

- T651 has low residual stresses after stretching and straightening

- T7351 has high resistance to stress corrosion cracking, which enhances its use in products involving sea air.

Figure 3: 7075 aluminum alloy bicycle stand.7075 aluminum alloy is known for its excellent strength, which is comparable to many steels.

What Makes a Professional Stainless Steel CNC Machining Service Stand Out?

Stainless steel CNC machining has posed difficulties in regard to work hardening and poor cooling. A professional stainless steel CNC machining service supplier must have targeted technology and strategies to ensure processing quality and efficiency.

Overcome Work Hardening: The Golden Rules of Tool Selection and Cutting Parameters

The stainless steel work hardens to a large extent and hence sharp tools with a coating of TiAlN should be used. The cutting depth and cutting speed should remain constant to avoid cutting pauses that will contribute to hardening.

Cooling and Removing the Chip: Essential Details in Stainless Steel Turning

Cooling and chip removal: These are highly important. High pressure and high flow rate coolant should be applied to the cutting area, and internal cooling tools should be used to blow the coolant onto the cutting edge. An efficient tool path design will help remove chips and prevent workpiece heating and deformation.

Ensuring Dimensional Stability and Surface Integrity: From Roughing Through Finishing

In this process, there are three steps: roughing, semi-finishing, finishing. Stress relief is performed after completing each of these processes, with a finishing allowance of 0.1-0.2mm. After which fine polishing/grinding is done.

How Can Design Optimization Drastically Reduce Your Titanium CNC Machining Cost?

The excellent properties of the alloys make them superior. However, the titanium cnc machining cost is high. The reason for this is the higher cost of the material (5-10 times higher than that of common steel), lower thermal conductivity (only 1/5 that of aluminum alloys), and high chemical activity.

A large cost-saving potential exists in DFM (Design for Manufacturability) optimization, such as the structure design with less deep and narrow cavities, the addition of fillets for less tool wear, and standardized hole diameters for more efficient processing.

In addition, the machinability of TC4 titanium alloy is superior, and the annealed condition is relatively easy to machine compared with the quenched condition.

What Really Drives The Price Difference In Aluminum Vs Stainless Steel CNC Machining?

The cost gap between aluminum vs stainless steel CNC machining is substantial and is pegged to several factors such as material cost, processing efficiency, and tool usage. Understanding this cost implication will also enable you to take smarter cost decisions.

From Blank to Chip: Direct Comparison of Materials and Process Efficiency

| Comparison Dimension | Aluminum Alloy | Stainless Steel |

| Material Cost (per kg) | $3-5 | $8-12 |

| Cutting Speed | 300-500 m/min | 50-100m/min |

| Tool Life | Long (approximately 1000 pieces per tool) | Short (approximately 200 pieces per tool) |

| Material Removal Rate | High | Low |

Post-Processing and Total Cost of Ownership (TCO) Considerations

The deburring and anodizing process of the aluminum alloy is cheaper, while, on the other hand, the deburring process of the stainless steel is relatively difficult, along with highly expensive polishing. On the whole, the overall cost of ownership of the aluminum alloy is generally 30-50% lower than that of the stainless steel.

35% Weight Reduction And 22% Cost Optimization: How Multi-Material Strategies Can Reshape Drone Landing Gear

Background and Challenges:

The all steel landing gear of a certain industrial drone enterprise undergoes plastic deformation under extreme load, and plans to switch to titanium alloy, but faces the problem of a 40% increase in titanium CNC machining cost and a 15% increase in weight, seriously affecting the endurance. The project is deadlocked.

JS Precision Solution:

Following the acquisition of the project by JS Precision, the firm proposed the following innovative solution that involved the use of multi-material combinations:

1.Material & Structure Redesign:

A landing gear structure made of 7075-T651 aluminum alloy with internal ribs was optimized using topology optimization to achieve a strong and light structure, while in the ultra-high stress Concentrated region of shaft holes, 17-4PH stainless steel Bushings which have wear-resistant properties and were manufactured using stainless steel CNC machining service was embedded.

2.Processing Optimization:

The production of the entire main body made of aluminum alloy was accomplished by five-axis high-speed milling, production of the bushing made of stainless steel was accomplished by turning and milling composite processing, ensuring that the inner and outer holes are coincident.

Finite analysis simulation contributed to ensuring that there are no interference during assembling and that the stress distribution is proper after assembling.

3.Quality Control:

Stress relief treatment for the aluminum alloy body and passivation treatment for the stainless steel bushings were performed, then extreme load testing and fatigue testing were carried out to verify compliance with the requirements after assembly.

Results:

The final landing gears designed met requirements but ensured a weight reduction of 35% over the original all-steel design and resulted in an extended flight life by 20%, and there was a reduction in total production cost by 22% over the all-titanium design, and cost of each set was lowered from $850 to $663.

In parallel with this, the optimized processing flow resulted in a delivery cycle reduction of 30%, down from 25 days to only 17 days, ensuring a smooth progress of the projects for the customers.

Do you have any other requirements of a similar nature for weight reduction or cost saving? If so, please contact JS Precision and let us know your part load and weight needs. We can then design a solution that combines various materials to meet your requirements.

Figure 4: 7075-T651 aluminum alloy unmanned aerial vehicle landing gear

What Certifications And Capabilities Define a Reliable China CNC Metal Machining Supplier?

In view of the international machining industry, while selecting a China CNC metal machining supplier, qualifications, technology, and collaboration are central to evaluating reliability. As a benchmark in the industry, JS Precision illustrates what it means to offer trust and partnership in terms of capabilities.

International Credentials: The Real Worth of ISO, AS9100, and IATF 16494 Certifications

International certification is a direct reflection of a company's ability to manage its business. The three major certifications that JS Precision possesses are ISO 9001, AS9100, and IATF 16949, which include general, aviation, and automobile sectors, thus ensuring that our level of management is at international standards.

The Embodiment of Technical Depth: More Than Just a Machine List

Real technical superiority is evident in the detail:

- Processing of difficult-to machine materials: We have developed mature processing technology for difficult-to machine materials like titanium alloys and high temperature alloys, thereby addressing industry pain points of material deformation and tool wear.

- Advanced programming skills: In this regard, we employ more than 10 senior five-axis programming specialists who can program complicated surfaces and difficult-to-cut features with high aspect ratios.

- Integrated services: Our company provides integrated upstream and downstream facilities like heat treatment, surface treatment, and assembly processes, which give us a competitive advantage by reducing customer communication costs.

- Test capabilities: We have 3 coordinate measuring machines and spectrometers, and through these equipment and others, the inspection is carried out from the raw materials through the finished goods.

Cross Geographic Collaboration: Digital Platform and Project Management

Distance will not be a barrier in jointly tackling issues. Our company achieves transparent order management through a digital platform, with dedicated project managers coordinating and responding throughout the entire process.

We cooperate with well-known logistics companies to provide door-to-door services, solve international transportation and customs clearance problems, and build a seamless cross-border collaboration experience.

Searching for a trustworthy China CNC metal machining supplier? At JS Precision, we are here to provide you with qualification documents, equipment lists, and success stories for a worry-free international business experience.

FAQs

Q1: How can I decide between using aluminum and stainless steel materials in my protective housing?

If you require light weight, low cost, and a pleasing appearance, you can use 6061 aluminum with anodizing. If you require very high strength, resistance to wear, resistance to corrosion, but aren't particular about weight, then use 304/316L stainless steel.

Q2: What are the reasons for the high unit price of small-batch machining of titanium alloys?

The processing parameters for cutting titanium alloys will have higher speed requirements for cutting, thus consuming a longer processing time with higher tool consumption. When producing in small batches, it is impossible to share the high cost of process debugging and specialized tools, so the unit price will be significantly higher than that of mass production.

Q3: Can different metals be mixed for a single part?

Yes, common ones include pressfitting, bonding, or mechanical fasteners. This would require the supplier to have experience in working with various materials. JS Precision can offer all these services to ensure that various metals work well together.

Q4: How to determine if a Chinese supplier's machine tools are advanced?

You can ask for specific equipment information from the supplier, like machine tool brands and models, year of purchase, and precision parameters. Emphasize if they possess high-grade models consisting of multi-axis linkage, turning and milling functions, and direct drive systems.

Q5: In what way can you ensure that the metal components imported from China do not rust?

We have a regular anti-rust treatment. Parts are cleaned immediately after machining. Then they are packed with VCI or anti-rust oil. Finally, they are put in moisture-proof bags. This ensures that the parts are not in contact with humid air in any phase. Thus, there is no rust on the parts while transporting them.

Q6: Is it possible to give a reliable quote for a 3D model alone?

Just a 3D model is insufficient. It is preferable to provide 2D drawings with requirements for tolerances. The material quality, production quantity, and surface treatment conditions should be specified. The more detailed the information, the more accurate the quotation will be, whether using the phrase "cnc milling services near me" or using our services.

Q7: How do I check the authenticity and reliability of a quality report from a supplier?

You can request the supplier to provide a report with CMM inspection point diagrams and raw data, and retesting the first article by a third party. Alternatively, other long-term business relationships might involve auditors going into the supplier's factory and auditing the manufacturing process.

Q8: What are the common stages in the lead time in purchases from China?

The stages in the delivery time are primarily divided into three stages: processing stages (including programming, machining, and inspection), the surface treatment stage if necessary, and international freight stages (about 3 to 7 days freight freight and 20 to 30 days freight freight).

Summary

Beginning with the efficiency of CNC machining aluminum parts, and through the challenging resilience of stainless steel CNC machining service, and throughout the balance of titanium CNC machining cost, each selection affects the end result of success for the product.

Within the worldwide supply chain, a high-end China CNC metal machining supplier represents far more than a mere metal-cutting machine—this is an intricate convergence of material science and project management.

Now is the time to get your design professionally evaluated.

Today, go to the website of JS Precision and upload your part drawings and requirements.For not only will you get a clear,comparative price quote of your product in different materials (aluminum, stainless steel, or titanium, and so on), but a "Material Selection Analysis Report" will also be generated for free, designed for your product by our senior engineering team.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com