Spur gear manufacturing services are essential in taking a high-performance spur gear design and turning it into a reliable part. When the designs need the power to be transmitted in a dependable and efficient way, the spur gears are the right solution.

But how do you solve the problem of manufacturing, that is, how do you get from design drawings to actual gears that can carry high loads and operate smoothly? Selecting a top-notch gear manufacturing service provider is very important not only from the component quality point of view but also for the performance and the life of the transmission system.

Since there are so many processes such as hobbing and grinding and materials to choose from, how can you manage to have the gear made with precision, strength, and at a reasonable cost? The article will discuss the main processes of spur gear manufacturing.

Besides that, it will show how JS Precision can become your trusted manufacturing partner with our ISP spur gear manufacturing services.

Key Answer Summary

| Your Core Concerns | JS Precision's Solutions | Core Value for Projects |

| Ensuring the performance of gears is in line with the original design intent | Providing a full spur gear manufacturing process starting from DFM analysis and material selection to precision machining and strengthening. | Getting the gears that can be trusted in terms of load, noise, and lifetime, thus, avoiding the failure of the system due to the deviations in manufacturing. |

| Striking the right balance between a complicated design and a budget | Advanced CNC gear machining along with various gear manufacturing techniques are utilized to provide the best solutions from prototyping to mass production. | High-precision (up to AGMA 12) and complex features (such as irregular bores and modified teeth) gear manufacturing can be achieved at a competitive cost. |

| Breaking down the complexities of cross-border procurement for on-time delivery | JS Precision, as one of Chinese gear machining companies with a wealth of experience, offers clear communication, the whole project management, and the delivery time guarantee. | Enjoy seamless collaboration experience, significantly reduce management costs and supply chain risks, and ensure projects proceed as planned. |

Key Takeaways

- Materials, heat treatment and manufacturing precision determine the performance of the gear, none of these can be overlooked.

- CNC gear machining is a key technology to maintain both the quality and flexibility when it comes to high-precision gears (>AGMA 10) or gears with complex geometries.

- Heat treatment (e.g. carburizing and quenching) is one of the most important steps to increase the gear load capacity and durable life. So, it should be taken into account in the process planning phase.

- A provider with multi-process capabilities is able to offer the most objective and cost-effective combination of gear manufacturing techniques.

Why Trust This Guide? JS Precision's Extensive Experience In Precision Spur Gear Manufacturing

JS Precision has been actively engaged in gear machining for a long time and has the developed capability to supply high-quality spur gears to customers worldwide.

We company has a full range of CNC gear machining equipment imported from abroad, which supports the entire process chain such as hobbing, gear shaping, and gear grinding. The company is capable of consistently producing ultra, high precision of AGMA 12 (DIN 2), with dimensional tolerances controlled within 0.005mm.

In quality facet, JS Precision has obtained ISO 9001 certification and employs a ZEISS coordinate measuring machine for full-dimensional inspection. Customer order on-time delivery rate of we company is 98.6%, and the repurchase rate stays above 45% at all times, which is profoundly greater than the industry average.

When it comes to technological expertise, JS Precision closely follows the ISO 6336-1:2019 standard to ensure the scientific accuracy and consistency of its heat treatment processes.

We company has been delivering premium high-precision gears to a wide range of industries, including agricultural machinery, heavy-duty trucks, and industrial automation, which have collectively amounted to over one million.

We can provide solid real-world examples to confirm our results:

For instance, we tailored AGMA Grade 10 spur gears for a heavy duty truck client, employing 20CrMnTi material in a batch of 50, 000 pcs. The defect rate was only 0.07% through precision hobbing and carburizing/quenching processes, the 100% on-time delivery rate with zero quality complaints so far.

Such concrete examples, figures, and advanced technology confirm JS Precision's capacity to address the manufacturing challenges of high-end clients.

Want to verify our gear machining capabilities? Submit your gear design drawings to receive a free, customized process feasibility assessment report. This will help you mitigate production risks and give your project a head start.

What Is The Scope Of Comprehensive Spur Gear Manufacturing Services?

With industrial development, modern professional spur gear machining services have evolved from mere processing to complete design, engineering, production, and verification solutions. Here we will dissect the service range in detail, so you will have clear insights into the benefits of a one-stop service.

One-Stop Solution from Design Support to Delivering the Finished Product

JS Precision's spur gear manufacturing services include a complete closed-loop service:

- Experience based gear design review and optimization (DFM) to avoid machining difficulties in advance.

- Engineering consulting in materials science is a continuous process whereby the metal or plastic engineering materials selected to be the most compatible are matched.

- Precision gear machining, which includes core processes like hobbing, gear shaping, and gear grinding.

- Professional quality heat treatment, including processes such as carburizing, quenching, nitriding, and tempering.

- Surface treatment processes, including phosphating, nickel plating, and blackening.

- 100% accurate checking of all products, including the most important features such as tooth profile, tooth direction, and runout.

- Component pre-assembly, which offers unitary service integration for gearbox modules.

Manufacturing Capabilities from Prototype to Mass Production

JS Precision can flexibly adapt to different production stages:

- Rapid prototyping and small batch production: Using CNC gear machining,orders of 5-10 pieces can be delivered within 1-2 weeks.

- Medium to large volume production: To meet the needs of large scale production exceeding 1, 000 pieces, the process is switched to hobbing/honing.

- Non-standard customization: Specially designed gear manufacturing is carried out with features like irregular holes and modified teeth.

Core Advantages of One-Stop Service

It is beneficial to pick one-stop spur gear manufacturing services if you want to easily communicate with suppliers, have a clear production responsibility, perfectly fit drawings with finished products, and greatly speed up your projects.

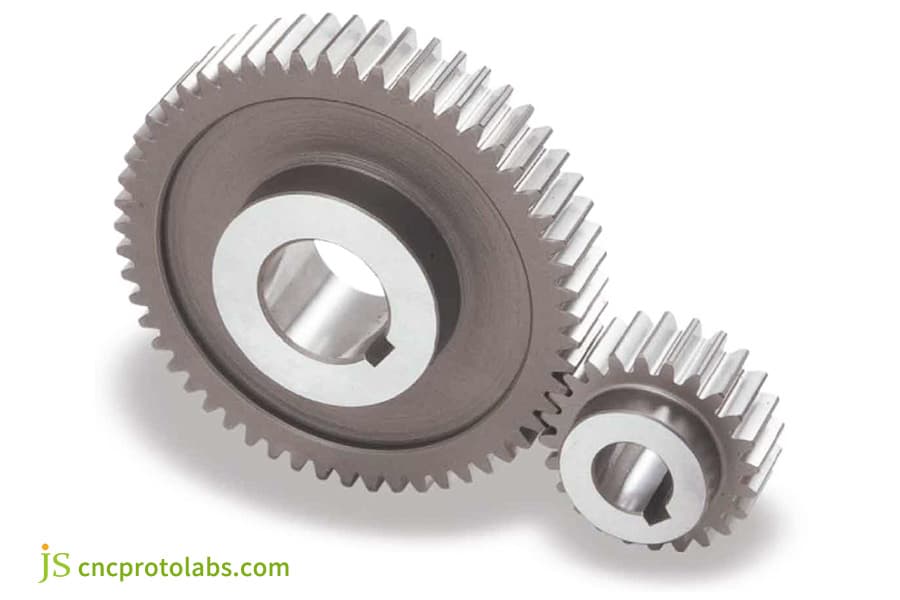

Figure 1: Two polished silver spur gears, one larger and one smaller, positioned diagonally on a white background to show their compatible tooth profiles for power transmission.

How To Integrate Heat Treatment Into The Spur Gear Manufacturing Process To Improve Performance?

Heat treatment is not a separate post processing step, but a fundamental performance guarantee step that is so closely associated with material selection and processing procedures, which spur gears strength and lifespan are directly determined.

The Purpose of Heat Treatment: From Forming to Strengthening

The heat treatment processes to some extent differ in the emphasis of their treatment:

- Quenching and Tempering: This process enhances the cores toughness of the gear, thus it allows the gear to be machined easily after this treatment.

- Carburizing and Quenching: Produces a very hard (58-62 HRC), wear-resistant layer on the gear surface, whilst the core of the gear is kept tough.

- Nitriding: Enhances surface wear and corrosion resistance without adversely affecting the accuracy.

| Heat Treatment Process | Applicable Materials | Processing Temperature (°C) | Holding Time (h) | Hardness Range (HRC) | Applicable Accuracy Grade (AGMA) | Applicable Accuracy Grade (AGMA) |

| Carburizing and Quenching | 20CrMnTi, 20CrNiMo | 900-950 | 2-4 | 58-62 | 0.03-0.08 | 8-12 |

| Nitriding | 38CrMoAl, 40Cr | 500-550 | 8-12 | 50-55 | 0.005-0.02 | 10-12 |

| Quenching and Tempering | 45# Steel, 40Cr | 820-860 | 1.5-2.5 | 22-28 | 0.02-0.05 | 6-9 |

| Induction Hardening | 40Cr, 20Cr | 850-900 | 0.5-1 | 55-60 | 0.02-0.06 | 7-10 |

| Carbonizing and Nitrogenizing | 20Cr, 15CrMn | 830-880 | 3-5 | 56-60 | 0.025-0.07 | 8-11 |

Key Node in Process Integration

The correct process sequence is crucial for ensuring quality. JS Precision's standard process is:

Rough Machining → Tempering → Finish Machining → Carburizing and Quenching → Gear Grinding.

Reversing this sequence is not possible as it will either cause excessive gear deformation or direct scrapping.The gear grinding process is capable of correcting 0.02-0.1mm deformations which may have been caused by heat treatment, thus making sure that the final precision complies with the standards.

Want to know how heat treatment can improve gear life? Contact our engineers to receive a free detailed flowchart of the spur gear manufacturing process, mastering core technological points to make your gears more durable.

Why Is CNC Gear Machining Crucial For High-Precision And Complex Spur Gears?

When it comes to high-precision or complex spur gears, CNC gear machining is the only technology that can be done without convenience. This chapter will focus on the main two advantages of CNC gear machining.

Flexibility and Precision Control

CNC gear machining is capable of producing gear tooth profiles directly from CAD models, thus it is a perfect choice for non-standard tooth profiles, large modules (>10), prototypes, or small-batch production scenarios.

It can reach the dimension accuracy of 0.01mm, thus it can meet the requirements of ISO 1328-1:2013 standards and the tolerance of AGMA 12 precision class are achieved continuously, which are the needs of high-end transmission systems.

Comprehensive Machining Capabilities Beyond Tooth Profiles

Using CNC equipment, machining of all features, such as gear blanks, mounting holes, keyways, and irregular structures, can be done on a single machine tool without relocating the workpiece. This guarantees achieving extremely high-dimensional and positional tolerances, such as coaxiality, and end face runout, which is hardly consistent with traditional special, purpose machines.

Need high-precision CNC gear machining services? Upload your 3D model file for a free production cost calculation, clear delivery time and quality standards – worry-free and efficient.

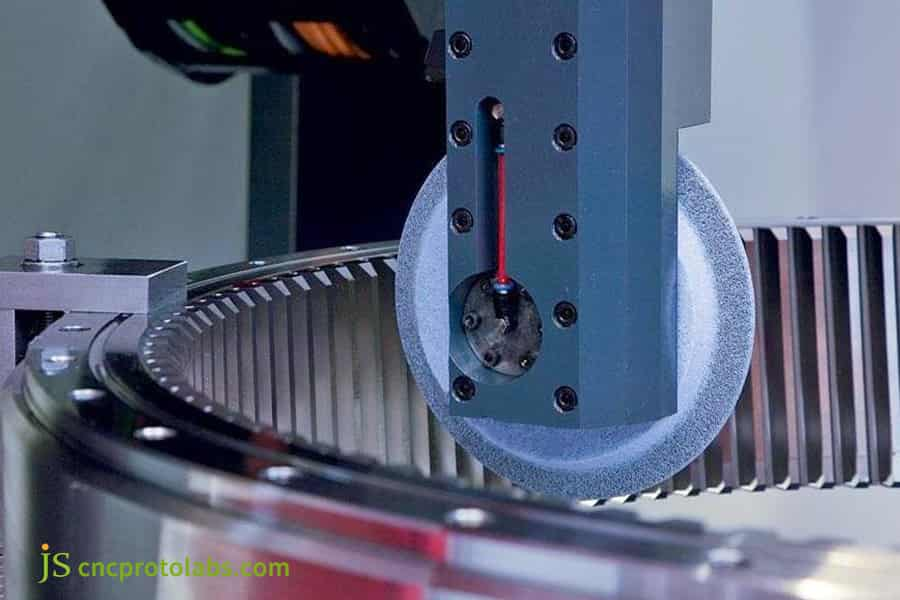

Figure 2: A close-up of a cutting tool attached to a blue and orange hose, machining the teeth of a silver metal spur gear held in a ribbed fixture.

How To Choose The Best Gear Manufacturing Techniques Based On Project Requirements?

Choosing the right gear manufacturing techniques is paramount in achieving a balance between precision and cost. JS Precision lays out a decision-making framework that simplifies your choice of an optimum solution.

Process Selection Decision Tree

Choosing a process involves thoroughly evaluating four aspects: type of material, quantity of production, level of precision, and whether there is need for heat treatment.

For example, for steel gears, AGMA Level 9, and medium-batch production, the recommended process combination is "hobbing + shaving". High precision requirements necessitate upgrading to "hobbing + carburizing and quenching + grinding".

Key Process Comparison

| Process Type | Precision Grade (AGMA) | Applicable Batch | Unit Cost (USD/piece) | Typical Material | Heat Treatment Compatibility |

| CNC Milling | 10-12 | 1-100 | 15-50 | Steel, Aluminum, POM | Compatible |

| Gear Hobbing | 6-10 | 1000+ | 2-8 | Steel, Cast Iron | Compatible |

| Gear Shaping | 6-9 | 500+ | 3-10 | Steel, Brass | Compatible |

| Gear Grinding | 10-12 | 500+ | 8-20 | Alloy Steel | Must be compatible |

Figure 3: A close-up view of a gray grinding wheel attached to a dark blue component, finishing the surface of a spur gear's teeth.

How Do Professional Gear Machining Companies Handle Custom Gear Design?

Excellent gear machining companies are capable of turning customer concepts into producible, high-performance products. JS Precision customizes designs through a three-step process.

Step 1: In-Depth Design Mechanism (DFM)

Engineers examine customer drawings and even go beyond by suggesting tooth root fillet optimization, checking the rationality of tolerances, and giving allowance for heat treatment deformation, thus preventing manufacturing problems from the very beginning.

Step 2: Material and Process Coordination Recommendations

According to the gear's load, speed, and the operating environment, the best material-heat treatment-machining process combination is figured out and recommended. For instance, if there is a high fatigue strength need, the "20CrMnTi carburizing and quenching + gear grinding" solution is suggested.

Step 3: Digital Simulation and Prototype Verification

For the most demanding applications, JS Precision offers Tooth Surface Contact Analysis (TCA) and Finite Element Analysis (FEA) simulation and also a prototype gears manufacturing is done very quickly for the bench testing to verify the design effectiveness.

Can You Provide a Fast And Transparent Quotation For Customized Spur Gear Manufacturing Services?

Efficient and transparent quotation procedure can be a great commencement to the whole cooperation. JS Precision makes this procedure easier and quicker for you to get an accurate price.

Components for obtaining a precise quotation

Customers should deliver the following basic information:

- 2D detailed drawings (PDF) or 3D models (STEP format).

- Material specifications, for example, 20CrMnTi, POM, 6061 aluminum alloy, etc.

- Precision level requirements, for example, AGMA grade 10, DIN grade 3.

- Heat treatment and surface treatment requirements.

- Needed quantity and delivery time.

JS Precision's Quotation Process: Clear and Efficient

Client uploads files → Automated system generates preliminary estimate → Engineering team completes process review within 4 hours with DFM recommendations → Provides a formal quotation including process breakdown, delivery time, and unit price details.

Want to get an accurate quote for spur gear manufacturing services? Submit your 2D drawings and detailed requirements, and receive a detailed quotation within 24 hours, allowing for worry-free and efficient project progress.

JS Precision Case Study: AGMA 11 Level Gearbox Gears, From Design Optimization To Mass Production

Challenge: Meeting Extreme Precision and Lifespan Requirements in a Compact Space

A customer was in need of alloy steel gears for a precision gearbox, with a 3 module, requiring AGMA Grade 11 level of precision, a tooth surface hardness of HRC60 or more, and the maximum torque transmission within the diameter restrictions. The original design was susceptible to undercutting, and conventional methods failed to maintain precision requisites constantly.

JS Precision Solution: End-to-End Precision Engineering

1. DFM Optimization:

In the first place, engineers carried out a thorough DFM optimization based on ISO 6336-1996 standards and the knowledge gained from the past similar gearbox cases. We suggested changing the tooth profile features by utilizing micro-tooth tip modification and root fillet optimization.

This way the original design's undercut risk was effectively eliminated, the meshing stress distribution was optimized, the operating noise was reduced, and the grinding allowance of 0.15mm was accurately reserved for the small deformations in the following carburizing and quenching process, thus, the final precision was ensured to meet the standards.

2.Process Route:

Considering gear precision requirements and material properties, the best route was figured out as "precision hobbing carburizing and quenching precision grinding." A German made Klingberg gear grinding machine was imported and core parameters such as grinding speed and feed rate were strictly controlled.

A cooling system was applied for the reduction of thermal deformation, thus making it possible to keep tooth profile and direction error under <0.005mm and fully meeting the AGMA Grade 11 precision standard.

3.Quality Assurance:

A very strict quality control process is being followed from the raw material stage till the final product. Moreover, a 100% online Keyence laser inspection is performed for every single gear, thus tooth profile, tooth direction and runout being some of the parameters thoroughly checked.

Besides, inspection data is simultaneously recorded and SPC statistical process control (SPC) reports are generated to monitor production consistency in real time, thus defective products being prevented from leaving the factory and stable quality in mass production being ensured.

Results

The first prototype arrived within 3 weeks and successfully passed the customer's bench test showing a gear life 30% beyond the design specification. The project thus, made it possible for the successful mass production of 50, 000 units per year with a maintained defect rate less than 0.1%. The customer eventually decided to hand over the entire gear series production to JS Precision.

Want to replicate a similar success story? Tell us your gearbox gear requirements, and we will customize a dedicated production solution for you, shortening product launch cycles and enhancing market competitiveness.

Figure 4: A single, highly polished metal spur gear with straight, precisely cut teeth and a smooth central bore, isolated on a white background.

FAQs

Q1: What is the highest precision you can manufacture for spur gears?

By precision gear grinding, JS Precision is able to produce spur gears of consistent ultra, high precision level of AGMA 12 or DIN 2, which are suitable for most high-end precision transmission systems.

Q2: What are the strength and lifespan of plastic spur gears?

Plastic spur gears made with POM, nylon or PEEK and modified by JS Precision can be used for low to medium load, quiet operation, corrosion resistance, etc. They will last for several millions of revolutions.

Q3: Why do gears still require precision machining after heat treatment?

The heat treatment process results in the gear distortion of 0.02-0.1mm. Therefore, the following grinding or honing is done to the gear to remove the twist and finally, the gear fully complies with the drawing high precision requirement.

Q4: What is your MOQ for small-batch custom gears?

With high-tech CNC gear machining, JS Precision can accept orders even for 1 pc. This makes the process very convenient for the customers who need product prototype and small, batch trial production.

Q5: How long does it take from receiving the drawings to delivering the prototype gear?

If it is a simple steel gear, a CNC machined prototype can be provided within 5-7 business days, in the case of a complicated structure or a gear that needs heat treatment, the manufacturing cycle will be about 2-3 weeks.

Q6: How can I ensure the security of my gear design intellectual property?

JS Precision will sign a strict NDA confidentiality agreement with the client. All paperwork is sent by encrypted system, and, to ensure 100% security of client designs, confidentiality management is carried out in the production area.

Q7: Can you supply gear components instead of only individual gears?

Of course, JS Precision offers "gearbox module" services that include gear, shaft, keyway machining, and component assembly testing, thereby providing clients with a more comprehensive solution.

Q8: What role does surface treatment play in gear performance?

Phosphating treatment can improve the running in performance and rust prevention ability of gears. Nickel plating or PTFE coating can enhance corrosion resistance. Oxidation blackening is mainly used for appearance beautification and basic rust prevention.

Summary

Choosing a spur gear manufacturing service provider is related to the reliability of the product transmission system. It involves acquiring the knowledge of the spur gear manufacturing process, skillfully adapting gear manufacturing techniques, and making CNC gear machining realizable complex designs.

JS Precision combines high-precision engineering, strict quality control, and smooth project collaboration to deliver the full range of spur gear machining services to you.

Act now and let knowledge be the power of your designs: Just send us your gear drawings or specifications, and you will get a detailed quotation within 24 hours with the analysis of the production feasibility and optimization suggestions. Together, let's convert the accuracy of every gear tooth into a higher level of product performance.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com