In custom gear cutting, this scenario often occurs: This is what happens: your lovingly designed transmission fails catastrophically because of premature wear on one of your gears.

When it comes to custom gear cutting, the highest cost of errors usually takes place even before the very first step—selecting the material. When the material is not suitable, even the most advanced gear manufacturing cannot hinder the happening of failures at particular operational conditions.

Looking for high-strength spiral bevel gears or low-noise helical gears, it is essential to comprehend how material property pairing relates to application conditions of different kinds of gears, and this awareness is what distinguished common components from excellence in design.

As a firm that has been in the industry for many years with expertise in gear machining, JS Precision has seen all too often the devastating impact that mistakes in material choices can have on finances. Therefore, I have compiled this practical guide to reveal the full chain knowledge from material selection to precision grinding, helping you make wise decisions when docking with gear cutting company.

Core Answer Summary

| Key Decision Points | Common Mistakes/Pitfalls | JS Precision's Expert Knowledge/Value |

| Material Selection | It is possible to encounter machinery breakdowns and machine failure due to reliance only on experience and cost. | Application of Material Selection Model: Material performance matching based on load and environment to ensure risks are contained at the root level. |

| Contractor Technical Evaluation | A solely price-based evaluation neglects basic processes like heating treatment and deformation. | Process Transparency: Visible process cards and heating treatment curves demonstrate the full process competence. |

| Process Economic Planning | One-size-fits-all process design results in wastage or precision damage. | Customized Processes: Pairing large module open gears with precision gears of small module through precision hobbing or grinding is ideal for cost-effectiveness. |

| Precision and Delivery Balance | Sacrificing precision machining (such as gear grinding) to meet delivery deadlines affects reliability. | Reliable delivery commitment: Standardized processes guarantee delivery time, and stable improvement to AGMA 10-12 level accuracy through gear grinding services, ensuring lifespan and low noise. |

Why Trust JS Precision? A Practical Guide To Custom Gear Cutting Material Selection

Who should you trust with regard to your custom gear cutting material choice? Of course, the answer will be found within our years of experience.

For the last 15 years, our company has specialized exclusively in gear machining. We have served more than 1,000 clients across more than 20 different industries like the automotive, aero-space, food, and industrial gearbox industries, doing more than 15,000 gear orders.

We deal with a complete range of materials, from conventional medium carbon steel S45C to special high-temperature alloys, from PM gears to precipitation-hardening stainless steel materials (17-4PH).

We are also highly experienced in material selections with various working conditions, such as overcoming the strength at high temperatures of spiral bevel gears for an aerospace manufacturer, and finding optimal materials for corrosion-resistant gears for a maritime equipment producer.

Our engineering staff has over 10 years of experience in gear machining. This not only makes them experts in the properties and processing of various materials, but they also have the capability to apply the exact solution for a particular load, temperature, and environmental condition.

This book helps to sum up our huge experience with projects. Every piece of advice described below has been tested in real-work projects, so it can be safely referred to as a book to trust completely.

Our approach to material selection complies with AGMA 2001-D04, a widely adopted standardization norm for a universal material selection approach to satisfy international gear industry needs.

Looking for AGMA-compliant material selection and evaluation for custom gear cutting jobs? Get in touch with JS Precision's application engineers today, and based on your project needs, get free recommendations related to material selection, which will make your selection more reliable.

How To Avoid Material Pitfalls In Custom Gear Cutting?

Having understood our capabilities, the most basic question is raised: How to avoid material pitfalls in custom gear cutting? This can only be done where the root causes for failure, along with the environments, pertain to the material selection processes to avoid the pitfalls.

Three Major Mechanisms of Material Failure and Selection Strategies

Firstly, there are several causes that may result in gear failure, but the major ones include three types, and the strategies in material choice are also quite clear:

1.Contact fatigue (pitting/sparging):

With high cycle loads, it’s not difficult to see that bottom activity cracks develop underneath the gear’s surfaces. In this case, alloy steel should be picked that has high purity, like 20MnCr5 or 9310, and processed using carburizing or induction hardening. Additionally, care has to be given to core toughness.

2.Bending Fatigue (Tooth Break):

This is mainly caused by overload or high-stress concentration around the root portion of the tooth, thus often leading to the breakup or fracturing of the entire gear. This problem can be corrected by ensuring optimal fillet designs at the roots of the tooth, with materials that have high hardenability for optimal hardness levels around the root parts.

3.Wear and scuffing:

This may be caused by improper lubrication or lack of hardness on the tooth surface, where in extreme cases, the teeth may stick together and seize.

This may be cured by selecting the material appropriate to the working conditions, phosphor bronze handles conditions involving low speed and high load, but in high-speed conditions, the hardness of the tooth surface ought to attain HRC58+ and the finishing ought to be enhanced by gear grinding services.

The Disruptive Influence of Environmental Factors on Material Selection

Environment is the hidden key to material selection. Failure to consider environmental issues will lead to the premature failure of the best material:

1.Corrosive environments (Food, Water, and marine):

The common alloy steel is vulnerable to corrosion and rusting due to humid, acidic, and alkaline environments. It is necessary to choose austenitic grades of stainless steel (304, 316 series) or precipitation-hardening stainless steel (17-4 PH) or apply a specialized coating to the common material.

2.High/Low-Temperature Environments:

Temperature has a significant effect on the strength of the material. Low temperatures require special consideration in the choice of material. Low temperatures need material with toughness at that temperature to prevent brittleness. High temperatures require special alloys.

What Technical Details Truly Define a Capable Gear Cutting Company?

Choosing the right material is only the first step, and the final performance of the gear also depends on the technical strength of the gear cutting company. A truly trustworthy gear cutting company will have a good accumulation in core technology. That is the core competence possessed by JS Precision.

Heat Treatment: The "Second Life" for the Gear

Definitely, a professional gear cutting company has to have very detailed control over the heat treatment process. You may ask the supplier directly if they outsource the heat treatment or have their own controlled atmosphere carburizing furnace. How do they control deformation during the quenching process? Do they carry out post-heat straightening processes?

JS Precision has its own heat treatment workshop and controlled atmosphere carburizing furnace, with specialized pressure quenching jigs to prevent deformation, by using slow cooling techniques.

Capabilities of Depth of Testing

Apart from a gear measurement center, are there analysis, residual stress, and tooth hardness testing capabilities? These are necessary for ensuring gear quality from within. Our company has all necessary testing equipment, such as material composition testing to precision testing of gear teeth surfaces.

Scope of Knowledge Base for Processes

Are you capable of addressing the entire scope of processes, from powder metal gears through hardened and ground gears? In many cases, the knowledge base offered by experienced engineers is much more valuable than the knowledge base from new equipment.

Our engineers are proficient in dealing with machining difficulties of different materials and types of gears, providing customers with the best process solutions.

One Process Does Not Fit All: Economical Cutting Strategies For Different Kinds Of Gears

Different kinds of gears require diverse applications, precision levels, and production quantities. A corresponding cutting process will then require a flexible adjustment for a balance between precision, production volume, and cost.

| Gear Type | Core Requirements | Economical Cutting Strategies |

| Mass Production of Automotive Gears | High Efficiency, Low Cost, Stable Mass Production | Hobbing/Shaping + Heat Treatment + Precision Honing, Striving for Ultimate Production Cycle |

| High Precision Reducer Gears | Low Noise, Low Transmission Error | Pre-grinding + Heat Treatment + Precision Gear Grinding Services, Improving Precision and Stability |

| Small Batch of Special Gears (Non-Circular Gears, etc.) | Fast Delivery, Cost Control | Five-Axis Milling or Wire EDM Forming, Without Investing in Special Tools |

Not sure which cutting strategy to use for your types of gears? Please send over the level of precision required in the gear, size in batch numbers, and drawings. Based on that, we can design the most cost-effective machining process for you.

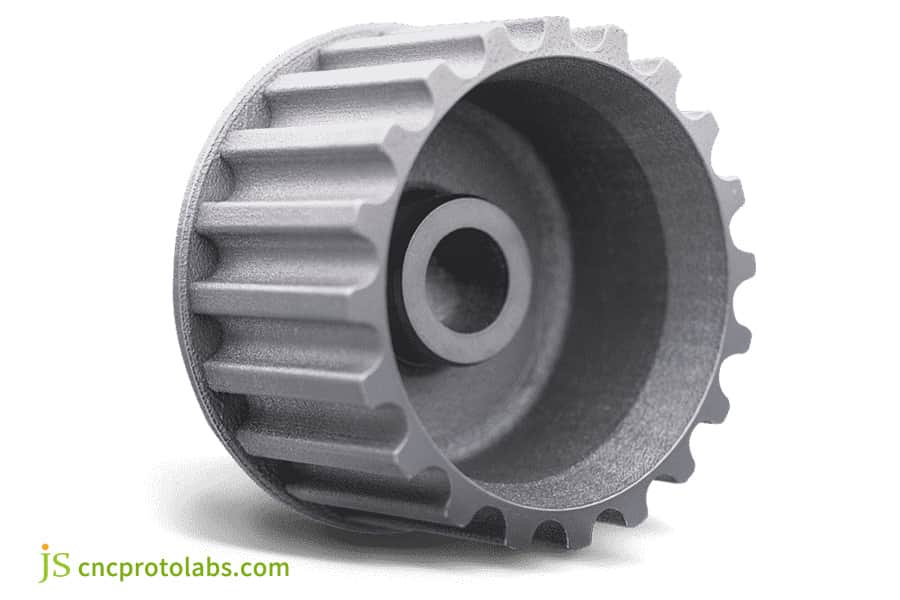

Figure 1 The gear hobbing speed is very fast, and the machine operation is also very easy.

Key Technical Challenges In Manufacturing High-Precision Types Of Gears

Manufacturing high-precision types of gears is one of the biggest challenges found in the field of gear manufacturing. Every type of gear poses its own technical challenges. These technical challenges can best define the technical abilities of the manufacturer.

Spiral Bevel Gears:The primary difficulty is related to the local-conjugate tooth contact area. This requires advanced machinery, which may be either Gleason or Klingenberger, as well as expert engineers.

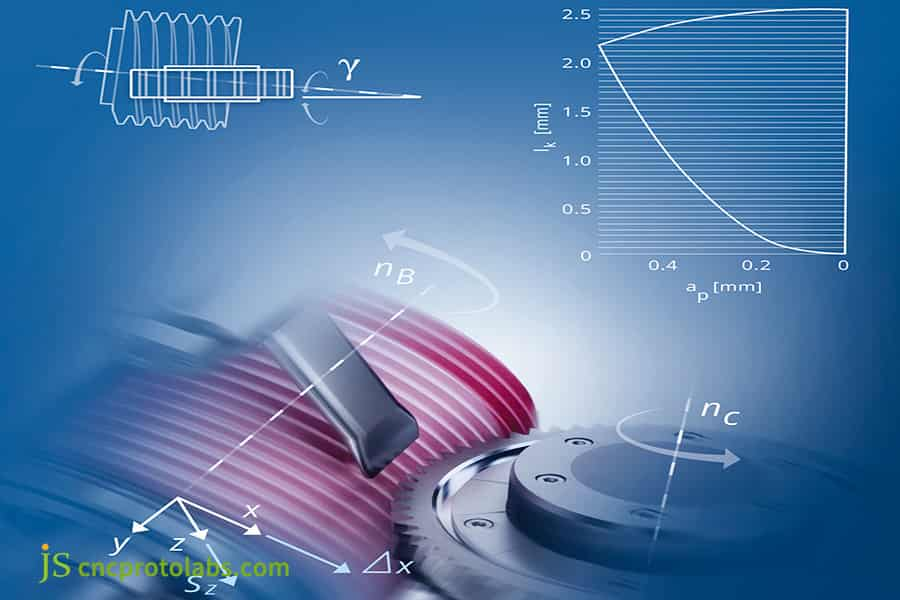

Worm Gears: The challenges involve precisionthread grinding of the worm and precision machining of the wormwheel's center envelope. Only by maximizing the contact area is the improvement of the transmission efficiency and life possible.

Face Gears: The main issue here is precision machining and inspection for non-generating profiles. Although they are mostly used in the aerospace transmission field, their quality standards are extremely high.

Worried about the manufacturing difficulties of high-precision types of gears?Upload your drawings related to gears and precision, and JS Precision's technical team will be happy to assist you with feasibility analysis and suggestions for optimizing gear manufacturing.

How Is Surface Roughness Controlled In Modern Gear Manufacturing?

Surface roughness influences noise, life, and efficiency of gear drives, therefore, this indicator cannot be ignored during gear manufacturing, as it has a direct impact on gear drive performance. Today, gear manufacturing is based on the ISO 1328-1:2013 standard, ensuring that surface quality is enhanced from tooling marks to a mirror finish.

Finishing Process: By using high precision sharp-edged hobs or gear shapers, with optimal cutting parameters (reducing the feed rate), a better initial surface with Ra in the range of 1.6 to 3.2 can be achieved.

Finishing operations after Heat Treatment: Gear honing results in the removal of the oxide scale and enhances the roughness values up to Ra 0.8-1.6μm, gear grinding is the only process capable of providing ultra-low values below Ra 0.4μm.

Super Finishing: In some critical applications, polishing and vibration finishing techniques are employed to achieve a value for Ra on the order of 0.1μm, thus reducing noise levels produced by gears during operation.

Looking for gears that are less noisy and have a long lifespan? Get gear manufacturing surface treatment services from JS Precision. Our precision cutting, grinding, and super-finishing services are able to meet your surface roughness specifications to precision.

Setting Realistic Expectations: What Are Typical Lead Times For Custom Gears?

The lead time for the custom gears is an important issue for most customers, and expectations are important for a smoother process during planning. There are a number of phases for the lead time for the custom gears, and each needs a specific cost of time.

| Production Stage | Required Time | Remarks |

| Process and Programming | 2-5 days | More time required in case of complex gears. |

| Materials Purchase | 3-10 days | Longer for high grade or specification material. |

| Soft Cutting | 5-10 days | To be adjusted according to the complexity of the gear train. |

| Heat Treatment | 3-7 days | Transportation and Cleaning Included. |

| Hard Cutting/Grinding | 5-15 days | Gear grinding – a bottleneck process with limited capacity. |

| Inspection & Shipping | 2-3 days | Full inspection for quality. |

For accurate custom gears that demand gear grinding, a turnaround time of 8-12 weeks can be considered normal in the industry. However, if the manufacturer promises you a much shorter turnaround time, you should question if they are bypassing essential stages of inspection for quality.

Case Study: From Catastrophic Failure To 20,000-Hour Life: Rescuing a Food Conveyor Drive System

Real-life examples are the most effective testimonies to proving a solution’s efficiency. In this example, we, with our professional custom gear cutting services, were able to improve the lifetime of a gear that catastrophically failed on a regular basis from 6 months to 20,000 hours.

Failure Analysis

A large food processing plant’s conveyor belt gearbox gear was made of 304-grade stainless steel and worked under a humid environment with corrosive chemicals containing acids and alkalis.

This gear experienced extreme wear, together with a constant increase in the meshing gap after only 6 months, which resulted in the conveyor belt stopping several times a month, resulting in a loss of production exceeding $5,000 per occurrence.

After intervention on our part, analysis revealed that the choices for materials were based on only resistance to corrosion and not on the contact loads on the gears. The hardness levels were only about HB180, and this was accomplished through only precision rolling and produced a surface roughness value of Ra3.2um. These standards are not sufficient for withstanding both corrosion and friction.

JS Precision Solution

For overcoming this problem, we conceived an innovative upgrade method that combines techniques and materials:

Firstly, we improved the materials, recommending and using 17-4PH precipitation hardening stainless steel. This material not only has high anti-corrosion properties, which are equivalent to 304 stainless steel, but after undergoing solution treatment and aging, its hardness also reaches HRC 40-45, which satisfies the contact strength of the driving gears.

Secondly, we integrated precision gear grinding services for the gear teeth profiles to have higher accuracy to the AGMA level of 10 and surface roughness of Ra 0.8μm to reduce the effect of friction and corrosive substances. This was achieved through the use of German gear grinding machinery.

Moreover, we have optimized the tooth root fillet, which prevents possible stress concentration.

Results and Data

Since then, this upgraded equipment set has been running perfectly and has already accumulated over 20,000 hours of running time. Not only did this customer completely resolve his problem of frequent downtimes, but he also saved over $150,000.

On the one hand, the gear meshing processing is smoother, the transmission noise has been reduced by 8dB, which further improves the workshop environment. This solution has also become a benchmark case for gear manufacturing in corrosive environments in the food industry.

Are your gears also experiencing problems with failures? Please provide details about your equipment usage environment and gear problems, and JS Precision will develop a solution for you based on custom gear cutting and gear grinding services.

Figure 2:17-4PH precipitation hardened stainless steel gear

How JS Precision Gear Grinding Services Elevate Gear Performance To Elite Levels?

Gear grinding services are one of the most crucial processes for gear improvement. JS Precision is very strong in gear grinding services. JS Precision gear grinding services make it possible for customers to achieve the best possible gear performance.

Greater Accuracy in Precision

Generally, in the case of normal precision hobbing gears, the grade of accuracy obtained would be only AGMA 8-9, whereas through our gear grinding services that involve complex German gear grinding machinery in a constant temperature processing setup, higher accurate gears with a grade of AGMA 10-12 can be produced.

Quantifiable Performance Improvements

- Firstly, the reduction of noise: By precise grinding of the tooth profile and surface finish, the working noise in the gears can be decreased by 5-10 dB, which is very important for noise-sensitive products like electric vehicles and office machinery.

- Secondly, increased lifespan. The detailed profiles and high level of surface integrity significantly reduce the contact fatigue damage, thereby increasing the gear contact fatigue life several times.

- Lastly, an increased load-bearing capacity due to the precision tooth profile modification, which enhances the load distribution, thereby ensuring that the gear's torque is maximized.

Figure 3 Continuous grinding has become the preferred method for hard precision machining gears.

FAQs

Q1: What is the most cost-effective material for general-purpose, low-load gears?

Materials made of medium carbon steel S45C, quenched and tempered, or powder metallurgy are economically priced options. They offer enough strengths while keeping expenditures in check, and these are suitable in light to medium loading conditions.

Q2: Can you cut gears from plastic materials like POM or Nylon?

We can machine gears using engineering plastic materials POM and nylon. Machining quality is assured using specialized machinery and optimized cutting conditions. The material is applied where there are light loads and where noiseless and corrosion-resistant operations are required.

Q3: What's the difference between hobbing and shaping in gear cutting?

Hobbing is a continuous and efficient processing method, suitable for making external gears and for large quantities, shaping can mill the inner gear and gear around the shoulder, and has more flexibility. We can suggest the most cost-effective processing approach according to the gear type.

Q4: What information do you need to provide an accurate quote for custom gears?

Please provide gear drawings (including key parameters such as module, number of teeth, pressure angle, etc.), material specifications, target accuracy level (AGMA/DIN standard), heat treatment requirements, and annual demand, so that we can provide an accurate quotation.

Q5: How do you control distortion during gear heat treatment?

We reduce deformations on the gear during the heat treatment process by optimizing gear design, such as through symmetry, the use of specialized pressure quenching equipment, and slow cooling methods.

Q6: What is the lead time for a small batch of prototype gears?

In cases of simple prototype gears, without requiring grinding, delivery times can range from 2-3 weeks, provided that the materials are ready. In cases of precision prototype gears that require grinding, due to their increased complexity, delivery times are 4-6 weeks.

Q7: Do you provide complete gearboxes or just the gear components?

We provide both. We are capable of the precise manufacture of individual gears. We also possess the entire design, machine, and assemble abilities of gearboxes.

Q8: What is the first step to avoid a costly material mistake in my next gear project?

Contact our gear application engineers immediately, and with your working condition description and your initial design plan, we can provide you with a professional material and process analysis report free of charge to help you avoid pitfalls in material selection.

Summary

In the precision industry of gear production, everything affects everything else. Having a real partner means hiring a skilled team that can optimize all these factors to give you the best possible solutions, and this requires a lot more than a simple contract manufacturer.

JS Precision, with its vast experience in gear machining, provides you with all-around assistance in the process, from material selection to final production delivery, owing to its expertise in gear grinding services.

Don't let the root cause of the next gear failure be buried in the initial design.

→ Download our “Gear Material Selection and Failure Analysis Guide” to get a structured approach to material selection.

→ Please submit your gear parameters and operational conditions to get a free analysis and quote for its feasibility for manufacturing.

→ Schedule an extensive technical consultation with JS Gear experts for your vital transmission projects.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com