Design for Manufacturing is key to solving these kinds of pain points: when you spend weeks designing an aerospace bracket, only to find it impossible to machine during CNC machining due to insufficient internal corner radii, or machining costs overrunning the budget by 40%, and so on.

The most ingenious designs in precision manufacturing are not those that win awards in CAD software, but those that can be transformed into high-quality products at the lowest cost and fastest speed. Statistics show that over 60% of product costs are determined during the design phase.

The guide will walk through key principles and practices of Design for Manufacturing, showing how JS Precision aids clients in attaining the triple goals of cost optimization, improving quality, and reduced lead times in CNC machining services through early DFM collaboration.

Key Answer Summary

| DFM Core Dimensions | Common Problems in Traditional Design | JS Precision's DFM Solution |

| Manufacturability | Unmachinable features, unnecessary complexity, or negligence in tool accessibility. | Early design reviews for manufacturability eliminate manufacturing barriers by ensuring designs can be produced efficiently within the bounds of their current CNC machining services capabilities. |

| Cost Optimization | Too tight tolerances, inappropriate material selection, and inefficient machining paths are just a few of the reasons. | We systematically analyze the influence of every design feature on the cost of custom parts manufacturing and provide data-driven optimization suggestions that can reduce costs by up to 40%. |

| Efficiency Enhancement | Design-related problems result in multi-stage machining, longer toolpaths, more frequent tool changes, and clamping. | We optimize the geometry of parts for high volume CNC machining to simplify toolpaths, reduce machining time, and enhance throughput and consistency. |

JS Precision Core DFM Principle: Based On Real-World Experience, Helping Your Projects Succeed On The First Attempt

For the last 15 years, JS Precision has been heavily involved with CNC machining, offering Design for Manufacturing services to more than 2000 clients in industries such as aerospace, medical devices, and automotive parts.

For example, we optimized an aluminum alloy bracket design for an aerospace company, and the topology optimization solution complied with the simplified design guidelines for geometric dimensions and tolerances (GD&T) in the ASME Y14.5-2018 standard of the American Society of Mechanical Engineers (ASME), reducing machining time from 4.5 hours to 2.2 hours, helping the client reduce costs by 42%.

We also solved the problem of non-standard hole machining for a medical device client, reducing tool changes and improving production efficiency by 30% by standardizing hole dimensions.

We have also independently undertaken more than 100 demanding projects in custom parts manufacturing, such as designing integrated structural parts for new energy customers to avoid assembly errors between multiple components. These practical examples have taught us an important lesson: DFM is indispensable to accomplish the goals of your project.

This guide is a systematic summary of our years of service experience. Every principle and suggestion in it has been verified in actual projects. You can fully rely on it to guide your Design for Manufacturability practices and help your CNC Machining projects be successfully implemented.

Want more DFM case studies from JS Precision? Submit your industry type, and we'll send you successful Design for Manufacturability case studies from the same industry to intuitively help you understand the value of DFM.

The DFM Framework: What Are The Foundational Steps And Principles In CNC Machining?

The very first step toward successful manufacturing is to set up a systematic, manufacturing-oriented design framework. In CNC machining, this DFM framework will help you mitigate risks from the early design stages. Below, we break down its core steps and principles in detail.

Early Involvement: Bringing Manufacturing Knowledge Up to the Design Stage

Introducing manufacturing experts during the conceptual design phase is the core value proposition of Design for Manufacturing.

JS Precision engineers intervene at this point to help determine whether the design meets the process requirements for CNC machining services, if the part's aspect ratio exceeds the tool's machining range, thus avoiding huge modifications at later stages.

Five Core Principles: Simplification, Standardization, Modularization, Accessibility, and Compliance

1. Simplify Geometry: Try to eliminate unnecessary complex protrusion or groove which can reduce programming time and difficulty, such as changing the irregular surface into a regular one.

2. Standardization of Hole/Radius Dimensions: Standardize various non-standard holes into industry standard dimensions, e.g., reduce 6 types of holes to 2, hence reducing tool changes.

3. Design in Modular Components: Divide complicated parts into individually machinable modules, such as dividing an integrated shell into a top cover and base to simplify machining and assembly.

4. Tool Accessibility: Allowance of adequate space during the design for tooling to prevent machining areas unreachable by the tool, like ensuring sufficient radii for deep cavity corners.

5. Meet Manufacturing Capabilities: The design should match the real CNC machining level, such as not requiring ordinary milling to reach the grinding precision to avoid unrealistic or excessively costly requirements.

Iterative Collaboration: A Closed Loop from DFM Feedback to Design Optimization

JS Precision provides clients with clear, actionable Design for Manufacturability improvement suggestions through structured reports. We list the problems, improvement plans, and expected results in that report, and adjust the plan based on client feedback, thus forming an optimization closed loop.

Figure 1: Standardization threading callouts. It enables manufacturers to optimize their processes while ensuring your functional requirements are met.

The Cost Engineering Mindset: How Does DFM Directly Influence Your Total Product Cost?

Emphasizing the mindset of "how to design a product for manufacturing" into every decision is paramount to cost control. Most clients are often interested only in functionality at the design phase and do not consider manufacturing costs at all. DFM can help reduce total costs right from the beginning itself.

Material Selection and Utilization: Intelligent Transformation from Blank to Part

By optimizing the contour and layout of parts and selecting standard size blanks, it is possible to increase material utilization from 50% to over 80%.

As an example, we helped a client increase the number of parts processed from 100mm x 100mm blanks from 2 to 4, thus reducing material costs by as much as 50%, and recommended the use of standard aluminum alloy blanks to avoid customization fees.

Machining Time: Every Minute Costs Money

By reducing tool changes, optimizing tool paths, and avoiding unnecessary 5-axis machining can directly reduce machine tool costs for CNC machining services.

One client, for instance, managed to reduce tool changes from 8 to 3 and reduced machining time from 3 hours down to 1.8 hours by standardizing hole dimensions, saving $96 per part at $80 per hour.

Post-processing and Assembly Costs: Easily Overlooked Hidden Expenses

Design can reduce the time needed for polishing, simplify the assembly steps, and eliminate special requirements for packaging to control the cost of manufacturing custom parts from a holistic perspective.

For example, adjusting the surface roughness of non-mating surfaces from Ra0.8μm to Ra1.6μm reduces polishing time by 30%, designing snap-fit devices instead of screws facilitates the assembly and reduces the labor cost.

How can your product design reduce costs? Simply inform JS Precision about your material type and production volume requirements, and we can tailor for you a cost optimization plan on how to design a product for manufacturing, reducing hidden expenses.

What Are The Non-Negotiable Design Limits In CNC Machining Services?

Understanding and respecting the physical limitations of the CNC machining services is key to successful design.

These limitations, such as the geometric constraints of cutting tools and the dynamic performance of machine tools, are clearly defined and limited in the Aerospace Materials Specification (AMS) and related machining guidelines published by SAE International.

Many design drawings are theoretically correct but cannot be machined due to limitations that exceed those of CNC machining services. Below, we list the key limitations.

Hard Constraints on Tool Geometry: Minimum Radius, Depth, and Angle

Different tools have clearly defined limitations on their machining capabilities. Below are common reference data summarized by JS Precision:

| Tool Constraint Type | Particular Limitation (Reference Value) | Applicable Scenarios |

| Minimum Radius | End mill minimum radius: 0.1mm in steel, 0.05mm in aluminum. | Internal angle, groove design |

| Depth-to-Diameter Ratio Limit | Ordinary end mill depth-to-diameter ratio ≤ 5:1, extended tools ≤ 10:1. | Deep cavity, deep hole machining |

| Internal Right Angle Machining | Cannot directly machine 90° internal right angles, a fillet radius ≥ tool radius required. | Part corner design |

Physical Boundaries of Machine Tools: Travel, Interference, and Clamping

Different specifications of CNC machining service equipment have certain limitations in the scope of machining, spindle interference circle, and the occupation of fixture space.

For example, the maximum travel of our vertical machining center is 1200mm × 800mm × 600mm, and the diameter of the spindle interference circle is 200mm. The design should avoid these limitations while reserving clamping space.

Deformation risks of thin walls and small features

For thin walls of aluminum alloy, it is recommended to set the thickness ≥ 1 mm, 0.8mm-thin walls need reinforcement, for slender arms, it is recommended to set an aspect ratio ≤ 5:1, more than which will cause deformation and requires support.

Concerned that your design exceeds the limitations of CNC machining services? Simply upload your part drawings to JS Precision, where our engineers will provide you with free diagnosis, allow you to avoid problems such as thin-wall deformation, and ensure conformance with the requirements of custom machining services.

Figure 2: Minimum radius. Larger radii enable the use of larger, more rigid cutting tools that resist deflection and provide superior surface finishes.

How Does DFM For High Volume CNC Machining Differ From Prototyping?

The logic of design optimization for high volume CNC machining is completely different from that for single-piece prototypes. While high volume CNC machining looks at factors like efficiency, stability, and cost, the approach when it comes to prototyping involves a speedy functional validation. Let's look at the main differences below.

Tool Life and Stability Become Primary Considerations

Tool life can be extended by avoiding abrupt toolpaths and balancing the load on the cutting instrument. This impacts the overall cost of a high volume CNC machining lot. For instance, optimizing toolpaths for a client saw tool life increase from 500 pieces to 1200 pieces-a $1750 savings for a batch of 10,000 pieces at $150 per tool.

Design for Automation: Simplified Clamping and Positioning

The design of unified positioning references and easily graspable geometry for robots to enable automated production lines.

For example, designing two standard positioning holes for a part allows a robot to be positioned and clamped rapidly. Clamping time can be reduced from 3 minutes to 30 seconds in this regard. Designing a flat gripping surface prevents slippage and improves stability.

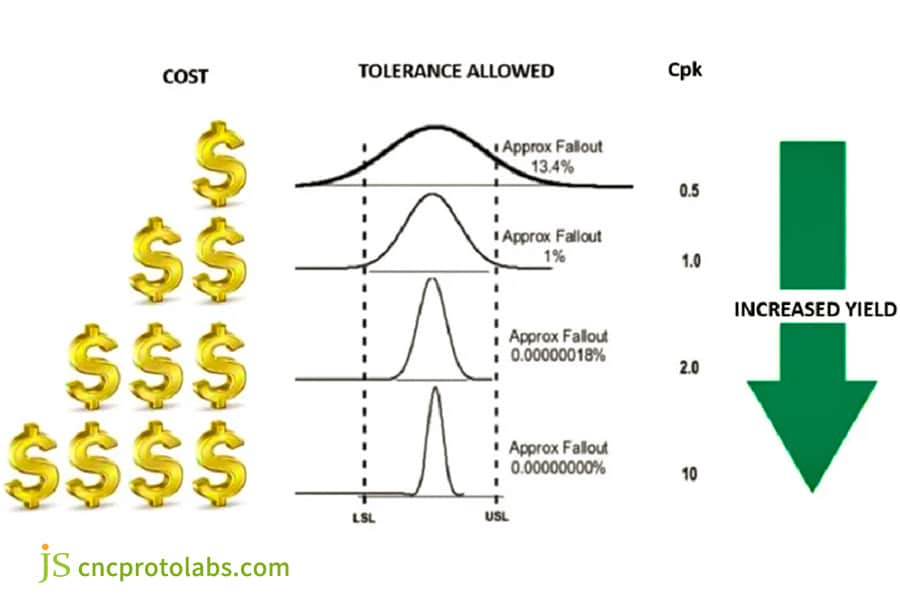

Statistical Tolerance Analysis: Ensuring Interchangeability Amid Variation

Use statistical methods to analyze the tolerance chains, appropriately relaxing tolerances with the view of ensuring assembly functionality for improved yield and production efficiency.

For instance, a batch of parts whose original tolerance was at ±0.01mm with a yield of 85% could be relaxed to ±0.015mm, reaching a yield of 99%, reducing scrap costs.

How To Design A Product For Manufacturing: Common Mistakes To Avoid

Knowing the pitfalls is the best way to avoid them. During the "how to design a product for manufacturing" process, many customers increase costs or cause machining failures by neglecting the details. Below, we list common mistakes.

Over-engineering: When "Perfection" Becomes the Enemy of Cost

We mark non-mating surfaces with mirror roughness and specifying micron-level tolerances for non-critical dimensions.

For instance, a customer marked Ra0.4μm surface roughness on a non-mating bottom surface and had to add a grinding process, incurring an extra $30. The marking tolerance of ±0.005mm added an extra hour's machining and incurred an extra $80.

Ignoring Stock Orientation: Leading to Unnecessary 5-Axis Machining

Classic example: Original customer tilt of part required 5-axis machining ($150/piece), we recommended re-orientation for 3-axis machining at $80/piece, saving $70 per piece and greatly reducing overall costs.

"Drawings Right, Manufacture Wrong" - Labeling Omissions

Clearly indicating information like draft angles, critical dimensions, and texture direction is important. As an example, plastic parts for a customer did not have draft angles labeled, resulting in 100 scrapped parts at a loss of $2000, additional time and costs were wasted since texture direction markings were also missing and required remachining.

Want to avoid common cost traps in design? Request JS Precision's "How to Design a Product for Manufacturing" error checklist to review your design and reduce unnecessary processing costs.

The Tolerance Tightrope: How To Specify Tolerances For Custom Parts Manufacturing?

In custom parts manufacturing, tolerances are the fulcrum that balances performance and cost. Excessively tight tolerances raise the cost, while excessively loose tolerances hamper functionality. Below, we teach you how to specify tolerances appropriately.

Function-Based Tolerance Strategy: Critical vs. Non-Critical

Mark critical features, like assembly interfaces and kinematic mating areas, with tighter tolerances, while applying more economical and looser tolerances for non-functional areas. For instance, mark mating holes with a tolerance of ±0.01mm and side markings with ±0.1mm, balancing functionality and cost.

Understanding Process Capabilities: What Level Can Your Supplier Achieve?

JS Precision has standard tolerance capabilities for different processes such as CNC milling and turning, helping customers set challenging and realistic goals. Below is our reference for common process tolerance capabilities:

| Machining Process | Standard Tolerance Capability (mm) | Applicable Part Type |

| CNC Milling | ±0.01-±0.10 | Brackets, housings, etc. |

| CNC Turning | ±0.005-±0.05 | Shafts, discs |

| Surface Grinding | ±0.001-±0.005 | High-precision mating surfaces |

Efficient Application of Geometric Tolerances

Geometric tolerances such as positional and profile tolerances are used to more effectively control part functionality, and how this is often more economical and accurate than specifying multiple linear tolerances.

For instance, φ0.02mm specified for the position tolerance of a hole is more accurate than specifying X/Y linear tolerances and will also be easier to measure to reduce inspection time.

Figure 3: The chart shows the drop in yield and the rise in cost as the tolerance increases.

Paradigm Shift: How Does Design For Additive Manufacturing Rewrite The Rules?

Design for additive manufacturing constitutes a real paradigm shift: from "manufacturing constraints" to "functional liberation." Design for additive manufacturing breaks down the geometric limitations of traditional CNC machining, enabling more complex designs.

From Subtractive to Additive: Embracing Geometric Freedom

DFAM enables the creation of designs that are impossible or very costly to achieve with traditional CNC machining services, including hollow lattices, complex internal flow channels, and integrated structures.

For instance, traditional CNC could not make complex internal flow channels, while additive manufacturing can deliver such features with a weight reduction of 30%+, hollow lattice structures save 40% of material.

Support Structures: Unique Design Considerations in DFAM

Support structures can be minimized during the design phase, or alternatively designed on non-critical surfaces, reducing postprocessing time and waste. For instance, if the tilt in the design surface is ≥45°, reduce supports, if supports are needed, place them on non-mating surfaces to avoid damage to critical surfaces.

Converged Manufacturing - When DFM Meets DFAM

Frontier trend: Designing high-precision interfaces for CNC machining and complex lightweight bodies for 3D printing for a product. For example, 3D printing of an aerospace body reduces weight, while precision CNC machining of the interface provides precision at 25% lower cost than pure CNC machining.

Want to get a taste of design for additive manufacturing and unlock your design potential? Call the JS Precision hotline today, and our team will be able to help you design structures such as hollow lattice structures and combine them with CNC machining for optimum efficiency.

Case Study: Cost Reduction Of 42%——Mass Manufacturing Of Aerospace Brackets Through DFM

Initial Design Challenges

An aerospace-grade aluminum alloy mounting bracket, originally designed to be very

"robust," utilized a solid block structure that resulted in considerable material waste. Moreover, it included 8 types of non-standard holes and 14 overly tight tolerances-e.g., ±0.005mm-which lengthened the machining time to as long as 4.5 hours.

With such a high cost, up to $200 per piece, it cannot meet the mass production requirements of high volume CNC machining. The customer's budget of 1000 pieces per month simply cannot cover the cost.

DFM In-Depth Analysis by JS Precision:

1. Topology Optimization and Lightweighting: Using CAE software, the simulation of the stress on the support structure highlighted three low-stress areas. Excess material was boldly removed, and the part went from solid block to a highly efficient ribbed structure while maintaining strength to meet aerospace requirements.

2. Standardization of Features: The eight non-standard holes were standardized to three standard sizes: φ5mm, φ8mm, and φ10mm. Such a step reduces tool changes and machining complexity. Similarly, five different internal corner radii on the part were standardized to 0.2mm to match standard cutting tools.

3. Tolerance Rationalization: 14 tight tolerances were reviewed and according to the capability of custom parts manufacturing, 9 of these were relaxed from ±0.005mm to ±0.02mm. Testing showed that the relaxed tolerances did not impact the assembly and functionality of the parts.

Final Successful Results

Optimized parts were 35% lighter (500g → 325g), saving $20 in material costs per piece, processing time was reduced to 2.2 hours, saving $26.4 in labor costs, total cost decreased from $200 to $116, a 42% reduction, and passed aerospace strength testing. For the customer producing 1000 pieces per month, this resulted in savings of $84,000.

Figure 4: CNC Precision Machining Aluminum Bracket for Aerospace Industry

FAQs

Q1: At what point in the design process should DFM be started?

The earlier the better. Ideally, DFM thinking should be introduced in the concept design phase of a product design, as design change costs are lowest then, averting problems in subsequent CNC machining phases. This is based on experience from JS Precision.

Q2: Is the DFM analysis free of charge?

Yes, we provide professional, free DFM analysis reports for all potential custom machining services projects. This is our standard service to give specific improvement suggestions.

Q3: What are the most common DFM suggestions?

Increasing internal corner radii to standard tool sizes, standardizing hole sizes, avoiding excessively deep cavities, and relaxing non-critical tolerances. These suggestions can solve 80% of manufacturability issues and are very practical.

Q4: Does DFM improve lead times for the custom parts manufacturing?

Significantly. Since DFM eliminates the manufacturing challenges and optimizes the process paths, programming and machining time can be reduced directly. We have helped clients shorten lead times by 30%.

Q5: Complex parts with several processes (for instance, machining + 3D printing), how do you DFM?

Our engineers are familiar with several processes and can evaluate the pros and cons of various manufacturing strategies to offer you the best hybrid manufacturing DFM solution, taking into consideration both effectiveness and cost.

Q6: Can you provide DFM analysis for our entire assembly?

Yes, we provide component-level DFM analysis to optimize the interface between parts and simplify the overall assembly process to help you reduce your assembly time and labor costs.

Q7: How does DFM help reduce the cost of high volume CNC machining?

The advantages in optimized designs are magnified in mass production. With shorter cycle times and longer tool lives, fewer changes are needed, saving a great deal of money in mass production.

Q8: How would I know whether your proposed DFM changes are effective?

We will quantify cost savings and cycle time reduction estimates for each of the changes in the DFM report using case studies, such as 42% cost reduction in aerospace brackets.

Summary

Design for Manufacturing is not a complex theory, but a practical tool verified through many CNC machining projects by JS Precision. Knowing it means that you can not only get your design right the first time but also optimize cost, efficiency, and quality so that every custom part is functional and economical, which is the value that this guide is meant to provide.

Do you want to delve deeper into topics related to manufacturing design? We recommend the following selected content for you:

Practical Guide to Tolerance Control

Comprehensive Guide to 5-Axis CNC Machining

Case study of 3D printing and CNC hybrid manufacturing

Choose JS Precision and make every step of your design process-from blueprint to product-precise and controllable.

Send us your design challenge today! Just visit the JS Precision website and upload your CAD files. You will receive, within 24 hours, a detailed and free DFM analysis report that will clearly outline optimization suggestions along with their impacts on estimated cost savings and delivery time. Let's start from the first step and create fantastic products together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com