Gear manufacturing services are widely present in our daily lives. If the critical gear in your design needs to be produced, the overall cost of the transmission system will depend on the manufacturing process selected.

Injection moulding or metal cutting? When confronted with a large range of types and materials of gears, how does one make the right choice? In the global supply chain environment, it is essential to locate a technically competent, responsive, and competitively priced precision gear manufacturing company.

This article will provide the answers to all the questions that you may have regarding gear machining, the tricks of the trade related to gear manufacturing techniques, gear materials, and gear machining prices, and go on to reveal how JS Precision may become your global partner if it is indeed the best in gear processing in China.

Key Answers Summary

| Decision-Making Core | Common Misconceptions | JS Precision Solutions |

| Process and Type Matching | A process can be selected exclusively based on 2D designs, without consideration for the machining equipment specific to the type of gears (e.g., worm gears, bevel gears). | On the basis of a gear type library and dynamic simulation, the recommended process chain, ranging from hobbing and shaping to form grinding, aims to provide an exact gear profile. |

| Material and Cost Balance | Blindly looking for materials of high strength (for instance, hardened steel), the increased processing difficulty and cost rise exponentially, or the inappropriate choice of plastics because of high material costs. | Provide in-depth analysis of gear material selection, selecting the most cost-effective material depending upon the operating parameters such as load, speed, and environment. |

| Vendor Rating Factors | The process chain integrity and testing services available from the supplier are beyond the scope of being compared based only on quotations or levels of precision. | The integrity of the process chain and the extent of the testing services available from the supplier will cover sample gear measurements and DFM examples. |

Key Points:

- Process Determines Possibilities: The type of gear will determine what kind of processing equipment will be required for the production process. For instance, it's impossible to produce true spiral bevel gears without the right machine tools.

- Materials are the backbone of performance. Close consideration must be given to material properties of strength, durability, noise characteristics, and cost. Material selection is a question of having the most suitable material, not the best.

- Miniature Gears Are the Technological Benchmark: The ability to produce high-quality, stably machined gears for a module of less than 0.5 represents a technological benchmark for evaluating the quality of the precision gear manufacturing supplier.

- Collaboration leads to value creation. Communicate with suppliers on gear design manufacturability (DFM) before quoting, which can optimize costs by up to 30%.

- Precision is a systemic endeavor: Precision is built into the entire system process of machine tools, tooling, heat treating, and testing, and not dependent on an individual process.

Why Trust This Guide? JS Precision Gear Manufacturing Services

This manual contains not only theoretical information but has been compiled after taking into consideration the past experience of over 15 years with gear machining at JS Precision, strictly following requirements of international standard ISO6336-1:2019 related to calculation of gear strength.

JS Precision has served over 500 clients in fields such as aerospace, medical equipment, and industrial automation, completing over 10000 custom gear machining projects.

For instance, we machined a custom micro gear for a client in the medical device manufacturing industry, reducing the module of the gear from 0.8 to 0.3 with a resultant 40% and 50% decrease in weight and time, respectively.

We have collected unique information on comparisons of material properties of gears and control of cost of manufacturing processes, so we can help you avoid common mistakes. Our team of more than 20 experienced engineers has already solved complicated problems for many customers, such as machining miniature gears of modules and precision noise damping.

All the points mentioned within the guide have been verified and proven through case studies. Partnering with JS Precision means aligning with a firm that has the capability and the background.

If you wish to assess our capabilities by checking out actual examples of projects, you may contact our sales team to get the actual success stories and technical reports for no extra fee. If you need the projects for gear manufacturing, you may submit your first requirement to get a customized technical solution.

What Types Of Gears Can Professional Gear Manufacturing Services Deliver?

Professional gear manufacturing services encompass numerous types of gears ranging from simple spur gears to intricate spiral bevel gears. There are different needs ranging from the transmission of industrial equipment to the miniaturization of precision instruments that our mature technologies are able to handle.

It could be the transmission requirements for various pieces of machinery or the miniaturization techniques for various instruments. There are corresponding gear types or solutions for manufacturing the required gears.

Cylindrical Gear family: Spur Gears to Helical Gears to Internal Gears

The application of cylindrical gears is widespread, and the properties of various types vary greatly.

- Spur gears: Simplicity of design, relatively cheap, used for low speed, lighter load, and hobbed/shaped.

- Helical Gears: Smooth transmission, with strong loading capacity and adaptability to the higher speed and larger loading, requires a special angle hobbing machine.

- Herringbone Gears: Resist axial forces, good for heavy machinery, difficult tooling is needed in their production.

- Internal Gear Teeth: More compact design, high transmission ratio, applies to planetary systems, made by gear shaving processes.

The Art of Spatial Transmission: Bevel Gears, Worm Gears, and Crossed-Axis Helical Gears

The specific geometry of spatial transmitting gears places higher demands on gear manufacturing services:

- Bevel Gears: The teeth are straight for low speed and light load transmission, but the helical teeth provide high precision and often require Gleason machine tools with expert experience.

- Worm Gear Pairs: High transmission ratio and self-locking capabilities make them suitable for lifting/precision instruments, requiring extremely high tooth concentricity.

- Crossed-Axis Helical Gears: Applied for transmission of non-parallel non-intersecting shafts, the main problem lies in adjusting the tool and machine tool angles.

Special and Micro Gears: Meeting Non-Standard Design Needs

Professional gear manufacturing services also involve special types like racks, face gears, and non-circular gears:

- Racks: They allow for rotary-to-linear motion. Used in linear modules, where there is a great need for guaranteed tooth surface straightness.

- Face Gears: These are suitable for special aerospace transmission. They depend on custom-made tools and high precision machine tools.

- Non-circular Gears: Allow variable speed transmissions, now applied in automatic control systems, these gears need complicated programming in their machining process.

Figure 1 Types of gears include several common categories based on their shape and shaft arrangement.

A Strategic Guide To Gear Material Selection

Materials are the backbone of gear life, noise, and cost. Wise gear material selection is the key to successful gear manufacturing, and the most suitable material should be selected based on the working conditions.

The Kingdom of Metal Materials: Steel, Cast Iron, and Non-ferrous Metals

Metallic materials have excellent mechanical properties and therefore have become the dominant material in gear manufacturing. The details are listed in the table below:

| Material Type | Mechanical Properties Testing | Heat Treatment Process | Typical Applications |

| Carburized Steel (20CrMnTi) | High surface hardness and high core toughness | Carburizing and quenching | Transmission shaft in cars, industrial reducers |

| Tempered Steel (for Example, 45# Steel) | Balanced Properties | Quenching and Tempering | General Mechanical Gears Under Medium Loads |

| Cast Iron (e.g., HT200) | Good wear resistance, low cost | Annealing | Low-speed, light-load gears in agricultural machinery, etc. |

| Copper Alloys (e.g., bronze) | Good wear resistance and corrosion resistance | Natural aging | Precision gears in marine equipment and instruments |

These metallic materials can be improved further by heat treatment for better hardness, wear resistance, and fatigue strength, in order to adapt them for various working conditions.

The Rise of Non-Metallic Materials: Engineering Plastics and Composites

Engineering plastics and composites show a growth in use within manufacturing, having the following core characteristics:

- Nylon (PA): light, self-lubricating, low noise, and suitable for household appliances/officialequipment, however, it has poor heat resistance.

- POM: High rigidity, stable precision, and suitable for use in precision gears within electronics/automotive interiors.

- PEEK: High heat and chemical resistant. Application areas include aerospace and medical equipment, but it's very costly.

Compositing plastics with reinforcing fibers improves strength enough to make the composites a new choice for high-performance gears.

Material Selection Decision Framework: Finding a Balance Between Strength, Cost, and Processability

Material selection can follow this framework:

- Choose materials based on load: alloy steel for heavy-duty, high-speed, plastics/ordinary steel for light-duty.

- Rotary speed: The material of high-speed gear should have very high abrasion resistance and fatigue strength.

- Suitable environment: Stainless steel/PEEK for humid/high-temperature/corrosive environments.

- Control budget: The use of high-performance, cost-effective material will be emphasized.

Is Custom Gear Machining Capable Of Micromodule Gears (Module <0.5)?

Micro-gears are the core of precision instruments and medical equipment. Whether custom gear machining can conquer this field is the ultimate test of precision gear manufacturing capability. It must meet the standard of ISO 1328-1 in gear precision, and its machining difficulty far exceeds that of ordinary gears.

Unique Challenges of Micro-Gears: Precision, Rigidity, and Small-Diameter Cutting Tools

The difficulties of machining micro-gears with module values below 0.5 are:

- Tooth profile error control: The error has to be controlled within a few micrometers since otherwise, the meshing will be affected.

- Machine tool rigidity: During machining, vibrations might affect the tooth surface in such a way that irreversible damage might occur.

- Small-diameter cutting tools and chip removal: Cutting tools may experience wear and breakage, and the restricted chip removal area contributes to the accumulation of chips.

JS Precision - Micromachining Solutions: Precision Machine Tools, Special Processes, Microscopic Inspection

JS Precision's Targeted Solutions:

- High Precision Machine Tools: Leverage ultra high precision wire EDM/gear grinding machines for achieving micron-accurate precision.

- Special processes: Special cutting fluid + vibration control system to reduce the effect of vibration and wear on tools.

- Microscopic Inspection: Optical Projector + Gear Measurement Center for precise control of tooth profile and direction parameters.

If you need to process micro modular gears, you can contact JS Precision to learn more about micro machining technology and successful cases. We will provide you with customized precision gear manufacturing solutions.

Figure 2 High precision micro gears are widely used in medical, aerospace, and industrial fields.

What Truly Drives The Cost In Custom Gear Machining?

Grasping the reasons behind custom gear machining cost determination is essential in cost control and comparison. Gears machining cost is influenced by geometrical features, batch sizes, and so on.

The Basic Effect of Geometric Parameters: Module, Number of teeth, Precision grade, Surface requirements.

Geometric parameters play a decisive role in cost:

- Module: The lower the value of the module, the greater the price. It will cost several times more for a gear with a module of 0.3 than for one with a module of 1.0.

- The number of teeth: The higher the number of teeth, the longer the machining time. The price of precise gears rises faster as the number of teeth increases.

- Precision grade: High precision grades like AGMA Q10 and DIN5 involve complex processing techniques. This results in an exponential rise in their costs.

- Surface requirements: The finer the surface finish, the higher the cost because there is a greater need for post-processing.

Batch Production and the Economics of Process Routes: From Single-Piece to Batch Production

Batch production determines process and unit cost:

- One-piece/prototype: Precision milling/wire EDM, short cycle time, no mold cost, high unit cost.

- Batch production: Gear hobbing + heat treatment + gear grinding, high fixed investment cost, yet individual price lowered by as much as 50%.

Post Processing and Full Chain Quality Cost

Post processing and quality inspection account for a large proportion of costs:

- Heat treatment: 15-30% of the costs depending on the material and performance characteristics.

- Precision machining: 20-40% of the cost to ensure precision and surface finish.

- Quality inspection: 5 to 10% of expenses, in order to prevent subsequent losses of non-conforming products.

To get an accurate estimate of the cost of a custom gear machining job, you will need to share specific parameters such as gear type, module, accuracy level, and quantity with JS Precision. We will be glad to offer you a clear free cost estimate.

How To Vette a True Precision Gear Manufacturing Company?

Choosing a qualified precision gear manufacturing company requires examining its full stack capability, which directly determines the quality, delivery time, and cost of the gears.

Completeness of Hardware and Process Chain: From Machine Tool List to Process Coverage

Completeness of the hardware and process chain is fundamental:

- Machine Tool List Verification: There must be a full range of machine tools including gear profile machining, heat treatment, and finishing, with important processes such as machining not outsourced.

- Process Coverage Verification: There has to be an overall process solution and expert-level experience for the machining of special gears.

Measurement and Quality Assurance System: Data on the Reliability of Accuracy

Measurement and quality system are key to ensuring accuracy:

- Professional equipment includes Gleason and Klingberg gear measurement centers, as well as 3D scanners.

- Traceable Reports: Complete inspection reports are available for every batch, enabling traceability of quality.

Engineering Support and Collaboration Culture: The Bridge from Drawings to Finished Products

High quality engineering support and collaborative culture create additional value:

- Proactive DFM Capabilities: Inclusion of the ability to provide optimization recommendations for gear profile improvement and materials.

- Effective Communication: Timely response to queries and flexibility in solution adjustments are key to the success of projects.

If you would like to verify whether JS Precision meets your requirements, you are welcome to visit our production facility. We will show you our complete equipment chain, quality control processes, and engineering team, allowing you to experience firsthand our strength in precision gear manufacturing.

Figure 3 Choosing the appropriate custom gear manufacturer is crucial to ensuring the success of the project.

Case Study: 40% Lighter, 50% Faster——Redesigning a Medical Pump Drive With Micromodule Gears

In the field of precision gear manufacturing, custom gear machining can help customers solve practical problems and create greater value through professional design optimization and process improvement. The following is a characteristic case where JS Precision assisted a customer in the field of medical devices to upgrade their product.

First Challenge

A manufacturer of medical portable pumps was experiencing three significant issues with the existing drive gear set:

The gear set employed standard module metal gears, making the size and weight substantial, making the portable medical pump a burden to transport.The noise of operation was above the industry standards, which affected the usage, and lead times from foreign companies were up to 12 weeks, which significantly affected the launch time of the customer's product.

In addition, the customer sought to lower the manufacturing cost of the gear set and increase its performance.

JS Precision's Solution

DFM Optimization:

After intensive communication with their customer, JS Precision engineers proposed that instead of using the original material made of metal, it would be better to use PEEK material. This material not only meets the strength requirements of the medical pump drive gears but also significantly reduces the weight of the gear set and decreases operating noise.

Technological Breakthrough:

JS Precision uses precision micro milling technology in custom gear machining to reduce the gear module from 0.8 to 0.3, achieving both component miniaturization and improving the transmission efficiency of the gear set.

Precision Assurance:

In order to ensure the precision of the micro-gears to the high standards of precision set by the medical industry, JS Precision adopts ultra-high precision five-axis machine tools as well as online measurement systems to ensure that the precision of the micro-gears reaches the high precision of the AGMA Q12 standard.

Results:

The weight of the final gear set had been lowered by 40%, and noise in operation had been lowered by 15 decibels.

Relying on its internal full chain production capacity, JS Precision not only reduced the total cost by 25%, but also shortened the delivery cycle from 12 weeks to 6 weeks, perfectly demonstrating the comprehensive value of precision gear manufacturing.

If your company has similar needs regarding upgrading the product and optimizing the cost, kindly get in touch with us, and we will provide a tailored solution once the project details are received. In fact, a one-on-one engineering consultation can be arranged.

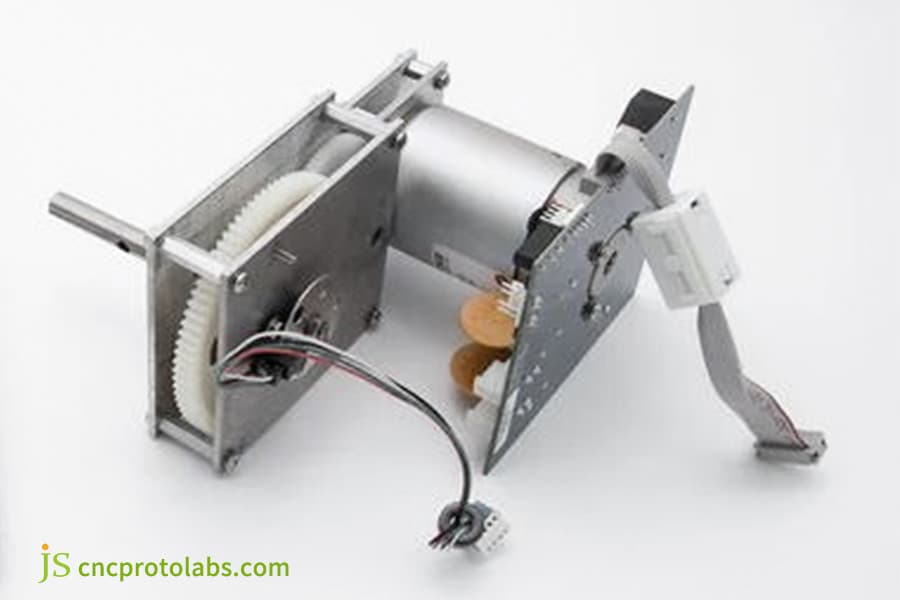

Figure 4 Disassembled pump gear assembly, with white plastic gears inside the metal casing.

What Unique Value Does JS Precision Bring To Your Gear Manufacturing Project?

JS Precision provides end-to-end gear manufacturing services solutions, relying on professional support throughout the entire process to help projects efficiently advance and maximize value.

Seamless "Full-Chain" Capacity Integration:

Vertical integration over the entire process chain including raw material cutting, rough machining, heat treatment, precision grinding, and testing with end-to-end quality control to prevent delivery time variability and quality variability associated with outsourcing.

Expert Team Categorized Under Micro and High-Precision Gears:

The advantages of our expert team: Well-established in the realm of micro gears in the range of 0.1-1.0 modules and aerospace gears in the range of DIN 3.

Intelligent Transparent Collaboration and Global Supply Chain Support:

We have established an online project platform. The customers can view the project status and the inspection results online. This is a fully transparent collaboration.

At the same time, based on China's efficient supply chain system, we can provide cost-effective services to global customers. This will further increase their market competitiveness. For further information about our services, kindly get a copy of our service manual.

FAQs

Q1: Plastic or metal gears-which to choose?

In selection, it is necessary to consider load-bearing, noise, temperature resistance, and cost. The strength of the metal gear is big and the heat resistance is good, which can be used in the heavy-load and high-temperature working condition, the plastic gear is light in weight and self-lubricated with low noise, used for medium and low load working condition.

Q2: What are ordinary surface treatments for gears?

The method of surface hardening and wear resistance, such as carburizing and quenching, nitriding treatment, is commonly used in metal gears. Of course, nickel plating and blackening can be adopted for rust prevention as needed. As for the plastic gear, it will generally be left in its original state or a lubricating coating can be added as needed.

Q3: What must be known to provide a quote?

Gear type, module, number of teeth, drawings with accuracy grade, material require, heat treatment target quantity, surface treatment. This will help us quote you more correctly.

Q4: Are there services offered from proof of concept through to volume production?

It is fully supported. We can perform flexible manufacturing services, including rapid prototyping (CNC/wire EDM), small to medium batch production (gear hobbing), and volume production (dedicated production lines), as suits the client's production requirements.

Q5: What is the typical lead time?

The delivery cycle for prototype parts is about 1-2 weeks, and for small-scale production it takes about 3-6 weeks. The specific delivery time depends on the complexity of the gears and the process route. For urgent orders, we can coordinate expedited channels to ensure the progress of the customer's project.

Q6: What are your criteria for manufacturing and inspection?

We know and comply with the current conventional international standards of gear manufacturing, including AGMA, DIN, ISO, and JIS. We are able to manufacture and inspect our products in compliance with the standards requested by the customer to meet the global norms of usage.

Q7: Can we work on my project even if I have only a concept or no drawings?

Yes, we can. Our engineering team is capable of providing you with a full process of cooperation, ranging from the design of gears and the calculation of their strengths to the production process, to turn your idea into a producible design solution.

Q8: How do you guarantee the effectiveness and quality of the communications when working together from a distance?

We provide each project with a project manager and share the 3D models, inspection reports, and progress photographs via an online platform. In this way, the remote teamwork will work as efficiently as the teamwork when working from the same location.

Summary

Gears, despite their smallness, represent the heart of any transmission system. The quality of gears impacts the functionality and reliability of the entire device. In the current global manufacturing environment, the most essential principle in identifying partners is to identify the best mix of technical knowledge, quality, and business efficiency.

JS Precision offers a one-stop capability, expertise, and a collaborative way of working that breaks down the complicated process of precision gears manufacturing into a simplified solution.

It is now time to bring precision power to your project.

Contact the JS Precision Gear expert team today to submit your gear design or requirements. Not only will you receive a competitive quote for custom gear machining, but also a "Gear Design Manufacturability and Performance Optimization Recommendation" from JS Precision Gear senior engineers.

Together, we can turn your brilliant design into a reality of superior transmissions.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com