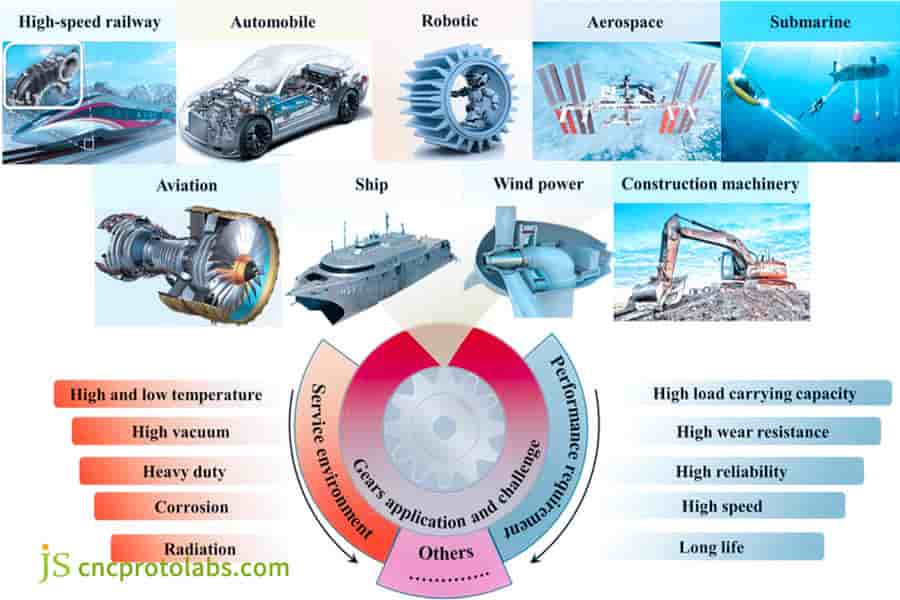

Gear cutting services are always vital in the field of industrial transmission. Gears are significant components in new energy vehicle transmission systems, aerospace machinery, and industrial robots.

Gear cutting services directly affect gear manufacturing accuracy, which is closely linked to equipment life, power consumption, and levels of equipment noise. Wrong machining techniques may result in exponentially increased manufacturing costs, equipment breakdown, and poor equipment performance.

This paper will concentrate on fundamental requirements in gear machining, giving a thorough examination of crucial points for commercial and technological value among the top three adopted methods in gear machining.

The intricacy involved in custom gear cutting calls for expert technical assistance. JS Precision is a professional partner that is heavily engaged in gear production and is able to provide a comprehensive solution for gear production from process selection to delivery. In other words, gear production would be precise and efficient.

Core Answer Table

| Core Issues | Key Technical Points | Business Decision Value |

| Significance of Process Selection | It is a direct determinant of the lifespan of gears, noise levels, as well as the efficiency of the overall system. There would be varying levels of precision and production rate based on the selected process. | It prevents wastage of costs while improving the marketability of products. |

| Three Key CNC Processes with Gears |

Hobbing (high-efficient cutting, ideal for large quantities of outer gears). Gear Shaping (reciprocating cutting, used for internal gears). Gear Grinding (grinding, correcting deviations in gear treatment. |

Choose a precise and optimal gear cutting solution according to production volume and financial budget. |

| Decision Making/Service Supplier Selection | Involves an elaborate process incorporating a technical matrix that considers gear type, material hardness, precision grade, project delivery time, and cost parameters. | JS Precision has an end-to-end solution for the complete process chain to cater to customized requirements by ensuring stable quality and controllable delivery times. |

Key Conclusions:

1.When the gear precision requirements are ≥ ISO 5 or the tooth surface roughness is < 0.8μm, the selection of the CNC gear grinding services will be required.

2. In the processing of internal gears or structure gears with medium output, the CNC gear shaping processing services possess unique economic advantages.

3. In choosing a service provider, it has to be ascertained that the equipment accuracy of the service provider, for instance the provision of testing equipment corresponding to the standards of the German Klingelnberg Gear Testing Center, is guaranteed, as well as their successful cases.

4. JS Precision offers custom gear cutting solutions combining all processes in gear hobbing, gear shaping, and gear grinding right from gear design optimization.

JS Precision's Experience: The Key To Improving Gear Stability

At JS Precision, we have over a decade and a half of experience in dealing with gear machining orders and more than 500 clients worldwide in different demanding industries like automobiles, aerospace, and robotics. Our main competitiveness advantage lies in our relentless efforts for perfection in gear manufacturing technology and our in-depth knowledge of our clients’ pain points.

In regards to equipment, we use superior equipment like German gear hobbing machines – LIEBHERR, Japanese gear shaping machines – OKUMA, and gear grinding machines – REISHAUER from Switzerland, along with all modules like modules 1-12, precision levels from ISO 3 to ISO 10.

By using Electronic Gearbox (EGB) and flexible synchronization technology, we are able to realize the precision locking between the tool and work piece, and guarantee the gear pitch error in micrometer precision.

The average industry experience of our team of engineers is over 10 years, offering valuable advice on Design for Manufacturability (DFM) to our clients. Previously, we assisted a new energy vehicle manufacturer in improving the design of their planetary gearbox by minimizing gear noise by 4 decibels and improving production efficiency by 30%.

Our strict quality control processes make us ISO 9001 and AS9100D registered. Each gear is thoroughly tested using 3D metric instruments, tooth profile gauges, among others, whose results can be traced right from the start to the finish.

Looking for ways to ensure that the performance of your gear products remains more stable with a longer lifespan? Contact the JS Precision engineering team now to share your gear needs, and we will offer a free process feasibility analysis and customized gear cutting services.

Why Is Choosing Gear Cutting Services Accurately The Key To The Success Of Your Project?

Gear cutting services are the core component of gear machining, and their selection directly determines the cost, delivery time, and final product performance of the project.

Selecting the appropriate process will not only ensure a smooth and efficient gears production process but also improve the performance of the equipment used. Selecting the wrong process could result in poor precision of the gears, cost spending, and project delays.

In mass production of external gears, inappropriate gear cutting processes can raise the unit cost by over 20%. The failure to select an appropriate gear cutting process in precise gear applications can result in goods that defy the purpose for which they must serve in their application use.

Professional gear cutting services can match the optimal process based on factors such as your gear type, production batch, and precision requirements, achieving a balance between cost, efficiency, and quality.

Still struggling with process selection? Click to download JS Precision's "White Paper on Gear Process Selection" and get free guidance on process matching for different scenarios; If you have preliminary requirements, you can directly contact our process consultant to obtain a 1-on-1 selection analysis for free.

Technical Depth Analysis: The Truth Behind The Three Core CNC Gear Machining Processes

Gear machining involves the control of profile, pitch, and surfaces to create quality gears. CNC hobbing, gear shaping, and gear grinding processes meet different needs. The following analysis of core principles and applicable scenarios.

CNC Hobbing Services: When is it Most Suitable for High Volume and High Efficiency Production?

The CNC gear hobbing services involve simultaneous cutting and gear production through a hobbing process. This is ideal and most preferred for high-efficiency cutting large volume external gears. In this service, gears with modules ranging from 1 to 12 can be produced.

It uses a German LIEBHERR gear hobbing machine with coated carbide hobs, enabling high-speed cutting speeds of up to 180 m/minute. The processing time per piece for a 4140 alloy steel gear is only 5 minutes, with quantities over 1000, the cost is over 30% less compared with gear shaping.

The disadvantage is that it can neither hob internal gears nor those with shoulders side by side. In the search for gear hobbing services near me, it has to be ensured that the hobbing machine is compatible with the gear modules and size of the production batch.

CNC Gear Shaping Services: How to solve the machining challenges of internal gears and complex gear structures?

CNC gear shaping services involve the reciprocal cutting of teeth of the cutter and the rotation of the workpiece to generate a gear. Its key advantage is that it is flexible and can perform complex shapes of gears that cannot be done by hobbing. These include internal gears as well as multi-stage gears.

These gear shaper machines from JS Precision work on internal gears with a module range of 1 to 10 units, along with an internal bore diameter that is greater than or equal to 20mm, while the precision is ISO 7. It is effective for precision machining of complex gears in a range of 50 to 500 units. It minimizes the use of special cutting tools, thereby reducing costs.

The surface roughness of 1.6 to 3.2μm directly satisfies the general requirements, but its efficiency ratio is lower compared to gear hobbing processes, which makes them less suitable for mass production of gears involving simpler forms.

CNC Gear Grinding Services: When is it necessary to invest in top-tier precision and surface quality?

The cnc gear grinding services are one of the main gear finishing processes. It uses grinding wheels to grind gears in order to eliminate errors in tooth profiles and surface roughness, so it can eliminate errors in quenching deformation and provide ultra-high precision processing.

JS Precision uses CBN grinding wheels as well as electrochemical dressing (ECD) technique to process HRC58-62 hardened steel gearings with ISO-3 accuracy and surface roughness as low as 0.2-0.4µm, thus making this process mandatory in high-quality transmission equipment due to its lower noise level and increased lifespan.

Its equipment investment is 3-5 times that of a gear hobbing machine, and the processing time for a single piece is 5-8 times that of a gear hobbing machine. It is suitable for high-speed (>5000 RPM), high load, and low-noise scenarios, and choosing professional gear CNC grinding companies is the key to performance assurance.

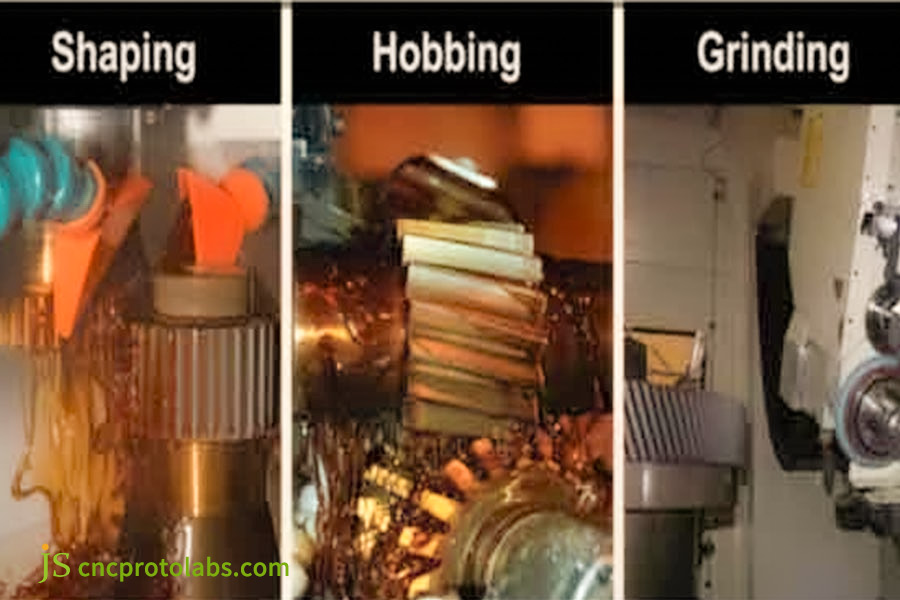

Figure 1 three core gear cutting technology

Technical Comparison Matrix: How To Drive Your Process Decisions With Data?

Selecting a gear cutting process must be based on data. The following parameter comparison table and key dimension analysis will help you quickly find the right solution.

Comparison Table of Core Parameters for Three Major CNC Gear Machining Processes

| Comparison Dimensions | CNC Gear Hobbing Service | CNC Gear Shaping Service | CNC Gear Grinding Service |

| Precision Grade (ISO) | 8-10 | 7-9 | 3-6 |

| Gear Surface Roughness Ra (μm) | 1.6-6.3 | 1.6-3.2 | 0.2-0.8 |

| Applicable Module (mm) | 1-12 | 1-10 | 1-12 |

| Applicable Gear Type | External Gears (Spur/Helical) | Internal/External Gears, Complex Structure Gears | Internal/External Gears (Requires High Precision) |

| Material Hardness Range | ≤HRC32 (Before Heat Treatment) | ≤HRC35 (Before Heat Treatment) | HRC58-62 (After Heat Treatment) |

| Single Piece Machining Time (Reference) | 5-15 minutes | 10-30 minutes | 20-60 minutes |

| Batch Adaptability | Large Batch (>1000 pieces) | Small to Medium Batch (50-500 pieces) | Full Batch (Focusing on High Precision Requirements) |

| Equipment Investment Cost | Medium | Medium | High |

| Typical Application Scenarios | Automotive transmission gears, general mechanical gears | Industrial reducer internal gears, multi-stage gears | New energy vehicle gears, aerospace gears |

Precision and Surface Finish: Which process can achieve an ultra-smooth tooth surface with Ra 0.4μm?

The precision of gear and its surface finish will directly impact the transmission efficiency and noise level of the transmission. Only CNC gear grinding services are capable of ensuring an ultra-smooth tooth surface with an Ra value of 0.2-0.4μm, ensuring high-speed operation (>5000 RPM) and quiet operation (<60 dB).

Ra 1.6-6.3μm is appropriate for general machinery. Ra 1.6-3.2μm is adequate for broad industrial applications. JS Precision gear grinding is conducted through nanofluid cooling to prevent thermal deformation with a tooth profile accuracy of <3μm. These specifications target applications within high-end equipment.

The Cost-Efficiency Ratio: How unit cost depends on batch size?

The unit cost is considerably dependent on the batch size for various processes, and accordingly, when it comes to batches above 1000, hobbing has the lowest unit cost, for a batch ranging from 50 to 500, cnc gear shaping services are more economical, and for precise applications, irrespective of batch size, gear grinding is the only necessity.

For instance, for a gear with a modulus of 2.5 and made of 20CrMnTi, the unit cost for gear shaping for a production lot size of 100 is around $80, for hobbing with a production lot size of 1000, the unit cost is as low as $35, and for gear grinding with an accuracy of ISO 5, the unit cost is around $150.

The Boundaries of Materials and Design: Have you ever reached beyond the boundaries of a particular process with your gear design?

Each process has its material and design limits, of which the validation is imperative for their selection:

Hobbing and gear shaping are appropriate for soft material before heat treatment (up to HRC35), and grinding for hardened steel (HRC58-62), the maximum module for hobbing and grinding is 12mm, and for gear shaping, it is 10mm, for inner gears, gear shaping and grinding processes require an inner bore of no less than 20mm, and the tooth width for hobbing is 150mm, for gear shaping, it is 120mm, and for grinding, it is 100mm.

If the gear design exceeds the above boundaries, JS Precision can provide feasible machining solutions through custom gear cutting schemes, combined with multi-process combinations or specialized tool designs.

Decision Guide: Which Gear Cutting Service Does Your Project Requirement Match?

The essence of gear cutting services selection revolves with “matching to needs.” The following decision trees have been provided in a scenario to immediately determine which is the most appropriate process.

Scenario 1: How to Choose for High-Precision Transmission Projects Requiring High Performance?

High precision demand projects such as new energy vehicle transmissions and aerospace transmission components require gear accuracy ≥ ISO level 5 Ra<0.8μm. And the material is mostly quenched steel, so you can directly choose CNC gear grinding services. JS precision is one of professional gear cnc grinding companies and has the capability to accomplish the full service for high-end gears.

Scenario 2: What are the Considerations when Machining an Internal Gear or a Gear Set with Shoulders?

When processing complex structures such as internal gears and multiple gears, CNC gear hobbing services should be selected. Three points should be noted:

- Provide detailed drawings with key dimensions for tool interference inspection.

- Clearly define batch size and accuracy.

- Confirm the simulation analysis capability of the service provider.

Scenario 3: How to locate a service provider for small-batch customization, which is urgently needed and calls for localized rapid response?

For "gear hobbing services near me," the core principles that should be checked are rapid response and process flexibility. This requires checking the capacity of the equipment, rapid process analysis capability, and delivery cycle of the providing service.

The following summarizes key matching information to clearly match needs with processes:

| Gear Machining Needs Type | Recommended Process | Typical Delivery Time | Unit Cost Range (USD) | Applicable Industries |

| Large-volume general-purpose external gears (>1000 pieces, ISO 8-10) | CNC hobbing service | 7-14 days | 35-60 | General machinery, agricultural equipment |

| Small to medium-volume internal gears (50-500 pieces, ISO 7-9) | CNC gear shaping service | 10-20 days | 60-100 | Industrial reducers, construction machinery |

| High-precision critical gears (unlimited batch, ISO 3-6) | CNC grinding service | 14-30 days | 120-200 | New energy vehicles, aerospace |

| Small-volume customized complex gears (<50 pieces, ISO 6-8) | Hobbing + grinding hybrid process | 7-12 days | 100-150 | High-end equipment prototyping, research projects |

Figure 2 When deciding which gear cutting service to choose, factors should be considered beforehand.

Practical Case:JS Precision Has Improved Delivery Efficiency For Its Customers By 200% Through Process Optimization

Project Context and Problems

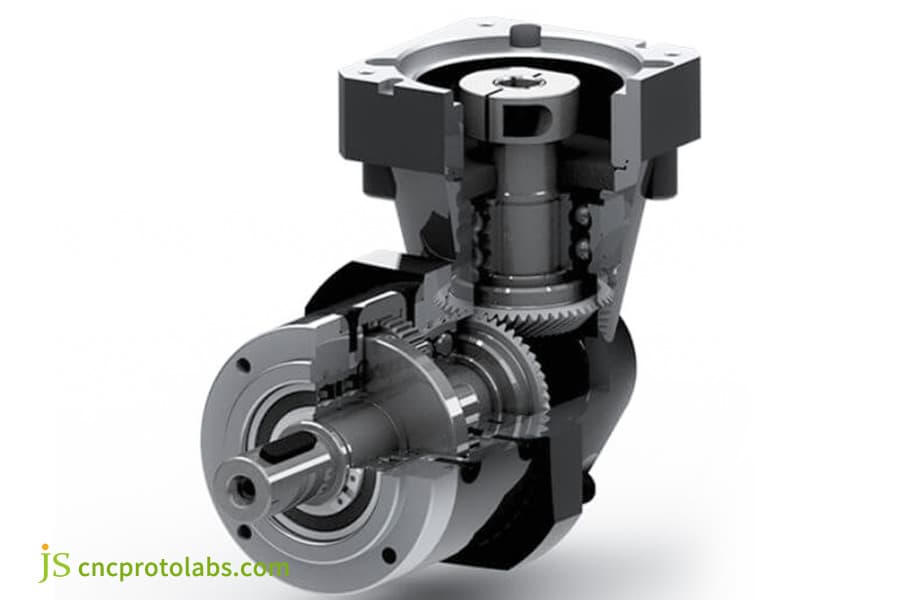

A high-end packaging machinery manufacturer urgently needs 500 planetary gearbox components with a module of 2.5, 20CrMnTi material, HRC58-62 hardness, and ISO grade 6 accuracy. Traditional single tooth grinding requires 21 days to deliver, while the project schedule is only 10 days left, facing the risk of breach of contract.

JS Precision Hybrid Process Solution: In what way is Gear Hobbing + Gear Grinding crucial to shattering this deadlock?

On receiving the order, a team of JS Precision engineers undertook a swift analysis of the process. In answer to the call for a hybrid process solution for ‘Roughing & Finishing’, we offered the following:

1. Process Decomposition & Roughing: In a non-critical surface finish for teeth and root sections of gears, high-speed gear hobbing services with a coated carbide hob with a speed of 180 m/minutes eliminated the excessive material in a pre-processing task accomplished within 5 minutes for each piece.

2. Precision Finishing: In the noise-conveying and fatigue resistance surfaces of the teeth, the gear grinding process that was carried out was the CNC gear grinding service that employed the CBN grinding wheel process with the tooth profile precision of ISO 6 standard and the tooth finish precision of Ra 0.8um standard.

3. Parallel Process: Both roughing and finishing processes were done in parallel at different stations. The roughed parts were transferred to the subsequent stage for finishing, with no waiting time and hence a significant reduction in cycle time.

Quantifiable Results

- Time: The delivery period has been reduced from 21 days to 7 days. This improved efficiency in deliveries by 200% and even enabled the customer to avoid a risk of default.

- Cost: There has been an optimization of 60% of the grinding allowance. There has been a reduction of 15% in overall costs of production. This gives overall savings to the customer of approximately $8,000.

- Quality: Quality in the precision of the teeth on identification gears was good, with the level of precision meeting ISO level 6. Noise levels in the operation of gears had been reduced by 3 decibels during the installation process with the customer, satisfying the requirements for better quality in the packaging equipment.

In this particular case, there is an extensive understanding about how gear cnc grinding companies with the utmost level of knowledge for process integration can achieve optimization for cost as well as for time.

To emulate this success story and achieve a win-win solution of efficiency and economy for your project, contact JS Precision, and we will provide you with our customized hybrid process solution.

Figure 3 Planetary gearbox for packaging machines

Beyond The Principle Of Proximity: Five Golden Rules For Choosing Gear Cutting Service Providers

Provider Instead, many customers would rather search for “gear hobbing services near me,” but it is impossible to ensure quality through location alone. The below mentioned five golden rules would ensure that you get a good gear cutting services provider.

Rule One: Does it have an entire process chain and top-rated equipment?

Top-rated service providers should have all-rounded abilities for gear hobbing, gear shaping, and gear grinding to offer impartial and optimal advice. JS Precision combines all three processes above and has top-rated equipment that allows them to engage in complicated gear processing services.

Rule Two: Is the quality control system strict? Does it have authoritative certifications?

The quality of gears is very important in relation to equipment quality and functioning. A service provider needs to have a quality control system that is comprehensive. JS Precision is ISO 9001 and AS9100D certified and provides full process quality control with German standard testing equipment from Klingelnberg.

Rule Three: What are the engineering support capabilities? Can it participate in front-end design optimization?

Providers for the service of gear cutting equipment should engage in front-end design optimization. JS Precision has engineers who offer DFM suggestions for optimizing gear shape and design, which would lower costs and maximize efficiency without compromising performance—this is the essential benefit of custom gear cutting services.

Rule Four: Does "near me" service mean reliable supply chain and rapid response?

The core of true "near me" service is efficient communication and quick responses. JS Precision uses a digital system to enable real-time tracking of order progress and data sharing, 24/7 engineer support, and rapid delivery provided through a global logistics network.

Rule Five: Does it possess the sustainable development capability for long-term cooperation?

Choosing a service provider is just choosing a long-term partner. It's very important to check the financial condition of this supplier: How much is the investment in R&D, and how about the capacity planning? Every year JS Precision invests 15% of the revenue in technology upgrading. New processes and equipment are constantly being introduced to ensure stable long-term cooperation.

FAQs

Q1: Which is the cheapest: gear hobbing, gear shaping, or gear grinding?

Approximately, the order from least expensive to most expensive for lot production is: gear hobbing, gear shaping, and then gear grinding. Gear shaping may be less expensive in small to moderate lots than gear hobbing for internal gears or other complicated gear geometries, it has to be evaluated on a case-by-case basis.

Q2: What is the highest precision achievable with gear grinding?

High-quality CNC gear grinding services can ensure ISO 3 accuracy standards for the tooth profiles, with errors of less than 3 micrometers for high-end industries like Aerospace.

Q3: Should gear grinding be performed before or after heat treatment?

Gear grinding is normally carried out after the heat treatment process, which might cause deformation, and grinding helps in removing this deformation in gears.

Q4: Can you machine gears made of superhard materials such as cemented carbide?

Yes, this can be categorized under custom gear cutting. JS Precision employs the use of diamond abrasives and processes to machine the gear made from superhard material like cemented carbide to meet the specific demands of the application.

Q5: Do you accept small batch orders (e.g., less than 100 pieces)?

JS Precision accepts small batch orders, but needs to evaluate the process economy. In the range of orders that are less than 100 pieces, gear hobbing or grinding can be more appropriate for flexible production to avoid the high cost of specialized cutting tools.

Q6: What is the typical lead time from design to finished product?

Depending on the process and the order quantity, the lead time will vary. Simple gear hobbing orders are delivered in 2-3 weeks, while the time needed for the completion of complex gear grinding orders can be 4-6 weeks. JS Precision provides fast-track facilities for the delivery of orders requiring high precision and are executed within 7 days.

Q7: Do you provide gear design and optimization services?

Yes, top gear CNC grinding companies typically provide full process engineering support. JS Precision's engineering team can provide customers with one-stop services such as gear design, parameter optimization, and process planning.

Q8: What is the first step in working with JS Precision?

First, you need to furnish us with drawings or specifications of your gears, such as gear type, module, number of teeth, accuracy level, material, production quantity, and time requirement. We would like to offer you a free process analysis and quote.

Summary

There's no such thing as a "best" for gear cutting processes, only the "optimal" one. Whether you are looking for efficient gear hobbing services, flexible CNC gear shaping services, or precise CNC gear grinding services, the bottom line is to find one that will cater to your needs.

With its whole process system, modern equipment, expert engineers, and quality control, JS Precision is able to offer you custom gear cutting services from design optimization through to finished goods, meaning you can optimize for cost, efficiency, and quality to get the best results.

End the agonizing over process choices. Contact JS Precision's gear expert team immediately and let us know what your needs are. We'll send you a free process analysis and quote to begin the process of building better transmission components.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com