CNC machining parts are widely used in automotive electronics, aerospace components, and industrial equipment, such as precision countersinks that secure automotive sensor housings or Countersunk Screws that fasten aerospace panels.

In the field of manufacturing, when there are thousands of cnc machining parts produced, what appears to be a minor defect in a countersink or counterbore-such as deviation in angle, inconsistency in depth, or burrs-can lead to stoppages in the assembly line, a decline in product reliability, and engender hidden costs.

It is a litmus test of process depth and control capability for a manufacturer when your project moves from prototyping to high volume CNC machining, therefore being able to ensure perfect consistency of these critical features.

Below is an article that explores the common root causes of countersink/counterbore defects in mass production, which provides solutions all the way from design to tooling, cost control, and quality consistency. The following are reasons why leading global companies partner with JS Precision for scalable excellence in precision CNC machining.

Key Answer Summary

| Common Challenges | Root Causes | JS Precision's Integrated Solution |

| Countersink angle/depth inconsistency | Tool wear, clamping error, and or lack of process monitoring. | A dedicated tool library based on materials and parameters, real-time tool life management, and online inspection sampling together guarantee consistent quality for several thousand parts. |

| Burrs and residues at the orifice | Sharp tool edges, poor chip removal, and inappropriate strategy. | By using high-precision chamfering tools and optimized cutting parameters, combined with specific deburring processes, the surface quality of "machining is completed" is achieved. |

| Uncontrolled Expenses in Mass Production | Only focus on the per-piece machining time and ignore tool consumption, scrap rate, and inspection costs. | Provide DFM optimization to simplify the feature, recommend an effective tooling strategy, and transparently perform cost analysis to lock in the best total cost solution. |

| Design-induced machining efficiency | Non-standard angle, over-tightened tolerance, or structure that restricts chip removal. | Early consultation of DFM guides the adoption of standard tools, reasonable tolerance, and optimization of feature layout to enhance the efficiency of parts CNC machining. |

Key Takeaways:

- Consistency is provided by the system: The success of mass production relies on the stability of a process system rather than the perfection of one single machining operation.

- Design drives cost baseline: The use of standard tool angles and reasonable tolerances is typically the best start for cost control in CNC machining metal parts.

- Specialized tooling is an investment, not a cost: Specialized tooling for certain materials and features can greatly enhance quality and reduce overall waste.

- Maximize value through early collaboration: Communicating with the manufacturer on DFM before drawings are finalised often can help avoid most manufacturability issues.

Trust JS Precision: Precision Solution For Countersunk Holes In CNC Machining Parts

CNC machining of countersunk holes and reverse holes requires not only advanced equipment but also deep engineering expertise, mature process control capabilities, and practical experience in solving complex high-volume machining challenges.

As a reliable partner of precision CNC machining, JS Precision has been dedicated to providing a whole range of CNC machining metal parts and CNC machining products in serving customers in the global automotive, aerospace, and electronics industries for more than ten years.

Our team, comprising more than 50 certified engineers, goes beyond just following drawings to proactively optimize designs and processes, eradicating potential risks even before production begins.

We have successfully delivered more than 500 high volume CNC machining projects, including a million-piece order for automotive electronic housings, reducing the scrap rate from 15% to 0.2%.

In our in-house lab, we have a 3D measuring tool and SPC monitoring system to ensure that every piece of countersink can meet high precision tolerance requirements up to ±0.01mm. Our end-to-end control system fully complies with the quality management system standard ISO 9001:2015.

What really differentiates us, however, is our transparency-we provide real-time production data, perform joint design reviews, and offer deep-dive DFM reports to equip clients with the right information to make informed decisions.

If any of the issues listed above, such as inconsistent hole quality, high rework costs, or delivery delays, are a big concern for you in high volume CNC machining, it is time to contact JS Precision. Just send your part drawings and requirements, and our engineers will offer you free DFM analysis and tailor-made precision machining solutions to mitigate risk and boost efficiency.

Common Flaws In Countersinks/Counterbores For High Volume CNC Machining,How To Prevent?

In high volume CNC machining, the countersunking/countersunking of CNC machining parts is prone to repetitive defects, and hidden problems in small batches can be magnified on a large scale. We need to strictly control the design, cutting tools, and manufacturing processes. The following are the core issues and prevention strategies.

Typical Design-related Issues

Poor design is one of the most critical causes of defects. For example, specification of other than standard countersink angles like 82 will increase custom tooling costs by more than three times and increase delivery terms.

Exorbitant tightness in matching between the depth of countersink and height of screw head, unclear drawing annotations like specifying only depth without angle can all lead to bad assembly and low yield rates.

Deformation in Manufacturing Processes and Execution

Manufacturing process deviations also have impacts on quality. Long-term mass production may result in wearing tools, which causes smaller diameters of the holes and distorted angles, improper cutting parameters cause vibration, resulting in irregular hole walls, poor coolant or insufficient chip removal results in scratched opening of the hole.

How to Avoid These Problems from a Design and Manufacturing Perspective?

| Types of Defects | High-incidence Cases | Rapid Judgment Methods | Emergency Treatment Measures |

| Counterhole Angle Distortion | Non-standard angle machining, long-term tool wear. | The sampling check shall be performed by using an angle gauge and comparing it with the deviation of the standard angle. | Replace the tool with a new one and reset the angle parameters of the machine tool. |

| Hole Burr Residue | Stainless steel machining, poor chip removal. | Visual and tactile inspection, or observe the edges with a microscope. | Visual and tactile inspection, or observe the edges with a microscope. |

| Poor Depth Consistency | Large volume and continuous machining, loose clamping. | Use a depth gauge to randomly inspect 10 pieces to check data dispersion. | Non-standard angle machining, long-term tool wear. |

Prevention should be a two-pronged approach: design and process.

- Design: standard angles, such as 90°, should be adopted, this should be clearly labeled, in the form of "diameter × angle / depth". ASME Y14.5-2009 standards should be followed in order to minimize communication mistakes.

- Process: there should be a regular tool inspection and replacement system, optimization of cutting parameters, and coolant supply. Every 200 pieces, randomly inspect key dimensions to catch deviations early.

Key Factors In Mass Production Of CNC Machining Metal Parts

Explicit and implicit cost factors are amongst the major concern that needs to be taken while doing mass production cost control for CNC machining metal parts. The optimization of the system is necessary for the attainment of cost reduction in the lifecycle of the entire system. The core factors that influence this can be explained as:

Explicit Costs: Materials, Labour, and Tool Consumption

Fixed costs include three parts: the price of raw materials like aluminum and steel, which fluctuates, machine depreciation and labor costs during occupancy time or processing cycle, and the total cost of tool wear and frequent replacement in mass production.

Implicit Costs: Quality Consumption and Efficiency Loss

And more importantly, implicit costs which are easily overlooked include quality assurance costs comprised of first article, process, and final inspection, scrap and rework costs in consequence of design or process issues, and loss of efficiency due to production line changes and programming debugging.

Want to analyze the cost structure of CNC machining metal parts for finding a breakthrough for cost reduction? Fill in the form and contact the cost accounting experts from JS Precision with your requirements on material, batch, and precision to get a free cost analysis report.

Designing For Excellence: Best Practices For CNC Machining Parts With Flawless Fastener Features

Excellent design is the very foundation of perfect fastener features in CNC machining parts. Core design principles, proved in practice, are as follows, which can make sure the quality and manufacturability from its source.

Following Standards, Embracing Efficiency

Prioritize the use of standard tool angles, such as 82° and 90°, and standard step drill dimensions to reduce tooling cost and delivery time. Label drawings clearly according to "diameter × angle/depth" to avoid ambiguity leading to production errors.

Design for Manufacturing: The Wisdom Behind It

DFM Design Techniques: The countersinking should leave a small flat surface at the bottom to reduce tool wear. In designing thin-walled parts, the wall thickness, its support, and prevention of deformation must be considered. Deep hole machining should also reserve chip removal space to avoid chip accumulation in the hole.

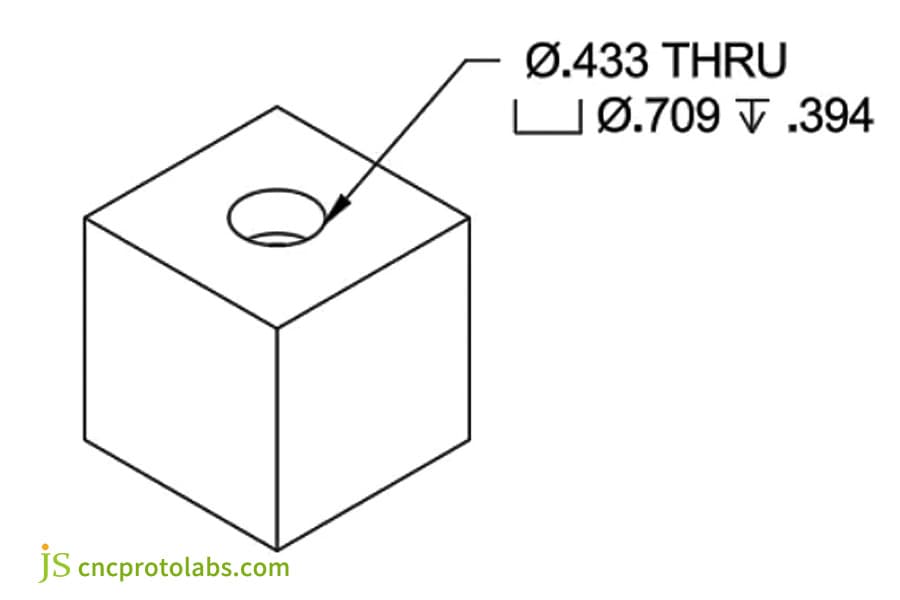

Figure 1 The manufacturer will need details such as tolerances, dimensions, and specifications for features such as threads.

How To Maintain Precision In Parts CNC Machining Across Thousands Of Units?

Achieving consistency across 10000 parts CNC machining is the core challenge of precision CNC machining, which requires strict process control. The following are some key methods of process control and tool management.

The Pillars of Process Control: Standardization and Monitoring

Getting stable machining benchmarks is the key to perfection.

- Formulate detailed SOPs to clearly specify the requirements for key elements, including the order of machining steps, method of cuts, and clamping.

- Fixed clamping schemes are applied to minimize the influence of clamping deviations on machining accuracy.

- Regularly perform precision calibration on machine tools to ensure that the equipment is in a stable state of accuracy.

- For monitoring, utilize SPC charts to monitor critical dimensions in real time, allowing prompt detection of small process fluctuations and preventing drifts or shifts from occurring.

Tool Management and Compensation with Intelligence

Professional tool management can offset accuracy drift: preset tool life and force timed replacement, use micron-level wear compensation function of machine tool to adjust tool position, establish a tool card to track the whole process of issuance and replacement.

Want to stabilize batch precision in parts CNC machining? For value-added process control and tool management, contact JS Precision. By using precision CNC machining technology, we ensure that lots are consistently produced within specifications or better.

Choosing Optimal Tools For Diverse CNC Machining Metal Parts

A good or bad tool selected will directly determines the quality, efficiency, and cost of CNC machining of mechanical metal parts. The following are key points for logic selection based on material property and characteristic.

Material Property-Based Selection Logic

Different metal materials have properties that are quite different in machining difficulties, which calls for targeted tool selection.

- Aluminum Alloys: A big rake angle and sharp cutting edge should be selected. The tool material can be carbide, and a coating can improve wear resistance.

- Stainless Steel: Tools with high hardness and good chip flute design should be selected, as this material has very high toughness and there is a tendency to stick to the tool. High-temperature resistant coatings like TiAlN are preferred.

- Titanium Alloys: Specific carbide tools should be used with lower cutting speeds and suitable cooling methods because of the poor thermal conductivity and high cutting temperatures.

Specialized solutions for feature types

| Machining Feature | Compatible Materials | Recommended Tool Parameters | Machining Considerations |

| Through Hole Countersinking | Aluminum Alloy, Carbon Steel | Solid Carbide, Rake Angle 15°-20° | High-speed feed to make sure the exit is burr-free |

| Blind Hole Counterboring | Stainless Steel, Alloy Steel | Indexable Inserts, Clearance Angle 8°-12° | Control feed speed, allow 0.2mm chip evacuation space |

| Thin-wall Edge Chamfering | Aluminum-Magnesium Alloy, Thin-wall Steel | Special forming tool, Cutting Edge Radius R0.5mm | Progressive feed to reduce the cutting force deformation |

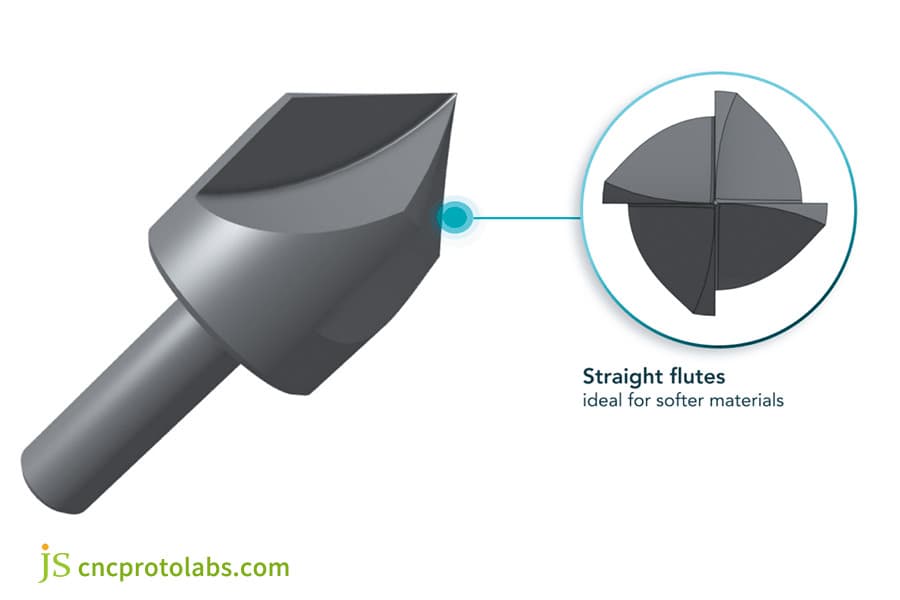

Figure 2 This is a general hand drill use for purpose countersink. It has straight flutes, ideal for softer materials.

Beyond Unit Price: Strategic Cost-Saving Tips For High Volume CNC Machining

Cost reduction in high volume CNC machining should consider the life cycle of a product. The following core strategic cost-saving techniques will help achieve major cost reductions without compromising on quality.

Design Optimization and Process Integration

Core Design Optimization: Reduce the number of assemblies and countersunk holes by integrating multiple parts through DFM, reduce tooling costs and tool change-over time by adopting standard tooling adaptation designs, simplify part structure to improve machining efficiency.

Optimization of the Supply Chain and Manufacturing Process

Supply Chain & Process Optimization: Reduce work-in-process inventory through rational batch division, eliminate waste like waiting and material flow by introducing lean manufacturing, and get the benefit of preferential pricing for post-processing services through bulk purchasing.

Want to pursue cost reduction in the full life cycle of high volume CNC machining? Please contact the project team of JS Precision to work out a multi-dimensional strategic solution to enhance the competitiveness of your CNC machining products.

From 15% Rejection To 99.8% Yield: How JS Precision Mastered a Million-Count Fastener Hole Challenge

The following case study demonstrates the technical strength of JS Precision in solving high volume CNC machining challenges related to countersunk hole machining.

Client and Challenge

A European automotive electronics client needed to mount shielding covers on an aluminum alloy housing with four precision countersunk holes.

Unfortunately, the original supplier was producing 100,000 high volume CNC machining parts each month with irregular countersunk hole depths, which caused uneven assembly pressure. Thus, he encountered a 15% monthly scrap rate with more than $250,000 in losses annually, which directly affected the assembly line schedules.

After taking over the project, the JS Precision team first conducted a comprehensive root cause analysis. We identified three core problems in the original process:

- There was also a very quick wear of the tool by applying a general-purpose chamfering tool, without using an effective mechanism to monitor wear.

- Micro-vibrations due to lack of rigidity in the fixture during machining affected the hole position accuracy.

- The lot was based on sampling at the end of the batch, so the detection of problems was usually very late, and a large number of products were defective.

Solution of JS Precision

To solve these problems, we had to adopt a comprehensive optimization plan.

- For this part, we customized a PVD-coated carbide countersinking tool to enhance its wear resistance and cutting stability.

- We redesigned the hydraulic fixture to increase rigidity and avoid micro-vibrations during machining.

- We optimized the tool feed strategy in CAM programming by using progressive feed to decrease the impact of cutting forces on the workpiece.

- Simultaneously, the process control system was upgraded. Automatic online depth inspection every 200 pieces was done, with the inspection data linked to the SPC system in real time to realize the dynamic monitoring of the machining process.

- We set the threshold for replacing tools as a preventive measure. When the tool reaches a preset quantity, it is forcibly changed, preventing quality problems caused by wear and tear at the source.

Results

After the project had been handed over for production to JS Precision, the countersinking depth CPK value of the first million-piece order reached over 1.67, while the first-pass yield jumped to 99.8%.

This optimization not only completely solved the problem of the customer's assembly line downtime but also saved the customer over $250,000 annually. The client highly recognized our technique capability and service quality, then signed a long-term strategic cooperation agreement with us.

Facing similar batch processing quality problems? Click here to view more JS Precision case studies, submit your processing challenges, and our engineers will provide targeted solutions to improve yield.

Figure 3 Precision countersunk holes

Why JS Precision? Your Partner For Scalable Precision In CNC Machining Products

Choosing a CNC machining partner means choosing a reliable quality, cost, and delivery system. JS Precision provides scalable precision assurance for large-scale manufacturing, making it a premium CNC machining products partner.

Deep manufacturing engineering capabilities and proactive DFM

Core Competencies in Engineering: Engineers develop programming and manufacturing experience, actively providing DFM analysis at the very start of the project, since finding and optimizing design issues reduces the cost of CNC machining products both functionally and economically.

Hardware and Processes Specifically Configured for Large-Scale Manufacturing

Large-Scale Manufacturing Configuration: The ability to be equipped with high-precision CNC machine tools and automatic material transportation to improve efficiency and reduce human error. An MES system will be able to introduce full-process visualization into production, besides, regularly performing equipment calibration can ensure the accuracy of parts produced.

Transparent Collaboration and Global Service Experience

Global Service Advantages: The same digital platform interfaces with clients in multiple countries in real-time production visualization. Dedicated project managers coordinate the entire process and provide cross-cultural and cross-time zone coordination for overseas clients, bringing local experiences to overseas clients.

FAQs

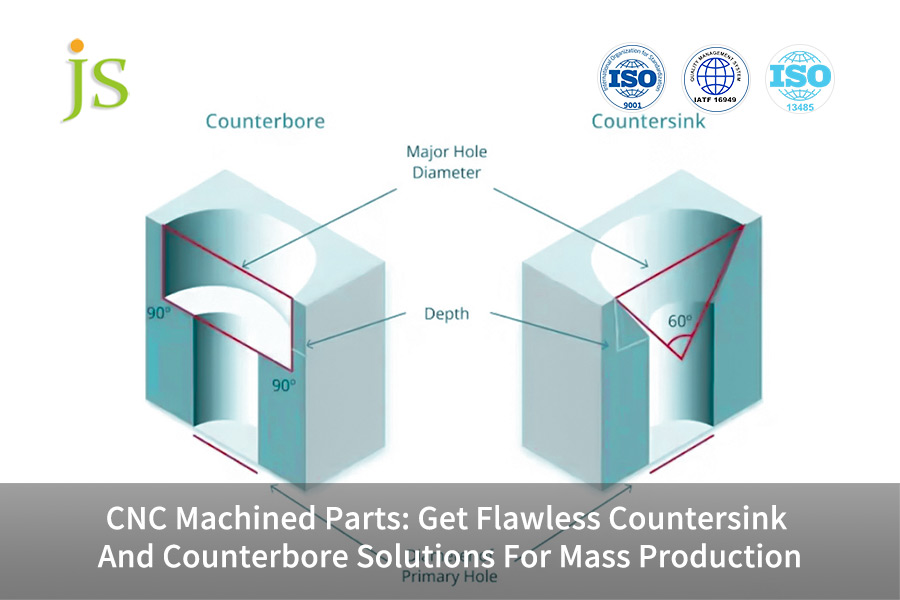

Q1: What is the main difference between countersinks and counterbores?

- Countersinks are a conical-shaped hole whose core function is to allow the head of a flat head or countersunk screw to stay flush with the surface of the part.

- Counterbores are cylindrical stepped holes mainly used to accommodate screw heads or nuts, allowing them to be lower than the surface of the part.

Q2: In mass production and at an economical cost, how can we ensure that the countersink depth tolerance does not exceed ±0.1mm?

In addition, to economically achieve this precision requirement, a combination of specialized cutting tools and rigid fixtures must be used, together with frequent process inspections and tool compensation. It is inadequate to simply rely on the machine tool's inherent precision to guarantee stable performance during long-term, high-volume production.

Q3: During stainless steel machining, countersinks are generally subject to burrs. What are some possible solutions?

The burr problem with the stainless steel countersinks can be solved by use of sharp carbide cutting tools, a lower feed rate, and sufficient cooling to decrease tool sticking. If the burr problem persists, a dedicated deburring process can be added if needed.

Q4: My design calls for countersinks with non-spec angles. Will this drive cost greatly?

For a non-standard angle, countersinks will play an important role in the cost. Due to their non-standard angles, customized cutting tools have to be made, which means high mold-making cost and longer tool delivery cycles, leading to increased inventory management costs.

Q5: When providing samples, the sinking holes were good, but there were problems during mass production. What could be the reason?

The most common reasons are two. One reason is that the precision changes caused by tool wear were not taken into account during mass production, and no corresponding compensation mechanism was established. Secondly, there are slight differences between the fixtures used in mass production and the sample fixtures, resulting in different rigidity of the fixtures.

Q6: My parts have multiple sizes of countersunk holes, and frequent tool changes can affect efficiency. How can I optimize?

There are mainly two directions of optimization. Firstly, through the evaluation of DFM, standardize or reduce the number of specifications of countersunk holes as much as possible and decrease the number of tool changes from a design perspective. Then optimize the sequence of the tool path in programming and group the same tool machining operation together.

Q7: How does JS Precision ensure timely delivery of high-volume orders?

We have comprehensive capacity planning-material management through our ERP/MES system, assigning a given project manager to each large-volume order for monitoring the whole production process. Moreover, we keep some safety capacity buffer to cope with unexpected situations.

Q8: What is the biggest advantage of choosing JS Precision compared to local suppliers?

We can provide precision CNC machining quality and professional engineering support comparable to top local suppliers, while leveraging the advantages of Chinese manufacturing to have more competitive cost advantages and flexible capacity adjustment capabilities, providing customers with the best comprehensive value.

Summary

The perfect realization of countersinking and reverse boring is a great epitome and representation of the maturity that has been reached so far as regards large-scale production CNC machining processes. It provides a profound test of expertise in every respect, from design understanding and tool science to process control and continuous optimization.

Under the dual pressure of cost and quality, choosing a partner who can convert precision into stable scale output is the key to project success.

Turn your disadvantages into advantages now!

Please visit the JS Precision website to upload part drawings containing countersinking/reverse boring requirements. You will not only get a high volume CNC machining quote that's highly competitive but also a free "Countersinking/Reverse Boring Manufacturability and Optimization Proposal" prepared by our manufacturing engineers. Allow us to make your manufacturing journey smoother.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com