Gear Cutting And Manufacturing is about more than just technology—it's about trust and partnership.

Ever felt confused by less than transparent pricing in gear cutting and manufacturing? Worried that small orders are not considered serious business? Or doubting whether manufacturers of gears are able to deliver on tight deadlines?

These are precisely those things that distinguish regular suppliers from strategic partners. JS Precision has come to believe that superior gear-cutting and manufacturing services should start with open, transparent cost breakdowns, thrive on effective order management, and end with dependable after-sales service.

This guide will take you through the entire process-from inquiry to delivery-step by step and turn you into a wise procurement expert who can make sure every gear job is completed on time and within budget.

Core Answer Summary

| Comparison Dimensions | Cost vs. Quotation | Process vs. Customization | Service vs. Delivery |

| Core Index | Materials, Process, Heat Treatment, Finishing, Quality Inspection. | Gear Type, Tolerance Grade, Tooth Profile Modification, Batch Size | One-stop service, from consultation to after-sales. |

| Key Influencing Factors | Material cost, gear complexity, precision grade, order quantity. | In custom gear cutting, the choice of process directly affects the capability and cost. | Project Management Process, Supply Chain Stability, Quality System |

| Optimization Strategies | Optimized Design, Reasonable Material Selection, Intelligent Layout, Batch Consolidation. | Early collaboration with engineers to select the most economical process combination. | Clear communication ensures that the progress of the order is transparent, comprehensive after-sales support. |

| JS Precision's Value | Transparent cost breakdowns and optimization suggestions. | Professional consultation on Custom Gear Cutting and Manufacturing. | On-time delivery and comprehensive technical after-sales service. |

Precision Gear Manufacturing: JS Precision Key Machining Techniques And Tolerance Control

In the gear cutting and manufacturing industry, experience contributes to the essence of ensuring product quality. Equipped with 15 years of practical experience in gear machining, JS Precision has provided service for three core industries: automotive, aerospace, and medical devices, processing over 2,000 different types for more than 500 clients.

Among them, the high-precision transmission gear tailor-made for an aerospace company reached a tolerance control standard of Grade 3 (Grade 12 in the accuracy class of the American Gear Manufacturers Association (AGMA)) and far exceeded the industry average of Grade 5.

We have also established a complete tolerance control system.Starting with the inspection of raw materials, every batch of steel is tested for hardness and composition.

In the processing process, each piece of equipment is equipped with a real-time monitoring system to immediately sound an alarm in case of deviation. Before the finished products leave the factory, comprehensive testing is carried out with a coordinate measuring machine and a tooth surface roughness tester.

Last year, our equipment product qualification rate reached 99.8%, much higher than the average in this industry at 98%.

Every point of this guide is based on practical experience accumulated by our team after the processing of almost 10,000 orders. Therefore, you can confidently believe that this content will help you avoid the most common pitfalls in gear manufacturing and find truly reliable partners.

Want to know how the tolerance control system works at JS Precision? Submit your gear precision requirements and get a detailed quality inspection process manual free to help you proactively mitigate the risk of substandard precision in gear cutting and manufacturing.

Demystifying Pricing: What Are The Components Of Gear Cutting And Manufacturing Costs?

Understanding the cost structure of Gear Cutting and Manufacturing is the first step in avoiding unnecessary expenses. The following breakdown into four parts lets you understand what each expenditure goes toward and will help you build trust in Gear Cutting Services.

Material Costs: the "Inherent Gene" of Gears

Material is one of the bases of cost. The price of various materials in different use scenarios is very different:

| Material Type | Unit Price (USD/lb) | Applicable Scenarios |

| Alloy Steel | 5.2 - 8.5 | High-strength transmission, such as gearboxes. |

| Stainless Steel | 7.8 - 12.3 | Corrosion-resistant environments, such as medical devices. |

| Brass | 3.1 - 4.5 | Low-load, lightweight scenarios. |

| Plastic (POM) | 1.2 - 2.8 | Low-noise, low-speed applications, for example - in household appliances. |

Process Costs: The Core of Gear Cutting Services

These gear-cutting services vary in cost and efficiency:

| Process Type | Unit Cost (USD/piece) | Processing Efficiency | Applicable Batch Size |

| Hobbing | 8 - 15 | High | Large batches (100 pieces or more) |

| Shaping | 12 - 20 | Medium | Low, medium-sized batches (10-100 pieces) |

| Scraping | 18 - 25 | High | High-precision orders |

| Milling | 6 - 10 | Low | Simple Gear Orders |

Post-processing and finishing: added value for performance

| Post-Processing Process | Unit Cost (USD/piece) | Function/Applicable Scenarios |

| Carburizing and Quenching | 5 - 8 | Improves the surface hardness of gears to extend service life. |

| Phosphating | 2 - 3 | Achieves rust prevention and friction reduction. |

| Zinc Plating | 3 - 5 | Applicable to gears in humid environments. |

Quality Inspection and Certification: Ensuring Reliability

| Inspection Items of Quality | Unit Cost(USD/pcs) | Function/Applicable Scenarios |

| Coordinate Measuring | 3 - 5 | Inspects gear dimensions and positional tolerances. |

| Gear Surface Roughness Inspection | 1.5 - 2.5 | Ensuring gear tooth surface smoothness to meet standards. |

| Dynamic Balancing Inspection | 4 - 7 | Suitable for high-speed gears, preventing vibration. |

How Does Customization Affect Price?: An In-Depth Look At The Price Factors For Custom Gear Cutting

Many customers wonder why the quotation for Custom Gear Cutting is higher compared to standard gears. Well, the reason is that "custom" implies special needs for specifications, precision, etc., which directly influence costs. Below are four key points:

Complexity of Gear Specification: Beyond the Standard Modules

The standard gear modules are 1-5mm. A module over 5mm or out-of-the-ordinary dimension requires changes in the equipment parameters, increasing costs by 30%-50% and doubling the processing time.

Precision Grade: The Cost of Going from Commercial to Aerospace Grade

Precision grades are divided into commercial grade (national standard 8-10), industrial grade (5-7), precision grade (3-4), and aerospace grade (1-2). Aerospace-grade materials are 2-3 times more expensive than commercial grade and need more precise equipment and much stricter quality control, increasing the processing time by more than 50%.

Special Tooth Profiles and Modifications: Paying for Performance

Standard tooth profiles are primarily involutes. Changing special tooth profiles or modifications requires redesigning tooling and cutting paths, adding 40%-60% to the cost of the gear. In fact, the cost of tooling customization alone can be as much as an additional $2000.

Order Volume: The Leverage of Economies of Scale

The volume significantly affects the unit price. For instance, for 3mm module, grade 5 gears, 10 pieces would cost around $35 each, 100 pieces around $22 each, while for 1000 pieces, the price can be reduced to $15 each.

Not sure how much your customization needs will add to costs? Fill in your specifications, precision, and volume for a free cost assessment report that helps you balance performance and budget in custom gear cutting and gear manufacturing.

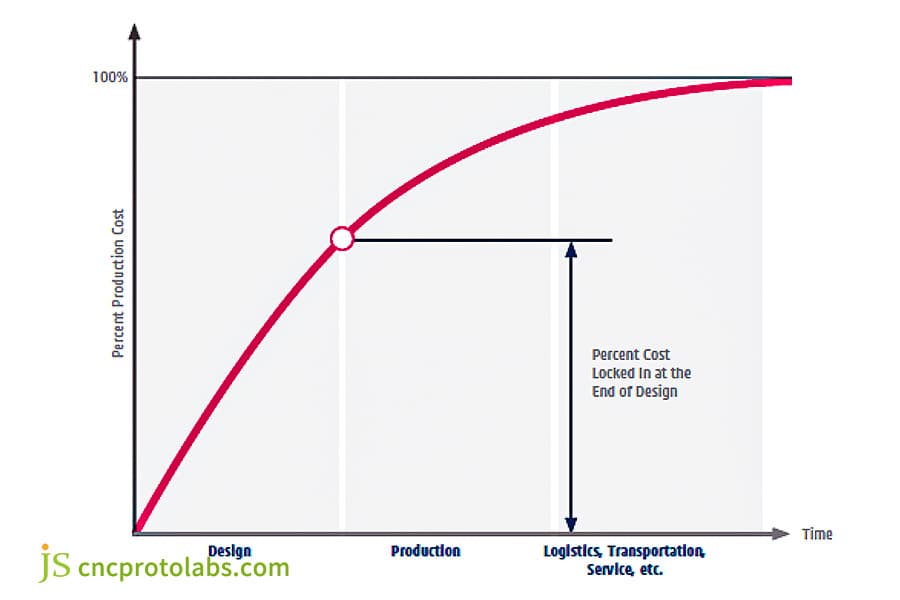

Figure 1: Up to 80 percent of product costs locked in at design.

Cost Optimization Strategies: How Smart Gear Manufacturing Saves You Money?

As one of professional gear manufacturing companies, JS Precision is not only a supplier but also aims to help you reduce costs. The following four practical strategies can make gear manufacturing both efficient and economical.

Value Engineering in the Design Phase

Optimization of the structure in the design phase contributes to the minimization of several machining steps. This can reduce unit cost up to 15%. The engineer will, according to the usage scenario, eliminate unnecessary high-precision requirements and complicated structures to reduce costs without influencing the performance.

The Art of Cost-Effective Material Selection

Never choose expensive materials by default. Appropriate material selection according to the scene can greatly lower the cost: in low-load cases, if the stainless steel can be replaced by brass, it will save 60% of material cost, in low-speed and low-noise conditions, replacing alloy steel with POM can save more than 70%. We recommend high performance and cost-effective materials.

Optimized Combination of Process Routes

A single process is not economical. Merging processes will result in cost reduction. In machining high precision gears, rough hobbing followed by finish scraping results in 10 - 15% cost reduction compared with full scraping, besides improving efficiency by 20%.

Design for Manufacturing and Assembly

Optimizing design makes it easy to process and assemble, and can also reduce costs. Changes to the tooth root fillet improve strength, reduce tool wear, and prolong tool life, indirectly contributing to cost reduction. Manufacturing and assembly perspective optimization will be performed by the design team.

Looking for cost reduction in your gear project? Book an appointment today with an engineer for a free design optimization plan, which will ensure cost reduction and high efficiency in collaboration with gear manufacturing companies.

Figure 2: A correct blueprint is crucial to convert ideas into high-performance gears.

From Drawings To Gears: Collaboration Process With A Custom Gear Manufacturer

Many customers are worried that dealing with a Custom Gear Manufacturer is convoluted and not transparent. At JS Precision, the process from drawings to gears is streamlined in just five easy steps, keeping you clear about the progress along the way.

Step 1: Consultation and Requirements Clarification

You can contact us by phone or email to inform us of the application scenario, performance requirements, batch size, and delivery cycle. Our sales engineers will reply within 24 hours to confirm such information in detail, including whether Custom Transmission Gears are required and the specific requirements for precision level.

Step 2: Design and Process Review

We will check the design for optimization possibilities with our technical team and identify a suitable machining process after you provide us with your 2D/3D drawings. If necessary, we will provide proposals to modify the drawings to ensure that the subsequent processing goes well.

Step 3: Formal Quotation and Contract Signing

Within 24 hours after completion of the design review, we can provide a detailed quotation containing an itemized cost breakdown for materials, processes, post-processing, quality inspection, etc. If everything looks fine according to your validation against the quotation, both parties sign a formal contract where the rights and obligations will be clearly stated.

Step 4: Production and Full-Process Quality Monitoring

We arrange production immediately after the contract is signed and after an advance payment is made. During production, we will be sending you progress reports twice a week with information on what stage the processing is at, along with the quality inspection status. If we encounter any problems, we will communicate with you for solutions as soon as possible.

Step 5: Final Inspection and On-Time Delivery

After production is finished, we will do an inspection to guarantee all the gears are up to the requirements. Immediately after passing the inspection, we will ship the goods according to the time and method agreed upon in the contract, and logistic tracking information will be provided so that at any time you can know where the goods are.

Is your gear project ready to take off? Please upload your 2D/3D drawings. We'll contact you within 24 hours and walk you through how to work with a custom gear manufacturer to make sure you get qualified Custom Transmission Gears with ease.

Is There A Professional Gear Cutting Services That Could Deal With Small Batch Orders?

Many startups or R&D projects require small batches of gears but are deterred by the high barriers to entry and costs of professional gear cutting services. However, JS Precision's flexible services can fulfill small-batch needs.

Advantages of the Flexible Manufacturing Systems

The flexible production lines can switch rapidly among different processing specifications. From 2mm module to 5mm module, for example, it only takes 30 minutes in parameter adjustment and meets the order of small batches with multiple varieties.

Mold-Free Technology Options

Small batch orders often use mold-free processes, such as CNC milling and scraping, saving $500-$1000 in mold fees, thus giving an overall cost reduction of 30%.

Pricing Strategy for Small Batch Order

We use the "actual labor time + material cost" pricing model without adding an extra premium for the volume. An order of 10 pieces is only 20%-30% more expensive compared with one lot of 100 pieces, far below the average premium of 50%-60% in the industry. This enables small-batch customers to enjoy high-quality service at a competitive price.

Need small-batch gears? Just call our hotline, mentioning "small-batch consultation." You will get a personal quote and enjoy equally excellent service provided by Gear Cutting Services and Gear Manufacturing Companies as large orders.

Committed Delivery: How Do Leading Gear Manufacturing Companies Guarantee On-Time Delivery?

For Gear Manufacturing Companies, on-time delivery is the key to success. After all, a day's downtime in a customer's production line could result in losses of hundreds of thousands of dollars. JS Precision, as one of the leading Gear Manufacturing companies, has three core strengths in ensuring on-time delivery, giving you complete peace of mind.

Advanced Production Planning System

We adopt an integrated production planning system with ERP + MES, which accurately calculates the processing time for each step and rationally allocates equipment and personnel. The system will automatically warn customers about orders that may be delayed, adjust plans in advance, and ensure on-time delivery of more than 98% of orders.

Deep Supply Chain Management and backup

We have established a three-tiered supply chain system for core raw materials: 3 Tier 1 suppliers and 5 Tier 2 suppliers, while maintaining a 30-day supply of commonly used materials. When one supplier was unable to supply last year due to the pandemic, we immediately switched to our backup supplier to ensure that no orders would be delayed.

Real-time Transparent Progress Tracking Mechanism

Each order has an assigned project manager whom you can contact at any moment to check the order progress. We will also upload real-time production photos and quality inspection reports to the order system, which you may log in and see. This way, you have no reason to worry about our working progress being not transparent enough.

Figure 3: On-time delivery directly reflects a manufacturer’s commitment to fulfilling its promises.

Case Study: The 72-Hour Turnaround—How We Saved An Automotive Line From Shutdown

Last year, an automotive parts supplier had an emergency: their automatic transmission assembly line was about to shut down because of premature wear in a critical batch of custom transmission gears. The original supplier estimated that replacements would take at least two weeks, and this put them in a bind.

Customer Emergency Situation

This customer's automatic transmission line produced 500 transmissions daily, for which a stoppage would incur a loss of approximately $800,000 dollars per day. They reached out to us when they had three days left before complete production shutdown and thus needed urgently 50 qualified custom transmission gears to save the day.

JS Precision's Response

Within an hour of receiving the request for help, we instituted the "Code Red" emergency procedure.

First, we had our technicians make precise measurements and failure analysis. Consequently, it was found that the poor heat treatment of the original gear led to inefficient wear resistance. Therefore, we optimized the carburizing and quenching temperature and time, increasing the surface hardness from HRC58 to HRC62 while maintaining core toughness.

Then we mobilized our dedicated gear cutting services flexible unit and employed a scraping process for rapid machining. This process is 30% more efficient compared to traditional gear hobbing, hence considerably reducing the processing time.

After machining, we sent the gears to do the carburizing and quenching immediately, and all the processes were carefully monitored by special personnel to ensure not a minute wasted.

We then adopted parallel operations during production: the quality control team prepared testing equipment in advance, immediately performing coordinate measuring machine (CMM) measurements and tooth surface roughness checks once the gears were heat-treated, the logistics team pre-booked air freight space to ensure immediate shipment upon passing inspection.

Our Final Results

From the receipt of the customer's old gears for reverse engineering, the delivery of 50 qualified new gears to the customer took a total of 72 hours. The customer's production line resumed operation on the fourth day after the emergence of the threat of shutdown, thus avoiding nearly $3 million in economic losses.

Afterwards, the client signed a long-term cooperation agreement with us, listing us as a core gear supplier.

Figure 4: Automatic transmission gears for automobiles

What Kind Of After-Sales Services Would An Authentic Custom Gear Manufacturer Offer?

A real custom gear manufacturer does not stop servicing once the gears have been delivered. For a company specializing in gear cutting and manufacturing, JS Precision will always be there for you with long-term after-sales service, to help solve problems in subsequent use and enhance customer loyalty.

Technical Support and Installation Guidance

In case any problem occurs during the gear installation process, our technical engineers will provide remote guidance within 24 hours. If the problem cannot be fixed with remote guidance, an engineer will be arranged to provide on-site service to ensure that the gear is correctly installed and used properly.

Routine maintenance and life assessment

We make a record of gear usage for long-term customers so that we can remind you to do gear maintenance every 6 months, and we also provide on-site inspection services. We check for wear on gears, assess remaining lifespan, and remind you in preparation for spare parts to avoid failures.

Spare Parts Inventory Management and Quick Response

For long-term clients, we will stock commonly used gear spare parts based on the volume of your usage. Once you need spare parts, we can ship in 48 hours and avoid waiting for a new production cycle, which significantly reduces downtime.

FAQs

Q1: What type of materials do you normally use in making gears?

We process alloy steel, stainless steel, brass, bronze, POM, and nylon. We will suggest the most economical material according to gear application scenario and performance requirements.

Q2: How long does it take from inquiry to receiving a quote?

For standard requirements, a detailed quote is usually provided within 24 hours. For complex, custom projects, a technical evaluation is required and usually takes 1-2 business days before a quote is provided.

Q3: What is the gear precision level you can achieve?

Our machining capability is up to national standard level 3 (AGMA level 12), depending on the process. We will recommend cost-effective precision levels according to your performance requirements.

Q4: Do you do gear design and optimization?

Yes! Our professional design team offers gear design review and value engineering services to help you optimize structure, reduce costs, and improve performance.

Q5: What effect does surface treatment have on gears?

Surface treatment has three main purposes: to prevent rust, reduce friction, or improve durability. Phosphating and galvanizing are for rust prevention, while carburizing and quenching are methods to increase hardness. We will recommend appropriate methods depending on the working environment

Q6: What should be included on our design documents?

Please provide a complete 2D/3D drawing with legible, identifying information including module, number of teeth, pressure angle, precision grade, material, and any required heat treatments.

Q7: Do you support shipping worldwide?

Yes, we cooperate with international logistics companies such as DHL, FedEx, and other international logistics providers that can provide safety, quick transit, and also logistics tracking information.

Q8: Can I check the progress of my order during production?

Of course, every order has a person in charge who can contact you at any time to check the progress and log in to the order system to view the real-time production and quality inspection status.

Summary

Gear cutting or manufacturing is not a challenge, it's about finding a knowledgeable and trusting partner. JS Precision is committed to making the manufacturing process of gears translucently efficient for you, so you can focus on your core business without headaches about the supply chain.

Your success starts with the right choice.

Ready to start your gear project? Whether you need Custom Transmission Gears samples or are looking for a reliable partner to handle the process of gear manufacturing, JS Precision is here to help.

We invite you to experience customer-centric gear manufacturing services!

Please access the JS Precision website, upload your gear drawings or technical requirements, and you will get a clear and transparent quote with no hidden fees, along with a professional DFM analysis report within 4 hours. Let us work together to inject reliable power into your project!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com