CNC milling services offer a fundamental assistance in the manufacture of precise parts for a wide range of industries. However, selecting an appropriate milling service provider might present a dilemma.

When customizing aluminum brackets with a tolerance of ± 0.01mm for optical instruments, you encounter the dilemma of local suppliers paying $200 per piece, a yield rate of 85%, and a 4-week lead time; When the small-scale production of 100 medical accessories is discouraged by high mold fees, the choice of service provider directly determines the success or failure of the project.

As a professional who has 15 years of experience in precision manufacturing at JS Precision, I have incorporated worldwide customer service experience and analyzed the essential logic of CNC milling to assist you in learning about potential surprises and discovering affordable customized solutions.

Core Answers Table

| Customer's Core Concerns | Common Market Challenges | JS Precision's Response and Value |

| Cost and Pricing Transparency | There are long quotation procedures with many hidden costs in the local market. | The online CNC milling quote system offers instant quotes with no hidden costs. |

| Quality and Consistency Assurance | Large variations in quality for complex CNC machining parts, incomplete data of inspection. | Digital traceability from start to finish, combined with first piece or final inspection (accompanied by CMM reports), ensures consistency for every lot of CNC precision machining parts. |

| Lead Time and Total Cost of Ownership | Local delivery time is limited by production capacity, time for international delivery is lengthy and the cost of transport is indeterminate. | Optimized scheduling of production will result in delivery times that remain comparable to local delivery even for international transport and transport estimates are also provided for door delivery. |

Key Conclusions

Total cost is better than unit price: When selecting a CNC milling services provider, quality consistency, delivery times, and technical support must be factored into total cost. The overall value of precision CNC milling China can typically exceed expectation.

Design determines cost: Difficult-to-manufacture designs, close tolerances, and specialized CNC milling surface finishing are high-cost factors. Downstream design-optimization activities, such as DFM, can lower costs.

"Near Me" is not necessarily the answer: Expert international suppliers are able to provide smooth communication enabled by digital tools such as instant price quoting and project management, and their technical know-how and scale are more equipped to meet the challenges of complex specialty parts customization.

The correct surface finish is critical: Making appropriate choices for surface finishes based on functionality, such as wear resistance, corrosion-resistance, or aesthetics, rather than making them based solely on looks, is an important aspect for enhancing the part's performance and longevity.

Why Trust JS Precision's CNC Milling Services? Ensuring The Manufacturing Of Precision Parts

At JS Precision, we boast over 15 years of experience in CNC milling and have served demanding sectors like automotive, aerospace, medical equipment, and optical instruments.

In addition to this, we have produced more than 1 million CNC machining parts and served reputed multinationals like German optical instrument manufacturers and American medical device manufacturers.

Our core processing machines are provided by DMG of Germany and Makino of Japan, along with specialized testing equipment, which helps us maintain a machining accuracy of ±0.005mm, and the accuracy of optical components within the high level of the industry at ±0.01mm.

Our quality management system fully meets the worldwide recognized standard ISO 9001:2015, which is a major guideline for quality management in international production and includes all steps from design and production to delivery.

This guideline summarizes our experience after having processed 5000+ customized orders, and all recommendations have been tested in production.

Do you want to check our qualifications and abilities? Contact our customer service department and get the free ISO 9001:2015 certification files and the cases of multinational customer cooperation in order to get more information on the guarantees of the CNC milling services from JS Precision.

From File To Receipt: How Does The Standard Delivery Cycle Of CNC Milling Services Consist?

Many customers are concerned about the delivery time of precision CNC milling China. The truth is that a transparent procedure guarantees international shipments are more manageable, even better than domestic companies.

Breakdown of Timeline: The Actual Time Spent on Engineering Review, Processing, and Logistics

Key stages in the whole delivery chain for CNC milling services:

- Engineering & Quotations: 1-2 hours (Brief review of the 3D file, preparation of quotations).

- Material preparation: 1-3 days (Common materials are always in stock. Special materials are already prepared).

- CNC Machining: 1-7 Days (Depending on Part Complexity).

- Post-processing and quality inspection: 1-2 days (including surface treatment and full-dimensional inspection).

- Overseas Logistics: 3-7 days via Air Freight (direct to major cities around the world).

How does JS Precision compress' invisible time '?

Our core system compresses non-processing waiting times by means of an agile manufacturing system:

- The processes in the standardized process library account for 90%+ of common parts.

- We also stock 20+ Common Materials and do not face any delay in procurement.

- The use of automated programming software shortens complex part programming time from 4 hours to 30 minutes.

- The cooperation with DHL and FedEx is ensured, ensuring priority delivery.

Is Local CNC Milling Services Really More Cost-Effective?

People looking for the search term "CNC milling services near me" are being deceived by the "low prices" offered by these services, in fact, the TCO will eventually be high.

Cost Structure Comparison: The interrelation of labor, equipment, and supply chains

| Cost Component | Local Small Workshop | JS Precision (International Manufacturer) |

| Labor Costs | High ($30-50 per hour) | Reasonable (Economies of scale reduce unit labor costs |

| Equipment Capacity | Limited (1-2 ordinary machine tools, no high-end testing equipment) | Sufficient (50+ high-end CNC machine tools, with supporting CMM and other testing equipment) |

| Material Procurement | Fragmented procurement, high unit price | Bulk procurement, 10-15% lower unit |

| Process Optimization | No standardized processes or very inefficient | Use of standardized processes and automated, 30% increase in efficiency |

| Unit Part Cost (Aluminum Bracket) | $180-200 | $110-130 |

Warning about Hidden Costs

Local low prices conceal hidden expenses:

- Lack of DFM optimization, design problems cause rework, costly at $50-100 per piece.

- Sampling inspections instead of full inspections, rework cycle of 3-5 days, projects delayed.

- Lack of equipment/material available without a contingency plan, 20% delivery delay rate.

- Outsourcing post-processing services, additional 20-30% charge.

How To Ensure The Quality Of Complex CNC Machining Parts?

It is difficult to control complex CNC machining parts regarding quality because of multifaceted curvatures, high precision. The company, JS Precision, maintains the quality of custom CNC machining services with end-to-end control.

Measurement Challenges of Complex Geometries

Besides meeting the requirements of ISO 9001:2015, the process of inspecting these products closely follows the international standard geometric product specification ISO GPS 1101:2017 by combining the definition and inspection processes of geometric tolerances in precision parts across the globe:

- Coordinate Measuring Machine (CMM): The measurement accuracy is ±0.001mm and includes complex surfaces and positional accuracy checks.

- Laser Scanning: Enables a swift comparison of 3D data in order to detect minute variations.

- Customized inspection fixtures: This increases efficiency in batch inspection.

- Full Dimensional Inspection: 100% parts inspection, accompanied by inspection report.

Process Control: prevention is better than screening

- Tool Life Management: Real-time tracking, proactive replacement to prevent accuracy issues.

- Online Probe Measurement: Probing while in process, parameters changed thoroughly.

- Cutting Parameter Optimization: Parameter matching based on material and structure.

- Staged Quality Inspection: Inspection after rough machining, semi-finishing, and finishing.

Concerned about quality stability for complex components? Schedule a call with our engineers to receive a complimentary quality control plan for your components, and discover how custom CNC machining services can provide accuracy through total control from start to finish.

Figure 1 When processing complex parts in CNC machining, the process may be challenging, but as long as the methods are appropriate, excellent results can be achieved.

The Optimal Solution For Small Batches: Why Is Custom CNC Machining Service The Right Time?

In small-series production (from 1 to 500 parts), flexible and favorable-turnaround custom CNC machining services have more advantages compared to mold manufacturing, and this is considered the key advantage of the CNC milling services.

Seamles Product Development Path

Our services are well suited for the whole product development process, ensuring perfect integration:

- Single Prototype: Facilitates "order from one piece," with rapid production of functional prototypes for feasibility evaluation, having an interval of 3-5 days.

- Small-Batch Trial Production: Move direct from proof of prototype to small batch production without re-adjusting processes or supply chain.

- Medium Volume Production: Production volumes are scaled up according to market feedback. This in turn further decreases the cost of processing as a result of medium-scale processing.

Economic Analysis (Aluminum Parts)

| Production Quantity | Production Cost of a Mold + $5000 Mold Charge | Production Cost Without a Mold + $80 Production Cost Per Unit | Cost-Effective Solution |

| 50 pieces | $6,000 | $4,000 | CNC machining |

| 100 pieces | $7,000 | $8,000 | Mold Production |

| 200 pieces | $9,000 | $16,000 | Mold Production |

As indicated in the graph, if the number of pieces produced is below 100, the total cost of CNC machining will be lower.

Figure 2 Small batch production can provide a solution that is responsive, high-performance, and easy to scale.

Behind Accurate Pricing: What Factors Affect The Cost Of Your CNC Precision Machining Parts?

The differences in prices pertaining to the CNC precision machining parts are due to core factors. The knowledge of those factors makes it simpler to optimize the cost, and our online CNC milling quote system provides the prices in light of those factors as well.

Three Major Cost Drivers

- Raw Material Costs: "The unit cost of titanium alloy is between 5 to 8 times higher than that of an aluminum alloy, also, it has a scraps factor of 30% for more complicated components."

- Processing Time: It takes 2-3 times longer for machining the parts with close tolerance values (±0.01mm) compared to parts with general tolerance values.

- Post-processing Costs: Anodizing: $5-10/piece, Hard Anodizing: $15-25/piece, Sandblasting+anodizing: $12-18 per piece.

Key Points for Cost Reduction Through Design Optimization

- Loosen non-critical tolerances: Reduce processing time by 40% from ± 0.02mm to ± 0.1mm.

- Avoid cavities that are too deep: Exceeding 3 times the length of the tool requires special tools, resulting in a 20-30% increase in cost.

- Standardize tool sizes: such as changing the rounded corner from R0.8mm to R1.0mm to save customization costs.

- Simplify complex features: A changeover from an integrated architecture to a modular architecture will decrease costs by 35%.

Want to lower costs with design optimization? Submit your 3D part file, and our engineers will offer a DFM analysis report with suggestions for cost savings as part of our online CNC milling quote process.

Figure 3 The type of material used is one of the factors that affect the cost of CNC machining.

One Click Access To Transparent Prices: How Does Online CNC Milling Quote Work?

The online CNC milling quote program developed by JS Precision simplifies the cost inquiry process for CNC milling services.

Three Easy Steps to Get a Quote: Upload, Select, View

The entire process of quotation is very simple, and there is no need for expertise:

- Upload 3D files: It accepts major formats like STL, STEP, or IGES. A secured internet link is used for the transmission of files.

- Select Key Parameters: You can select materials (aluminum alloy, stainless steel, titanium alloy, etc.), production volume (1 to 1000 pieces), processes of surface treatment (anodizing, sandblasting, etc.), or even accuracy level, depending upon your requirements.

- View detailed quote: The application instantly displays a quote with the price for each unit, total price, processing time, and times for logistics.

More Than Just Price: Your Free Manufacturing Feasibility Report

The online CNC milling quote program gives you much more than just pricing information–it’s also a method that helps you reduce risks of manufacturing and other losses by providing you.

- Capable of analyzing design files automatically for possible production errors such as thin walls that can deform and corners that are hard to machine.

- Offers targeted recommendations for optimizations to ensure you fix designs before production and prevent costly rework.

- Creates process instructions, enabling you to comprehend the process of machining and important control points for the parts.

Precision Across The Ocean: International Logistics Details Of Precision CNC Milling China

When making decisions on precision CNC milling China, the cost of transportation, time, and safety of international shipping are the topmost factors considered. We provide solutions that are transparent.

Shipping Cost Calculation Logic

- Air Freight: Ideal for urgent deliveries/limited quantities, with cost basis on weight/volume, whichever is greatest, transit time of 3-7 days.

- Sea Freight: Good for quantities of 500 pieces and above. It coasts 60-70% lower than air freight and takes 20-30 days to arrive.

- Customer Service will recommend the best choice depending on the orders you place.

Guaranteed Safe Arrival

- Customized packaging solutions such as multi-layer shockproof, moisture-proof, and scratch-resistant

- Independent packaging: This helps to avoid contact between the components.

- Transportation insurance: The premium is calculated at 0.5-1% of the value of the goods, and full compensation can be made for damages.

- Logistics tracking: Tracking number made available for real-time location tracking.

Case Study: Precision Improved To ± 0.01mm, Cost Reduced By 35%: Cross Border Manufacturing Of An Optical Instrument Bracket

This is an actual case study illustrating the technological and cost efficiency of precise CNC milling China and showing that transnational manufacturing of CNC precision machining parts is an effective way of taking advantage of such efficiency.

Customer Background

A German optical equipment manufacturer requires 100 pieces of aluminum brackets for laser calibration systems, with flatness<0.02mm, installation hole position tolerance ± 0.01mm, and material 6061-T6 aluminum alloy.

The original European supplier charged $200 per piece, with a yield rate of 85% and a delivery time of 3 weeks. The project was frequently delayed due to frequent rework.

JS Precision Solution

Upon receiving the request, we optimized the process from three dimensions: design, production process, and inspection.

1.Design Optimization: The original design that incorporated all the necessary components in the project into an integrated design had to be changed to an assembly design. The complex integrated design is simplified into 3 components. The components are assembled together with high precision after processing.

2.Process Upgrade: Instead of using milling, ultra-precision grinding is applied to key mating surfaces to ensure a positioning accuracy of flatness within 0.015mm, and work is done in a temperature-controlled workshop with a temperature of 22℃ to prevent dimensional variation due to temperature variation, along with artificial aging processes in rough machining to relieve internal stresses.

3.Improved Inspection: 100% of the parts will be fully dimensioned inspected using an ultra-high-precision coordinate measuring machine, focusing on inspecting the location of the mounting holes. Every part that passes through our hands also gets an analysis report that helps our customers see for themselves how our accuracy truly is.

Final Results Achieved

The optimizations carried out ensured that the end product completely satisfied customer needs and exceeded them in the following ways:

- Accuracy achieved: The accuracy achieved in the critical dimensions of the components was within ±0.01mm, and the flatness was <0.015mm, surpassing the requirements by a considerable margin.

- Increased Yield: The product pass rate improved from 85% to 99.8%, where only two pieces needed to be worked on again because of minor scratches, leading to no quality issues in the batch.

- Lowered Costs: The cost per piece was decreased to $130, a 35% decrease from that of the original supplier, thus providing a total cost savings benefit for the customer of $7000.

- Reduced Delivery Time: It took only 2 weeks to make the delivery to the customer in Germany, which was 5 days sooner than previously required.

Want to leverage the savings and optimize the efficiency of the optical bracket’s cost cut and efficiency optimization? Upload your 3D file and attach the note "Optical Grade Optimization" to receive free customization of a processing solution that boasts an accuracy of ±0.01mm for CNC precision machining parts and saves costs by 30%+. Enjoy the advantages of precision CNC milling China's cross-border manufacturing.

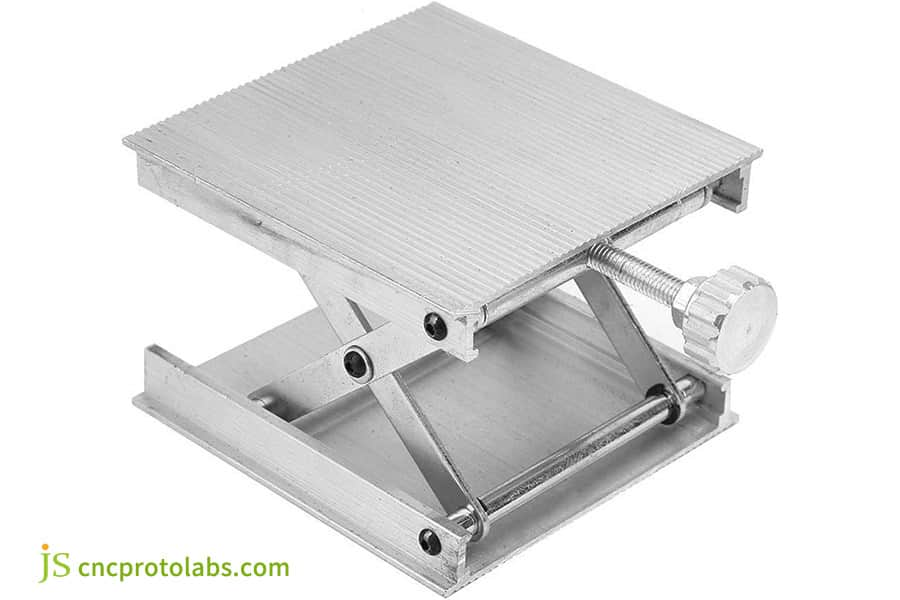

Figure 4 Aluminum Alloy Laser Level Bracket

Choose The Perfect CNC Milling Surface Finishing For Your Parts

CNC milling surface finishing has a significant influence on the performance and durability of CNC precision machining parts. The selection should not be made based solely on aesthetics.

Function-First Processing Options

| Requirements | Processes | Materials | Cost Range (USD/piece) |

| Wear Resistance | Hard Anodizing | Aluminum Alloys | 15-25 |

| Improve Corrosion Resistance | Stainless Steel Passivation, Zinc Plating | Stainless Steel and Carbon Steel | 8-15 |

| Enhance Conductivity | Conductive Anodizing, Silver Plating | Aluminum Alloys, Copper Alloys | 20-30 |

| Reduction of Friction Coefficient | Teflon Coating | Various Metals | 25-35 |

| Raise Hardness | Nitriding Treatment | Alloy Steel, Stainless Steel | 18-28 |

Aesthetics and Identification: Solutions for Color, Texture, and Logo

If your parts involve appearance and/or identification features, then you can use:

- Colored Anodizing: Permits a variety of colors (black, red, blue, and so on), with a uniform and resistant-to-wearing color finish, suitable for parts that require differentiation of product models.

- Sandblasting: Produces a matte or fine sandblasted finish that hides machining marks to improve product quality, usually combined with anodizing.

- Laser Engraving: engraves logos, specifications, and other data on the surface of the component, this data is permanent and visible and does not in any way affect component functionality.

- Polishing: Produces a mirror surface finish, surface roughness Ra<0.2μm, used in optical components or display parts that require high surface quality.

Are you in doubt about the surface treatment suitable for processing your parts? Please provide us with information about your operating environment and requirements for function and appearance, and we will recommend the best CNC milling surface finishing solution for free, balancing performance and cost.

FAQs

Q1: Is your online quote the final price?

Yes, the final price quoted is the result of the files you submit and the parameters you choose, and there are not any hidden costs involved. Once you change the design according to the suggestions from DFM, the system will give you a correct quotation.

Q2: What kind of materials do you handle?

We currently support a wide range of materials like 6061 & 7075 Al alloys, 304 & 316 SS alloys, Titanium alloys, Brass alloys, Copper alloys, and other Engineering Plastics like POM, Nylon, & PEEK.

Q3: In what ways do you assure me of your design file security?

We will draw up a binding NDA contract for you. The files will be sent and archived via encrypted connections. Also, upon completion of the project, the files will be erased for good to keep your designs confidential.

Q4: Do you have any photographs or footage related to the manufacturing process?

Absolutely! For major orders, you could ask for that, and we could take photos or videos of the major processes, including precision machining, to enable you to check on the manufacturing process from a distance.

Q5: What if there are quality problems with the parts post-delivery?

We promise 100% quality compliance. With regard to the issue of quality that falls under our engineering/manufacturing responsibilities, we will repair the components at no charge and cover all shipping costs in relation to their return.

Q6: Are dimensions influenced by surface treatment?

The effect is going to be small, for instance, the anodizing will result in a thickness increase of a few micrometers to tens of micrometers. This effect will be factored into the compensation calculation prior to processing to achieve the desired size.

Q7: What is the fastest delivery time for urgent deliveries?

We offer expedited services. For simple parts, we can process, inspect, and then ship them worldwide via air within 72 hours. The delivery time will, however, depend on the level of complexity of the parts. You can reach us for details.

Q8: Are taxes and duties included within the quote?

The quote will not include import taxes and destination country customs (VAT, customs fees). These fees must be paid by the consignee in accordance with destination country regulations. We will assist in providing all required customs documents.

Summary

When selecting CNC milling services, it is certainly never a question of "proximity" or "cheap price," but rather finding a "complete solution."JS Precision has operational experience of 15 years and an effective quality control process over an entire chain of production, which makes its CNC milling service simple and efficient.

Take action already and experience the efficiency and power of precision manufacturing:

Click on our website and upload your files for an instant analysis and quotation in 30 seconds! JS Precision's expert professionals can be your strong foundation for success in your business.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com