Titanium alloy—a tech metal referred to as the "space metal"—today is a material of choice in aerospace, medicine, and high-end production due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility. But before it was milled using CNC, engineers feared its complexity.

It provides the best in performance and the trade-off in price: chatter, tool chipping, thermal management issues. All of these issues not only eat up your tooling budget but also ruthlessly bring your production efficiency to its knees. But the truth is, titanium is not unmanageable. It's about understanding its behavior and employing precise process parameters.

This book will lead you through titanium CNC milling difficulties overcame, from parameter optimization to equipment selection, through cost control, to be able to have more economical and effective machining.

Summary Of Key Answers

| Optimizing Parameters | Core Goals | Key Tactics, and Adjustment Directions |

| Cutting Speed | Finding the balance between heat generation and heat dissipation. | Begin conservatively: Use the lower-mid range recommended by the tool maker, prioritizing tool life, and gradually raise the speed. |

| Feed per tooth | Ensure 'cutting' rather than 'friction'. | Maintain appropriate feed: avoid friction heating and work hardening caused by too small a feed, use high-feed milling inserts and practices. |

| Axial depth of cut | Control cutting forces and chatter. | Associated with radial depth of cut: Employ a small depth of cut, large width of cut, or large depth of cut, small width of cut to avoid full cuts. |

| Radial depth of cut | Regulate the tool's engagement and heat transfer. | Maximize tool utilization: In side milling, the radial depth of cut may be 30%-50% of the tool diameter in order to utilize a larger tool nose radius to aid in heat transfer. |

| Cooling and lubrication | Adequate, accurate, and high-pressure. | This is no ordinary cooling: High-pressure internal coolant must be used to supply cutting fluid to the tool-chip interface accurately for lubrication, cooling, and chip removal. |

What Lies At The Centre Of Titanium Milling? JS Precision Provides An In-Depth Analysis Of The Five Most Critical Parameters

To succeed with milling titanium, you must first appreciate the worth of a solid source of experience. JS Precision has been deeply involved in the field of CNC milling for nearly 10 years, strictly following the ISO 9001 quality management system, and has completed over 3000 types of CNC milling parts for titanium alloy processing.

This includes machining Ti-6Al-4V aircraft engine brackets for over 200 manufacturers of aircraft parts and producing pure titanium implants for medical device companies. This has created over 50,000 hours of actual data on titanium milling.

For example, JS Precision reduced the machining time of a Ti-5553 part of an auto components customer. By adjusting radial depth of cut and coolants, they doubled tool life from eight pieces to 14 and reduced machining time by 25%.

This handbook is the culmination of the effort of the JS Precision team in bringing these practical cases and process data together. Each parameter recommendation has been validated in real shop floor conditions. It will allow you to clearly understand the nature of titanium milling with Milling Machine with CNC and provide theoretical support for subsequent custom CNC milling manufacturing solutions.

Milling Machine with CNC of JS Precision have considerable experience in titanium milling and can process a tremendous range of CNC milling parts with high accuracy. Please let us know your processing requirements first, and we will take you through the normal process to process your order and offer professional service to you.

Why Is Titanium Alloy The "Ultimate Test" For CNC Milling Machines?

While, in titanium alloy machining, the majority of engineers wonder: Why are the requirements for Milling Machines with CNC so tight? The answer lies in four characteristics that make it the "ultimate test" for CNC milling machines and impose even higher requirements on the performance of CNC milling machine components.

1.Low thermal conductivity:

The thermal conductance of titanium alloy is merely 1/5 of that of steel. Heat is difficult to be removed by chips in machining, and most of it flows to the edge of the tool to gather, easily resulting in crater wear and rapid tool wear.

2.Hard work and high strength:

Titanium alloy is strong, and on machining, a hardened surface layer is formed. The next cut is like machining through this "hard shell," once more accelerating tool wear.

3.Chemical affinity:

At high temperatures, titanium chemically reacts with tool coatings (for example, carbides), causing diffusion wear and adhesion, influencing tool life and part surface finish.

4.Low elastic modulus: Workpieces will "bounce" when subjected to cutting forces, reducing machining accuracy and easily causing chatter while cutting thin-walled parts. This requires CNC milling machine components with enhanced vibration resistance.

Overcoming Challenges: Pragmatic Methods And Techniques For Effective Machining Of Titanium Alloys

As titanium alloy machining is so difficult, are there viable methods and strategies to overcome these issues? The reply is affirmative. JS Precision, which has been in the CNC milling business for decades, has boiled four key strategies down to allow you to successfully machine titanium alloys, both for routine and complex CNC milling parts.

1.Thermal management is of the highest priority:

All optimizing activities must revolve around reducing heat generation and achieving maximum heat dissipation, such as selecting appropriate cooling methods to prevent heat accumulation at the tool cutting edge.

2.Sustained load:

Programming methodologies such as trochoidal milling and dynamic milling prevents violent load variations when entering and exiting the tool, which limits tool damage and maintains the Milling Machine with CNC stably operating.

3.Rigidity is the priority:

Ensuring proper rigidity to the system of the process, such as machine tool, fixtures, tooling, and workpiece, is crucial in the battle against workpiece bounce and chatter and is critical in order to ensure machining precision. It requires premium CNC milling machine components.

4.Sharpness is important:

Cutting forces are reduced by using sharp, positive rake angle cutting geometries and cutting edges, which make cutting a shearing process instead of a compression process and one that work hardens less.

JS Precision concentrates on thermal management and rigidity in order to overcome the challenges of machining titanium alloys using Milling Machine with CNC. If you require bespoke CNC milling parts, contact us by email to place an order for service. Utilize the simple process to order and quickly go into production.

Figure 1 Three specifications of CNC milling cutters with internal cold hole and spiral groove design.

The Science Of Optimization Sequence: Optimize The Most Important Parameters

Once the techniques are mastered, the order of parameter optimization is critical. Most individuals would adjust the cutting speed first, but JS Precision, with numerous years of CNC milling experience, discovered that the correct order of optimization needs to be "solving the 'geometry' parameters first, and optimizing the 'kinematic' parameters next."

It can deliver the best performance of the Milling Machine with CNC and address the online CNC milling service's requirement for efficiency more suitably.

Step 1: Choose the depth of cut.

Based on part properties and stiffness of process system, first determine safe and feasible axial and radial depths of cut. This lays the foundation for remaining parameters' optimization. If the depth of cut is set incorrectly, then modifying other parameters later on won't benefit the efficiency.

Step 2: Select the feed per tooth.

Depending on part surface quality requirements and tool life, pick a feed rate that avoids friction and work hardening. In finishing, for example, the feed must be kept as low as possible to avoid sacrificing surface smoothness.

Step 3: Set cutting speed.

This is the most important parameter. Starting from the previous two steps, set conservative values and test them. Through tool life monitoring, you can optimize step by step and find the best compromise between efficiency and cost.

Following the scientific parameter optimization sequence and referring to the ISO 13399 cutting tool data standard, JS Precision's technical staff will write a solution to your milling machine with CNC according to your needs. If you are in need of online CNC milling services, do not hesitate to make contact at your convenience. Our order procedure is simple, allowing us to serve your machining needs in no time.

Detailed Optimization Of The Five Major Parameters: Theory To Practice

Now that we have determined the optimization order, let's move on to cover optimization methods for the five basic parameters. Based on the practical experience of JS Precision with CNC milling, these methods will allow you to connect theory to practice of Milling Machine with CNC.

JS Precision has compiled a reference table for optimizing five major parameters in titanium alloy milling, based on 50000+hours of titanium alloy processing experience:

| Machining Stage | Cutting Speed (m/min) | Feed per Tooth (mm/z) | Axial Depth of Cut (xD) | Radial Depth of Cut (xD) | Cooling Pressure (Bar) | Applicable Scenarios |

| Roughing (Ti-6Al-4V) | 70-90 | 0.15-0.25 | 0.5-1.0 | 0.3-0.5 | ≥100 | Batch production, removal of large allowances |

| Semi-finishing (Ti-6Al-4V) | 90-100 | 0.10-0.15 | 0.3-0.5 | 0.2-0.3 | ≥80 | Accuracy transition, reserving finishing allowances |

| Finishing (Ti-6Al-4V) | 100-110 | 0.05-0.10 | 0.1-0.3 | 0.1-0.2 | ≥70 | Surface quality requirement Ra≤1.6μm |

| Roughing (Ti-5553) | 55-70 | 0.12-0.20 | 0.4-0.8 | 0.2-0.4 | ≥120 | High-strength titanium alloy, ensuring rigidity |

| Precision machining (pure titanium Gr.2) | 110-125 | 0.08-0.12 | 0.2-0.4 | 0.15-0.25 | ≥70 | Adhesive material, avoid adhesion |

Cutting Speed: The Double-Edged Sword of Thermal Management

Cutting speed too high or too low is not acceptable.Excessive speed will cause impact build-up, yielding poor surface quality and tool failure due to abrasive wear, while insufficient speed will cause abnormal rise in cutting temperature, resulting in plastic deformation and chemical wear of the tool.

Optimization Tip: Start at a speed of 70-100 m/min when cutting Ti6Al4V, record the tool life per cut, and then increase by 5 m/min until you find the best speed.

Feed Per Tooth: Controlling Chip Thickness - The Art

There is a golden rule: Ensure the minimum chip thickness is greater than the tool edge radius, otherwise, you're rubbing and crushing material instead of cutting as it ought to be.

Optimization Tip: For finishing, start from 0.05-0.1 mm/z, for roughing, try 0.15-0.25 mm/z. High-feed milling is an aggressive tool for titanium alloy roughing and may increase the efficiency of CNC milling parts.

Axial Depth of Cut: A Balance Between Cutting Force and Stability

Full-cut cutting is prohibited. Avoid using the total groove width (radial depth of cut = tool diameter) and full-edge cutting.

Optimization Tip: Try ramping with a low depth of cut (0.5-1xD) and high width of cut (0.7-0.8xD), or side milling with high depth of cut and low width of cut (10-30% of D). This will distribute heat and cutting forces.

Radial Depth of Cut: Tool Life Controller

Optimization Tip: In side milling, set the radial depth of cut to 30%-50% of the tool diameter. This optimizes tool tip radius, optimizes heat dissipation volume, and significantly improves tool life. This is a method JS Precision uses in machining CNC milling parts and can be applied to batch processing conditions in online CNC milling services.

Lubrication and Cooling: The Unsung "Sixth Parameter"

Pressure is the key to cooling. At least 70 bar of internal pressure of coolant is required to break the air barrier and supply the cutting fluid into the cutting zone.

Optimization Tip: Use an oil-air blended cooling method to both lubricate and micro-cool. Use a cutting fluid that is specifically for use on titanium alloys to provide extreme pressure protection.

Want to improve efficiency and extend tool life? Get the titanium alloy processing parameter table tailored for you immediately.

Figure 2 Complex CNC milling of titanium alloy shell with grid weight reduction structure.

Cost Equation: How Parameter Optimization Impacts Your Total Machining Cost

Every company cares about machining cost, and titanium milling parameter optimization has a proportional impact on total machining costs. It's an easy formula for calculating cost: Total cost = (labour cost + machine hour rate) × time to machine + tool cost.

To more clearly show the impact of parameter optimization, JS Precision has provided cost comparison data for a customer machining Ti-6Al-4V parts:

| Parameter Status | Machine Hourly Rate (USD) | Labor Rate (USD/hour) | Machining Time (Minutes) | Tool Cost (USD/piece) | Total Cost (USD/piece) |

| Before Optimization | 80 | 25 | 45 | 90 | (80 + 25) × 0.75 + 90 = 161.25 |

| After Optimization | 80 | 25 | 28 | 40 | (80 + 25) × 0.47 + 40 = 93.35 |

As the table shows, increasing feed and depth of cut reduces machining time dramatically, by directly reducing machine and labor costs, optimizing speed and cooling can expand tool life and reduce tool costs.

JS Precision's experience is not to simply pursue the highest speed or longest tool life, but to find the balance point that minimizes the sum of "time cost+tool cost". JS Precision provides transparent CNC milling prices based on different requirements of parts, so you can control costs beforehand.

Nuanced Material Differences: Parameter Adjustments For Different Grades Of Titanium Alloy

Processing conditions for different grades of titanium alloys must be tailored, they cannot be universal. JS Precision has developed special adjustment methods for CNC milling of parts from different grades of titanium alloys, as shown in the following table:

| Titanium Alloy Grade | Description | Cutting Speed Adjustment(relative to Ti6Al4V) | Feed Per Tooth Adjustment(relative to Ti6Al4V) | Points to Ponder |

| Ti-6Al-4V (Grade 5) | Widest application, with excellent all-round performance. | Benchmark (70-100 m/min) | Benchmark (0.05-0.25 mm/z) | Employ the standard parameters listed above. |

| Pure Titanium (Grades 1-4) | Low strength, high viscosity. | Increase by 10-15%. | Increase by 5-10%. | Prioritize chip evacuation to avoid sticking. |

| Ti-5553 | High strength, difficult to machine. | Reduce by 15-20%. | Reduce by 10-15%. | Prioritize tool rigidity. |

| β Titanium Alloy | Tough, high impact resistance. | Reduction by 20-25%. | Reduction by 15-20%. | Using sharper cutting edges. |

For certain titanium alloy types, we further personalize parameters by integrating the functionality of CNC milling machine components in order to balance quality machining and efficiency.

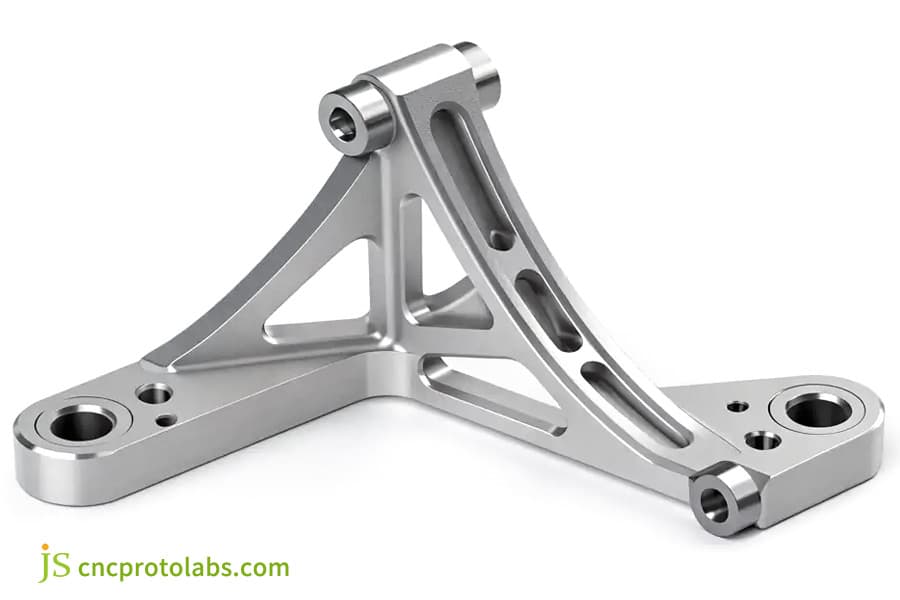

Figure 3 Typical parts for CNC milling of titanium alloy grades GRADE 2 and GRADE 5 (Ti-6Al-4V).

Choosing The Proper Machine: Five Key Factors For Choosing A CNC Milling Machine For Titanium Machining

Despite proper parameters and procedures, the right CNC milling machine is crucial. JS Precision, being a company with years of experience in CNC milling, has listed five critical factors for choosing a CNC milling machine to mill titanium to help you make the right machine selection:

Rigidity and Weight:

The heavier and more rigid the machine frame, the less the machine will vibrate, cutting down on chatter during milling and keeping parts accurate.

Spindle Power and Torque:

Titanium machining requires high torque, not high speed. Meet the torque ability of the spindle in the low and medium speed ranges to yield sufficient cutting force.

High-pressure Internal Coolant System:

The "entry ticket" for titanium machining and essential. The higher, the better (above 100 bar optimal), to ensure adequate cooling of the cutting area.

Stability and Accuracy:

These include features like linear motors, roller guides, and others that provide high dynamic accuracy and stability and are suited for machining precision parts of titanium alloys.

Control System and Software:

Advanced controllers are capable of dealing with complex tool paths better and providing proactive control to achieve a smooth machining process and reduce tool wear.

JS Precision offers milling machines with CNC of great rigidity and internal high-pressure coolant to enable machining of titanium, with stable machining assured. If you require custom CNC milling parts, kindly contact us for discussion. We will then go through the normal order procedure to ensure quality machining service.

Case Study: How JS Precision Saved Aerospace Brackets Customers 40% Of Tool Costs through Parameter Optimization

Customer Pain Points

JS Precision previously worked with a drone business that had classic pain points:

When the Ti-6Al-4V was used to machine the high-strength fuselage bracket (150 × 80 × 30 mm), initial process conditions were conservative, utilizing φ10mm end mill for full-cut slot milling at a feed rate of just 0.08 mm/z.

Machining time for one piece was up to 45 minutes, and tool life was highly unstable. Average consumption of an insert per part was 1.5, and hence tool cost was $90 per piece, while the overall cost was maintained high.

Being a key CNC machining part, the machining effectiveness and expense of the bracket directly affected the customer's production schedule.

JS Precision Solution

JS Precision personnel conducted a process audit upon receipt of the order and determined that full-cut milling resulted in concentrated cutting forces and severe friction, the main cause of violent tool wear. The following specific solution was then developed:

- Full-cut milling was changed to dynamic milling method, with a φ12mm end mill to provide an even cutting load.

- Cutting speed was increased from 60 m/min to 85 m/min and feed per tooth from 0.08 mm/z to 0.18 mm/z.Ramping was used with shallow depth of cut (0.8xD) and broad width of cut (0.7xD).

- Additionally, the 120-bar internal cooling system of Milling Machine with CNC was used to the maximum possible level to allow ease of heat removal.

Comparison of Results

The results of the optimization were dramatic: machining time per part was cut from 45 minutes down to 28 minutes, a productivity gain of 38%. Tool life was also much longer, with a single insert capable of machining three parts. The tool cost per part was lowered from $90 to $40, a decrease of 55%.

Customer testimonial: "JS Precision's engineers didn't recommend more expensive tools. They actually addressed the pain points in a parameters optimization done scientifically. Real cost savings are from process intelligence, which performs better than optimizing CNC milling machine components."

Do you want to replicate this case of reducing costs by 55%? Submit your part information immediately and you will receive a free exclusive 'Titanium Alloy Processing Parameter Optimization Plan'. Our engineers will calculate the accurate cost for you within 2 hours.

Figure 4 CNC Milling Titanium Aerospace Bracket

FAQs

Q1: In machining titanium alloys, do we use cutting fluid or compressed air?

High-pressure cutting fluid is the most appropriate fluid used in machining titanium alloys in roughing operations because of the fact that it effectively removes a lot of heat from the cutting area, holding the tool firmly in position and reducing wear. An air-oil mixture or compressed air will suffice for some finishing operations but cannot withstand high heat that comes with roughing operations. Cutting fluid is therefore more suitable in such operations.

Q2: I know "high-feed milling." Is it suitable for titanium alloys?

High-feed milling is indeed very suitable for machining of titanium alloys. High-feed milling utilizes special inserts, machining at small axial depth of cut and high feed per tooth, with thin, thick chips. This chipping helps in heat removal and reduces radial cutting forces, making it an effective means of rough machining of titanium alloys, with improved machining efficiency.

Q3: What are the most common tool failure modes in machining titanium alloys?

Flank wear is a common progressive mode of failure in machining titanium alloys and can be expected. But chipping, thermal cracking, or abnormal notching, being unusual, will most probably be due to incorrect cutting speed, feed rate, or coolant conditions, the rectification of which should be done on time to prevent failure.

Q4: Can I perform parameter optimization experiments independently?

You can attempt parameter optimization experiments yourself, but caution must be exercised. Single-variable approach must be employed in which one parameter only (e.g., cutting speed) is altered at a time and tool life and surface quality noted. Experiments must be initiated from safe and conservative conditions and conducted in a safe machining arrangement to avoid hazards. If in doubt, call our expert team for custom CNC milling manufacturing advice.

Q5: How do you ensure pricing competitiveness for titanium CNC machining projects?

Inefficiency has been eliminated as an element within our pricing by prioritizing process efficiency over material savings. As evident through the case analysis conducted for you, parameter optimization knowledge does have a direct effect of minimizing machining time as well as tooling, which are the largest expense variables. We give you detailed estimates so that you can account for what you are specifically getting as your expense. Get an estimate today!

Q6: What is your typical lead time for manufacturing titanium parts?

In the case of standard complexity parts, our lead time starts from 3 days. This can vary depending on the geometry of the parts and the post-processing involved. A commitment to fast production and accuracy will be made when our engineering team reviews the project plan that you submit to us. A quick estimate of lead time can be obtained if you upload your drawings with us.

Q7: How do you manage quality control and consistency for high-performance materials like titanium?

We perform a multistage process: FAI with CMMs, in-process checks through the machining, and a final dimensional and visual inspection to your specifications. For critical aerospace or medical components, we can provide full inspection reports with material certifications. Our ISO 9001:2015 certification ensures a systematic quality management system.

Q8: What is the process to start a project and how do we communicate during manufacturing?

To start a project, it is as easy as:

- You upload your CAD files and requirements.

- We perform a DFM analysis and give you a detailed quote.

- When confirming the order, you will get a designated project manager who will become your single point of contact to update you through delivery.

- Email us today to begin your project and get your dedicated project manager.

Summary

Pushing the limits of titanium milling is a personal discussion with the physical properties of the material. That requires that you make the transition from "machine operator" to "process engineer." Mastering the adjustment of these five parameters will find you no longer quietly incurring high costs, but instead actively managing production efficiency and profitability, with custom CNC milling manufacturing being easier to choose.

However, theoretical knowledge needs to be confirmed on real machines. If you're fighting with titanium alloy machining cost and efficiency, or wondering whether your present parameters are as good as they can be, JS Precision is your technical support.

Let us empower you!

Send us a drawing of your most difficult titanium alloy part and you'll get two useful documents:

- A data-based "Titanium Alloy Machining Parameter Optimization Proposal" for your part.

A "Manufacturability Analysis and Cost Optimization Plan" by our experienced process engineers, with a definite CNC milling price quote, so you can plan your machining needs ahead of time.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource