CNC machining milling can be considered a backbone service for precision components production, but often, researchers believe that technicians and procurement managers are caught up in a dilemma: A low-quality surface finish impacts assembled product accuracy, Unreliable deliveries disturb project timetables, machining intricate shapes requires multiple passes.

It usually occurs due to a lack of understanding about CNC milling operations, dimensional mismatches between equipment and materials, or unavailability of knowledge on optimization from suppliers.

As a 15-year-old company with expertise in the sector, JS Precision have witnessed too many customers taking the wrong turn because they opted for ineffective solutions. Because of that, we have created this article based on our expertise and knowledge so that you can properly address your machining issues and select the best CNC Milling solution.

Core Answer Summary

| Core Issues | Core Solutions | Key Supports | Applicable Scenarios |

| Surface Finish / Delivery Time / Complex Machining Challenges | Customized CNC Milling Processes + DFM Optimization | 5-Axis Equipment + Full-Process Quality Control | Aerospace / Automotive / Medical, etc |

| Insufficient Precision / Cost Overruns | Process Parameter Optimization + Cost Breakdown Analysis | In-Machine Measurement + Specialized Tools | High-Precision Parts Manufacturing |

| Confusing Supplier Selection | Verify Five Core Capabilities | Cross-Industry Case Studies + Certifications | Small-Batch Production |

Why Has CNC Milling Become a Core Process In The Manufacturing Of Complex Parts?

I have been deeply involved in the field of CNC milling at JS Precision for 15 years and has served more than 2000 customers from various sectors, including aerospace, automotive, medical, and electronics. We have also successfully completed more than 5000 projects.

We have expertise and experience with CNC machining processes on many hard-to-machine materials like titanium alloys, high-temperature alloys, medical-grade stainless steel, and engineering plastics. We have an efficient solution for all these materials.

For instance, we performed machining on some structural components for an aerospace business with a tolerance of ±0.003mm, eventually acquiring AS9100D certification.

Additionally, components we have manufactured for medical businesses have maintained a yield percentage above 98% for three years running, and these comply with all standards specified under ISO 13485.

At our workshop, we own more than 50 highly advanced machines, among which there are 20 five-axis milling machines from highly recognized global brands. We have also set up a quality control system involving in-machine measurement, post-processing verification, and traceability.

The guide contains not only theories but our summarization of experiences obtained in addressing customer problems, no matter how insignificant they appear, like adjusting parameters on tools. All recommendations have been obtained from hands-on experiences.

Only after implementing these solutions on thousands of projects can we learn valuable solutions, which is the fundamental reason why you can trust this CNC machining milling guide.

Looking for reliable CNC machining milling services? Please share with us your project pain points, and we will refer you to a senior engineer at no charge. We will share with you successful case studies within the industry so that CNC machining becomes a worry-free experience for you.

What Key Factors Need To Be Considered When Choosing The Appropriate Types Of CNC Milling Operations?

CNC milling is a key technology in subtractive manufacturing, and the reason why it can become the core of complex part manufacturing is that it breaks through the limitations of traditional machining.

Conventional machining, either manually or generically, uses human control and, as a result, lacks precision. CNC milling, on the other hand, completely eliminates human error with the control and movement of either the cutting tool or the workpiece via a computer program.

The main idea here is that a rotating cutter with a cutting edge is employed to remove excess material from the workpiece, thus giving it a preferred shape. The CNC machining process for various complex components at my workplace, JS Precision, has already been perfected to achieve intricate curved and multi-dimensional shapes.

Compared with traditional machining, CNC milling is almost indispensable in terms of high complexity, precision, and consistency. It not only blends several machining operations but also reduces the turn-around time of workpieces with micron-level consistency. That is why it is preferred for machining critical components in high-end sectors like aerospace and healthcare.

Figure 1:Numerical control milling has strong adaptability and flexibility, which can meet various application requirements and the complexity of parts.

What Technologies And Processes Guarantee The Realization Of Precision CNC Milling?

Choosing the right type of CNC milling operations directly affects the success or failure of the project. We cannot blindly follow the trend and select high-end equipment. We need to build a decision-making framework based on actual needs.

Compatibility Table for Various Milling Processes

| Milling Type | Use Cases | Core Benefits | Important Points to Note |

| Important Points to Note | Basic planar components, general precision needs, low volumes, tight budget constraints. | Lower cost, easy programming, short preparation time. | Not capable of machining intricate curved surfaces and multi-angle components. |

| Four-Axis CNC Milling | Cylindrical components with side details, medium scale production, semi-complex components. | Offers better machining productivity and shorter clamping times. | Relatively expensive as compared to three-axis machining, requires expertise for programming assistance. |

| Five-Axis CNC Milling | Complex shapes with high precision needs, aerospace/medical devices, valuable goods. | Finishes multi-face machining in single clamping, very high precision. | Large equipment cost and technical barrier. |

| High-Speed CNC Milling | High surface finish, production of thin-walled components, and production of high-hardness materials. | Low cutting forces, deformation-free workpieces, and short machining times. | High rigidity machine tools and specialized cutting tools are required. |

Three-Step Selection Method

1. Identify the fundamental characteristics inherent within the part: It may have curved surfaces/ 1. Cavity depth, tolerance, and surface roughness requirements.

2. Production conditions for match production: Ensure limits on budget and size to prevent over-investment.

3. Decision based on compatibility charts: Three-axis machining is more economical for small batches and simpler components, while five-axis machining is more economical for large batches and more complex components.

Not sure which types of CNC milling operations are suitable for you? Upload your own component designs and requirements, and JS Precision will offer a free process review so that we can work together to achieve an optimal cost and efficiency solution – no blind investment.

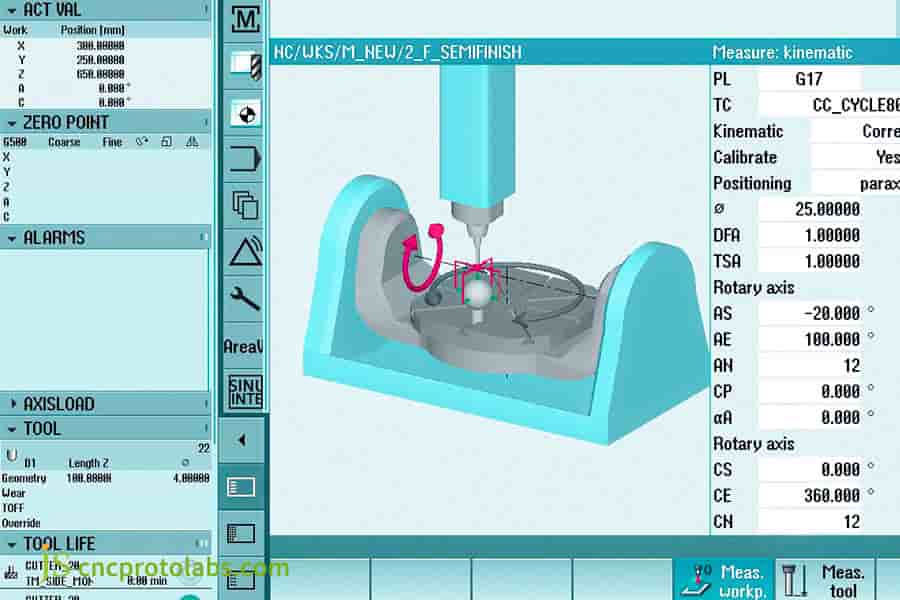

Figure 2:Programming of 5-axis CNC milling

How To Scientifically Evaluate The Cost Structure Of CNC Machining Milling?

Precision CNC milling with micron accuracy can be achieved not only on a CNC machining center of high accuracy but by an optimal combination and collaboration of various technologies and processes. At JS Precision, precision and accuracy are achieved on four basic dimensions:

- High rigidity CNC machine tools: We make use of high-precision milling machines from well-reputed global brands. These machines possess high rigidity and offer high precision with regards to position.

- Tool and path optimization: We align specific tools with the properties of materials and use CAM software for optimal cutting path planning.

- Cooling and lubrication control: We control cooling and lubrication for various materials to reduce cutting temperatures and prevent deformation of workpieces.

- In-Machine measurement and precision: As we are monitoring and adjusting these measurements on the production line, we reduce production error.

All these apparently trivial factors have a direct impact on the end result obtained in precision CNC milling. The medical implant components machined by us have a tolerance of ±0.005mm.

Looking for an even greater degree of precision CNC milling expertise? Contact us for a meeting with a JS Precision technical engineer. We will discuss the highlights of process control and develop a precision assurance solution for you.

How To Scientifically Evaluate The Cost Structure Of CNC Machining Milling?

Many customers have chosen suppliers based on price per unit alone and then paid more as a result. —CNC milling costs have to include the whole process, five factors have to be considered.

A Simplified Cost Model for CNC Milling and JS Precision Optimization Solution

| Cost Component | Cost composition before optimization | JS Precision Process Cost Reduction | Cost composition after optimization | Cost savings per unit |

| Material Cost | 30% | Layout optimization and controlling scrap rate, thereby reducing difficult-to-cut material loss from 18% to 8%. | 22% | 27% |

| Machining Time Cost | 28% | CAM path optimization+parameter tuning, reducing empty travel by 30%. | 19% | 32% |

| Tool Wear Cost | 15% | Specialized tool matching+cutting parameter optimization, extending tool life by 50%. | 9% | 40% |

| Programming and Preparation Costs | 12% | Modular programming library+standardized process, reducing preparation time by 40%. | 7% | 42% |

| Post-processing and Inspection Costs | 15% | Integration of detection process+prediction of on machine measurements to reduce duplicate detections. | 11% | 27% |

| Total Cost | 100% | Collaborative optimization of the entire process technology. | 68% | 32% |

All numbers are averages from 100+ projects done for similar clients at JS Precision. Cost savings percentages might be slightly different depending on materials and product volume but will not affect the overall process changes.

We never simply compete through low prices but focus on optimizing certain processes for our customers with the ultimate goal of helping them save on costs at all cost levels.

JS Precision Case Study-Medical Device Core Component Precision Milling

Client Challenges:

A premium medical device company required an immediate shipment of titanium alloy implant supports based on the ISO 13485 standard, and they were confronted with two challenges.

Titanium alloy exhibits high hardness and low thermal conductivity, so it will easily deform under conventional machining. The previous suppliers' production yield rate was 65%.

Delivery problems delayed product launch. The component had a tolerance requirement of ±0.008mm and surface roughness Ra 0.8µm. It had to be biocompatible and devoid of machining defects.

JS Precision Solution

After receiving the request, we formed a special team to develop a plan:

- A five-axis linkage high-speed milling approach enabled machining on multiple faces within a single setup, preventing cumulative errors that would have occurred with multiple setups.

- Special high wear-resistant PCD tools were employed, and it took several hundred tests to optimize the cutting speed and feed rate so as to eliminate the problem of tool sticking.

- A constant temperature control system maintained a stable ambient temperature with a deviation of no more than ±2°C.

- Each process is accompanied by machine measurement, real-time correction of deviations, and full traceability of inspection data.

Results and Output

The end yield rate rose from 65% to 98%, the supply chain cycle reduced by 40%, and unit cost lowered by 15%. The product also passed certification for ISO 13485 and launched soon after. This clearly shows that there is indeed technological competence at JS precision CNC milling.

Facing difficulties in processing medical components? Upload your part drawings and note 'Medical Components'. JS Precision will provide customized solutions that comply with ISO 13485 standards to ensure yield and delivery efficiency.

Figure 3:A CNC milled medical implant

What Are The Specific Requirements For CNC Milling Applications In Different Industries?

CNC milling applications cover multiple industries and have vastly different requirements due to different usage scenarios:

1. Aerospace industry: Must comply with AS9100D certification, commonly used difficult to machine materials such as high-temperature alloys and titanium alloys, parts require high strength and lightweight, tolerances must be controlled within ± 0.005mm, and fatigue testing must also be passed.

2. Automobile Industry: It complies with IATF 16949. It emphasizes consistency and cost-effectiveness for mass production. The materials that are commonly used are aluminum alloys and steel. The main components should have wear and impact resistance capabilities.

3. Medical Industry: Here, the main requirement will be certification with ISO 13485. The materials should be biocompatible, like titanium alloys and medical-grade stainless steel. Also, very high precision and surface finish with no microcracks should be ensured.

JS Precision has accumulated rich cross industry experience and can accurately match the special requirements of various industries.

Do you need a CNC milling applications solution that meets industry standards? Contact our CNC hotline at JS Precision and share your industry and compliance needs with us, and we will connect you with a qualified technical specialist.

What Are The Explicit And Implicit Advantages Of CNC Milling Compared To Traditional Machining?

Many people only know that CNC milling has high precision and fast efficiency, but advantages of CNC milling can be divided into explicit and implicit categories, comprehensively enhancing competitiveness:

Explicit Advantages of CNC Milling:

- Smaller clamping times: Complex parts can be processed and formed in one go, shortening the production cycle.

- High consistency of quality: Computer control reduces error caused by humans, and thus there are fewer defective products.

- Fast Delivery: Process optimization+efficient equipment, quick response to order requirements.

Implicit Advantages of CNC Milling:

- Less need for manual labor: No need for utilizing qualified technicians, and thus fewer effects on quality due to labor fluctuations.

- The traceability of data: Machining variables and inspection information are documented at various stages, making it easier for there to be traceability with regards.

- Facilitating design iteration: Modifying the design only requires adjusting the program, reducing iteration costs.

Based on internal data, after customers switched to CNC milling, their average production efficiency rose 40%, and defect rates were reduced 80%.

How Can Product Design Improve Milling Efficiency And Reduce Costs Through DFM Optimization?

DFM or Design for Manufacturability plays an integral role in linking product designs and CNC machining services. Small designs carry considerable weight in making machining easier. Many times at JS Precision, I deal with designs that have doubled machining costs for my customers due to unoptimized designs. The following are really beneficial:

- Standardized corner radius: Do not use special corner radii but specify sizes capable of being matched with standard tools, thus minimizing tool changes.

- Reduce deep cavity design: Deep cavity machining requires elongated cutting tools, which are prone to vibration and low efficiency. Optimize cavity depth without affecting performance.

- Reasonably set tolerances: Higher precision requirements result in high costs. Set your tolerance based on the usage scenario.

- Eliminate unnecessary complexities: Certain complexities don't significantly enhance product functionality. Eliminated complexities remove machining operations.

We offer these services for free. Our engineers will make specific recommendations based on your designs and thus cut down on the costs associated with CNC machining services.

What Are The Five Core Capabilities To Verify When Selecting a High-Reliability CNC Machining Milling Supplier?

Selecting a reliable source for your milling needs can be a big help. Based on JS Precision’s experience, here are five things you should look for:

- Equipment and Technical Capability: Look for high rigidity machine tools and five-axis milling machines, as well as information about the maintenance status and calibration. A high level of equipment sophistication underlies precision.

- Quality Certification and Control: Does the supplier have certifications for ISO 9001 and industry certifications like AS9100D? Do they have a comprehensive testing process?

- Industry Case Experience: Do they have machining cases with similar products? Do they have relevant quality reports and customer experiences available?

- Technical Capability for Support: Do they offer DFM analysis and process optimization recommendations? How is their response time?

- After Sales Service and Supply Chain: Do they have a comprehensive after sales service facility? Is there a stable supply chain and are they able to maintain delivery times?

These five factors are essential for smooth cooperation. JS Precision not only meets all these factors but also has qualification documents and case examples that can be refereed. As such, customers can have peace of mind.

FAQs

Q1: Is there a specific tolerance that can be achieved by CNC milling at JS Precision?

Based on the use of advanced high rigidity CNC machines, optimal tool paths, and very tight process control, precision milling services offered by JS Precision have the capability of maintaining a tolerance of no more than +/− 0.005mm. Even tighter tolerances can be achieved based on special needs.

Q2: Do you have capabilities that enable working with special materials such as the Invar alloy

Yes. At JS Precision, we have ample experience working with special materials like Invar alloy, stainless steel, and titanium alloys. We can also develop machining parameters specific to the materials based on their properties.

Q3: Is there a considerable price difference between small-batch prototyping and mass production?

The main difference lies in the allocation cost of molds and programming. The ratio of allocation will be higher in small batches and substantially lower in large batches. We have introduced transparent tiered pricing, thus reducing the gap brought about by process optimization and ensuring completely protected interests for small batches.

Q4: How long does it typically take from providing drawings to receiving a quote?

To fulfill regular CNC milling orders, we assure a preliminary quotation within 2 hours, and for intricate orders requiring technical judgment, we will generate a quotation within 24 hours.

Q5: How can I be assured that my design drawings and intellectual property are protected?

We enter into very tight confidentiality agreements with our clients. We use an independent project management system and encrypted file transfers for controlling design drawings and technical data with 100% guaranteed security for intellectual property.

Q6: Do you offer services like anodizing and electroplating after your milling services?

Yes. JS Precision provides one-stop CNC machining services, covering various surface treatment processes such as anodizing and electroplating, to achieve complete delivery of parts and save the trouble of multi-party coordination.

Q7: What is your after-sales handling process for quality issues?

We have a fast response channel and will develop a solution within 24 hours after problem confirmation, including rework, return, or compensation, to ensure zero risk for customer rights.

Q8: Can we conduct small-scale trial production first before deciding on large-scale cooperation?

Of course, we encourage customers to first verify our capabilities through trial orders, and trial production orders also enjoy complete technical and quality support.

Conclusion

CNC machining milling never performs “simple part cutting” but instead plays an integral role as the central bridge spanning design intention and high-quality product fulfillment due to its value lying in precise process matching and cost control.

At JS Precision, we have demonstrated, based on 15 years of experience, that it is possible to make complex machining easier and optimize cost and accuracy perfectly with the proper milling solution and with a reliable partner.

Do you still have worries about precision, lead times, and cost with your projects? Feel free to contact JS Precision expert team today and share your part designs, and we will be glad to provide you with a free DFM analysis report and cost quote. We protect your product with our advanced equipment, mature processes, and strict quality control.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com