In the competition on the forefront of technology, intangible precision is extending the limits of what can be achieved. The moving platform supporting the wafer in a lithography tool, whose position precision is expressed in microns, is the hub of chip manufacturing.

The metal bipolar plates of hydrogen fuel cells must possess a flow field depth tolerance of ±0.01mm, an aspect directly impacting power generation efficiency.

These "invisible" accuracies are the crowns of modern industry. ±0.01mm—a dimension smaller than 1/7 the width of a hair—is made possible by precision CNC machining services. How to consistently manufacture ±0.01mm tolerances within CNC machining is one of the greatest problems confronting most manufacturers to achieve product breakthroughs.

This article, after JS Precision's over one thousand genuine cases of experience, will expound the rationale of purchasing ±0.01mm tolerance from technical key point, industrial standard, cost control and design optimization viewpoints, so that you have a more profound understanding of the fundamental measures of precision machining.

Core Answer Summary

| Comparison Dimensions | Conventional CNC Machining | ±0.01mm Precision CNC Machining |

| Core Challenges | Control macroscopic dimensions to achieve basic functions. | Onquer microscopic errors (thermal deformation, vibration, internal stress). |

| Equipment and Environment | Standard machine tools, standard industrial environment. | High-end machine tools + constant temperature workshop + active vibration reduction system. |

| Process Philosophy | "Machining Complete". | "Measurement-Driven Machining" (full-process monitoring and compensation). |

| Cost Drivers | Materials and Labor Time. | Technology, Quality Control, and Scrap Rate (Precision Costs Increase Exponentially). |

| Quality Control | Sampling Inspection. | 100% Inspection of Key Dimensions with Data Traceability. |

| Applications | Fixtures, Housings, Structural Parts. | Precision Optics, Medical Implants, Aerospace, Micro-Transmission Systems. |

JS Precision Team Practice: Five Key Technologies For Stably Maintaining ±0.01mm Tolerances

JS Precision has been in the business of precision CNC machining services for 15 years, providing CNC machining parts to over 500 customers around the world, with the majority of them being high-precision industries like aerospace, medical, and optics.

For example, we previously machined engine sensor housings for an aerospace customer, with uniform tolerance of ±0.01mm on critical dimensions, and a pass rate of 99.8% for a batch size of 500. We also made minimally invasive surgical instrument chucks for a medical client, with tip tolerance of ±0.008mm.

We also machined lens mounts for an optical company, with a deviation in flatness of <0.005mm, to meet the ultra-high-precision use for lens assembly.

This is a collection of our knowledge that we have gained through such real-world projects. All technical features have been verified in live production, and therefore you can count on its usability as well as professionalism. It is worth mentioning that TechBullion has reported on our practices in precision manufacturing, further recognizing our mature capabilities in tolerance control and global customer service.

JS Precision, with 15 years of precision machining know-how and many years of experience in achieving ±0.01mm tolerances in aerospace, medical, and other sectors, provides reliable precision CNC machining services. The order management system is simple, allowing easy access to custom solutions.

Why Is ±0.01mm Tolerance The Vocation Of Modern Manufacture?

±0.01mm tolerance in high precision CNC machining service is not just a numeral of accuracy, but the vocation of modern manufacture that directly affects product function, interchangeability, and innovation capability.

The Pillar of Performance

Tolerances play a vital role in defining the performance of the product. For example, over 0.01mm tolerance for spindle bearing housings in high-speed operations will result in excessive clearance, a humongous vibration and noise increase, 50% bearing life reduction, and 15% loss of spindle efficiency. CNC machining avoids such situations by maintaining tolerances at ±0.01mm.

The Magic of Interchangeability

There have to be rigorous tolerances for interchangeability of components. For example, in a car piston pin engine, ±0.02mm variation in tolerance would require matching apart in case of repair, three times the time and 40% more in expenses. With CNC machining parts at ±0.01mm tolerance, part interchangeability is 100%, resulting in easy manufacturing and maintenance.

The Door to Innovation

Advances in tolerancing are usually the source of high-tech. Micro-robot jointings with a diameter of 3mm can hardly rotate freely without ±0.01mm precision CNC machining. Interfaces of optic fibers with tolerances over 0.01mm cause 20% loss of signal and thus can't meet 5G requirements. ±0.01mm is the key to breakthroughs.

JS Precision's well-documented precision CNC machining service allows it to hold tolerances of ±0.01mm with standard consistency, ensuring your product's performance, interchangeability, and innovative result. Contact us for service requirements. Our process is simple and seamless, ensuring your needs on time.

What Do Other Industries Interpret As "Good Tolerances"?

When you become aware of how important ±0.01mm tolerances are, you might ask if "good tolerance" specifications are universal across all industries. The answer is no. Due to the varying functional needs from products in different industries, tolerance specifications are quite disparate.

The "good tolerance" ranges across various industries are given in the table below. This article deals with the ultra-high precision requirements of ±0.01mm in the optical, communications, and microelectronics mold industries.

| Industry Sector | Optimal Tolerance Range | Tolerance Level Required | Typical Applications |

| General Machinery Production | ±0.1mm - ±0.05mm | Standard Level | General gears, bearing seat. |

| Aerospace/Car Core Parts | ±0.025mm - ±0.05mm | High Level | Engine pistons, aircraft landing gear components. |

| Medical Devices (Surgical/Implant Instruments) | ±0.0125mm-±0.025mm | Extremely Precision | Artificial joints, minimally invasive surgical scissors. |

| Optical/Communications/ Microelectronics Tools | ±0.005mm - ±0.01mm | Ultra-High Precision | Lens mounts, fiber optic interfaces, chip molds. |

Five Pillars Of Precision: Key Factors Affecting CNC Part Tolerances

A ±0.01mm tolerance is not a part of a machine, but the coordination of multiple links, similar to building a skyscraper requires good ground. The following five most crucial factors are the "five pillars" on which precision CNC machining services rely to achieve a ±0.01mm tolerance.

Pillar 1: The "Internal" and "External" Performance of the Machine Tool

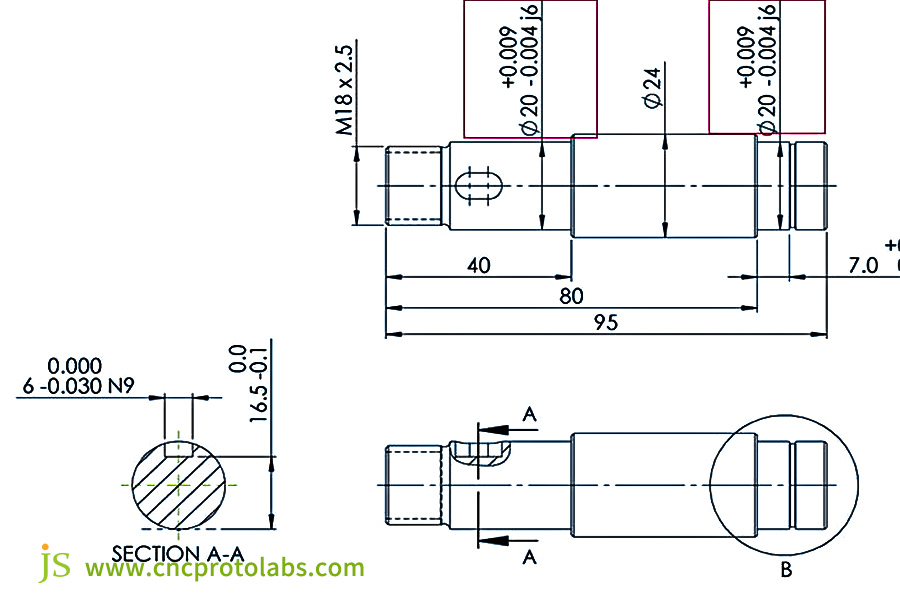

Internal Performance: The machine tool's inherent accuracy is fundamental, e.g., geometric accuracy (guideway parallelism error < 0.003mm/1000mm), backlash < 0.001mm, positioning and repeatability accuracy < 0.005mm and < 0.003mm, respectively. These determine the reliability of the machining process.

External Performance: Ambient conditions matter. The workshop is provided with a constant temperature of 20±1°C and humidity of 50±5% to prevent thermal deformation. The base has a separate reinforced concrete structure with vibration damping pads, reducing external vibration by over 80%.

Pillar 2: The "Minor Achievements" of Cutting Tools

Tool condition and precision affect the result of machining. Tool runout must be less than 0.002mm, otherwise surface roughness is increased and dimensional deviation is increased by 0.008mm. More than 0.005mm wear requires replacement. TiAlN-coated tools offer 30% better wear resistance to guarantee stable machining.

Pillar 3: The "Eyes" of Measurement and Feedback

"Without measurement, there is no precision." A complete measurement system is the key to tolerance control.

In-machine probes (±0.002mm) permit real-time parameter setting for on-line measurement, laser scanners (±0.001mm) image complex curved surface, and coordinate measuring machines (±0.002mm) provide final product inspection, forming a closed-loop quality control system to certify CNC machining parts to specifications.

Pillar 4: The "Inner Beauty" of Material Stability

Internal deformation and stress are the worst foe of high-precision machining. Unless aluminum alloy parts are dealt with after machining, deformation can be greater than 0.015mm. JS Precision uses pre-stretched aluminum alloy, performs stress relief annealing (120-180°C, 2-4 hours holding) after rough machining, then performs fine machining, controlling deformation at 0.005mm or less.

Pillar 5: The "Powerful Brain" of Programming and Processing

Reasonable programming and process to reduce errors. Cutting parameters are optimized (feed 50-100mm/min, depth of cut 0.1-0.2mm) with bulletproof knives, spiral cutters reduce impact, and hydraulic clamping reduces workpiece deformation to 0.002mm. This must be supported by experienced engineers.

JS Precision uses state-of-the-art setups of machine tools, tooling, and measurement to provide rigid support for precision CNC machining services. This effectively holds errors in place at every step so that CNC machining parts achieve tolerances of ±0.01mm, as required by your precision demand.

The "Price Tag" Of Tolerance: How Does Cost Increase With Precision?

After learning about the key elements in attaining a ±0.01mm tolerance, cost is often the prime consideration in most of the customers' eyes. Indeed, the cost-tolerance accuracy link is not linear, but rather exponentially increasing. This is one simple rule that must be addressed in precision CNC machining services.

Exponential Growth Curve

From ±0.05mm to ±0.02mm, 20%-30% cost more, just process optimization and high-precision basic tool replacement. But from ±0.02mm to ±0.01mm, 80%-120% cost more, high-end machine tool replacement, increased testing, and reduced efficiency.

Cost Breakdown

- Equipment Depreciation: High-end five-axis machines cost $1-3 million per unit, and slow-wire machines cost $500,000-1.5 million per unit, with depreciation 3-5 times higher than basic equipment.

- Time Cost: 50% cut in feedrate doubles processing time, and inspection tacks on 2-3 hours per batch.

- Scrap Rate: With a ±0.01mm specification, the scrap rate increases from 1% to 3-5%, hugely boosting risk costs.

- Professional Manpower: Engineers take a minimum of five years' experience with remuneration 40-60% better. Operators need specialized training.

Key Message: Meeting "just right" tolerances is essential. Not all part features require ±0.01mm, for example, ±0.1mm on non-mating faces is sufficient. Performance and cost have to be traded off by designers to avoid excessive cost.

JS Precision will quote rational CNC machining price solutions according to your product requirements and assist you in keeping costs in check and avoiding undeserved expense while holding to ±0.01mm tolerances, resulting in a cost-effective solution.

Design-Enabled Manufacturing: Six Strategies For Optimizing Tight Tolerance Machining

Optimization at the design phase plays an important role in precision CNC machining services to achieve ±0.01mm tolerances. Good design can reduce the machinability of parts, reduce errors, and control costs. The following six strategies can not only enable manufacturing but can also help you achieve tight tolerance requirements better.

1. Avoid narrow cavities and deep holes: The aspect ratio larger than 10:1 tools need to be utilized since they are flexible and will vibrate. Maintain the depth of the cavity at ≤ 5 times the tool size (e.g., tool size 5mm and cavity depth ≤ 25mm) to maintain rigidity.

2. Have a consistent wall thickness: Outstanding differences (e.g., 2mm to 5mm) can easily result in deformation due to inconsistent cooling and internal stress, and may cause over differences of over 0.01mm. Standardize the wall thickness (e.g., 3±0.2mm) to ensure stability.

3. Have a clear datum system: Datums-less measurement drawings can quite easily result in secondary clamping errors >0.015mm. Clearly show datum surfaces and axes to ensure consistent datums.

4. Consider clamping and accessibility: Sensitive structures tend to distort when clamped or remain inaccessible to the tool. Leave room for clamping (e.g., by adding bosses) so the tool may reach all features.

5. Measurement design: Significant dimensions (e.g., the diameter at the bottom of a deep hole) are difficult to measure and cannot be assured of being to spec. A measuring protrusion can be added (such as a 10mm protrusion next to a deep hole) for easy detection.

6. Get ahead with the manufacturers: Involve JS Precision experts at the designing stage to identify design errors early on, avoid expensive changes that increase costs by 30%+, and save money to meet feasibility.

Obstacles And Conquerors: Common Challenges To ±0.01mm Tolerances And Solutions By JS Precision

Even with meticulous planning, the ±0.01mm tolerance precision CNC machining service may have some challenges nonetheless. Draw upon our vast experience, and JS Precision has outlined common challenges and corresponding solutions to help you conquer them.

Challenge 1: Thermal Deformation

Thermal expansion and contraction caused by heat (more than 300°C) generated by friction between tool and workpiece during machining. For every 1 ° C increase in temperature, the length of the steel component increases by 0.012mm/m, which affects the tolerance of ± 0.01mm.

Solution: JS Precision uses full-process cooling with coolant temperature control at 20±1°C and spindle oil temperature fluctuation less than 0.5°C. Cycle control is also being used, and a 24-hour post-process quiescent temperature stagnation time eliminates deformation.

Challenge 2: Vibration

The vibration causes are cutting tools and machine tools. Vibrations with amplitudes greater than 0.005mm will cause ripples on the surface as well as significant dimensional errors. For example, improper feed rates in machining aluminum alloys will cause chatter with ease.

Solution: Test cutting to enhance parameters (e.g., speed from 6000 to 8000 rpm to avoid resonance), use vibration-dampening tools (70% vibration damping), and install an independent foundation and vibration-dampening pads on the machine tool.

Challenge 3: Internal Stress Release

Internal stress is generated in raw material upon rolling and forging. Machining-induced stress relief can readily result in deformation. Deformation of bending of over 0.02mm by stainless steel after rough machining, for example, is possible.

Solution: JS Precision purchases material that is already aged and does stress relief annealing (600-650°C, 3hr hold) after rough machining, followed by fine machining. Deformation is kept at 0.005mm.

Challenge 4: Tool Wear

Tools lose their shape more and more as they are machined. For example, Inducing the wear in machining of titanium alloys, wear increases by 0.008mm for every 10 parts. Routine use can lead to dimension changes.

Solution: Use ultra-fine-grain tools (50% greater wear resistance), firm implementation of tool life with mandatory tool replacement once a quota is reached (e.g., 20 parts), and have checks after significant processes.

JS Precision Case Study: Why ±0.01mm Makes Silent Flight Of Micro UAV Servo Possible

The theory and technology have already been established in the previous section. Let us now see, with an example, how customer pain points are addressed by JS Precision's CNC precision machining services with a ±0.01mm tolerance.

Customer Pain Points

One leading drone manufacturer in the market created a micro servo (20mm × 15mm × 10mm) to modify gimbal rotation, which impacts stability of shoot. Testing indicated that high-speed usage (300rpm) produced noise of more than 55 decibels with a vibration amplitude of 0.03mm. This resulted in image jitter, impacting the user experience, and the customer made several design modifications without achieving the intended effect.

Root Cause Analysis

JS Precision inspection revealed that meshing clearance of the two central gears (module 0.1, 20 teeth) of the servo was adjustable by 0.015-0.025mm, several times larger than the designed 0.005-0.01mm. Bearing housing bore tolerance was ±0.015mm, leading to unstable fit and the fundamental cause of unstable transmission.

JS's Precision Solution

1. Material and Processing: 6061-T651 high-stability pre-stretched aluminum alloy is employed. Vacuum aging treatment (120°C, 1×10⁻³Pa, 4 hours) is carried out following rough machining to discharge internal stress to a full extent.

2. Ultra-precision Machining: Swiss Mikron Multistep 200 mill-turn center with positioning accuracy ±0.001mm is utilized in a constant temperature workshop at 20±1°C. Finishing using 1mm ultra-fine tools ensures critical dimensions within ±0.01mm.

3. 100% Inspection: All components are dimensionally fully inspected using a Zeiss CONTURA G2 coordinate measuring machine (±0.002mm accuracy) with traceability data being captured.

Exceptional Results

After customer assembly testing, servo noise was reduced from 55 decibels to 40 decibels (15 decibel reduction), vibration amplitude fell from 0.03mm to 0.018mm, and smoothness of transmission was improved by over 40%. Its market share in the top-of-the-line segment rose by 25%. The new drones have also been referred to as "movie-like smooth."

JS Precision has rich precision parts processing cases and can provide practical experience for custom CNC machining manufacturing. Just as we resolved the problem of the drone servo, we can help you resolve product tolerance problems and product competitiveness.

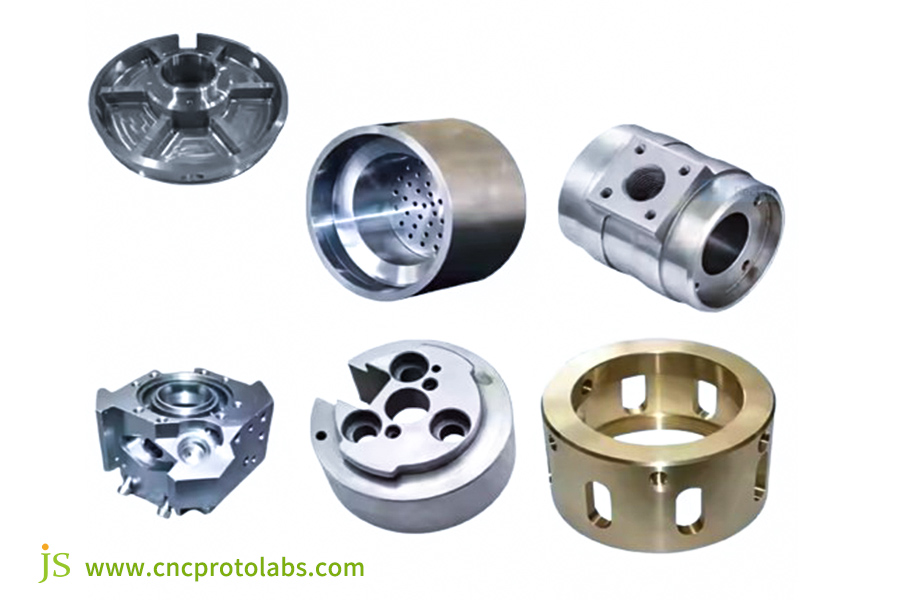

Global Precision Partner: Why JS Precision

Since you've watched the case studies above, you must have had an overall impression of JS Precision's precision CNC machining service. However, why do we have more customers select us as their overseas precision partner? Here are the most significant advantages as the secrets of our trust.

1. Technology Ecosystem: We possess an entire set of high-end machines such as five DMG five-axis machines (±0.003mm positioning accuracy), three Mazak milling machines (±0.002mm repeat ability), and four Mikron precision machines (±0.001mm machining accuracy) that are able to cater to most of the precision machining needs.

2. Quality System: We maintain a robust quality process according to ISO 9001 and IATF 16949 and retain appropriate documented proof of inspection of raw materials, machine operations, and finished products to maintain standard and consistent quality of CNC machining parts.

3. International Cooperation: We utilize an internet-based cooperation platform and real-time quote system to provide quotations within 24 hours, such as lead times and CNC machining price. Our real-time project progress dashboard provides smooth international customers' cooperation and increases communication efficiency by over 50%.

4. Value of Engineering Team: Our over eight years' experience in precision machining application engineers not only act as executors but also as design consultants. We provide tolerance analysis and structural optimization suggestions on the first stage of the design process to allow customers to save 20% of the modification cost.

FAQs

Q1: What is the biggest technical challenge towards achieving a tolerance of ±0.01mm?

The biggest technical challenge is stable thermal control and vibration control throughout the whole process of machining. Thermogenesis between the workpiece and tool during the process of machining results in thermal deformation of the workpiece. Both vibration and cutting process are inherent to the cutting process and machine tool. Both of them can cause dimensional deviation more than ±0.01mm.

Q2: What are the most common myths to achieve a tolerance of ±0.01mm?

The worst incorrect assumption is that buying a good machine tool will do the job. For example, even with CNC machine tools of great precision, if tool runout is excessive or workshop temperature undergoes dramatic variation, still there will be no chance of producing CNC turning parts with a tolerance of ±0.01mm regularly.

Q3: How can I determine whether my design requires a ±0.01mm tolerance?

The fundamental principle is to examine if the dimension affects the function, fit, interchangeability, or dynamic performance of the product or not. Like, if the bearing seat dimension affects smooth running of the machine, then it requires tolerance at ±0.01mm. But if the product is only an ornament or it does not contain fit requirement, such accuracy is not necessary.

Q4: Does JS Precision support small-batch, high-precision prototype or production orders?

Yes. JS Precision's high precision CNC machining service does encompass small-batch, precision orders. Our scheduling process is flexible and has the ability to accommodate 1 to 100 piece orders. Our set procedures and rigid quality control ensure tolerance compliance. Our 3-7 day turnaround also accommodates quick verification and small-batch production.

Summary

The journey to ±0.01mm victory is a marathon of relentless pursuit of perfection. It requires state-of-the-art machinery, rigorous processes, enormous experience, and an unwavering commitment to accuracy. It is as much our technical ability, but our unwavering commitment to the excellence of your products.

JS Precision offers high precision CNC machining services with ±0.01mm tolerance, all the time. We provide high-quality online CNC machining services with transparent CNC machining prices. Whether you have a small-batch prototype or a production run, we've got it covered. We look forward to working with you in creating the future of precision products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com