The CNC machining services often faces the following dilemma: whereby you may spend weeks detailing 3D designs for vital components of a new product, and then be set back because of inefficiency in manufacturing, or you get components with tolerance levels that are no more than 0.01 millimeters, yet this freezes the entire assembly line.

High speed and high precision CNC machining has actually become the engine behind all manufacturing operations, thanks to the current emphasis on rapid product iteration and maximum performance.

Real high speed and high precision, however, are not merely functions of higher spindle speed. They involve an elaborate system's approach that includes design, materials, processes, and tools.

This guide will show you how to accomplish an efficient, cost-effective, and guaranteed translation of your design ideas into quality CNC machining parts by partnership building with reliable CNC machining service providers.

Key Answer Summary

| Key Considerations | Common Challenges and Misconceptions | The Essence of JS Precision's Solutions |

| Process and Design | Non-manufacturable designs result in complicated and inefficient process sequences. | DFM pre-collaboration: Actions taken during the design stage to optimize functional and tolerance characteristics set the stage for high-speed and efficient machining. |

| Materials and Cost | Inappropriate materials chosen or ambiguous cost estimates lead to either cost overruns or underperformance. | Materials Science Library & Transparent Pricing:Based on a rich database, recommend the best cost-effective materials and provide clear and structured CNC machining price analysis. |

| Equipment & Precision | In some cases, a trade-off between "speed" and "precision" is assumed, but such is not the case with advanced machine tools. | High-performance CNC machining center complex: Uses high-performance machine tools with linear motors and thermal compensation methods for dynamic precision stability. |

| Partnership&Value | Considers suppliers only as contract manufacturers—and misses their engineering potential. | Solution Partner: Offers end-to-end support for technical consulting and process optimization through project management—and much more than machining. |

Key Takeaways:

- Success Starts with Collaborative Design: The earlier DFM analysis with suppliers, the better for unlocking the efficiency and cost benefits of CNC machining services.

- Precision comes from systems engineering: Precision depends on high dynamic-performance CNC machining center and highly reliable process chains.

- The wise choice of materials and processes directly affects the CNC machining price and part performance, and requires comprehensive decision-making based on application scenarios.

- Selecting a supplier means selecting their engineering skill, a real supplier partner would work towards optimizing the entire process from concept through finished product.

JS Precision Guide: How To Balance Accuracy And Efficiency In CNC Machining Services

For the past 15 years, JS Precision has been a trusted provider of CNC machining services, having the honor of serving more than 2,000 clients.

We have shipped in excess of 500,000 precision components with sizes measuring to the micron level in medical implant components and high-performance aerospace parts with a rate of delivery of 99.8% and a successful quality rate of 99.5%. The work done in the format of ASME Y14.5-2009

The internationally authoritative standard ASME Y14.5-2009 "Dimensional and Tolerance Annotations" emphasizes that the efficiency improvement of precision machining cannot be achieved without the early collaboration between design and manufacturing, which is highly consistent with our practical experience.

We are able to excel at handling complicated projects, including machining titanium alloy components to a tolerance level of ±0.005 mm for major aerospace organizations, or optimizing production processes for consumer electronics clients, cutting their CNC machining price by 30 percent while improving efficiency at the same time.

This guide is far more than a theory - it represents what we have already achieved in practice. Everything that is advised in this guide has been fully tested in thousands of projects and has already led to the triumph of hundreds of clients who turned design difficulties into a production triumph.

Interested in utilizing our knowledge base for your project advancement? Please provide your part requirements and 3D models for a free accuracy and efficiency analysis with our engineers for a right fit for your CNC machining services requirement.

What Is The Typical Process Flow Of CNC Machining Service?

An understanding of the standard procedure associated with professional CNC machining is the key to establishing trust and an efficient working partnership. This encompasses much more than familiarity with machine tools, it involves an engineering cycle in which CNC machining is part of an organized methodical procedure to turn raw materials into precision parts.

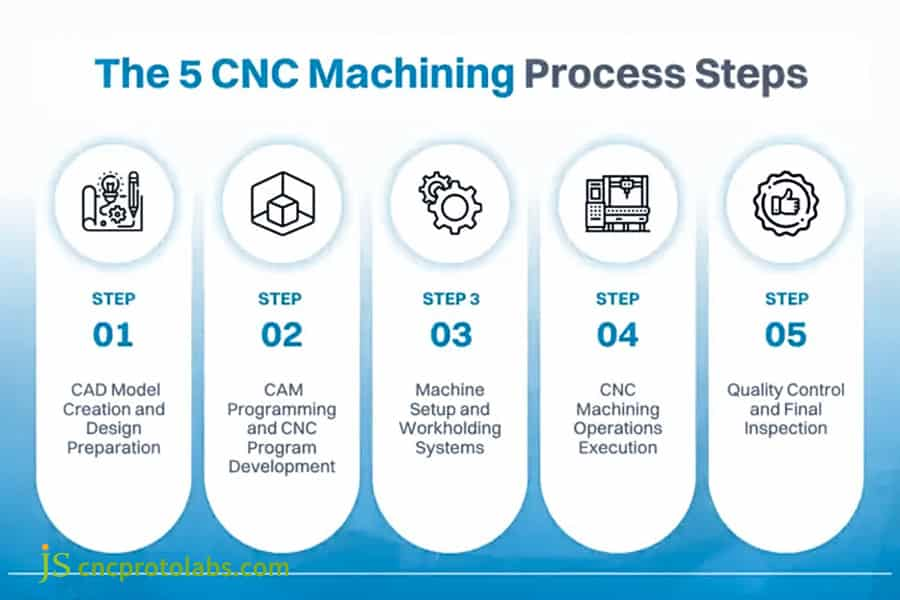

Construction of Preliminary Engineering Analysis/Design Preparation

DFM Review: Here, engineers would review your three-dimensional model to detect possible errors and advise improvements in terms of design optimization and tolerance rationalization to prevent manufacturing-related problems like tool breakage and errors in dimensions.

Process Planning and Programming: We will devise a precise machining plan that takes into consideration the complexity of the piece to be made. Programmers create optimal, collision-free CNC code allowing for a maximal machining rate while assuring accuracy—the "brain" controlling the machining process.

Production Execution & Quality Closed Loop

Precision Clamping and In-Machine Verification: Top-quality fixtures are employed to hold the work part firmly in place during the processing stage. At the same time, in-machine measurement is conducted to establish precise part references, which leads to improved processing precision.

Multi-Process Machining and Real-Time Monitoring: The CNC machining center is capable of performing milling, drilling, tapping, and more through the program. Real-time monitoring of the cutting process is carried out by our team, with adjustments being made when necessary.

Full Process Quality Inspection: Starting right from our initial sample submission to our final batch shipment, we employ precise measurement instruments like coordinate measuring machines to check every cnc machining parts. Every part is 100% quality-controlled as per drawing specifications.

Figure 1 The CNC machining process begins with systematic workflow from initial design through final inspection, ensuring consistent quality and dimensional accuracy.

How To Choose The Best Metal For Your CNC Machining Parts?

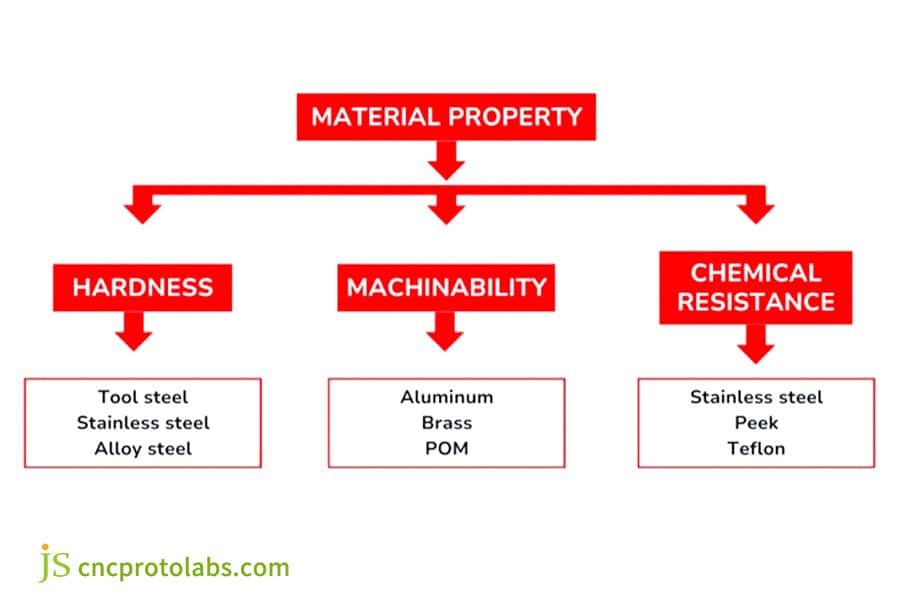

The material is the "skeleton and muscle mass" of a part. In metal CNC machining, material selection is a functional consideration, to be sure, but it also directly relates to the complexity involved in processing and ultimately costs. The material choice can be the key to success or failure for a project, so a selection must be made that meets both functional and practical needs.

| Common Metal Materials | Key Benefits | Uses |

| Aluminum Alloy | Light weight, easy to machine, moderate cost | Electronic device housings, automobile parts |

| Titanium Alloy | High specific strength, good biocompatibility | Aerospace components, medical implants |

| 316 Stainless Steel | Corrosion-resistant and Strong | Marine equipment, medical equipment |

Define Material Requirements based on Application Scenarios

- Strength and weight considerations: The strength and low weight of aerospace parts require the material to be made from titanium alloys, on the contrary, an electronics case could be made from aluminum alloys because it has to be strong yet lighter.

- Environmentally tolerant requirement: For implants of medical devices, biocompatible materials like stainless steel alloys of titanium are needed, for marine equipment, corrosions-resistant materials like 316 stainless steel are required as marine environments are severe.

Machining Performance and Cost Practical Considerations

Differences in processability: Aluminum alloys are easy to machine at high speeds, but Inconel alloys need to be machined at low speeds and with high power, which leads to increased tool wear and machining time.

Total Cost of Costing: Rather than just looking at unit costs per piece of the material, look at overall costs. For example, a slightly higher-cost material with higher machinability may bring down the final CNC machining price.

Not sure what the appropriate metal is for your task? Please describe your application situation and requirements, and we will offer you a free metal selection guide on your metal CNC machining task.

Figure 2 Factors influencing the selection of metal materials for CNC machining

How To Optimize The Design To Unleash The Full Potential Of CNC Machining Services?

Good designers design for functionality and manufacture. Then, following the principles of DFM, your design will flourish in the CNC machining services. Optimized design not only simplifies the manufacturing process, but also improves accuracy, reduces costs, and shortens delivery cycles.

Golden Rules of Geometric Design

- Internal Corners And Tool Rounding: Do not create too small of corners with internal fillets, they need to be cut with small tools, which lack rigidity to perform well. It is desirable that the corners correspond to the tool radius as closely as possible.

- Aspect Ratio and Rigidity: Deep holes and tall sides create difficulties for rigidity, resulting in poor surfaces and large errors in size. It has to be ensured that the aspect ratios of the features are in a reasonable range for good processing performance.

Design for Precision and Assembly

- Clear Datum System: The design phase should establish a clear machining and inspection datum system to simplify the machining process and ensure proper positioning of CNC machining parts.

- Standardization/Simplification: Standardization of drill bit sizes can ensure that similar features can be clamped together. Reduced numbers of clamping result in less chance of errors and thus less expensive CNC machining services.

How To Achieve Significant Cost Savings Through Professional CNC Machining Services?

Controlling the CNC machining price is not about blindly suppressing prices, but about optimizing every cost link through scientific decision-making. By doing it, you can lower the cost while ensuring improved or same levels of quality.

The Detrimental Impact on the Design Phase

Tolerance Rationalization: Excessively tight tolerances exponentially raise machining and inspection costs. Only specify tight tolerances for key characteristics—and our group is here to assist with key tolerance necessities.

Part Integration Design: Make use of CNC machining capabilities to integrate various parts together as one component thereby eliminating the need for assembly and decreasing overall CNC machining price.

Process and Production Optimization

Intelligent Process Scheduling: Providing a compromise between cutting speed and precision, roughing and detailing processes offer a good balance between productivity and precision.

Batch and Scheduling Optimization: Smarter order quantities and production scheduling lower costs per unit. We provide flexible batch solutions ranging from prototyping to mass production to assist you in optimizing CNC machining price.

Looking for project budget savings? We want to hear about your budget and units, and will work on tailoring budget-saving solutions for your CNC machining service, all without sacrificing quality.

Figure 3 In the field of CNC machining, it is crucial for enterprises aimed at maintaining competitiveness to optimize cost-effectiveness while ensuring high-quality output.

Precision Core: How Can An Advanced CNC Machining Center Achieve Micrometer Level Trajectory Control?

Precision is not random. Rather, it has its foundations in the collaboration of all key components and systems in a CNC machining center.

Support for this is found in authoritative worldwide standards like ASME B5.54-2020, which specifically states parameters related to precision in CNC machining center and summarizes the pivotal part played in this aspect of precision through collaboration of key components. Micron-level precision requires meticulous engineering and collaboration of quality components.

Mechanical Structure and Drive System

- High Rigidity Bed and Linear Motor: High-quality cast iron or granite bed construction for our CNC machining center ensures resistance to deformation when moving at a high speed. Use of a linear motor eliminates the problem of backlash present in ball screws.

- Thermal Stability Control: It features high-quality cooling systems that monitor changes in temperature levels within the machine and the workpiece. A unique compensation technology eliminates the effects of thermal expansion errors.

CNC Systems and Feedback Technology

- Advanced CNC Core and Look-Ahead Control: The CNC core system will process complex coding at a high speed with look-ahead control. It will not stop cutting at corners or overcut material during operations.

- Full Closed-Loop Feedback System: With a linear encoder, there is real-time positioning feedback that eliminates errors of mechanical transmission to keep the CNC machining center at micron accuracy throughout all processes.

Is high accuracy on the order of microns required for your project? Let our technical support team inform you about our high-accuracy CNC machining center's ability to meet your strict accuracy specifications.

How To Accurately Understand And Evaluate The CNC Machining Price You Receive?

A detailed quote is a test of professionalism on the part of the supplier. Learning how to read a detailed quote will allow you to make educated business choices. A clear and detailed quote enables you to avoid unnecessary expenses while maximizing value for money.

Elements of a Quote

- Detailed Breakdown of Costs: A professional quote should further divide the costs into material costs, programming costs, machine tool labor costs, and fees for post-processing services like anodizing and electroplating, so that you can see the flow of money clearly.

- Process and Assumption Explanation: The quote must contain a specification of the machining process and any assumptions that can create future disputes, such as batch size assumed in the production cycle, in order to ensure consistency in assumptions between yourself and the CNC machining service provider.

Key Dimensions for Evaluating Quotations

- Value vs. Price: While final cost is to be compared, it must be remembered that quality assurance processes and technical solutions offered must also be considered. Sometimes, firms charging a little higher may be more reliable and must be preferred to avoid risks associated with technical deficiencies or quality.

- Long Term Cost Factors: Suppliers with greater consistency and fewer defects will be preferred. Fewer defective parts mean less rework, lower material waste, and in the long run, can lower the overall CNC machining price.

Case Study: Topology Optimization+High-Speed Milling Helps Robot Joints Reduce Weight By 40% And Increase Speed By 20%

Challenge:

One of the challenges we received from a top robot producer was that their traditional cast aluminum articulated arms tended to be too heavy, making their dynamic response slow and their strength unstable because of inconsistent grain structures.

Their aim was a substantial reduction in weight with no loss of rigidity, at the same time enhancing motion velocity and accuracy, which were key requirements for their next-generation robots.

JS Precision Solution

JS Precision team has proposed a dual innovation plan for design and manufacturing.

First, they employed algorithms for generative design to design a biomimetics-inspired lightweight design with optimal distribution of material, reducing redundant mass and optimizing regions of stress concentration.

Later, high-performance CNC machining center was employed for five-axis high-speed precision machining. With 7075-T6 aviation aluminum billets used as material, the complex internal and external lightweight structure machined in one setup avoided casting problems and ensured consistent material properties.

Quantitative Results

The results were quite dramatic: robot joint weight decreased by 40%, robot loads were significantly eased, and energy usage was made more efficient, dynamic performance improved by 20%, with the lighter-weight robot having better speed and agility, one-piece machining removed casting problems entirely, and key assembly surfaces were completed with IT7 tolerances to assure easy assembly and reliable performance.

Want to achieve the same success in your project? Then share your part performance goals with us. We will apply the latest technology of CNC machining center to the design of your CNC machining parts.

Figure 4 Aluminum Alloy Multi-joint Collaborative Robot Arm

Why Is JS Precision Your Ideal Partner For High-Speed And High-Precision CNC Machining Services?

When selecting a supplier, you essentially select and choose their systemic strength in terms of converting technological promises into reality. With us, you can expect much more than what a machining supplier can offer. At JS Precision, our motto is to act as your technology partners right from concept development to completion.

Technical Expertise & Engineering Support

- Equipment Investment and Process Database: We invest heavily in top-of-the-line CNC machining center, equipped with advanced machining tools. We also have a large database of process parameters on hard-to-cut material machining, and this results in stable machining operations.

- Professional Engineering Team: Since the inception of the project, a professional engineering team is being utilized to provide technical support for our customers. We are well versed with your needs and challenges, making design solutions into optimized manufacturable solutions.

Quality Culture and Project Assurance

- Digital Quality Closed Loop: The quality control is totally digitalized. From the CAM simulation until the end report, you can trace all steps and therefore you can rely on the quality of the CNC machined parts totally.

- Project Management: Every project has a specific project manager that will most importantly be one contact person for properly managed communication processes with delivery at all times, and this will enable monitoring of projects at all times.

FAQs

Q1: How much precision can CNC Machining offer?

Even in conventional CNC machining, the accuracy can reach ±0.025mm. Using precision machine tools with optimized processes, some critical parameters of the key features can reach as high as ±0.005mm in terms of accuracy, which is well above the required standards.

Q2: What is the minimum order quantity (MOQ)?

We do not have a hard-cut minimum order quantity, accommodating all possible scenarios from single piece prototyping to mass production. This is highly flexible for R&D projects and also fulfills mass production demands.

Q3: How long would it take to get a quote after receiving the documents?

Usually, when it comes to standard CNC machining parts, it takes a matter of 24 to 48 hours to give a detailed quotation, and it comes with free DFM analysis to improve your design before manufacturing.

Q4: What is available for the surface treatments?

We provide different surface treatment services such as anodization, sandblasting, nickel plating, passivation, and painting. We may be able to suggest which treatment service will work best based on your appearance preference or protection needs.

Q5: I would like to know how I can maintain the confidentiality of my design drawings.

We will enter into a rigorous confidentiality agreement (NDA) with you and use an encryption file transfer and management system to ensure that your design drawings are not leaked.

Q6: What is the typical processing cycle?

The cycle time is based on part complexity and quantity ordered. For prototyping, this will typically take 3-7 days, but for production volumes, this will be judged based on individual case volumes. We will make every effort to honor cycle time and delivery requests.

Q7: Do you offer assembly?

Yes, we not only offer the service of CNC machining but also assembly testing of the CNC machining parts, which helps in giving you a one-stop manufacturing solution as per your requirements.

Q8: Can you optimize my design to minimize expenses?

Of course, free DFM analysis is one of our standard services. Our engineers will optimize your design with respect to manufacturing and thus will decrease the CNC machining price without compromising the functionality of the part.

Conclusion

CNC machining is a field of art as well as technology. Where focus is not only on cost-effectiveness and efficiency but also in the aspect of accuracy. By taking advantage of the right materials, effective designs, proper knowledge of the processes involved, you can maximize the use of CNC machining services.

Take immediate action and experience professional value:

→ 【Get Free DFM Analysis】 Upload your 3D model, and our engineers will give you professional DFM advice and cost optimization in 24 hours.

→【Consult an Expert】Talk to our sales engineers about configuring a cost-effective solution for CNC machining services.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com