CNC machining services are an essential part of the global manufacturing supply chain. It is important to select the right partner if your project is time-sensitive and budget is limited.

Does it mean that you will have uncontrollable quality if you choose a Chinese supplier? Will high costs and long delivery times be the only consequences if you source locally in Europe and America? The decision, making for this classic dilemma is the complex interplay of the market structure, technological capabilities, and supply chain efficiency.

This guide will compare with data and a few case studies the real differences between CNC machining services in China, the United States, and the United Kingdom, so you can have a clearer view and make the best supply chain decisions.

Quick Overview of Core Answers

| Key Considerations | Key Insights | Value to You |

| Balancing Cost and Technology | China CNC machining depends on a complete supply chain and large, scale production to provide outstanding technology at a normal cost of 30%-50% of that in Europe and America. | Clearly identify the best balance between budget and technology so you don't waste money on unnecessary performance. |

| Decisive Factors for Delivery Time | The delivery advantage of CNC machining services China comes from production capacity and logistics, including international transportation. Faster response time for urgent small items in Europe and America | Properly determine the total project duration, help production time to be in line with sales time, and disallow delays. |

| Suitable Project Types | China CNC machining service can provide everything attending to prototype and mass production. Besides that, the company has a very strong position in multi-axis and complex surface machining. | Get the right service provider based on the project's stage and part complexity. |

Key Takeaways

- China has the best comprehensive cost-effectiveness:

For most parts that require high complexity, strict tolerances (such as ± 0.01mm), and medium to large batches, CNC machining in China provides unparalleled cost-effectiveness.

- Delivery time aspects should be comprehensively reviewed:

It is important to first consider the production scheduling of a CNC machining USA or the UK when deciding based on delivery time.

Whereas, when measuring delivery times in China, one should consider an extra 7-15 days for international logistics. In the case of a prototype, an online quotation and Chinas fast prototyping might allow for a significant reduction in time-to-market.

- The quality benchmark is set by certification:

Locating suppliers who have obtained international certifications such as ISO 9001, AS9100, or IATF 16949 ensures the quality level is consistently maintained between CNC machining services UK and China.

- The hybrid strategy is the leading trend of the future:

Utilizing a hybrid model where the main production is in China (CNC machining services in China) + local emergency/small batch supplementation in Europe and America (CNC machining UK/USA) can lead to optimizations in the supply chain resilience.

Why Refer To This Guide? JS Precision's Track Record In Multi-Country CNC Machining Services

Trust is the most important prerequisite when it comes to choosing the right CNC machining partner.JS Precision is a company that has been deeply involved in the global CNC machining industry for 15 years.

We have helped more than 1000 companies in over 50 countries worldwide, including high end sectors such as aerospace, medical equipment, and automotive parts. Our main strength is the ability to combine first, class manufacturing capacities in China, the US, and the UK to offer tailored supply chain solutions to our customers.

JS Precision is triple internationally certified: ISO 9001, IATF 16949, and ISO 13485. All our manufacturing processes are controlled by SPC statistical process control standards. Our five-axis machining centers can regularly deliver extremely tight tolerances of 0.005mm, with surface finishes reaching Ra0.4m, which totally satisfy the requirements of high end industries.

By 2025, we will have finished more than 1200 complex parts projects, with a customer retention rate of 85%. One German automotive parts company, by working with us, was able to lower its unit cost for mass production by 42% and its delivery time by 30%.

According to the Association for Manufacturing Technology (AMT) in their "2025 Global CNC Machining Trends Report, " "Top-notch cross-border CNC services need to find a good balance between technical precision, cost efficiency, and supply chain resilience."

JS Precision is a practitioner of this philosophy. We achieve global capacity visualization through a digital management system, allowing clients to monitor production progress in real time and completely breaking down communication barriers in cross-border cooperation.

Want to verify our capabilities? Submit your part drawings, and JS Precision will provide you with a customized solution free of charge, including technical feasibility analysis, cost comparisons across three locations, and delivery time estimates, helping you quickly identify the optimal supply chain strategy.

What Are The Foundational Differences In Global CNC Machining Services?

The main distinctions in CNC machining between China, the US, and the UK are their different industrial bases, technological lead, and market positioning, which in turn, directly influence the collaboration potential.

Comparison of Core Technology Capabilities and Equipment Level

The US leads in aerospace, grade ultra, precision machining (tolerance 0.005mm), with 3 axis machining hourly rates of $80-150, the UK specializes in small batch complex parts, with hourly rates of $60-100. China features a strong production capacity, with 5 axis machining hourly rates of only $20-35, and multi-axis machining giving excellent cost-effectiveness.

Differences in Industry Standards and Quality Certification Systems

High end certifications in Europe and America are standardized but have high management costs, thus prices go up, top-tier Chinese service providers such as JS Precision have obtained international certifications, and their end-to-end quality control can satisfy the high end requirements.

Typical Service Scope and Customization Capabilities

The US is geared to the aerospace field, with extremely high costs for small batch production, the UK is fitted for small batch iterations in Europe, with limited capacity. China can handle the whole process from prototype to mass production, thus flexible to various orders.

Want to understand which service model is best suited for your project? Contact JS Precision engineers now. We will provide a one-on-one adaptation analysis based on your part complexity, order volume, and budget to help you accurately match the optimal capacity.

Figure 1: Close-up of a CNC lathe in operation, with a rotating workpiece, cutting tools, and copper coolant pipes visible in an industrial setting.

Figure 1: Close-up of a CNC lathe in operation, with a rotating workpiece, cutting tools, and copper coolant pipes visible in an industrial setting.

How Does China CNC Machining Balance Cost-Efficiency With Technical Capability?

The core of China's cheap, top-notch CNC machining is fundamentally based on its industrial ecosystem and technology investment, and not merely on labor.

Analysis of the Cost Advantage of Scaling China's Supply Chain

The price at which companies in china buy commonly, used materials is 15% to 30% cheaper than those in Europe and the United States, the manufacturing hubs of the Pearl River Delta and Yangtze River Delta minimize the cost of transportation, and the fact that production runs 24 hours a day enables the utilization of machinery to be over 85%, which in turn helps to lower the unit cost.

The following is a cost comparison table for complex aluminum alloy housings (500-piece batch):

| Cost Drivers | US Factory Cost (USD) | UK Factory Cost (USD) | China Factory Cost (USD) | Remarks |

| Materials (Aluminum 6061) | 12.50 | 11.80 | 8.50 | Advantage of local sourcing in China |

| Processing Time (45 minutes) | 67.50 (USD 90/hour) | 52.50 (USD 70/hour) | 22.50 (USD 30/hour) | Advantage of labor and equipment utilization |

| Setup & NRE (Amortization) | 1.00 | 0.80 | 0.30 | Cost dilution through economies of scale |

| Anodizing (Type II) | 8.00 | 7.50 | 2.50 | Advantage of industrial cluster synergy |

| Logistics (DDP Air Freight) | 0.00 | 0.00 | 4.50 | International transportation costs |

| Tariffs (estimated 25%) | 0.00 | 0.00 | 9.50 | Geopolitical costs |

| Total Unit Cost | 89.00 | 72.60 | 47.50 | Net Savings of 30%-47% in China |

Technological Advancement and the Latest Trends in High End Manufacturing Transformation

China cnc machining has totally changed the perception of "low-quality." Top, tier factories can reliably produce parts in IT7 level precision and Ra 0.8m surface finish. JS Precision's five axis machine tool is capable of producing complex curved surface parts in a single setup with a 0.005mm tolerance.

Hidden Cost Considerations: Logistics, Tariffs, and Communication Costs

Choosing CNC machining in china requires consideration of logistics, tariffs, and communication costs: logistics can be optimized through "emergency air freight, bulk sea freight", while US tariffs can reach up to 25%, but the total cost is still lower when combined. Choosing a supplier with a 24/7 English team can avoid communication barriers.

Is CNC Machining UK The Ideal Middle Ground For European Markets?

UK CNC machining is still a good option for European clients, but after Brexit and due to limited capacity, the cost, effectiveness of CNC machining services uk was no longer sufficient.

UK's Precision Engineering Advantages:

The UK is a leader in precision component machining and offers great customization capabilities. Therefore, it is a perfect fit for luxurious small batch projects in Europe.

The Effect of the Post, Brexit Trade Environment on Price and Delivery Time:

Less favorable trade conditions between the UK and the EU after Brexit have led to an increase of 3%-8% in customs clearance costs and a delay in delivery time of 1-2 weeks, thus damaging the competitiveness and delivery time advantage.

Service Flexibility and Small-Batch Production Benefits:

The UK is quick to respond and is ideal for small batch iterations, however, it does not have the cost advantages for batches of 500 or more, thus it is not able to meet China's large scale production capabilities.

Want to know the best sourcing strategy for the European market? JS Precision can provide a hybrid sourcing solution of "UK emergency + China batch" based on your project location, order volume, and delivery requirements, ensuring rapid response to urgent orders while controlling the cost of batch production.

How Do Lead Times Truly Compare: China CNC Machining Service Vs. Western Counterparts?

The notion that "China has long lead times" is a misconception. After calculating the total "production + logistics" cycle, China's lead times are often better than expected.

Comparison of Delivery Cycles for Standard and Rush Orders

| Order Type | USA (excluding logistics) | UK (excluding logistics) | UK (excluding logistics) | Remarks |

| Standard Aluminum Alloy Parts (500 pieces) | 4-6 weeks | 3-5 weeks | 4-5 weeks | China Air Freight 5-7 days |

| Rush Aluminum Alloy Parts (100 pieces) | 2-3 weeks | 1-2 weeks | 2-3 weeks | China Rush Production + Air Freight |

| Complex 5-Axis Parts (200 pieces) | 6-8 weeks | 5-7 weeks | 5-6 weeks | China 5-Axis Capacity Sufficient |

| Prototype Parts (1-5 pieces) | 2-3 weeks | 1-2 weeks | 1-2 weeks | China Rapid Prototyping Service + Air Freight |

Impact of Production Scheduling, Capacity, and Seasonal Factors

- Most factories in Europe and America have tight schedules, low capacity flexibility, and are easily delayed during holidays.

- China has densely packed capacity, 24-hour production, high equipment utilization, and is hardly affected by the season.

Efficiency in the Logistics Chain and Breakdown of International Shipping Time

The total time of delivery in China is made up of local production, domestic logistics, and international shipping. JS Precision's coastal base has the potential to increase efficiency.

- Local Production: Standard parts 10-15 days, expedited parts 5-7 days.

- Domestic Logistics and Documentation: 2-3 days.

- International Shipping: Air freight 5-7 days, sea freight 25-35 days.

JS Precision's coastal base is capable of shortening domestic logistics and raising delivery efficiency.

Figure 2: Palletized and stretch-wrapped cardboard boxes labeled for international export sit in a warehouse with shelving and a forklift in the background.

Figure 2: Palletized and stretch-wrapped cardboard boxes labeled for international export sit in a warehouse with shelving and a forklift in the background.

Is a China CNC Machining Service Suitable For Both Prototypes And Complex Production?

China CNC machining technology covers the whole range of processes from prototype to final mass production and the capabilities are far beyond just dealing with simple parts.

Rapid Prototyping Service:

JS Precision offers a quote and DFM report within 24 hours upon uploading your 3D model. Normal prototypes are done within 5-7 business days and fast delivery by air freight. Single-piece orders are available, and design validation is assured.

Complex Parts and Mass Production:

CNC machining of complex parts in China has attained international advanced levels. JS Precision's five axis machines can handle deep, cavity and thin, walled parts in one operation. The costs of automotive bracket mass production can be cut by more than 40%, with various surface treatments included.

End-to-End Support from DFM to Assembly:

JS Precision offers a complete range of services including DFM design optimization, multi-axis precision machining, and surface treatments, thereby helping to lower the costs of management.

Want to experience the efficiency of China's rapid prototyping service? Upload your 3D drawings to the JS Precision platform now, receive a quote and DFM analysis within 24 hours, and receive your customized prototype in 5-7 days.

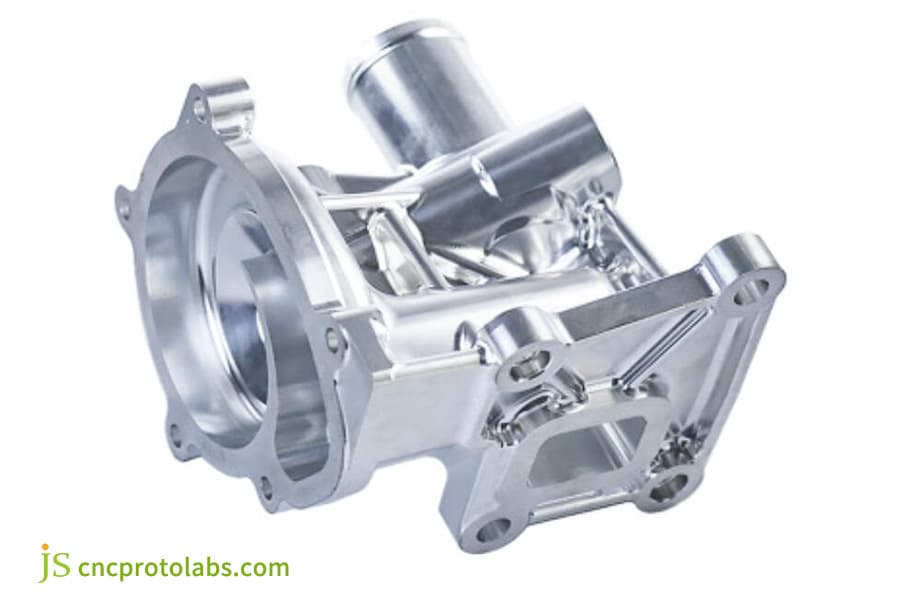

Figure 3: A single, shiny metal component with a complex geometry featuring multiple holes, slots, and smooth, rounded edges.

Figure 3: A single, shiny metal component with a complex geometry featuring multiple holes, slots, and smooth, rounded edges.

Case Study: German Medical Device Company Accelerates Product Launch With The Help Of Chinese Precision Machining

Challenge

A German start-up medical company needs to produce 200 sets of new minimally invasive surgical instrument core handles (Ti6Al4V titanium alloy, requiring biocompatibility certification).

German local quotes offered high prices (more than $280 per unit), with an 8-week lead time, which was above the budget and development schedules, the parts had complex curved surfaces and very tight tolerances of 0.025mm, hence five axis machining and medical-grade quality control were needed.

Solution

The medical device company teamed up with JS Precision and we came up with a tailored solution targeting their major pain points:

1.Close DFM Collaboration:

JS Precision engineers proposed that some non-critical right-angle designs be replaced by more manufacturable rounded corners which facilitated the parts' machinability and the time of machining was reduced by 15%, while the functionality was preserved.

2.Process and Material Optimization:

In conformity with ISO 13485, Ti6Al4V titanium alloy blanks of domestic production are used, 5 axis machining center is coupled with medical-grade coolant, and after the use of the burr-free surface is ensured by high rigidity machining. Also, the surfaces pedal bio-compatibility requirements.

3.Parallel Process Management:

A project manager in the performing of different tasks concurrently (machining, polishing, cleaning, and aseptic packaging) has been appointed to coordinate these parts and thus to reduce the time of waiting between the transitions. Quality traceability is 100% compliant, including material traceability (MTR) allowance for each batch of materials.

Outcomes

The components perfectly satisfy the drawing requirements (tolerance 0.025mm), the unit cost is lowered to $155 (about a 45% reduction), and overall lead time is kept within 5 weeks, enabling the customer's product to get into clinical trials 3 weeks ahead of schedule.

During the following mass production, the order quantity escalated to 1000 sets, which led to a further unit cost drop to $130, thus greatly increasing the product's market competitiveness.

Would you like to achieve similar cost reductions and efficiency improvements? Share your project challenges, and JS Precision will customize a solution for you, providing comprehensive support from DFM optimization and process selection to supply chain management, helping your product reach market quickly.

Figure 4: A shiny, metallic T-handle drill chuck with a knurled surface, placed on a white background alongside a smaller metal piece.

Figure 4: A shiny, metallic T-handle drill chuck with a knurled surface, placed on a white background alongside a smaller metal piece.

How To Make The Final Decision Between CNC Machining Services In China, USA, And UK?

The core of CNC selection is matching project needs. The following framework will help you make an informed decision.

Decision Matrix: A Selection Framework Based on Order Volume, Complexity, and Budget

| Project Characteristics | Priority Selection | Core Advantages |

| High Complexity + Medium-to-High Batch Volume + Strict Budget Control | CNC Machining Services China | Excellent cost-performance ratio, matching technology, scalability advantages. |

| Small Batch Volume + Rapid Iteration + High Communication Needs | Europe & America CNC Machining Services | Fast response, convenient communication, adaptable to design verification. |

| Ultra-High Precision + Special Certification Needs | Comprehensive Evaluation of Top Suppliers in Three Countries | Balancing technology and cost, adaptable to high-end needs. |

| European Market + Emergency Replenishment + Small-to-Medium Batch Volume | CNC Machining Services UK | Geographical proximity, fast logistics, timely response. |

| Global Market + Mass Production + Cost Optimization | China CNC Machining Service | Strong competitiveness, superior cost, sufficient capacity. |

Risk Assessment: Quality, Supply Chain, and Geopolitical Factors

To select CNC one has to consider three different risk types and thus avoid them:

- Quality risk that can be lessened by the supplier through peer review and certification, and the customer can also require test reports.

- Supply chain risks that are the risk of failures in deliveries, are the guaranteed risks by dual-source procurement.

- Geopolitical risks that are very difficult to understand and measure can be controlled by trading of HS codes and selecting DDP terms.

Hybrid Procurement Strategy: Combining Several Sites to Optimize the Supply Chain

The mixed mode of "China's main production+European and American emergency" has the strongest resilience:

- Large quantities of non emergency parts are placed under Chinese control budget.

- Emergency spare parts are handed over to Europe and America for production guarantee.

- Prototype development is quickly verified by China to shorten the cycle.

FAQs

Q1: How much lower is the average price of CNC machining in China compared to the US and UK?

Approximately 30%-50% less than Europe and America, the final figure also varies depending on the complexity of the parts, materials, and the quantity of the order. When the batch size is bigger, the cost advantage of China will be more significant, the price gap for complicated components can even exceed 50%.

Q2: What is the typical shipping time from China?

Scheduled air shipments usually take 5-10 days to any major cities around the world, while shipping by sea normally takes 25-40 days. Using priority air freight, it is possible to shorten the delivery time to 3-5 days which is suitable for most urgent orders.

Q3: How do you ensure the processing quality of Chinese suppliers?

Opt for plants with international certificates like ISO 9001 and AS9100. Insist on first article inspection (FAI) reports, process quality data, and material quality reports (MTR). In some cases, third, party inspections are a must.

Q4: What is the minimum order quantity (MOQ)?

Typically, Chinese suppliers are more accommodating, allowing the production of prototypes and small batches including single, piece production. Local European and American suppliers may be less flexible offering higher MOQs, usually starting at 50 pieces since small batches are more costly.

Q5: How many axes can you process? What precision can you achieve?

JS Precision provides 3 axis, 4 axis, and 5 axis simultaneous machining. Standard precision can go as far as 0.025mm, and high precision demands can be met up to 0.005mm, thus pretty much satisfying the requirements of the automotive, medical, and aerospace industries.

Q6: What if parts are damaged during transportation?

We shall pack the goods properly and purchase transportation insurance. When it comes to damage, we shall help with the insurance claims and give priority to reproduction so that your project schedule won't be affected.

Q7: How do I get a quote?

Simply upload your 3D drawings (STEP/IGS format) to our platform. You normally can get a detailed quote and DFM analysis within 24 hours, totally at no cost.

Q8: Are my design files secure?

We enter into strict confidentiality agreements (NDAs) with each of our clients and treat your design files as top-secret trade secrets, keeping them in encrypted storage and using access control to ensure no information leakage.

Summary

When deciding on a CNC machining supplier in the worldwide supply chain, the choice should be aligned with the project requirements:

China is the best choice for the majority of medium-to-high volume highly complex parts due to its complete industrial ecosystem, technological upgrades, and cost advantages, on the other hand, Europe and America are the only ones capable of high end small batch production, urgent orders, and local response.

JS Precision, as a world CNC machining integrator, breaks down geographical barriers, offering a one-stop solution for technology matching, cost optimization, and supply chain resilience. We are not only a machining service provider but also your strategic supply chain partner.

Act now to obtain your personalized comparative analysis! Kindly send us the part drawing, and JS Precision will give you a very competitive CNC machining quotation in China along with a free comparative report on the procurement strategies for this part in China, the US, and the UK, thus, facilitating your decision-making.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com