CNC machining services create many miracles in daily life: a complicated 3D design model can be turned into a micron-precision, mirror-smooth metal functional component in just a few days.

From the high-strength parts in aerospace to the complex contours of medical implants, precision CNC machining services have become the cornerstone for high-end manufacturing.

But with so many CNC machining parts suppliers in the market, it's challenging to differentiate who the genuine ones are from the fake, and to be sure every custom machined parts you get perfectly meets your expectations.

The following guide dives into the core activities behind best CNC machining services to show the full process, from process selection to quality verification, to help you make the most informed decisions.

Figure 1: Precision CNC machining process

Key Answers Summary

| Customer Core Concerns | Technical Responses to the Top CNC Services | The Unique Value of JS Precision |

| Precision and Quality | Relying on multi axis linkage, precision cutting tools, online measurement, and strict quality control system to ensure. | We integrate the best practices in end-to-end quality control-from certification at the raw material stage to final inspection-so as to meet the drawing requirements or even better. |

| Capability and Flexibility | A strong cluster of powerful CNC machining centers, such as 5-axis ones, a wide material library, and process knowledge, are keys to complex work for custom machined parts. | We have a complete equipment chain from 3-axis to 5-axis. It provides a seamless transition from rapid prototyping to small-batch production, offering a true one-stop solution. |

| Collaboration Experience and Efficiency | The features of an best online CNC service include clear communication, predictable delivery times, competitive pricing, and professional DFM support. | We have a transparent online quotation system, free in-depth DFM analysis, and full-process project manager follow-up to guarantee an efficient and worry-free procurement experience. |

Complex Parts Experts: JS Precision CNC Machining Services & Customization Capabilities

When sharing the difficulties in machining with customers, I first need to explain the core strength of JS Precision in solving them-we have 15 years of practical experience in CNC machining, possessing an AS9100 aerospace quality certification and ISO 13485 medical quality management system certification.

Our material selection and process validation also strictly follow the material standards and biocompatibility testing guidelines published by ASTM International for aerospace and medical materials (such as TC4 titanium alloy).

Based on this system, we have served over 500 clients, including domestic and foreign aerospace technology groups, global top 3 medical device companies, semiconductor equipment manufacturers, delivering over 20,000 sets of complex parts with a pass rate as high as 99.8%.

For example, last year, 100 groups of customized TC4 titanium alloy orthopedic implants were produced for medical customers. The finished implants reached a surface finish of Ra0.2μm and tolerances controlled within ±0.008mm and passed FDA biocompatibility certification, enabling them to be directly used in the assembly of artificial joints.

The components of the wafer transfer robot that we fabricated for a semiconductor client were treated in a Class 100 cleanroom, having magnetic permeability less than 1.005, perfectly suitable for the non-magnetic environment of semiconductor workshops.

Our responsiveness to urgent projects is also proven: during the past three years, we have completed 27 urgent orders, such as delivering satellite brackets within 48 hours, with customer satisfaction exceeding 98%.

This is not a theoretical guide, instead, it is a practical solution culled from more than 20,000 fabrication cases. Every suggestion can be directly implemented, and you can trust it to help you solve real-world problems.

Would you like to confirm our fabrication capabilities in your industry, or would you rather customize highly complicated custom machined parts? Why not schedule an appointment to view our free database of successful industry case studies and directly understand our technical capabilities with one of our engineers?

Behind The Scene: What Does A Professional CNC Machining Services Process Look Like?

From here, you might be thinking about how professional CNC machining services work. Great results start with detailed processes. Professional CNC machining services go far beyond simply "machine on a machine." Every step in CNC machining affects part quality and delivery time. Below, let me take you through our typical process.

Step 1: Collaborative DFM Analysis

Immediately upon receiving confirmation of your order, we initiate a free Manufacturing Feasibility Analysis.

For example, in the case of a deep cavity part that does not allow a tool to reach directly into it, our engineers will suggest adjusting the angle of the cavity wall, which will not affect functionality but improve machinability, reduce costs, and shorten delivery time.

Step 2: Digital Twin & CAM Programming

Our engineers create a "digital twin" model of the part using professional CAM software and then generate the tool path. The path will simulate collision avoidance multiple times, which is important for machining complex custom machined parts, such as multi-curved impellers. The digital twin can avoid pitfalls in advance and reduce material waste.

Step 3: First-Article Inspection & Continuous Monitoring

First-article inspection is critical to batch quality. We will conduct full-dimensional measurements on the first piece to confirm that it conforms to the drawings.

During batch production, precision measuring tools are used, such as micrometers, and online monitoring. For example, when machining stainless steel bolts, we sample 5 pieces per hour to avoid deviations.

Figure 2: Steps to get custom parts with precision machining services. Every step of CNC machining affects the quality and delivery time of parts.

The Pursuit Of Microns: Key Technologies Powering Precision CNC Machining Services

The process is the foundation, but cutting-edge technology is the core to achieve micron-level precision. Precision CNC machining services can meet high requirements precisely because of the systematic application of these technologies.

The Revolution of Multi-Axis Machining: 5-Axis and Beyond

The core of machining complex parts is 5-axis simultaneous machining, which reduces the number of setups.

For example, when 3-axis machining is used for an irregularly shaped curved surface, 3 setups are required, while 5-axis machining can complete the process in one go, reducing errors, improving accuracy and surface finish, and enabling complex shapes that cannot be achieved by 3-axis machining.

High-Performance Tooling and Coolant Systems

High-performance tools for a strong impact: the life of 3 times than the ordinary tools in machining stainless steel, the ceramic tool is suitable for high-temperature alloy, an intelligent cooling system controls thermal deformation, for example, keeping the temperature of a part within about 25°C to ensure the accuracy of titanium alloy machining.

In-Process Metrology: Closing the Loop with On-Machine Probing

In-machine probe technology realizes auto-positioning, alignment, and measurement during machining. For example, when the big part is machined on the machine tool, the probe gap automatically measures and compensates the critical dimension, then forms a closed-loop "measurement-compensation-machining" process for high accuracy.

Who Relies Most On High-Tolerance CNC Machining Services?

High precision CNC machining services have become the backbone of various high-technology sectors. Precision CNC machining services and custom machined parts are highly crucial in these industries.

Aerospace & Defense

Parts in the aerospace and defense industries have very critical requirements, for instance, aircraft engine turbine blades use high-temperature-based alloys, are able to bear temperatures over 600℃, have ±0.01mm tolerance, and are fully traceable. We have machined such blades and they meet the standards.

Medical & Life Sciences

There are special requirements in the medical industry for custom machined parts. Surgical instruments require a Ra0.1μm mirror-grade finish to prevent bacteria, and any orthopedic implant application requires biocompatibility. Our titanium alloy joint components have passed testing and are used in medical projects.

Semiconductor & Robotics

The semiconductor and robotics industries have very high demands on environmental conditions and precision: transport robotic arms of wafers have to be dust-free and non-magnetic, components of vacuum chambers need high rigidity. The machined parts manufactured by us meet cleanroom requirements.

If you come from the aerospace, medical, or semiconductor industry, please state your industry below to receive your FREE Custom Machined Parts Solutions manual. It will include the key points of material selection and precision control.

Figure 3: Applications of CNC precision machining. CNC precision machining has a broad range of applications across many industries.

Navigating Complexity: How To Select The Optimal Process For Your Custom Machined Parts?

By now, you know which industries use these, but you may wonder how you would decide on the processing technology for your custom machined parts. Different parts are suited to different processes, choosing the right one ensures both quality and cost-effectiveness.

3-Axis vs. 5-Axis: It’s More Than Just a Number

The following decision tree helps you choose:

| Machining Type | Applicable Parts | Advantages | Disadvantages |

| 3-Axis Machining | Plate-like, block-like parts, without complex curved surfaces. For example, simple brackets. | Low cost, simple programming. | Cannot machine complex-curved surfaces or negative angles. |

| 5-Axis Machining | Complex-curved surfaces, negative-angle parts, such as impellers and irregular molds. | High precision, single clamping, and good surface finish. | High precision, single clamping, and good surface finish. |

The Milling-Turning Hybrid Solution

Milling-turning centers are suitable for shafts and disc-like parts, such as shafts with gears. Traditional processes involve separate machinings on lathes and milling machines, leading to errors due to multiple clamping operations. A milling-turning center completes all processes within one machine, thus ensuring coaxiality within ±0.005mm.

When to Combine CNC with Other Processes (e.g., EDM, Grinding)

Materials of ultra-high hardness, such as steel with hardening strength HRC60 or higher, or an internal sharp corner that cannot be reached by CNC, should be combined with other processes. For example, for a 0.1mm sharp corner inside an HRC62 mold, perform CNC machining, followed by EDM treatment, and finally grinding to achieve a high surface finish.

Not sure whether to choose 3-axis, 5-axis, or a hybrid process for your part? Simply upload a 2D drawing of your part-it can be very simple-and our engineers will provide a free process diagnosis and recommend the most suitable CNC machining center machining solution.

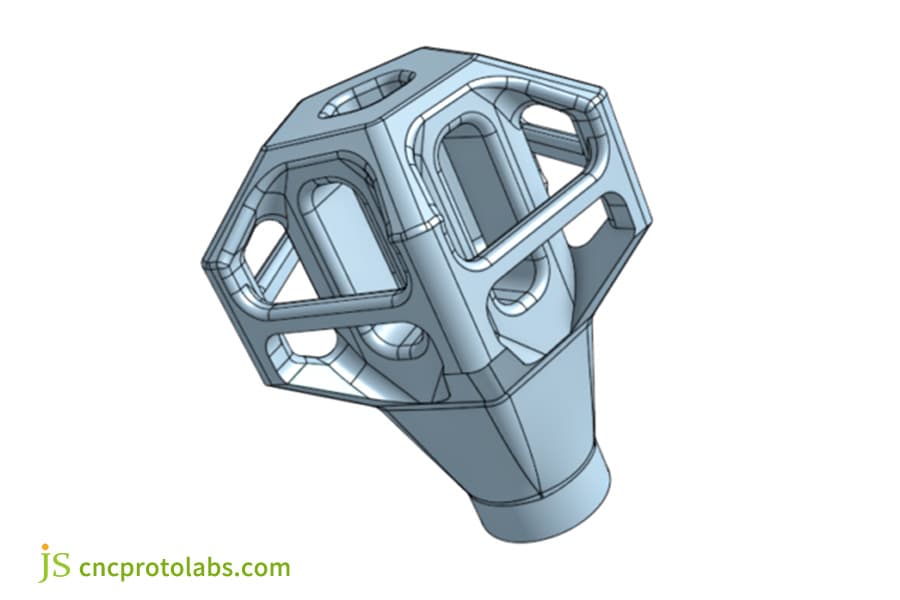

Beyond 3-Axis: Unlocking Design Freedom With An Advanced CNC Machining Center

Speaking of 5-axis machining, an advanced CNC machining center is indispensable. It is the key to design freedom, and many complex designs can only be realized with the help of a 5-axis machining center.

Advanced CNC machining centers are able to perform five-sided machining in one setup without accumulated errors. As an example, the single-setup positional error for the machining of a cubic part on all five sides is within ±0.003mm, an important factor for ultra-high precision.

Apart from that, it overcomes the limitations in 3-axis machining, machining deep cavities with negative angles, and continuous curved surfaces. Such machining cannot be carried out by 3-axis because of insufficient tool angles, while 5-axis can handle such workpieces with ease.

From a commercial perspective, while the hourly rate for 5-axis machining is higher, this is somewhat offset by the fact that its machining time for complex parts reduces from 20 hours with 3-axis to 8 hours, with lower labor and error rates to give a significantly more economic solution.

Figure 4: This component exploits the capabilities of 4+ axis machining to deliver a complex but highly machinable part for an aerospace application.

The Hallmarks Of Excellence: What To Look For In A CNC Machining Parts Supplier?

Good processes and equipment are important, but the supplier is equally important. Choosing a good, reliable CNC machining parts supplier will make projects smoother. So, how to choose?

Certifications as a Baseline

International quality certifications are the bottom line, ISO 9001 certification standardizes the process, ISO 13485 is suitable for healthcare, AS9100 is for aviation, and JS Precision has both ISO 9001 and AS 9100 certifications to meet the demands of different industries.

Does Their Machine Match Your Needs?

Pay attention to equipment from suppliers: brand, DMG (Germany), Mazak (Japan), year of purchase-our equipment has been bought within the last 5 years, which means accuracy is stable, type-whether multi-axis or mill-turn, and automation-we use robotic loading and unloading systems to increase efficiency. These factors affect quality and delivery time.

The Human Factor

An experienced team is important: even the best equipment calls for human operators. Our engineers have at least 8 years of experience in solving sophisticated problems, project managers provide full-process communication, following up on turning the potential of the equipment into a product that meets your satisfaction.

If you are in the process of selecting a CNC machining parts supplier, request our "Supplier Evaluation Checklist." This covers 8 core indicators, like certifications, equipment, and team, that will help one correctly identify whether a supplier fits their needs.

Trust, But Verify: How Is Quality Assured In Precision CNC Machining Services?

After selecting a supplier, how is the quality guaranteed? The quality of precision CNC machining services is not all talk, it is based on concrete verification methods.

From CMM to Optical Scanners

We use multiple devices for final inspection: For complicated parts, 3-D dimensions are measured by a CMM with an accuracy of ±0.001mm. A roundness meter is used for shafts in order to check roundness, and there's a roughness meter for checking surface finish. Full-size scanning is done by a blue/white light scanner to create 3D models for comparing with the drawings to confirm no deviation.

Material and Performance Certification

We provide full reports on quality: material quality assurance certificates proving compliance with the grade, heat treatment reports describing the processes applied along with hardness, reports provided in case non-destructive testing is needed, such as penetrant testing, and checks on internal cracks to ensure intrinsic quality.

Consistency Between Batches

SPC ensures batch-to-batch consistency: critical dimension trends were monitored during production, and every 10 parts machined, critical dimensions were measured. Deviations from the process are analyzed and adjusted using SPC software to prevent batch deviations.

How DFM Analysis Elevates The Best Online CNC Service?

Besides processes, technology, and quality control, the DFM analysis plays an important role, too. This maximizes the added value of the best online CNC service through engaging you with more than simple machining to help you optimize your design.

The Cost-Saving Magic of Standardizing Features

Standardized features can greatly reduce the cost. For example, in your design, the 5.2mm drill bit is used, in our standard tool library there are 5mm and 6mm drill bits. If a customized tool is used, it will increase the cost by US$20 with 3 more days in lead time.

We would recommend changing the diameter of the hole without affecting the function and reducing costs, therefore shortening lead time.

Strategic Tolerance ReviewAvoiding the "Tolerance Stack-Up"

Reasonable relaxation of non-critical tolerances can contribute to cost reduction. Our engineers review every tolerance. For example, a non-mating surface tolerance of ±0.01mm can be relaxed to ±0.05mm without affecting usability. This reduces machining time, lowers costs, and avoids extra expenses of "tolerance stacking."

Material and Process Recommendations

We recommend materials and processes based on their intended use. For example, instead of stainless steel, we would recommend an aluminum alloy for a lightweight component that reduces weight by 40%, cuts costs by 15%, and is easier to machine.

In case it needs high-temperature resistance, we will recommend high-temperature alloys and matching processes to make sure the performance will meet the standards.

Have you finished designing a part? Upload your design documents and get one free DFM analysis report in 24 hours. This report will point out areas to be optimized and help you reduce costs and boost efficiency with the best online CNC service.

Case Study: The 48-Hour Mission- From CAD Model To Flight-Ready Satellite Bracket

Instead of providing theoretical explanations, a real-life case study will give you a better idea about the capability of precision CNC machining services and CNC machining centers.

Customer Dilemma

The company is engaged in the R&D of low-Earth orbit satellites. To test for sinusoidal vibrations in the 10-2000Hz range, they require a prototype of a custom titanium alloy bracket meeting such requirements within 48 hours.

The bracket requires extremely lightweight (original design 1.2kg, needing weight reduction over 30%), reliable strength withstanding 500N tensile force, tolerance ±0.025mm, and is made of difficult-to-machine TC4 titanium alloy.

JS Precision Solution

Within one hour after the request, we formed a working team and began an emergency DFM analysis.

There were three non-load-bearing ribs in the original design, 3mm thick. Those not only increased the weight but also complicated the toolpaths. So we suggested changing them into 1.5mm, which could reach the requirement of weight reduction (estimated at 35%) while optimizing the toolpath and reducing machining time.

In the selection of the process, we directly applied the use of the German DMG MORI DMU 50 5-axis CNC machining center. This equipment has a positioning accuracy of ±0.002mm and is capable of completing the processing of the bracket's complex curved surface in one setup, avoiding multiple setup errors.

In machining, we chose dedicated titanium alloy tools with a TiAlN coating, together with a cutting speed of 60m/min and feed of 0.1mm/r.

Meanwhile, we started the high-pressure cooling system with a pressure of 70bar to solve chip removal and heat deformation problems occurring in the machining process of TC4 titanium alloy. Every two hours, engineers checked tool wear to guarantee that the accuracy of the machining was constant.

Meanwhile, the quality inspection team prepares synchronously:

Calibration of coordinate-measuring machines and vibration testing equipment was completed in advance. Full-dimensional measurement testings were done just after rolling off production lines, in which 28 key dimensions were tested and all passed. Pre-vibration testing was then conducted to ensure the parts met customer requirements.

Our Results

Eventually, we delivered the fully qualified parts in 45 hours, weights reduced to 0.78kg, and weight reduction of 35%. Verified by a third-party testing agency, under the condition of a 10-2000Hz sinusoidal vibration test, the maximum deformation was only 0.012mm, which was far below the customer's limit of 0.03mm.

The customer's subsequent feedback revealed that the bracket was fitted to a meteorological satellite in low Earth orbit and served for 6 months on board without any problem related to the structure, thereby offering stable support for the satellite data acquisition missions.

Besides, the surface finish of the parts reached Ra0.8μm, which is higher than the customer's requirement of Ra1.6μm. Later on, the customer ordered three more satellite brackets from us.

Figure 5: CNC machining titanium alloy satellite bracket

FAQs

Q1: What information does your online quotation system require?

We need a 3D model in STEP/IGES format, and 2D drawings in PDF format. Besides that, please specify the material of the part, surface treatment requirements, production quantity, and desired delivery date. Then we will be in a better position to give an accurate quotation.

Q2: What is the main difference between 3-axis, 4-axis, and 5-axis CNC machining?

- 3-axis machining has only three linear motion axes along the X, Y, and Z axes. Such a machine tool is used only for simple parts.

- 4-axis machining has an extra rotary axis, normally along the A-axis, used for cylindrical parts.

- 5-axis machining contains five related axes which are able to process complex three-dimensional spatial curved surfaces.

Q3: What materials can you machine?

We can process 6061, 7075, and so on, all kinds of aluminum alloys, stainless steel including 304, 316, and so on, and titanium alloys like TC4, TA15. Copper alloys contain brass and copper. Engineering plastics include PEEK, POM, totally hundreds of materials.

Q4: Minimum - Maximum processing size range?

We are able to process micro-holes from 0.5mm diameter like medical needle holes to cubic parts of 800mm such as large device bases. Specific details will be confirmed based on the structure and precision requirements of your parts. Please consult with our engineers.

Q5: What is "first article inspection"? Is it included in the quotation?

It refers to the full dimensional checking of the first product against the drawing requirements in mass production. First Article Inspection is a must-have procedure for a batch quality control. It's included in our standard quotation without extra charge.

Q6: How is the confidentiality of my design files handled?

We will sign a strict confidentiality agreement with you. All of the design files are put on an encrypted server, and only authorized people have access to them. They can be deleted upon your request after the project is finished so that your intellectual property is safeguarded.

Q7: How does it work if my design requires modification?

We need only the updated design files. We will do the DFM analysis, update the process plan, and quotation. After confirmation, we will update the production plan. During this period, we will communicate with you on the progress in time.

Q8: How is the delivery time usually calculated?

The delivery time consists of material procurement time (1-5 days, depending on the type of material), production programming time (2-3 days), machining time (3-15 days, depending on the complexity of the parts), and post-processing and quality inspection time (1-2 days). We will specify the time for each link when quoting.

Summary

Precision manufacturing requires that every micron represent the pursuit of excellence in each part. The choice you make in choosing any CNC machining service is not about buying the capability for machining but selecting a strategic partner to understand your needs, solve your challenges, and accompany you to success.

Equipped with rich technical capability, whole-process manufacturing capability, and a customer-first service philosophy, JS Precision is committed to becoming your most trustworthy CNC machining parts supplier.

Now experience truly professional, the best online CNC service!

Just go to the official website of JS Precision, upload your CAD files directly, and you will get comprehensive feedback within hours, including an elaborate process plan, transparent price display, and professional DFM analysis. Let's bring your perfect design together into reality!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com