CNC machining services have long permeated core verticals such as the manufacture of medical devices, aerospace, and automotive industries. Within highly competitive product development, every decision involving material selection and process optimization directly determines the product performance ceiling and cost floor.

When faced with a dazzling array of CNC machining services quotes, do you truly understand the gap between "low price" and "high value"? The choice between aluminum alloy CNC machining and high-performance CNC plastic machining has far-reaching implications beyond material unit prices.

At JS Precision, I understand what kind of pain points our clients face in striking a balance between performance and budget.

It covers the core of manufacturing, from how scientific material selection and sophisticated process design can be used to maximize performance and minimize total lifecycle costs in customized CNC machining services through proactive manufacturing collaboration. It helps you avoid falling into the "pseudo-low price" trap and make truly intelligent decisions.

Figure 1: The rotating drill bit is drilling silver metal workpieces on the CNC machine.

Key Answers Summary

| Decision Objectives | Common Misconceptions and Risks | JS Precision's Value-Driven Solution |

| Cost Control | Pursuing low-priced CNC machining services while ignoring subsequent rework, quality risks, and delay costs. | Through in-depth DFM and materials science, we optimize from the design stage, providing truly cost-effective CNC machining material selection and process solutions. |

| Precision Guarantee | Some believe that precision depends only on the brand of the machine tool and totally disregard thermal management, tooling strategy, and process control. | The core of the precision CNC machining services is in the systems engineering of the end-to-end stability. We guarantee micron-level repeatability by closed-loop manufacturing. |

| Performance Realization | Material selection may be "overkill" or "underkill," not fitting the real application scenario. | We are your extended engineering team analyzing the load, environment, and functional requirements to find the best balance between metal CNC machining and plastic CNC materials on your order. |

CNC Machining Services Material Selection: JS Precision Helps You Reduce Costs and Increase Efficiency

JS Precision has been deeply involved in CNC machining services for 15 years, focusing on providing customized precision machining solutions for global clients.

Our team has handled 5000+ projects from such industries as medical, aerospace, automotive, and electronics, and is familiar with the CNC machining characteristics of 20+ materials-from aluminum alloys and stainless steel to titanium alloys and PEEK.

For example, we once optimized the processing plan for engine brackets for an aerospace company, and the project strictly followed the AS9100D aerospace quality management system standard issued by the International Aerospace Quality Group (IAQG). Through material replacement and process adjustment, we helped the customer reduce unit costs by 30%.

We also solved the problem of low machining efficiency for titanium alloy parts for a medical equipment client, shortening the production cycle by 25%.

Our engineers have more than 8 years of average working experience in the industry and completed more than 1000 DFM optimizations to help clients avoid massive cost waste caused by unreasonable design.

This guide is a condensation of our practical experience, every suggestion has been validated by real projects, so you can refer to it with complete confidence.

Want to avoid detours with professional CNC machining services? Fill in your industry and core needs, and schedule a free consultation with JS Precision now. We will then match you with corresponding experienced engineers who provide customized preliminary material and process solutions.

How To Truly Optimize Costs With Professional CNC Machining Services?

Optimization of costs is never just about reducing labor rates, it's all about tackling the whole process from design, materials, and processes. That's the fundamental difference between professional CNC machining services and ordinary services. Most of the hidden costs of CNC machining begin with inappropriate choices in design, material usage, and process routes.

Design Efficiency is the Biggest Cost Leverage

Good design can reduce costs from the beginning. We recommend the simplification of part geometry, such as converting complicated surfaces to regular ones, standardization of feature dimensions, like applying consistent hole diameters, and avoiding unnecessary 5-axis machining. Most projects can be achieved by using 3-4 axes, which directly cuts down time by 30%-50%.

Smart Material Use and Inventory Management

This intelligent layout software can optimize sheet metal layout and raise the material utilization from 60%-70% to over 85%. Besides, keeping common materials like 6061 aluminum alloy, 304 stainless steel, and PEEK eliminates the premium that one needs to pay for when buying in small batches.

Smart Process Route Selection

Replacing EDM by high-speed milling for parts with moderate hardness improves the efficiency by more than 2 times, and integrating many small parts into one for machining before cutting reduces clamping and positioning time.

What Factors Ultimately Define Your Precision CNC Machining Services Outcome?

The core of precision CNC machining services is "accuracy," requiring control of all variables throughout the process. Many customers mistakenly believe that only machine tool accuracy determines the quality of parts, in reality, thermal stability, tool condition, and clamping methods all affect the final result.

The International Organization for Standardization (ISO) ISO 230-1:2012 Machine Tool Inspection Standard provides an internationally recognized method for evaluating the geometric accuracy of machine tools and is the foundation for establishing a full process accuracy control system.

Thermal Stability: The Overlooked Precision Killer

The workshop adopts a constant temperature design of 20±2℃. Machine tools are preheated before machining, and cooling strategies are adjusted according to material characteristics during machining (e.g., high-pressure cooling for titanium alloys) to avoid dimensional deviations caused by machine tool thermal expansion and workpiece temperature rise.

Tool Lifecycle Management

Tool coatings are chosen according to material: diamond coating for aluminum alloy, TiAlN coating for stainless steel. Wear is monitored by data, and predictive models are established and forced tool change system to assure machining consistency.

The Art of Clamping and Datum

Design specialized fixtures for complex parts that allow for the completion of multiple processes in a single clamping setup, unify process datums, reduce positioning error, and control geometric tolerances within ±0.01mm.

How To Balance Performance And Budget With Cost-Effective Materials For CNC Machining?

The key to choosing cost-effective materials for CNC machining is finding a balance between performance and cost, avoiding paying for excessive performance. Aluminum CNC machining has wide applications, but different materials have their advantages. We will recommend the optimal solution based on part function, load, and environment.

| Material Category | Common Grades | Strength | Machinability | Corrosion Resistance | Cost (USD/kg) | Applicable Scenarios |

| Aluminum Alloy | 6061 | Medium | Excellent | Good | 3-5 | Applications: Structural parts, general, housing. |

| Aluminum Alloy | 7075 | High | Medium | Medium | 8-12 | High-strength parts, aerospace components. |

| Low Carbon Steel | A36 | Medium | Good | Average | 2-4 | Structural supports, non-load-bearing parts. |

| Stainless Steel | 304 | Medium | Medium | Excellent | 6-10 | Corrosion-resistant parts, medical equipment. |

| Free-machining Steel | 12L14 | Medium | Excellent | Average | 4-6 | High-volume machined parts, fasteners. |

| Engineering Plastics | PEEK | Medium | Medium | Excellent | 80-100 | High-temperature, insulating, corrosion-resistant parts. |

The Kingdom of the Aluminum Alloys: A Rational Choice from 6061 to 7075

6061 provides exceptional value and is suitable for most general applications, while 7075 possesses strength close to steel and is recommended only for aerospace and other extremely high-strength applications.

Cost-Effective Spectrum of Steels: Low-Carbon Steel, Pre-hardened Steel, and Stainless Steel

A36 is lowest cost but requires subsequent rust prevention treatment, 4140 has no heat treatment required and can be used for medium strength mechanical parts, 304 has excellent corrosion resistance and is suitable for medical and food machinery.

Hidden Value of Free-Cutting Alloys

12L14 steel and C36000 brass increase machining efficiency by more than 30 percent while reducing tool wear by 50 percent, meaning these materials are generally less costly and therefore appropriate for high-volume turning applications.

JS Precision offers cost-effective materials for CNC machining. Upload your part drawings with performance requirements, and get free material recommendations from us. This way, you can ensure that your performances are matched, meanwhile controlling your budget and unnecessary cost inputs.

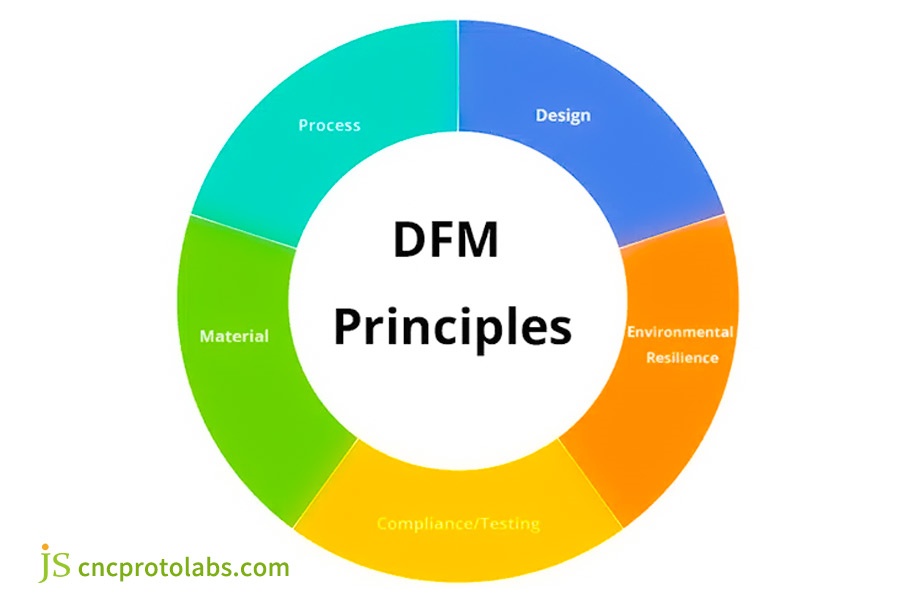

What Are The Non-Negotiable Steps In DFM For Custom CNC Machining Services?

Success of custom CNC machining services depends upon a thorough DFM process. Most customers first design their parts and then look for a manufacturing source, and most often, they have to make drastic alterations because the part does not comply with the requirements of machining, which wastes time and money.

JS Precision implements Design for Manufacturing, or DFM, at the very front end of a project.

Step 1: Early Design Review & Goal Alignment

The clarification of part functions, loads, environmental factors, and budget targets by engineers and clients prior to prototyping sets the right direction for optimization and ensures no rework occurs due to misunderstandings of the requirements.

Step 2: Feature Analysis and Modification Suggestions

Systematically review the key features including internal corner radius, recommended ≥0.5mm, aspect ratio, ≤4:1, and thin wall, metal ≥1mm, plastic ≥2mm. Provide quantitative solutions for modification and explain the effects on cost and yield.

Step 3: Tolerance Rationalization and Standardized Annotation

Guide clients in distinguishing between critical and non-critical dimensions and advise GD&T annotation accordingly to avoid blindly pursuing high precision and increasing costs.

Figure 2: Ignoring DFM can lead to costly redesigns and production delays. Applying DFM principles is key to avoiding these issues.

How To Identify And Avoid The Pitfalls Of A Cheap CNC Machining Services?

Many customers easily get attracted by low prices offered by cheap CNC machining service, but they usually overlook the compromises made by the service in materials, processes, and quality control, and thus eventually bear rework, scrap, and delay costs.

Sacrificing Material and Process Consistency:

Low-priced suppliers might use non-standard/substandard materials, like recycled aluminum alloys or even worse grades of stainless steel, or apply aggressive cutting parameters. This would lead to a shortened lifespan and unstable precision of the parts.

Squeezed Quality Control:

Without first-piece inspection, full-dimensional reports, and process inspection, quality risks are directly passed to customers, and when any problem crops up, the losses cannot be repaired.

Communication and Support Black Holes:

Inadequate professional project management and technical support lead to buck-passing in cases of a problem, further causing disputes, delays in projects, and product launches.

Want to avoid the pitfalls of cheap CNC machining service? Contact JS Precision, note "Avoiding Low Price Risks" and submit your requirements to obtain our quality control manual and understand the core standards of professional processing services.

What Are The Unique Challenges In CNC Metal Machining Of Titanium?

Though titanium alloys have extensive uses in aerospace and medical fields, the difficulties in CNC metal machining are much more significant compared with aluminum alloys and stainless steel, representing the ultimate test of technical capability.

The Dual Challenges of Low Thermal Conductivity and Work Hardening

The thermal conductivity of titanium alloys is very poor, hence the tool is worn out rapidly because of the generation of heat due to machining, and severe work-hardening occurs. We address this with a low-speed, high-feed, continuous high-pressure cooling strategy.

High Chemical Reactivity and "Tool Sticking" Phenomenon

At elevated temperatures, titanium has a strong affinity to react with tool materials, chips tend to weld to the cutting edge. Specialized coated tools like AlTiN, in conjunction with high-pressure coolant, help in optimized chip removal.

Dimensional Control Challenges Due to Elastic-Plastic Deformation

Titanium alloys have "elastic memory" that causes springback after machining. We guarantee final dimensional accuracy through compensation programming and multiple micro-finishing operations.

Need professional CNC metal machining services for titanium alloys? JS Precision has extensive experience in titanium alloy machining, equipped with specialized equipment and tools, and can effectively solve various challenges in titanium alloy machining. Send in your requirements about titanium alloy parts, and we'll provide you with customized machining solutions.

Figure 3:Due to its excellent performance, titanium is one of the most popular materials in CNC machining. However, processing titanium metal also faces many challenges.

When Are CNC Plastic Materialss Superior To Conventional Aluminum CNC Machining Parts?

Conventionally, clients always opt for aluminum CNC machining, but in numerous applications, the usage of CNC plastic materials has distinct benefits.

Lightweight with Natural Advantages in Insulation and Chemical Resistance

Materials such as PEEK and PEI have only half of the density of the aluminum alloys. They are naturally insulating, resistant to electromagnetic interference, and very resistant to chemical corrosion, hence, they have a wide usage in medical, aerospace, and chemical applications.

Low Coefficient of Friction and Self-Lubricating Properties

The friction coefficients of acetal (POM) and PTFE are very low, therefore there is no need for external lubrication. Acetal (POM) and PTFE wear more slowly than metals in transmission applications such as gears and bearing bushings, which reduces maintenance costs.

Rapid prototyping and small-batch production of complex structures

Plastics offer fast processing speeds, less tool wear, and easy modification of complex structures. In small-batch production, the costs are over 25% lower than for aluminum alloys, with a 40% reduction in cycle times.

Which Process Parameters Are Critical For CNC Machining Parts Surface Finish?

The appearance, function, and lifespan of CNC machining parts depend directly on the surface finish. It requires precision control of the parameters of cutting, tool selection, and path strategies.

The Cutting Parameter "Iron Triangle": Linear Speed, Feed Rate, Depth of Cut

The combination of these three determines surface quality: High linear speed + medium feed rate + appropriate depth of cut is suitable for aluminum alloy finishing, up to Ra 0.8. It is necessary to avoid excessively high linear speeds that create burns or excessively low linear speeds that create roughness.

The core role of tool selection: number of flute, geometry, and coating

Multi-flute end mills could guarantee a much finer cutting effect, and their sharp tips are proper for finishing. Diamond coating is proper for non-ferrous metals, while TiAlN coating is proper for steel materials in improving machining stability.

Overall Effect of Path Strategy and Stepover

Climb milling produces the best surface quality. Finishing stepovers are calculated based on the desired Ra value, such as Ra 1.6 = 5%-10% of tool diameter in conjunction with a "finishing cutter" path to remove chatter marks.

Figure 4:The surface smoothness is influenced by various factors, such as cutting tools, machining parameters, material properties, and post-processing techniques.

35% Weight Reduction, 20% Cost Reduction: High-End Equipment Casing Redesigning With PEEK Replacement And DFM

In custom CNC machining services, very often the combination of DFM optimization and material replacement yields results way beyond imagination. We once served a medical device customer whose high-end testing equipment casing faced numerous pain points, with the optimization solution reaching significant improvements.

Original Client Solution:

The client initially used 6061 aluminum alloy for aluminum CNC machining to create the casing. As a result, the casing weighed a total of 3.5 kg, affecting the device's portability.

The metal casing also slightly interfered electromagnetically with the internal precision sensors, for which an additional insulating layer and more assembling steps were required, this had a total cost of $280 per unit.

JS precision solution:

The requirements had arrived, and our engineers immediately made a detailed DFM analysis and came up with a comprehensive solution of "material revolution + structural reconstruction + process integration".

As for the materials, we suggested using 30% carbon fiber-filled PEEK as the main material. This kind of CNC plastic materials has strength near to that of 6061 aluminum alloy but has a density only half that of aluminum alloy. It thus achieves lightweight design, naturally insulates, and resists electromagnetic interference, hence, an extra insulation layer will not be needed.

We structurally redesigned the shell to be of a modular, kit-like structure without the deep cavity design of the original, which reduced machining difficulty. We standardized the dimensions of all connection features for easier assembly. We further optimized the wall thickness distribution to achieve even more weight reductions with no sacrifice in strength.

In terms of manufacturing processes, we pre-embedded inserts in key metal connector areas. By a special process, it can be reliably connected between plastic and metal without the loosening risks associated with traditional assembly methods.

Results:

The final weight of the shell was reduced to 2.3 kg (a 35% reduction), electromagnetic interference was eliminated, the accuracy of detection improved by 15%, the insulation layer assembly process was eliminated, and the cost per shell was reduced to $224 (a 20% reduction). Mass production of 1000 units can save $56,000.

Besides solving all customer pain points, this solution also enabled upgrade foundation for products, enhancing product competitive advantages in the market.

Want to realize such cost reduction and efficiency gain? Please submit your parts' requirements and pain points, and JS Precision will give you customized DFM optimization and material replacement solutions to help attain breakthroughs in both performance and cost with their custom CNC machining services.

Figure 5:PEEK carbon fiber parts

FAQs

Q1: How do I obtain an instant quote from your online platform?

Just upload your 3D file or PDF drawing in STEP/IGES format and select the required materials, production quantity, and surface treatment requirements. The AI engine, combined with our process database, will present transparent quotation within minutes.

Q2: What are typical tolerances achievable in precision CNC machining?

For the medium-sized metal parts, our standard precision CNC machining services can achieve high precision up to ±0.025mm, in some high-requirement cases, special process control can provide ±0.01mm or even higher accuracy.

Q3: Between aluminium and stainless steel, which one would be more expensive to machine in a CNC?

Generally speaking, the machining of stainless steel through CNC is more expensive. This is due to the fact that stainless steel is harder and shows severe work hardening, it therefore contributes to quicker wear of the tools and longer machining times-all raising the general cost of machining.

Q4: How can I tell if the supplier is "low-price" or "high-performance"?

You can ask them what the DFM process is, whether they will provide first-article inspection and full-size reports, how their equipment is set up and what kind of experience their engineers have with it. High-quality and cost-effective services shall clearly demonstrate the process of value creation rather than price reduction only.

Q5: Can PEEK plastic replace aluminum for structural components?

PEEK is a kind of CNC plastic materials that might replace aluminum in most of the structural parts because of its lightweight, insulation, corrosion resistance, and non-extreme impact load applications. Its superior specific strength will satisfy most of the structural requirements.

Q6: Is there a significant difference in the processing cost between Ra 0.8 and Ra 3.2 surface roughness?

The processing costs are quite different. Special finishing tools and slower feed rates for Ra 0.8 are required, and supplementary polishing processes are required in some cases. This almost raises the cost by 30%-50% over Ra 3.2.

Q7: Is it also possible to use the DFM and cost optimization services for small batches, say 10 pieces?

Of course, JS Precision offers DFM and process optimization services for orders of any batch size. Here, design-for-manufacturing optimization on small batches reduces the cost for future mass production without the waste of investments in redundancy.

Q8: What is the normal lead time from placing the order to receipt?

CNC machining parts, fabricated with standard material and in a moderately complex design, will take 5-10 days for prototypes, and 2-4 weeks for small-batch production. Specific times will be clearly stated in the quotation.

Summary

Scientific material selection, strict DFM design, and professional process optimization are the keys to an ideal performance-cost balance in CNC machining.

As an experienced CNC machining services provider, JS Precision always integrates years of practical experience into every project for customers.From suggestions on material to optimizing the process, from precision control to cost reduction, we provide one-stop solutions.

It is now more about using engineering wisdom rather than comparing prices.

Start your optimization project right away!Please visit the JS Precision website to upload your part design. You will receive not only a quote but more importantly, a "Performance and Cost Optimization Potential Analysis Report" by our team of senior engineers. Let's collaborate to redefine manufacturing value for your product.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com