5-Axis aerospace manufacturing is the key to overcoming high intensity manufacturing in aerospace. It is not only an upgrade, it is an entirely new philosophy of design and manufacturing by which aerospace parts with near artistic precision can be produced from high strength materials.

However, in the face of the diverse 5 axis CNC machining services in the market, how to understand their core values, evaluate the true cnc 5 axis price, and choose truly reliable partners?

JS Precision has world-class CNC machining 5 axis technology. This guide will show you the answers, and the way JS Precision has become your reliable aerospace-grade manufacturing supplier.

Core Answer Table

| Core Challenges | Common Misconceptions | JS Precision's Solutions |

| Achieving Ultimate Precision and Consistency | Believe that as long as the machine tool is advanced, high-quality parts can be naturally produced. | Build a complete precision assurance ecosystem from constant temperature workshop, fully closed-loop control, on machine measurement to strict first article inspection (FAI), ensuring that every 5 axis CNC parts complies with the drawings. |

| Controlling Overall Manufacturing Costs | Only comparing the unit price of labor hours, ignoring the total cost reduction brought about by process optimization. | By optimizing the manufacturability of parts through deep DFM and utilizing the advantage of five axis one-time clamping to reduce processes and fixtures, we can deliver higher value while providing competitive CNC 5 axis price. |

| Ensure Supply Chain Reliability and Compliance | It is believed that remote suppliers are unable to meet the stringent requirements for aerospace documentation and traceability. | Establish a full process that complies with the AS9100 aerospace quality management system, provide complete material certification, process records, and traceability documents, and support seamless remote auditing. |

Key Takeaways:

- The salient strength of the 5 axis aerospace manufacturing is based on the "holistic" perspective, where there is enhanced accuracy, light weighting, and reduced lead time.

- The benefit of CNC 5 axis price for the actual machining process is in the total cost of ownership for the machined piece rather than just per hour.

- When choosing suppliers, it is recommended to concentrate on certifications related to quality systems, cooperation in engineering, and their past experience with aerospace.

- It is important that engineers who have experience in 5 axis CNC machining services become involved in a design review early in a project.

JS Precision: High-Precision 5 Axis CNC Machining Service Guide

As a leading supplier in the field of 5-axis CNC machining services, the company has been actively involved with the aerospace sector for the last 15 years and has handled Aerospace orders from over 200 customers across the world.

Through our advanced technology infrastructure and worldwide service offerings, we have been providing steady and trustworthy manufacturing services to numerous high-grade aerospace projects on a regular basis. We are AS9100D certified, and our 5 axis CNC machining services have been audited successfully by many global aerospace firms.

Our team has 50+ senior engineers, having successfully processed more than 5,000 batches of 5 axis CNC parts, boasting a product quality qualification ratio of 99.8%. For instance, we fulfilled the processing of a structural component made of titanium alloy in a passenger aircraft. The achieved accuracy was within ±0.015mm, while the project cycle was reduced by 40% for the customer.

In addition to manufacturing, we offer expert design advice on design for manufacturing (DFM), ensuring our clients enhance their design through our guidance.

Want to assess JS Precision’s 5-axis aerospace manufacturing expertise firsthand? Get in touch with us today and get a complimentary feasibility analysis report and an accurate quote within 24 hours.

The Uncompromising Precision Standards In 5-Axis Aerospace Manufacturing

When it came to aerospace parts, it was imperative to consider how important those parts were in making an airplane safe. 5-axis aerospace manufacturing not only pursues dimensional accuracy, but also emphasizes absolute reliability and consistency of performance, which is also the core requirement of 5-axis CNC machining.

Stringent Specifications for Linearity and Key feature Geometric Tolerances

The key feature tolerances for general aerospace structural parts and aerospace engine parts require ±0.025mm and ±0.05mm. Other geometric tolerances regarding flatness and perpendicularity require even stricter specifications. This is considered as an important aspect of ensuring the quality of 5 axis CNC parts.

The Secret to Surface Integrity: More Than Ra Values

In applications such as turbine blades, which are subject to high cyclic fatigue loading, surface roughness (Ra) values constitute only the first level of consideration.

It is essential to manage values associated with surface residual stress and modifications in the microstructure, which form the basis of ‘surface integrity’, and such values affect the fatigue life of the part directly. This is the core competitiveness of 5-axis aerospace manufacturing and an important reason why customers choose 5-axis CNC machining services.

Material Consistency Certification & Full Traceability

The raw material supplies for aerospace parts require accompanying data on comprehensive melt flow indices, performance test results, and certificates of compliance. Full traceability from receipt into storage through manufacturing is required. This is necessary for identifying specific areas with potential issues—a crucial consideration in 5-axis aerospace manufacturing.

How 5 Axis CNC Machining Services Guarantee Part Integrity?

Quality requires the presence of the complete "ecosystem" for manufacturing. The best 5 axis CNC machining services offer the ecosystem for 5 axis CNC parts to be of the highest possible quality.

Environmental Control

Precision machining cannot be performed under varying or uncontrolled environments. For advanced precision 5 axis CNC machining, a constant temperature and humidity-controlled environment (20°C ± 1°C) with independent, vibration-resistant foundations must be provided, which forms a basis for reliable 5-axis CNC parts manufacturing.

Closed-Loop Manufacturing and In-Machine Measurement

Advanced 5-axis machine tools provide closed-loop feedback and are equipped with in-machine probes that make real-time compensation for the toolpath and positioning errors possible.

Preliminary measurements can be taken after the machining of key features without disassembly, thereby providing a "machining-inspection-compensation" closed loop, which can significantly improve the first-piece success rate and batch consistency.

Systematic Quality Documentation

In respect to the MBD drawing interpretation, creation of FAIR reports, process logs, and final release certificates to IAQG 9102 standards, every phase develops organized electronic records. This quality information flow is the fundamental proof that the parts are fit for aerospace standards.

Would you like to know more about the detailed quality control process of 5 axis CNC machining services? Download our free Quality Management White Paper, which details the entire process of quality control measures from the raw material inspection stage to finished product delivery. This helps in fully grasping the key points of quality assurance for 5 axis CNC parts.

Figure 1 Five axis CNC machining technology can complete the processing of complex parts in one clamping, minimizing assembly errors and reducing scrap rates to the greatest extent possible.

A Realistic Look At CNC 5 Axis Price In a Global Context

Knowledge about the constituents of CNC 5 axis price is imperative for decision-making. The price effectiveness of 5 axis CNC machining services is quite disparate across different geographic locations within the global supply chain network.

Price Composition: The Sum of Technology, Time, and Rigor

The quotation for CNC machining 5 axis mainly includes: High depreciation costs for machines in operation, CAM programming and simulation complexity, Machining times because of precision involved, and Quality assurance and documentation costs, which are quite high in the aerospace sector.

Made in China Price Equation: Cost Factors in a State of Technological Equalisation

JS Precision and other leading Chinese manufacturers have already caught up with the West in terms of CNC machining 5 axis equipment, software, and processes. Thus, the benefit of the cnc 5 axis price lies in improved operating costs and the resultant cost-effective supply chain. This makes the standard 5 axis CNC machining services rather competitive.

Total Cost Analysis

To assess the cnc 5 axis price, it is important to determine the total cost of ownership, considering the quote, delayforloss, and rework costs. Companies quoting ever so slightly higher but being more reliable usually end up having less total cost.

Below is a cost comparison for 1000 aerospace 5-axis CNC parts:

| Cost Item | Low-Cost Unstable Supplier | High-Quality Reliable Supplier (e.g., JS Precision) |

| Initial Quote | $150,000 | $170,000 |

| Rework Costs Due to Quality Issues | $30,000 | $30,000 |

| Project Delay Losses | $40,000 | $0 |

| Total Cost | $220,000 | $175,000 |

Do you want to obtain a transparent and detailed CNC 5 axis price breakdown? Please enter your project details on our official platform, and our cost accounting team will perform a detailed analysis and give you a Total Cost of Ownership report so you can make informed and economic decisions.

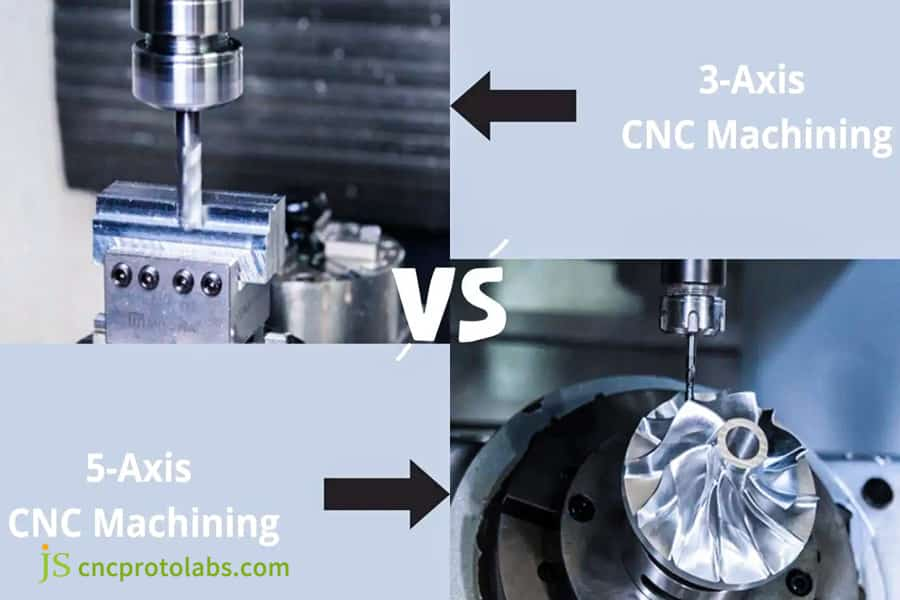

What Is The Difference Between CNC Machining 5-Axis And Traditional Three-Axis Machining?

The transition from three-axis to five axis is not just about adding two rotation axes, but a paradigm shift from "segmented manufacturing" to "holistic creation", and the CNC machining 5 axis has significant advantages.

Overcoming Continuously Complex Surfaces

Deep cavities, negative angles, and continuously complex surfaces such as wings and bladed discs are very challenging for 3-axis CNC machining.

However, in CNC machining 5 axis, the cutting tool direction is continuously varied so that the ball end mill is positioned in the best cutting position, thus completing the process in one pass, which is aerodynamically efficient.

Process Integration: From Multiple Clampings to "One-Step Forming"

Conventional machining involves multiple clamping and positioning processes. These processes are prone to accumulated errors. 5-axis machining involves the machining of the entire features in one clamping process, except for the bottom surface. The main reason for choosing 5 axis CNC machining services is that it prevents errors altogether.

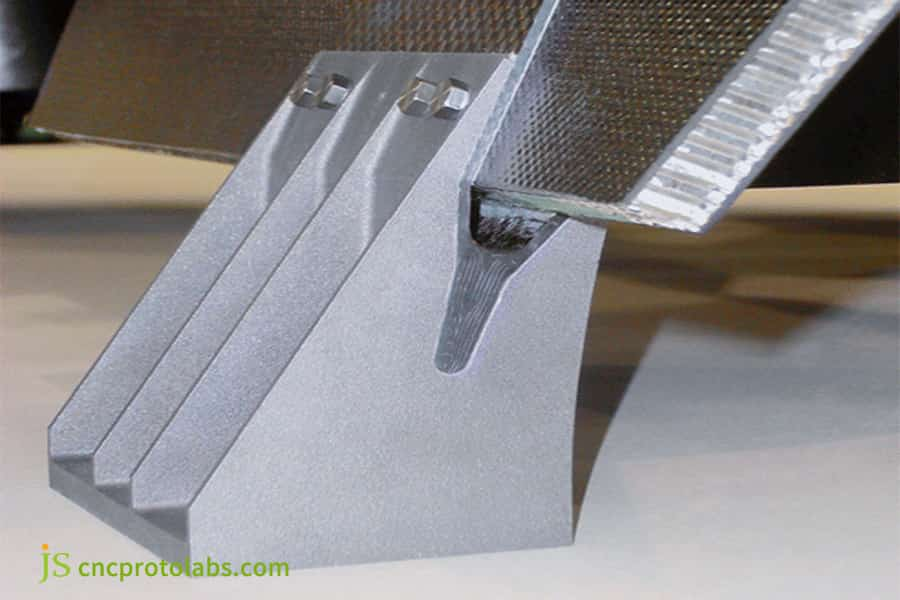

Realizing Lightweight Construction and Functional Integration

Topology optimization design made possible by 5-axis technology enables ‘less material and greater rigidity.’ Such intricate geometries are either impossible or difficult to produce as a whole via conventional processes but are manufactured as complete 5 axis CNC parts, thus yielding a lighter weight due to material reduction.

Are your parts processing facing the bottleneck of traditional three-axis machining? Consult our technical advisor to describe the structural features and machining difficulties of your parts, and we will tell you how CNC machining 5 axis can help you efficiently solve problems.

Figure 2 Both three-axis and five axis machine tools can achieve high-precision machining, but five axis machine tools often outperform in surface smoothness of complex geometric shapes.

Is Your Flight-Critical Project a Candidate For 5-Axis Aerospace Manufacturing?

Not all aerospace components are candidates for 5-axis machining. You could easily assess project viability and choose suitable 5 axis CNC machining services for your project needs by examining the following:

Feature List: If you need these, please consider five axes

Components with two or more characteristics mentioned below provide even more benefits to economy and functionality in 5-axis aerospace manufacturing:

- Multi-directional holes or bevels.

- Deep cavities or complex internal structures.

- Freeform or composite surfaces.

- Strict overall geometric tolerances.

- Lightweight, integrated design.

If two or more criteria are satisfied, then the chances are that there are greater benefits of the process in terms of cost and functionality, and the 5 axis CNC parts would be better suited to meet your requirement.

Material Considerations: When dealing with difficult-to-machine materials

High-temperature alloys and titanium alloys are prone to cutting conditions when being machined. The five-axis machining process provides optimal contact angles for tools during cutting, thus, smooth cutting is done with low cutting forces and low generation of heat. This is one of the important benefits derived from 5-axis CNC machining services.

A shift in design thinking from "component" to "part":

The core adaptability lies in the design phase: merging multiple assembly parts into whole 5 axis CNC parts, eliminating the weight of connecting parts and improving structural efficiency, which is a five axis machining tailored design that can maximize project value.

Figure 3 The main reason for choosing five axis machine tools is that they meet the high-performance industry standards for aerospace CNC machining.

Can You Produce 5 Axis CNC Parts To NASA Standards?

The highest level of ability for any 5 axis CNC machining service is to meet the requirements of NASA standards. At JS Precision, we have the experience needed to manufacture 5 axis CNC parts according to the standards.

Beyond AS9100: Special Processes and Material Control

The standards issued by NASA or the aerospace industry, based on AS9100, specify more particular requirements for special processes such as heat treatment and welding. The standards include compliance with the requirements of SAE AMS6400 A for control of material purity and stress corrosion sensitivity. JS Precision has all the testing capabilities for certifications.

Impeccable Documentation and Traceability

Aerospace eng ineerings demand "record full, traceability full," thus entailing a comprehensive Production History Record with melt numbers for raw material, process information, and inspection data. The electronic quality management system is a basic requirement and integral part of 5-axis CNC machining offered by JS Precision.

Cleanrooms and Contamination-Free Assembly Environments

Components of precise optical and propulsion systems need post-processing in designated cleanrooms to avoid particle contamination. JS Precision maintains a Class 1000 cleanroom and is competent in handling aerospace components of the highest order.

35% Weight Reduction, 50% Faster Delivery: A Breakthrough In Five-Axis Manufacturing Of Satellite Titanium Alloy Payload Supports

Background:

There was a requirement to develop a high rigidity, light-weight titanium alloy (Ti-6Al-4V) payload carrier for a low Earth orbit satellite.

The original design was assembled from multiple aluminum and titanium parts using dozens of fasteners, with overall weight and cumulative tolerances being the main challenges. Additionally, the high cnc 5 axis price and long lead time were due to the processing and assembly of multiple parts.

JS Precision Solution

Integrated DFM Reconfiguration:

The engineering team at JS Precision suggested the redesign of the component as a topology-optimized solid structural shape in titanium alloy instead of the aluminum alloy used before. The creation of biomimetic ribs on the stress paths further enhanced the component's stiffness. This proved to be the basis of the subsequent 5-axis aerospace manufacturing.

Machining Strategy on Five Axes:

There were many deep and narrow curved cavities in our new design, and our machining strategy involved only one fixing step using CNC machining 5 axis. In order to achieve high-quality machining on 5 axis CNC parts, our strategy involved controlling heat generation and deformation when machining titanium alloys on five axes.

End-to-End Quality Control:

Ensuring aerospace quality requirements are strictly followed through AMS certification of raw materials, process management, 3D CMM inspection of the first piece, and delivering a comprehensive traceable documentation pack.

Results

- Large Weight Reduction: The final unit now weighs 35% less than the original assembly, making it heavier as far as payload is concerned.

- Performance Leap: Stiffness improved by more than 200%, and the product passed the launch vibration tests.

- Overall Cost and Efficiency Optimization: Considering the unit CNC 5 axis price is not low, by canceling all assembling component costs, assembling time, and connectors' weight, it was a cost-equivalent project. More importantly, the total delivery cycle saved as much as 50% and thus saved critical time for the satellite launching window.

Customer Testimonial: "The JS Precision team not only provided manufacturing services but redefined the boundaries of our understanding of lightweight structural design."

Looking for similar cost reduction and efficiency gains for your aerospace projects? Contact JS Precision to learn more about their success stories in 5-axis aerospace manufacturing, and let our team customize a solution for you.

Figure 4 Titanium alloy bracket for satellites

Selecting Your Partner: Key Criteria For Evaluating 5 Axis CNC Machining Services

With so much competition, choosing a cnc machining 5 axis services partner becomes more critical than comparing 5-axis CNC prices. The core dimensions of evaluation will include:

First Qualification: Certifications and Proof of Experience

The primary verification is the AS9100 aerospace quality system certification, which is the fundamental guarantee for the quality of 5 axis CNC parts. At the same time, reviewing past aerospace project experience, successful cases are the best proof of capability, and JS Precision can provide relevant case references.

Engineering Depth: Proactive DFM and Collaboration Capabilities

In the inquiry phase, one can see if the engineering staff is proactive about providing design optimization recommendations. A good supplier should be a partner to the engineering department, anticipating manufacturing difficulties and costs. JS Precision engineers possess substantial knowledge in DFM services.

Transparency and Culture: Communicative Openness and Quality Data Evaluation

The timeliness and professionalism of the communication, as well as the willingness to share data on the quality of the documents produced, must be evaluated. JS Precision has placed importance on the transparency of the communications exchanged, introducing their diligent processes while safeguarding intellectual property rights.

FAQs

Q1: What is the best possible tolerance in a 5-axis machine?

In the best possible conditions (size small, parts stiff), the possible tolerance limits for line tolerances are 0.0125mm. However, these tolerances must be assessed in the context of the design of the component. In aerospace applications, the usual requirement is to have the tolerance within the limits of ±.025mm and beyond. JS Precision is able to provide the required satisfaction.

Q2: Do you hold AS9100 certification?

Yes, JS Precision has AS9100D aerospace quality management system certification. This is the minimal requirement for offering 5 axis CNC machining services to the aerospace industry. We are able to produce certification for customers when required.

Q3: How do you prevent deformation in aerospace thin-walled components during machining?

There are several techniques that we adopt for preventing deformation in thin-walled aerospace components during machining. These techniques are symmetrical machining, layered milling, optimum machining parameters, flexible machined fixtures, or compensation through in-machine measurement.

Q4: Do you have original manufacturer certification documents for these materials?

Of course. All our suppliers for aerospace-grade materials are qualified suppliers, and we receive a complete original manufacturer material test report with each shipment to ensure that our material specifications are met.

Q5: Are there risks involved in shipping aerospace parts from China?

Yes. To ensure complete safety, we provide customized anti-static and shock-resistant packing. In addition, we provide complete tracking services in logistics. With years of experience in international shipments of precision aerospace parts, we ensure safe delivery.

Q6: Does the quotation include all costs of quality inspection and documentation?

Yes, all the costs associated with the quality activities of First Article Inspection (FAI), In-Process Quality Control (IPQC), and Final Inspection Report (FCR) would automatically be included in the professional aerospace quotation.

Q7: What are some major benefits offered by 5 axis machining services in China over elsewhere?

The key benefit is: "the golden balance of technology, efficiency, and cost," particularly incorporating world-class technology/equipment knowledge, the ability to respond quickly in the supply chain, engineering collaboration knowledge in-depth, and harnessing the large advantage on total costs, enabling the capability to offer 5 CNC machining at a low cost for the customer.

Q8: In what respects does the provision of five axis machining services by China remain superior to the rest of the world?

The in-absoluto-strength is "in the golden balance of technology, efficiency, and cost": world-class equipment and process knowledge, flexible response to the value chain, deep collaboration support in engineering, and substantial overall cost advantage.

Summary

In terms of high precision and high reliability, when it comes to aerospace manufacturing, 5-axis aerospace manufacturing has ceased being an alternative and is now an essential service for success.

The company has expertise in precision manufacturing with an AS 9100 compliant process powered by globally leading 5-axis CNC machines. We are renowned for providing top-notch 5-axis CNC components ranging from mission-critical structural components to main engine components for aerospace for over a hundred valued aerospace customers.

Your future flight mission can be built on a stronger, lighter, and more intelligent production basis.

Contact with JS Precision aerospace team today for the submission of your preliminary designs or technical specifications.

In addition to receiving a thorough assessment of CNC 5 axis price and solutions, you also get an opportunity to participate in an indepth conversation with an engineering expert who knows aerospace manufacturing inside out. Join me in delving into the possibilities of lightweighting.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com