Plastic CNC machining plays a vital role in product development, which is being done at a rapid pace. As a result, plastic parts have become the number one choice of innovations due to their lightness, non, corrosive properties, and almost unlimited design possibilities.

However, every material poses a different challenge when it comes to processing, which in turn affects the performance, looks, and price of the CNC machining part.For example, a plastic part made of ABS might experience deformation and melting during processing, while a nylon gear might have wear and tear issues.

The decision of choosing a partner should not be limited to machine tools only, but rather the combination of materials science and process technology.

In this article, the author addresses the core issues of high, precision plastic machining and reveals how process optimization and supplier collaboration can assure quality and keep CNC machining price at a reasonable level.

It illustrates how JS Precision, through a materials knowledge base and digital processes, can be your stable and reliable partner in providing high, precision CNC machining services.

Key Answer Summary

| Core Decision-Making Challenges | Common Misconceptions and Risks | JS Precision's Integrated Solution |

| Ensuring Consistent Quality in Small Batches | Reliance on operator experience and fluctuations in process parameters lead to batch-to-batch variations. | Establishing a dedicated materials and process database, verifying the performance of each batch of incoming materials, and employing standardized, parameterized machining procedures ensure repeatability. |

| Controlling the machining costs of complex parts | Simply comparing unit prices ignores the impact of design manufacturability, material utilization, and post-processing necessities on total cost. | We offer free, in-depth DFM analysis to optimize part geometry to reduce machining time and recommend the most cost-effective material-process-post-processing combination. |

| Achieving ultra-high precision and perfect appearance | Believing high precision relies solely on machine tools ignores the decisive role of material internal stress, thermal effects, and tooling strategy in the final result. | We apply multi-stage machining strategies (e.g., roughing-stress relief-finishing), combined with specialized tools and cooling solutions, to simultaneously ensure dimensional tolerances and surface integrity. |

Key Takeaways

- The key to quality in plastic CNC machining is in understanding and controlling the unique machining responses for materials: for example, the absorption of moisture by nylons and the brittleness of acrylics.

- Early collaboration on DFM has a much greater impact on cost and risk control than later negotiations on price.

- Evaluate suppliers based on their material-specific process libraries and problem-solving case studies for various plastics.

Why Trust JS Precision's Precision Plastic CNC Machining?

In the plastic CNC machining industry, trust can only be established through capabilities and experience. JS Precision has deeply participated in the processing of CNC for many years and always insists that material properties and process optimization are the core competitiveness rather than merely equipment.

We follow several authoritative industry standards. Among them are ISO 230 for machine tool precision inspection and ISO 13485 for medical device processing. These above-mentioned standards certify that our products have quality, including the calibration of the machine tool performance, verification of precision machining accuracy, and quality control of special industries.

In order to tackle the difficulties in machining various materials such as ABS, nylon, acrylic, we have set up a specific process parameter library in key areas like speed, tool, and cooling technology to ensure the correct machining support for each CNC machining part.

We have rich experience in processing complex components, and we specialize in high precision cnc machining and small-batch production. In our "inspection of incoming materials, standardized processing, and inspection of the entire processing procedure," we have reached the same consistency as mass production.

Whether it is matters of optimizing the yield rate of medical-grade acrylic components or the management of melting in precision components made from nylon, we have shown through our success stories that the application of expert plastic CNC machining services is more than just providing solutions to problems, but also allows for the reduction of costs.

Want to verify our capabilities? Submit your part drawings and material requirements, and JS Precision will provide a free, customized DFM analysis report, offering process optimization suggestions based on your application scenario, allowing you to intuitively experience the value brought by a professional team.

How To Ensure Quality Consistency In Small-Batch Plastic CNC Machining?

By systematically controlling the process in small-lot production, one can realize the consistency of quality. The key point is that experience should be transformed into repeatable and verifiable standardized data, which is the essential logic for the stability in the quality of plastic CNC machining.

Building a Material Process Parameter Library

Different plastics have different optimal cutting parameters, tools, and cooling methods. JS Precision will establish validated process parameter packages for commonly used materials, fine-tuning them for grades to ensure an optimal starting point for processing.

Implement Incoming Material Inspection and Batch Management

Properties in plastics are affected by batch, moisture content among others. Consistency begins with the raw materials. JS Precision conducts tests for performance on every batch of incoming materials, records batch numbers, and achieves full traceability.

Standardised Clamping and Machining Sequences

We design dedicated, low-stress, flexible fixtures to avoid clamping deformation.

Standardized machining sequence documents are developed for each typical CNC machining part (such as thin-walled shells and precision gears), including tool usage sequence and measurement timing, in order to guarantee the identical results when different operators execute the same procedure and eliminate human error from the process.

Mastering Thin-Wall Parts: Deformation Control In Abs CNC Machining

The materials used in the industry are in high demand, but in the processing of ABS CNC machining, there can be deformation in thin-walled products as a result of the release of stresses inside the materials as well as heat generation during machining.

Reducing deformation during machining can therefore involve interventions at various levels from design to machining, in order to guarantee accuracy in CNC machining part.

Clamping Strategy Optimization, Cutting Force Control

Do not exert high clamping pressures in thin-walled regions, or use a vacuum chuck or dedicated fixture to better distribute the pressure. Minimize elastic deformation by using shallow cut depths and rapid feeds.

Efficient Thermal Management and Stress Relief

Though ABS is less heat-sensitive, localized heating can cause deformation when done continuously. In ABS CNC machining, sharp cutters and proper removal of chips are required to avoid the generation of heat. A series of processes involving removal, with natural cooling in between, can be employed for parts with complicated designs to relieve stresses in the parts.

Clever Machining Sequence Design

Machine from the inside out, symmetrically. The rationale here is to machine the cavities inside prior to machining the outer surface as well as to divide machining the outer surface last. In symmetric components, symmetric regions machined alternatively will provide symmetry to the stresses as well as assist to prevent deformations during ABS CNC machining.

Are you struggling with deformation problems in thin-walled ABS components? Just provide us with your part dimensions, thickness, and required accuracy, and our engineers will devise a customized machining solution exclusively for you. By employing scientific methods of clamping, cutting, and stress relief, we can remove your deformation problems with ease.

Figure 1 ABS is a thermoplastic widely used in CNC machining due to its excellent performance and cost-effectiveness.

Beat The Heat: Strategies To Prevent Melting In Nylon CNC Machining

The difficulty in machining nylon CNC machining lies in its lower melting point and lower thermal conductivity. The heat that is generated during machining tends to accumulate easily, resulting in softening, melting, or even sticking to the cutter in some cases, thereby greatly affecting the surface finish qualities and inaccuracies in dimensions.

Ranges vary with the types of nylon, while the adaptation point for machining also varies as indicated in the table below:

| Nylon Grade | Core Processing Characteristics | Key Process Adaptation Points |

| Nylon 6 | Low melting point (215-225℃), strong hygroscopicity, prone to deformation during processing | Thorough drying before processing, using medium-high speed, medium feed, and high-pressure air cooling preferred |

| Nylon 66 | High melting point (250-260℃), good rigidity, slightly higher cutting force required | Appropriately increase depth of cut, use sharp carbide tools, and ensure smooth chip removal |

| Nylon 1010 | Good toughness, excellent wear resistance, prone to tool sticking during processing | Use high speed, low feed, and dedicated tools with polished chip removal grooves |

Special attention should be directed to devise a strategy for overcoming the melting problem in nylon processing, which would involve forming a combined solution from three dimensions: tools, cooling, and parameters, according to the above characteristics.

1. Sharp Tools: Provide brand-new, dedicated plastic end mills. Achieve shearing cutting to reduce the amount of heat generated at the source.

2. High-Pressure Air Cooling: No cutting oil is used, instead, cooling is done with dry, high-pressure air that acts to remove chips and keeps the machining area clean.

3. Optimized Parameters: A high speed reduced to a suitable feed rate produces flaky chips, without frictional heat or vibration.

Constant melting and tool sticking when working with machined nylon parts? Fill in your nylon CNC machining needs now! JS Precision will match you with a customized process solution, using specialized tools and scientifically cooling strategies to completely solve the problem of accumulation of heat, guaranteeing the precision and efficiency of parts machining.

Mitigating Chipping And Cracks In Acrylic CNC Machining

Acrylic (PMMA) has a hard and brittle texture, and acrylic CNC machining is prone to edge breakage and microcracks. Optical grade surface processing is more difficult and requires precise control from three aspects: cutting tools, processes, and post-processing.

The Decisive Role of Tool Selection: Use single- or multi-flute spiral end mills with polished cutting edges. Avoid double-flute straight flute end mills. For finishing, use diamond tools or coated tools for smooth cutting.

Exquisite refinement of process parameters: Precision machining utilizes high speed and slow feed in conjunction with rounded tool entry and exit to avoid vertical cutting and thereby minimize the chance of chipping.

Magic at Support and Post-processing: Fragile areas will be supported with materials or backstops, after machining, micro-cracks are removed through flame polishing or chemical polishing, making it transparent and lustrous again.

Figure 2 CNC machining provides a reliable and safe way to manufacture acrylic parts with high precision.

Pushing The Limits: Achieving ±0.01mm In High Precision CNC Machining

Realizing metal grade ultra-high tolerances (such as ± 0.01mm) on plastics is the ultimate test for machine tools, processes, and environmental control systems, and is also the core goal of high precision CNC machining.

According to the ISO 2768 precision machining tolerance standard, this is far from just inputting a coordinate, but requires precise control of the entire chain from equipment, process to detection.

Stability is the Cornerstone of Precision: The selected CNC machine tools have high rigidity, and comprehensive preheating coupled with constant temperature and humidity operation eliminates dimensional drift that may be environmentally induced.

Micro-managing of Tools and Cutting: Using high-precision tools, minimal radial depth of cut, and "climb milling" techniques, final measurement is made only after the parts have cooled down to room temperature to avoid temperature errors.

Full-process measurement and compensation: using a "machining-measurement-compensation" closed-loop control system, check the key dimensions with machine measure or CMM, feed back the deviations, and perform compensations on them to ensure the access of tolerance requirements.

Ultra-high-precision plastic parts (±0.01mm) are developed. In JS Precision, there is professional high precision CNC machining equipment and a mature closed-loop control process to realize customization of processing solutions according to your needs. Free precision feasibility analysis can be carried out to meet the high precision needs of customers.

Decoding The Cost Drivers: What Influences Your CNC Machining Price?

Understanding the composition of CNC machining price helps in making economic decisions. Plastic CNC machining costs are mainly influenced by materials, machining time, and complexity.

Raw Material Cost and Utilization: Engineering plastics are far more costly than general-purpose plastics. Raw material cost is a prime factor, and the rate of scrap directly influences the material cost, which will clearly be reduced by layout optimization.

Machining time costs exactly the same as cost. The part’s complexity, precision required, programming difficulty, tool usage, and time required are determined by the part’s complexity itself. Five-axis machining of complex curved surfaces increases the cost of time involved and also significantly influences the cost of CNC machining.

Post processing and quality assurance activities add value. Examples of post processing, such as sandblasting and polishing, as well as inspection activities requiring high accuracy, add to the costs and are factored into the cost of CNC machining.

Case Study: From 55% Scrap Rate To 98% Yield——Conquering a Medical Fluidics Acrylic Window

Challenge: The Ultimate Test of Sealing and Reliability

The manufacturer of an in-vitro diagnostic device produced an acrylic viewing window for medical-grade liquid solutions. This CNC machining part involved intricate microchannels, and the demands were strong optical clarity (Ra < 0.8) and resistance to sterilization and fluid pressure.

Historically, the supplier had an average failure rate test for leakage at 55% because of edge chippings and micro-cracks, incurred unstable CNC machining costs.

JS Precision’s Medical Grade Acrylic Solution

1. Targeted Tooling and Cooling Solution:

The properties of medical-grade PMMA dictate that in the finishing stages, a single-flute spiral end mill optimized for acrylic CNC machining procedures should be employed. Additionally, the use of low-temperature dry air at -10°C cooled the entire process, eliminating any internal stresses that result from accumulated cutting forces.

2. Phased Machining and Stress Relief:

For this project, the phased machining process is categorized into three steps. These include rough machining, the process whereby the machined piece is left to stand before the final machining. There is also the stress relief step. Here, the machined piece is allowed to stand.

3. Biocompatibility Followed by a post-processing step:

The inner walls of all the flow channels and sealing surfaces are precisely milled by high-gloss diamond milling. The external area of the observation window undergoes flame polishing. A medical-grade cleaning and packaging procedure is completed at the end.

Results:

- The yield was raised from 55% to over 98%, and the first-pass rate for the leak tests improved considerably.

- Reduced overall manufacturing costs by 35%: removed batch scraps and minimized CNC machining costs through optimization.

- Time to delivery: Reduction in delivery time of 45%, from 3 weeks to within 10 working days.

Facing similar high-difficulty acrylic CNC machining challenges? Contact JS Precision. We will leverage our successful case experience to customize a solution tailored to your needs, helping you improve yield, reduce costs, shorten timelines, and ensure smooth project progress.

Figure 3 CNC machined medical grade acrylic (PMMA) plastic window

The Partner Selection Guide: Choosing Your Ideal Plastic CNC Machining Service

Selecting a plastic CNC machining services provider is just like partnering with an R&D firm. Besides the equipment and costs involved, engineering support competence, the culture of excellence, and professionalism in project management become key considerations, as they directly influence the excellence of CNC machined parts and the effectiveness of project development.

Evaluate their Knowledge in Materials and Processes

When evaluating suppliers, it is necessary to inquire about the processing solutions for target materials (such as nylon CNC machining), review similar cases and samples, and verify the completeness of their material process library.

Examine the depth and proactivity of its DFM feedback

Send preliminary design to investigate whether the supplier actively provides DFM improvement suggestions (reducing deformation, cost reduction, etc.). Passive processing suppliers cannot optimize the total cost of ownership, while high-quality plastic CNC machining services can avoid risks in advance through DFM collaboration.

Verify its Quality Process and Communication Transparency

Review their quality control points (First Article Inspection (FAI), In-Process Quality Control (IPQC)) and quality control measurement tools. Also, inquire if there is an established project communication process: whether there is an allocated project manager, project progress update communication, and project error communication process, resolution, and completion.

An open communication process is the only assurance of on-time project delivery and an important aspect of shortlisting any Plastic CNC Machining service provider.

In search of a trustworthy plastic CNC machining solution? JS Precision offers a vast material and process knowledge base, collaborative DFM capabilities, and an open-and-shut quality control process. Schedule a consultation with us today and gain a free project evaluation and design, putting you at ease with regards to trusting all your CNC machining part with us.

Figure 4 The most competitive CNC machining partner is no longer an independent processing factory, but a multi process manufacturing supplier capable of handling all major links from raw materials to finished product assembly.

FAQs

Q1: What do I need to provide in order to obtain an exact quote for plastic CNC machining services?

It is preferred that a 3D model in STEP or IGES file formats, along with PDF drawings highlighting critical tolerances, surface treatment, and materials, be supplied. This will enable the vendor to calculate the CNC machining price.

Q2: What are the typical tolerances for plastic parts?

The tolerance levels for commercial-grade products are typically ±0.1mm, while that for precision grades can go down to ±0.025mm, and for high precision CNC machining, it can reach ±0.01mm for selected materials and advanced machines.

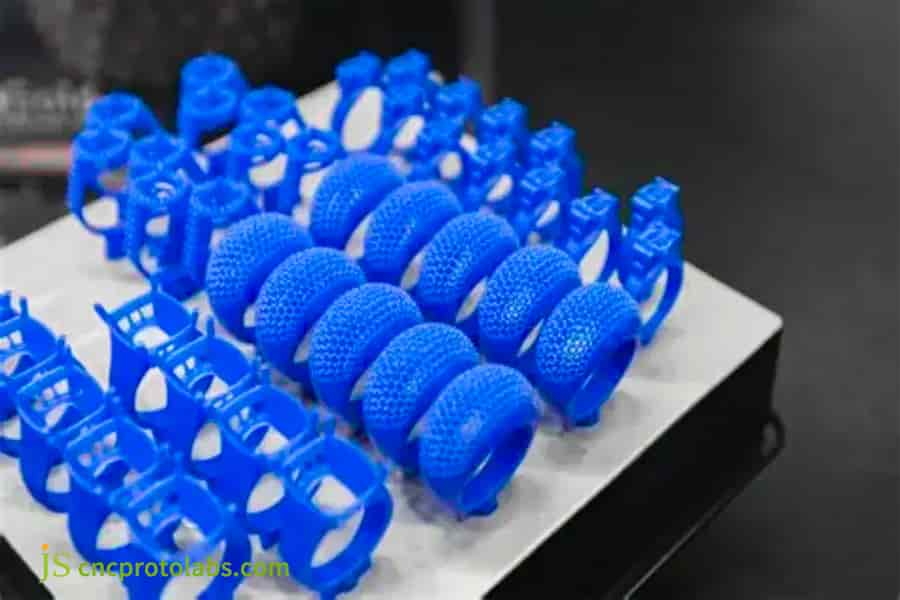

Q3: How do I need to compare and contrast CNC machining and 3D printing for plastic components?

Plastic CNC machining is appropriate for functional test parts and small-batch productions with enhanced material properties and higher precision. 3D printing is appropriate when it comes to extremely complex models, small-batch productions, or verification of designs. The selection of one method of manufacturing over another depends on requirements.

Q4: What can be done for my plastic components that tend to warp when machined?

Warping in plastic CNC machining can be well controlled by using optimized design (homogeneous wall thickness), appropriate materials (materials with low residual stress), and staged machining with stress relief.

Q5: Is the price of small-batch plastic machining very high?

The cost of plastic raw materials tends to be relatively lower when compared to metal materials in general. Regarding small-batch CNC machining services, the cost depends on programming and preparation time, but this factor can easily be managed by optimizing designs, such that it won’t result in higher costs.

Q6: How much lead time does plastic parts generally require?

For CNC machining parts that are generally complex, the normal lead time to ship from document confirmation can range from 5 to 10 working days, depending on the quantity and any post-processings required. The turnaround time for complex parts will naturally take longer.

Q7: There are thin-walled areas in my design. Will that be a problem?

Yes, this is indeed an expertise of ours in CNC machining. We will analyze this particular design and ensure that there are no problems with the thin-walled areas. We can prevent any deformations or chipping.

Q8: How do you protect plastic parts from scratches during transportation?

The anti-static foam, PE bags, or the plastic pallets can be made separately to individually package the parts depending on the surface requirements for the CNC machining part. This ensures the parts are not scratched during shipment.

Conclusion

The difficulties of plastic machining serve as the benchmark for professional value. Excellence in CNC machining can first start with appropriate regard for the properties of materials, with its very essence in delicate attention to detail in machining factors, which is essentially a question of directing the actions at the microscopic scale for the desired performance and aesthetics.

For us in JS Precision, plastics machining involves a blending of materials science and precision tech.

We have mature process packages that can readily solve some challenging areas such as deformation in ABS CNC machining and melting in nylon CNC machining, among others. Additionally, early-stage engineering collaboration enables us to work with you in minimizing risks and costs associated with your creative ideas from inception design.

It's time to experience materials science-driven precision manufacturing.

Contact the JS Precision team today and send us your part design. You will receive not only a clear CNC machining price quote, but also potentially a professional advisory document on material selection, process optimization, and reliability enhancement.

Let us work together to transform complex plastics machining challenges into impeccable details and reliable performance advantages for your products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com