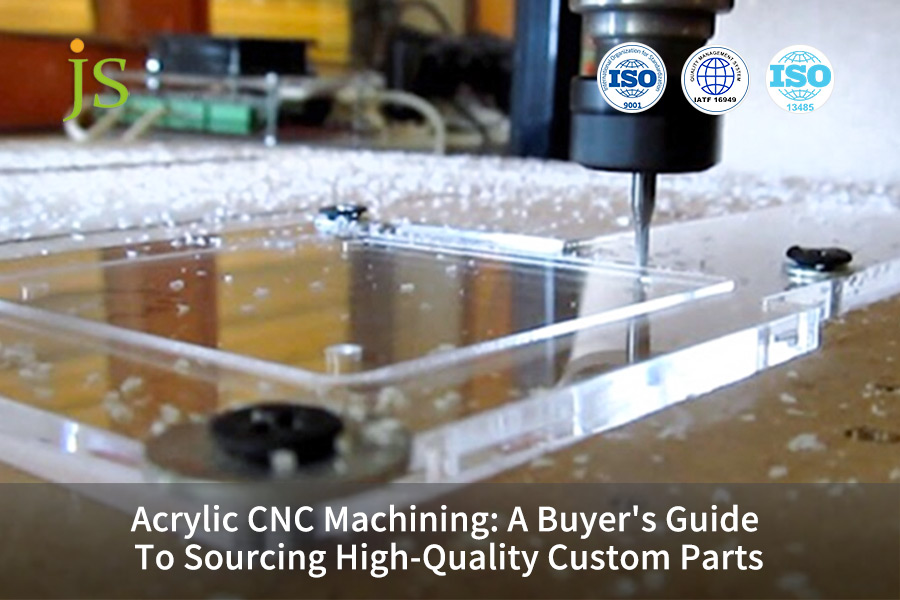

Acrylic CNC machining is one of the essential technologies for producing high-end design transparent components. With your design requiring a component with crystal-clear appearance properties coupled with high structural integrity, acrylic or PMMA is the material of preference.

Ranging from display racks to medical device skins, car headlight skins to architectural models, acrylic CNC machining plays a crucial role. But to turn an acrylic blank into a customized component and to find economical CNC machining suppliers, this process requires expertise.

This article wishes to be that guide along the way to help you with not only the analysis of acrylic properties and manufacturing processes, but also to tell you how to choose the best global CNC machining companies like a professional, to ensure that your project turns out successfully.

Core Answer Table

| Comparison Dimensions | Core Advantages of Acrylic (PMMA) | Key Actions for Successful Procurement | JS Precision Company's Differentiated Value |

| Material Properties | High transparency, excellent weather resistance, good mechanical strength, easy to process. | Clearly define application scenarios, surface treatments, and tolerance requirements. | We offer professional material selection advice and maintain a wide inventory of acrylic sheets. |

| Process and Quality | Advance CNC machining technology achieves high precision, smooth edges, and complex 3D structures. | Assess the factory's process control procedures and quality control system. | Our precision 5-axis machine tools and polishing experts ensure optical-grade surfaces and micron-level precision. |

| Supplier Selection | A supplier's capabilities directly determine the final quality and cost-effectiveness of the parts. | Systematically evaluate their technical capabilities, communication efficiency, pricing transparency, and past case studies. | As a one-stop CNC machining parts factory, we provide complete solutions from design optimization to post-processing, offering excellent value for money. |

Key Conclusions:

- Acrylic is more than “ ordinary plastic ” since it has many superior optical and physical properties.

- To have successful procurement, one needs to define the requirements and use the process of evaluating the supplier's technological skills.

- When it comes to picking professional CNC machining suppliers such as JS Precision, it immediately ensures machining accuracy for parts as well as cost-effectiveness in terms of projects.

Acrylic CNC Machining: JS Precision Manufacturing Delivers High-Quality Parts

In the acrylic CNC machining world, perfection, consistency, and professionalism are the primary requirements of a discerning client. It is exactly these qualities that JS Precision has been developing for a number of years.

As a firm that has over 15 years of experience in the domain of Precision Machining, our thrust is on providing solutions to the most difficult problems associated with acrylic machining, and we have already provided customized services in the domain of CNC machining to over 500 clients across the globe.

Our core competitiveness stems from solid technological accumulation:

- Equipped with more than 20 advanced machining devices, including 5-axis CNC machine tools, it can handle the Curved Surface and multi-dimensional structure in high precision.

- Established an industry-leading dust-free polishing workshop to ensure the optical grade in surface quality for the acrylic parts.

- Qualified by ISO9001 and ISO 13485 quality systems, with key dimensional tolerances maintained within ±0.005mm.

Within the past three years, we have completed more than 300 difficult acrylic machining projects, with customer satisfaction of 98% and a repurchase rate of over 80% in the medical field.

One of the clients wanted an acrylic instrument panel with the light transmission ≥ 91%, flatness error < 0.05mm, while withstanding -40 ℃ ~ 80 ℃ extreme temperature environment.

With the selection of imported optical-class PMMA materials, optimization of toolpaths, and the determination of a constant-temperature machining environment, we made sure the delivered product passed the client's acceptance test on the first try and thus positioned ourselves as long-term strategic partners.

If you are looking for an acrylic CNC machining partner who can solve challenging needs and guarantee consistent quality, please contact JS Precision's technical team immediately. Please send in your part drawings and requirements, and we can give you free DFM analysis and an accurate quote, in order for our professional staff to protect your project for you.

Why Acrylic? Unlocking Its Potential With Precision CNC Machining

Among many materials for CNC machining part, acrylic (better known as PMMA, the "Queen of Plastics") is distinguished for many exclusive advantages. Acrylic CNC machining parts make it the material of choice for high-end applications, since the core value proposition exists in three dimensions.

King of Optical Performance: Unparalleled Transparency

Acrylic has a light transmittance of 92% compared to common glass. Additionally, acrylic is UV-yellowing-resistant. To this end, acrylic has an unparalleled viewing experience for applications such as display cases, instrument panels, among others, due to its suitability for optical applications.

Physical and Chemical Properties: The Practicality Beyond a Material’s Appearance

Its resistance to impact is 10 times stronger than that of glass, and it has admirable weather resistance. It also encourages easy cutting and other CNC machining processes. It meets requirements that combine beauty with strength.

Infinite Design Possibilities: From Flat to Three-Dimensional

Acrylic CNC machining can precisely realize complex two-dimensional cutouts and three-dimensional structures with chamfered edges/round holes. With its multilayer bonding technology, rich three-dimensional shapes can be created to unlock infinite design possibilities.

Figure 1 Acrylic sheets can be used to manufacture products that require extremely high optical transparency and have more complex geometric shapes.

The Ultimate Guide To Sourcing: From Drawings To Finished Acrylic CNC Machined Parts

Choosing the right CNC machining parts factory is a key to project success. Scientific processes could help you select partners from quite a few numbers of CNC machining companies and avoid procurement risks.

Step 1: Clearly Define Your Needs

Clearly define your needs-the prerequisite for accurate procurement. You need to provide complete 2D/3D drawings, marking key dimensions and tolerances, acrylic brand/color/thickness, and other material specifications, surface treatment requirements, and intended use. The more detailed it is, the more effective the quotation and communication will be.

Step 2: In-depth Evaluation of the Supplier's Core Capabilities

A supplier contract should not be based solely on cost, since the foundation of core capabilities is the quality guarantee. Focus on the four aspects:

- Equipment list: Does it possess advanced equipment such as multi-axis machine tools to cater to the processing of complex parts?

- Process expertise: Does it have its own dust-free polishing workshop and other process expertise related to production?

- Quality control system: Does the manufacturer possess full testing equipment for the control of defects in dimensions and surface quality?

- Communication response speed and professionalism: The ability of the manufacturer to respond promptly to technical inquiries and make reasonable suggestions.

Step 3:Examine the quote to grasp the actual cost.

A professional quote should clearly break down the cost of the materials, the cost of the programming and start-up charges, the cost of the machining time, the cost of the post-processing fees, and the cost of the logistics."Fixed prices" are questionable because they might entail cost changes down the line.

If you feel bewildered when selecting a CNC machining parts factory, JS Precision can help. You only need to upload the part drawings, and we will provide you with free cost accounting and supplier evaluation suggestions to help you accurately select a high-performance partner.

Beyond Cutting: Advanced CNC Processing Of Perfect Acrylic

High quality acrylic parts rely on advanced CNC machining precision control that complies with ISO 23218 standards. JS Precision has upgraded the high-end processing procedure after years of experience. The essential elements involve the following:

Cutting Tools, Spindle Speed, and Feed: Application of a Scientific Combination of Parameters

The core lies in the matching of specialized cutting tools with scientific parameters: using acrylic special single/double-edged spiral milling cutters, combined with high-speed slow feed parameters, supplemented with sufficient air cooling or specialized coolant, to ensure smooth cutting edges without chipping or melting patterns.

Stress and Deformation Control: Pre-processing Strategy

Acrylic sheet itself has internal stress, and if not handled properly during processing, the release of stress can cause deformation of the parts. JS Precision engineers will proactively prevent through three methods:

- Optimize the clamping method to avoid excessive clamping force and stress.

- Adopting a layered processing strategy, gradually removing materials to release internal stress.

- Perform pre machining stress relief treatment on some high demand parts to ensure dimensional stability of the final product.

From Machining Marks to Art: The Magic of Post-Processing

What the post-processing entails is ensuring the final resulting effect: the use of several polishing processes in order to achieve the optical-grade mirror finish, distinct markings from the screen/UV printing process, as well as the use of compound adhesives for flawless bonding.

If you are looking for advance CNC machining for producing quality acrylic parts, kindly contact the engineering team from JS Precision. They will give you a complete description of machining steps and parameters, and also give you free recommendations for machining process improvement.

Figure 2 Choosing sharp and sturdy cutting tools is crucial when CNC machining acrylic.

Quality Assurance: Your Checklist For Inspecting CNC Machining Parts

Once you receive the CNC machining part, inspect them for quality in accordance with the following checklist:This is your last line of defense in ensuring that your projects go through without any problems due to quality concerns.

Appearance and Dimensional Initial Inspection

First of all, the appearance of the part’s surface is checked with even illumination to ensure that the part is scratch-free, free of bubbles, and devoid of contaminants and polishing defects. Next, the part’s size is checked with the use of calipers and projectors to ensure that the size is within the drawing tolerance.

Functional and Assembly Testing

When the parts need to be assembled, actual trial assembly operations are conducted to check whether the hole alignment and fit tightness meet assembly requirements. For optical components, specifically test the uniformity and absence of light transmission to ensure optical performance meets the intended use scenario.

Documentation and Consistency

Check the quality inspection report provided by the supplier to ensure that all test data match standards. Meanwhile, conduct sampling measurement to check if the parts manufactured in batches are consistent and do not have individual defects in the products. Professional suppliers will attach complete shipping documents for traceability.

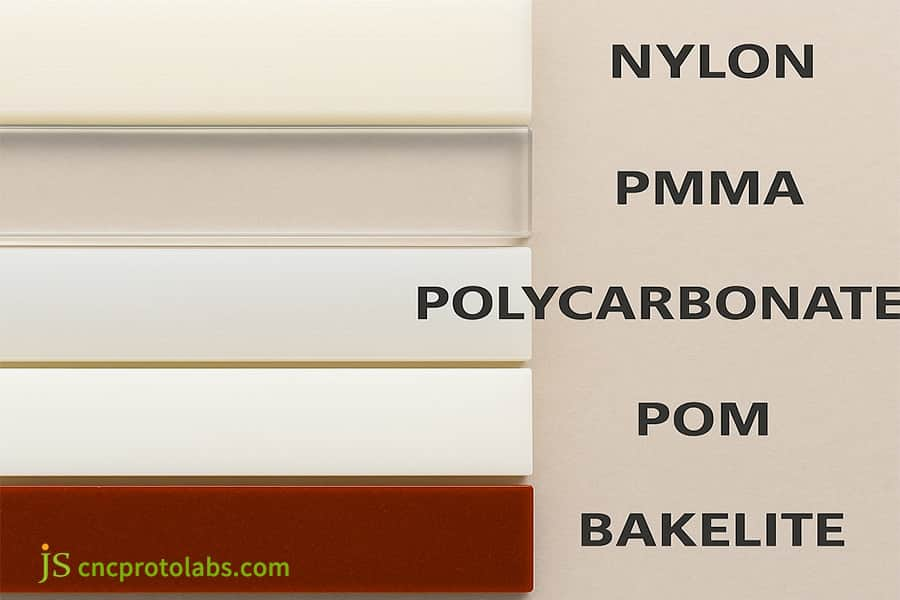

Acrylic Vs. Others: A Comparative Lens On Common CNC Engineering Plastics

Professional CNC machining suppliers should be able to recommend the most suitable material based on your needs. Below is a comparison of acrylic with three common engineering plastics to help you clearly understand the material differences and make the optimal choice.

| Material Properties | Acrylic (PMMA) | Polycarbonate (PC) | ABS | Nylon (PA) |

| Light Transmittance | 92%, optical grade transparency | 88%, semi transparent | Opaque | Opaque |

| Impact Resistance | Medium (10 times that of glass) | High (250 times that of glass) | Medium | High |

| Weather Resistance | Excellent (UV resistant, non-yellowing) | Good | Average | Poor |

| Processing Difficulty | Medium (requires edge chipping prevention) | Medium (prone to burrs) | Low | Medium (prone to moisture absorption) |

| Core Advantages | Light transmittance, scratch resistance, aesthetics | Extreme impact resistance | Low cost, easy to paint | High strength, abrasion resistance |

By comparison, it can be seen that acrylic has significant advantages in transparency, glossiness, and weather resistance, making it particularly suitable for structural components that require optical effects or outdoor use.

PC is more suitable for scenarios with extremely high impact requirements, ABS focuses on cost and ease of processing, while nylon has more advantages in high-strength and wear-resistant scenarios.

Figure 3 The properties of plastics vary, especially in CNC machining.

Case Study: Precision In Transparency – A 0.02mm Tolerance Challenge For Medical Imaging

Client Needs

A prominent European medical equipment distributor was working on the production of a window observation system for a high end computed tomography scanning system.

The stringent requirements of this component included: Flatness error less than 0.1mm, Critical mounting hole tolerance of ± 0.02mm, Optical mirror surface, Biocompatibility with sterilization resistance.

This client had previously failed with two suppliers, mainly because of dimensional inaccuracies and surface scratches.

JS Precision Solution

1. Material Selection: For this project, imported German optical-grade acrylic was selected. Not only do these materials offer an excellent rate of light transmission of 92.5%, but they also meet requirements for biocompatibility for medical applications and can withstand disinfection chemicals.

2. Programming Design: The engineering team employed micron-level precision for path-programming and software with the ability to simulate the machining process and calculate the risks of thermal deformation.

3. Processing Environment: The product is processed in a clean environment with a constant temperature of 22℃ with high-end five-axis CNC machines. The entire processing environment utilizes atomizing cooling technology, which prevents any size variation due to temperature changes.

4. Post-processing: In a dust-free polishing room, mechanical polishing with highly skilled technicians having more than 10 years of experience is conducted three times, followed by a single chemical polishing process, resulting in a surface gloss of more than 100 GU with the absence of any machining marks.

Results

A total of 150 acrylic viewing windows submitted to CMM testing passed with a 100% success rate by the customers' CMM measurement system for accuracy of dimension and surface quality.

The customer's new scanner successfully received the EU CE mark. JS Precision, with its quality and capabilities, established itself as a critical supplier for this client in the Asia-Pacific market, with subsequent annual orders in excess of US$500,000.

If you are also facing the same challenge of acrylic processing with tight tolerances and high surface quality requirements, please feel free to contact JS Precision. We will give you personalized customized solutions by recreating the same technical experience in successful cases to let your products grasp market opportunities.

Figure 4 High precision acrylic for medical equipment

Why JS Precision Stands Out As Your High-Value CNC Machining Suppliers

Amongst many competitors for CNC machining services, JS Precision focuses on value creation to achieve long-term value with overall optimization of technology, quality, cost, and services. The core competencies of JS Precision are as follows:

1.Technical Depth: We have a cluster of advanced CNC machining equipment ranging from three to five axes, equipped with a professional acrylic processing and post-processing team, capable of handling complex structures and strict tolerance challenges.

2. Quality System: Throughout end-to-end quality control, with strict standards for inspection in each process, we are assured that 100% of the CNC machining part meet their designs by virtue of a consistently high pass rate in excess of 99.8%.

3. Cost Optimization: JS Precision, as a highly efficient cnc machining parts factory, cuts down costs by carrying out process optimization, optimal scheduling, and bulk purchasing, providing highly competitive prices while ensuring quality.

4. Service Experience: Offers an end-to-end service experience in DFM analysis and prototyping to mass production along with an expert team that operates around the clock for inquires that make procurement completely worry-free and safe.

If you are searching for high-quality CNC machining suppliers, you may want to approach JS Precision. Just send us your project requirements, and we will give you a free project assessment and solution design to personally experience efficient precision machining services.

FAQs

Q1: What is the maximum size and thickness that can be achieved with acrylic CNC machining?

The largest machining size depends upon the traveling of machines. The machining of JS Precision can perform an acrylic sheet up to a size of 2000x3000mm. The thickness ranges from 1mm to 100mm. Beyond that thickness can be obtained by certain bonding techniques.

Q2: How to avoid chipping or cracking of acrylic during machining?

The secret is in these three things: the use of high-quality cutting tools that specifically target acrylics, high-speed cutting with slow feeds, and air cooling or a coolant. At the same time, optimize your clamping technique to reduce stress concentration.

Q3: To what extent can mirror polishing be achieved? Can it reach glass-like quality?

Professionally processed acrylic materials can provide a gloss value above 100 GU, ensuring optimal levels of clarity and smoothness to the material. The optical appearance is comparable to or even better than regular glass. The surface of the material is optimal for optical use.

Q4: What temperature can acrylic parts withstand?

The safe continuous operating temperature for acrylic is around 80°C, and the heat distortion temperature is around 100°C. When the surrounding temperature is invariably above 80°C, the best suited materials would be those with highly robust heat-resistant properties. Needless to say, PC would be the apt choice.

Q5: Can threads be machined on acrylic?

Yes. For threads with larger pitches, direct tapping with the CNC tapping machine is possible. For disassembly or assembly or strength purposes, threaded inserts made of metal can be inserted into the thread to strengthen the threaded joint.

Q6: What is the minimum order quantity (MOQ)?

JS Precision, as one of professional CNC machining suppliers, supports a flexible minimum order quantity policy. Sample orders usually start with 1 piece, and the MOQ for bulk orders can be negotiated and determined based on the complexity of the parts.

Q7: How long does it take from placing an order to receiving a sample?

For simple acrylic components, the delivery cycle for samples is 3 to 5 days, for complex components or components that involve complex processing, the delivery cycle for samples is 1 to 2 weeks. In addition, we provide expedited sampling services.

Q8: How do you ensure the consistency of parts in large-volume orders?

To provide high consistency in the size, appearance, and performance of mass-produced parts, there are four levels of control: Standard Operating Procedures (SOP), first-piece inspection, production inspections, and sampling inspections before shipment for finished products.

Summary

Acrylic CNC machining is a precision bridge for creative design implementation. By selecting the right materials, mastering core processes, and collaborating with a CNC machining parts factory with solid technology, projects can be transformed from blueprints to high-quality physical products.

JS Precision, with its expertise in Acrylic CNC machining solutions, is ready to turn your ideas into reality. We invite you to share your part drawings. You will receive a free manufacturability analysis (DFM) and a transparent and competitive quote from our engineering team, who will construct your "transparent" competitiveness.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com