The operation of every car's transmission, each positioning of an industrial robot's joint, and the torque conversion of every wind turbine have something in common: they involve gears. A well-designed gear, at its best, is a blend of power, efficiency, and reliability.

However, a lot of people think that gear machining is the same as "tooth cutting." People sometimes feel confused when facing customized needs: how to guarantee the precision, how to control the cost, and what should be concerned about while cooperating with the gear making company.

This guide will explore the heart of modern gear machining and reveal why partnering with a company like JS Precision is a key step toward your powertrain's success.

Summary Of Key Answers

| Comparison | Traditional Gear Machining | Modern Precision Gear Machining |

| Precision Grades | Standard Commercial Grade | High Precision Grade (up to AGMA 12-13 or higher) |

| Consistency Guarantee | Relies on experienced technicians and batch variations. | CNC control, and full-process monitoring to ensure consistency for every batch. |

| Material Adaptability | CNC control and full-process monitoring ensure consistency for every batch. | It covers a broad area, from powder metallurgy to high-strength alloy steel. |

| Design & Customization | Long lead times, high cost of modification. | Digital design, rapid prototyping, and easy customization. |

| Overall Cost | Low upfront cost with a high potential failure risk. | Reasonable upfront investment with optimal overall lifecycle cost. |

| Core Values | Realize the function of transmission. | Provide reliable, efficient and quiet power transmission service. |

Why Trust This Guide? JS Precision Focuses On Gear Machining Precision

In the field of gear machining, experience translates to a guarantee of precision, and JS Precision has had its experience validated through the completion of thousands of projects.

In the past 15 years, we have served more than 500 clients in over 20 industries: the automotive-aerospace and medical equipment-manufacturing fields, such as the Tesla supply chain, military research institutes, surgical robot manufacturers, among others, and we have processed over 100,000 gears in total.AGMA Grade 14 high-precision gears make up 30% of our business, and the customer repurchase rate exceeds 80%.

We once customized differential gears for a certain Formula team, providing an 18% weight reduction while guaranteeing zero failures under extreme torque. Such real-world cases gave us a profound understanding of pain points related to gear machining in different scenarios.

This manual is much more than a theory compilation, it's a hands-on tool that condenses our team's experience in material selection, process optimization, and cost control. Any suggestions can be directly used in your own project.

As a gear making company specializing in gear machining, JS Precision is able to provide you with service from design review down to mass production of gears. Contact us now, provide your gear drawings, get a tailored solution, and a transparent quote within 48 hours.

What Is Gear Machining? The Transformation From Blank To Power Hub

While many believe gear machining is simply "cutting teeth," it is, in fact, a precision-manufacturing system-from raw material to power hub.

Gear machining refers to the entire procedure, which includes the selection and preparation of raw materials, machining of gear profiles, heat treatment, and finishing. The fundamental aim in this regard is to achieve smooth and efficient power transmission at the point of gear meshing, with minimum generation of noise, vibration, and wear.

Gear Machining at JS Precision, a professional gear making company, is way more than just machining.

We recommend the best material for customers in consideration of their usage scenarios, optimize heat treatment processes such as vacuum carburizing and quenching, and even 3D model topology optimization, so that each product will be precisely matched as a power core rather than any simple standard part.

How Are Modern Precision Gears Manufactured? Revealing The Core Manufacturing Process

Now that you know what Gear Machining is, let's get into how precision gears are made. The manufacturing of precision gears generally involves three stages, all requiring special machines for gear cutting and close quality control.

Process 1: Soft Machining Stage

- Turning and Drilling: The blank is machined into the reference surface, outer diameter, and inner hole through a CNC milling and turning center to ensure precision in the positioning of subsequent procedures.

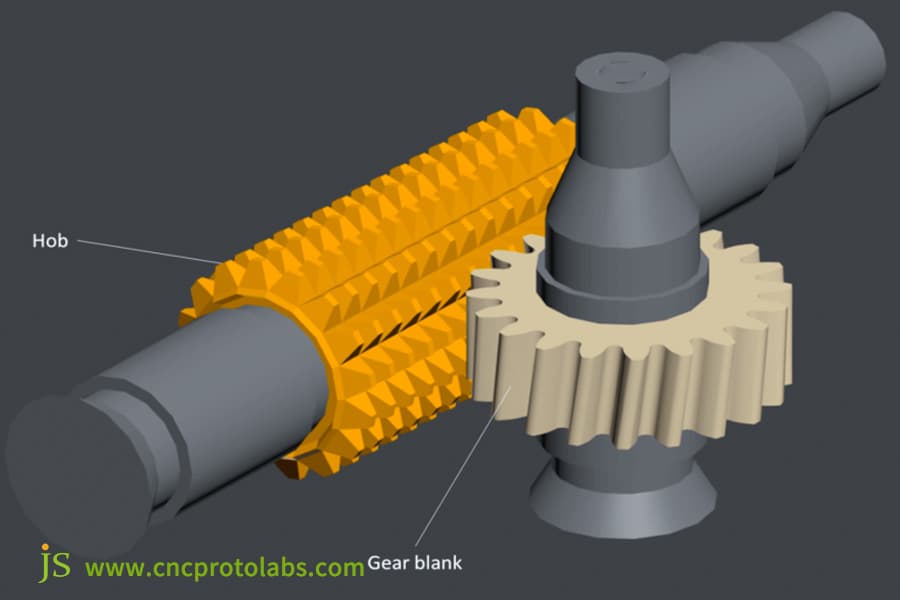

- Hobbing or Shaping: The initial tooth profile is machined on a gear cutting machine, which directly determines the basic tooth shape.

Process 2: Heat Treatment Stage

Improvement in performance by carburizing and quenching: After putting gears in a carburizing furnace to form the high-carbon layer on the surface, they undergo quenching treatment, which gives a highly hard, wear-resistant surface and enough toughness at the core to avoid breakage while in use.

Process 3: Hard Machining Stage

After heat treatment, the gear will slightly deform, requiring correction through gear grinding or honing: A high-precision gear grinding machine is used to control the error to the micron level, reaching AGMA 12-14 level accuracy. JS Precision uses German Reishauer gear grinding machines and achieves a consistent precision within 0.002mm.

JS Precision possesses a complete gear machining process chain, from rough processing to tooth hobbing. Equipment is regularly calibrated, and each process has its own process card and inspection standards for optimal performance of gears.

JS Precision will meet all your gear machining needs efficiently and with high precision with the help of gear cutting machines and end-to-end process control. The advantage of choosing us is the evasion of precision loss caused by outsourcing in multiple stages.

Figure 1:As shown in the figure, gear hobbing is achieved by rotating a rolling cutter to machine gear teeth.

What Are The Major Factors That Influence The Price Of Custom Gear Machining?

There are many factors influencing the cost of custom gear machining. Understanding these factors will help balance "precision requirements" with "cost control." Based on industry data and experience, here is a breakdown that includes a detailed cost table:

The effect of different precision grades and modules on the cost of custom gear machining (based on AGMA Grade 8 & 1mm module)

| Precision Grade (AGMA) | Cost Increase Percentage | Major Additional Operations | Primary Applications | Module (mm) | Unit Cost (US$, AGMA Grade 10) |

| Grade 8 | Baseline (100%) | Hobbing + Honing | General Transmission Equipment | 1 | 35 |

| Grade 10 | 150%-180% | Added Semi-precision Gear Gears | Automotive Transmissions | 2 | 58 |

| Grade 12 | 250%-300% | Full Precision Gear+ Multiple Inspections | Aerospace Auxiliary Equipment | 3 | 82 |

| Grade 14 | 400%-500% | Ultra-Grinded Gears + Full Inspection at Gear Measurement Center | Racing Cars, High-End Medical Devices | 4 | 115 |

Core Influencing Factors

1. Design Complexity: Module, number of teeth, helix angle, and special profiles such as drum-shaped teeth increase the machining time and tool wear. Machining cost for drum-shaped teeth is over 30% higher than that of a standard spur.

2. Materials and Heat Treatment: Aerospace-quality AISI 9310 steel costs three or four times more than 45# steel, whereas vacuum carburization plus quenching costs 50% more than direct quenching.

3. Quantity of Order: The unit cost of small batches (1-10 pieces) is 5-8 times that of large batches of 1000 pieces+. JS Precision can provide "batch splitting production" to reduce costs.

JS Precision does not compromise on precision to reduce costs but achieves cost efficiency through optimization of the cutting parameters and suggestion of cost-effective material.

If you are wondering how much custom gear machining costs, JS Precision will provide you with a solution that will balance accurate gear and machining with cost-effectiveness, considering your accuracy requirements and batch size. For a detailed cost analysis, contact us now.

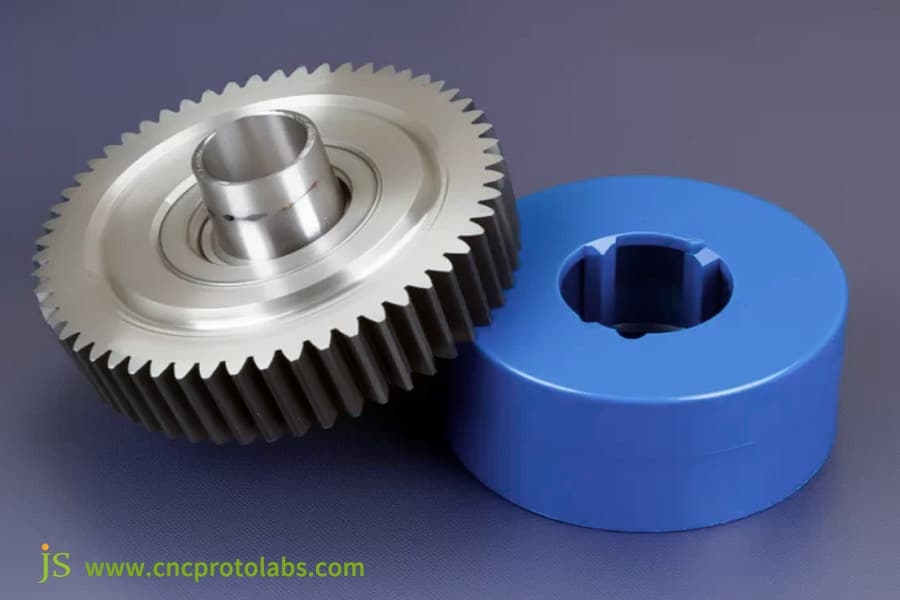

Figure 2:Material choice creates significant cost variations in gear machining quotes.

What Is The Price Range For Investing In a Machine Tool&Gear Overall Solution?

When enterprises implement gear machining independently, the investment varies greatly depending on equipment, and blind investment can easily result in waste. The following table supplements the maintenance costs and payback period to help you make a more comprehensive decision:

Machine Tool & Gear Overall Solution Price and Operating Cost Table

| Solution Level | Price Range (USD) | Core Equipment Configuration | Applicable Business Type | Maintenance Cost / Year (USD) | Investment Payback Period (Years) |

| Economy | 50,000-200,000 | Basic CNC milling and turning center, ordinary gear hobbing machine. | Small Hardware Factory, Standard Gear Wholesaler. | 5,000-12,000 | 5-8 |

| Professional | $300,000 - 800,000 | High-precision gear hobbing machine, CNC gear shaper, conventional gear grinding machine. | Automotive Parts Supplier and Medium-Sized Equipment Manufacturer. | 20,000 - 45,000 | 3-5 |

| Advanced | 1M-5M+ | Five-axis linkage gear hobbing machine, imported gear grinding machine, gear measurement center. | Aerospace manufacturer, high-end medical device company. | 80,000-150,000 | 8-12 |

The cost of advanced cutting-edge solutions requires enormous investment and requires professional technical personnel, which most companies cannot afford. Cooperating with JS Precision will be a wiser choice.

We have state-of-the-art machine tool and gear equipment, such as a five-axis gear cutting machine, and a process team with over ten years of experience to optimize machining parameters.

You don't have to bear the high costs of equipment investment and technical risks. You can directly enjoy the accurate gear and machining results brought by top-of-the-line equipment and professional processes with the comprehensive machine tool & gear service provided by JS Precision. If you're interested in cooperation, then please consult for details.

How Does The Price Of Custom Gear Machining Get Calculated?

There is an overall logic for a quote on custom gear machining. JS Precision explains the formula and then adds batch processing fee data to give you a more transparent cost:

1.Quotation Formula Analysis

Final price= material cost + machining cost + heat treatment and surface treatment cost + management fee of 15% to 20%, inclusive of equipment depreciation, quality check etc.

- Material Cost: Computed by multiplying weight × density × unit price. For example, a 0.5kg AISI 9310 steel gear will be approximately $40.

- Machining Cost: A core variable and directly related to complexity, precision, and batch size. AGMA level 12 machining time is 2-3 times that of AGMA level 8.

- Heat Treatment Cost: Vacuum carburizing and quenching US$20-30/piece, galvanizing US$5-10/piece.

2.Comparing Processing Costs of Various Batch Sizes

Custom Gear Machining Cost Comparison at Varying Batch Quantities for AGMA Grade 10 and Module 2mm

| Order Batch Size (pcs) | Single Piece Processing Cost (USD) | Total Processing Cost (USD) | Processing Time (days) | Tooling Cost Allocation (USD/pc) |

| 1-10 | 85 | 680-850 | 5-7 | 25 |

| 50-100 | 42 | 2100-4200 | 10-12 | 8 |

| 500-1000 | 28 | 14000-28000 | 18-22 | 2 |

| 1000+ | 22 | 22000+ | 25-30 | 1 |

3.Three Key Elements to Get the Right Quote

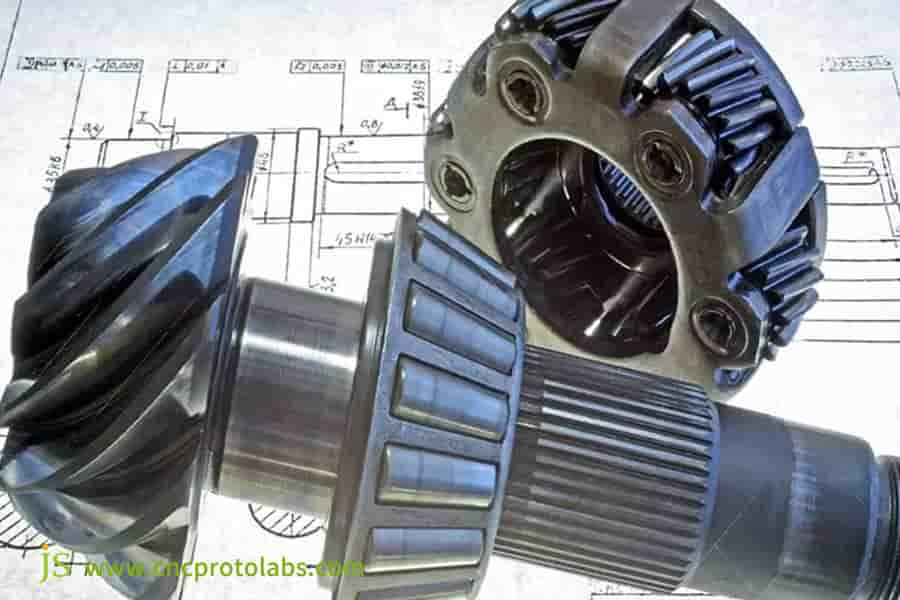

- Full drawing of the gear, marking precision, tooth profile tolerances, etc.

- Material and heat treatment - clearly stated.

- Annual requirement and single batch quantity.

JS Precision provides itemized quotes, elaborating on the required expenses. For example, ultra-precision gear grinding would be required for AGMA Level 14.

Figure 3:Provide gear drawings to the gear making company to obtain a quotation.

Partnering With A Gear Making Company: What Is The Standard Process For Custom Services?

After finding the right gear making company, the smoothness of the process is what affects project efficiency. JS Precision has helped hundreds of clients through a standardized process to complete their customizations. The core stages include:

- Consultation and Design Review (1-3 days): This is the stage where the engineers link the requirements and optimize the design, like material selection and simplification of the gear profile.

- Process Planning and Quotation (2-5 days): The supplier will develop a custom gear machining process card, providing a detailed quote and delivery time.

- Sample Manufacturing and Approval: Manufacturing the first sample, submitting the full-size inspection report, and then mass production after confirmation by the client. (1-2 weeks)

- Mass Production and Quality Control: Complete by following process cards, checking every 50 pieces, report immediately if any abnormality arises.

- Delivery and After-sales Service: qualified products are delivered as agreed, and technical support is provided free of charge.

JS Precision treats its customers as partners and is supportive with the provided feedback in every stage.

If you are looking for a gear making company that has transparency in processes and efficiently communicates, the normalized custom gear machining collaboration process at JS Precision will save your time and effort. Please feel free to contact us now to get started with your customized gear project.

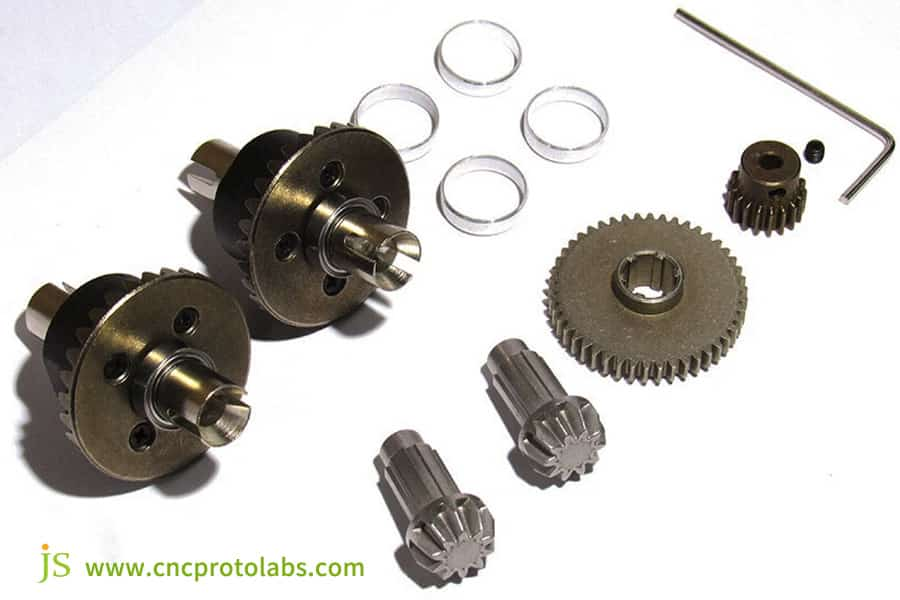

Case Study: How JS Precision Customized Lightweight Differential Gears For Formula Racing

Client Challenge

The client is a Formula E racing team in need of a differential gear set. The key requirements will be:

- The structure shall be able to bear high torque-peak torque up to 800 N·m.

- Extremely lightweight design-over 15% weight reduction.

- Low noise-the racing cockpit is very small, too much noise affects the judgment of the driver.

- Absolute reliability shall be ensured, in a race, gear failure directly leads to retirement.

JS Precision's Solution

Facing these problems, our team came to the following solution through several technical discussions:

1. Material and Structural Optimization:

Instead of using the traditional 42CrMo steel, higher-strength, lighter-weight alloy steel was chosen: aerospace-level AISI 9310. Meanwhile, ANSYS software for topology optimization design removes excess material in non-critical load-carrying areas of the gear, such as the non-mating surface of the hub, this does not compromise the strength while reducing weight.

2. Precision Soft Machining:

Gear hobbing was done on a five-axis linkage gear cutting machine. By controlling the real-time cutting parameters, such as speed and feed rate during machining, it was possible to control the gear tooth profile machining error within 0.005mm and create the preconditions required for subsequent precision machining.

3. High-performance Heat Treatment:

Perform vacuum carburizing and quenching. During the process of placing gears in a vacuum furnace, avoid oxidation and decarburization. The depth of the carburized layer shall be controlled within the range of 0.8 - 1.2mm. After quenching, the surface hardness is HRC58-62 with core hardness of HRC30-35 considering the balance of wear resistance and toughness.

4. Final Finishing:

The gear surface was ground by a German Reishauer RZ301S gear grinding machine. Meanwhile, the tooth profile was modified to have a crowning effect, and the tooth tip edge was trimmed to reduce impact and noise in meshing. The final gear accuracy reaches the AGMA 14 level, and the cumulative pitch error is only 0.008mm.

Our Achievements and Value

The final delivered gear set is 18% lighter than the customer's original design: from 2.5kg to 2.05kg. It also improves the transmission efficiency to 99.5% from the original design of 98.2%. It realized zero-failure operation in all 12 games of the season.

It also contributes to a reduction of 15dB in noise for gear meshing and effectively improves the driver's cockpit experience. According to customer feedback, this gear set has become one of the core advantages of their racing car's powertrain and helps the team improve its ranking by three places.

Figure 4:Customized lightweight differential gear

How To Start Your Next Gear Project?

Based on the understanding of gear machining, if you're preparing to start a gear project, here are three essential steps that will help you get going fast and avoid detours.

Step 1: Prepare the Technology Package

The technology package is the base for the project. Please, prepare 2D drawings and 3D models of gears. Drawings shall reflect accuracy grade, parameters of tooth profile, materials, heat treatment, surface treatment requirements, and key dimensional tolerances. If the design is incomplete, you can give a preliminary solution, and our engineers will help with optimization.

Step 2: Performance Requirements Definition

It will be necessary to tell us about where the gear is intended to be used and the related requirements, like operating speed, maximum load, expected life, and noise control. In this way, we will be able to make appropriate selections of materials and processes.

Step 3: Consult Experts

After preparing your technology package and requirements, kindly contact JS Precision. Just reach our sales engineers through our official contact information below. We will get in touch within 24 hours, and provide a detailed quote within 48 hours upon receiving your technology package.

Working with JS Precision, you get professional support right from the very first step and never have to worry about the progress of the project.

FAQs

Q1: What does a gear precision grade, such as AGMA 12, mean?

AGMA precision class is a comprehensive standard for gear quality, which provides the limit range of major parameters such as pitch error, tooth profile error, and tooth direction error. As the grade increases, errors become smaller for smoother transmission with low noise and longevity. AGMA 12 is used widely in aerospace auxiliary equipment.

Q2: Must there be grinding of gears?

Not all gears have to be ground. High-precision, high-speed, or high-load applications, such as gears in racing differentials, must be ground if they are to function properly. For ordinary commercial gears, either hobbing or honing is generally good enough.

Q3: Can you process plastic gears?

Yes, we use specialized gear cutting machines and tools for the processing of POM, Nylon, PEEK, and other engineering plastic gears. Besides, we offer integrated injection molding solutions for metal inserts and plastic gears.

Q4: How long does the gathering of a sample from drawings take?

Sample delivery time depends on the complexity and precision of the gear. For standard spur gears, AGMA 8-10 grade, the minimum time required is 5 working days, but for complex gears, such as helical gears or specially modified gears, the delivery time will be about 2-3 weeks.

Q5: How to check whether the gear is qualified?

For the full-size inspection, we adopt gear measuring centers from Germany or Japan, checking tooth pitch error, tooth profile error, and tooth direction error. Finally, an authoritative report will be given to ensure the transparency of data as well as reliability.

Q6: Do you offer gear heat treatment services?

Yes, we have both deeply cooperative top-tier heat treatment plants and our own heat treatment workshop, enabling us to strictly control the whole heat treatment process to make sure that the hardness and toughness of gears meet the requirements of design.

Q7: My project requires a strict confidentiality agreement. Can you provide one?

Of course. JS Precision respects the intellectual property of our clients. We can sign a strict confidentiality agreement before the start of the project to ensure that your design and technical information is not leaked.

Q8: How can I get a quotation for gear machining from JS Precision?

Please send your gear drawings in PDF or DWG format and performance requirements to our official contact. We will offer a detailed quotation, including material costs and machining fees, within 48 hours.

Conclusion

A single gear with a minor mistake can bring the whole system down in power transmission. Choosing the right gear making company means choosing the foundation of reliability and superior performance for your products.

With in-depth knowledge of gear machining, advanced gear machines, and unremitting pursuit of accurate gear and machining, JS Precision has become a trusted partner with many leading companies in every industry.

Gears shouldn't be your weak link. For professional-grade customized gear machining services, contact us today. Let us work together to turn your gear requirements into high-quality products that will enable your projects to succeed!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com