Gear hobbing services lie at the very core of gear machining with a host of critical applications that range from the quiet operation of electric vehicle reducers to aerospace actuation systems that require a maximal level of reliability and go without saying in the field of medical equipment where micron-level accuracy becomes a life-saviningsafety factor.

Gears, nicknamed the "heart of the machine," have their functions, noise, and service life directly dependent on the precision and reliability of the manufacturing process in which they are being made.

This piece will give you an insight into the basics of gear machining technology, specifically into Precision gear hobbing, and will give you a complete blueprint from the basics of the technology to the selection of the finest gear machining companies, such as JS Precision.

Core Answer Summary

| Guideline Highlights | Key Assessment Dimensions | JS Precision Core Value |

| Understanding the Process | Principles, Efficiency, Process Maturity | Decades long experience in gear hobbing, process database for 1000+ gears. |

| Precision Assurance | Machine tool performance, tolerance control, inspection system. | Imported high-end equipment, attained ISO 5-8 accuracy level, all processes under SPC real-time monitoring. |

| Service Matching | Customization flexibility, batch scalability, technical support. | Supports production from 1 prototype to 1 million units, providing DFM and full-process engineering support. |

| Partner Selection | Technical expertise, quality system, experience in the industry, broad service coverage. | ISO 9001:2015 quality management system, involved in the development of electric vehicles/precision transmission and relevant areas, one-stop service. |

Key Takeaways

- The core value of precision gear hobbing lies in stable high precision and excellent repeatability, which directly determines the performance and reliability of end products.

- In evaluating a gear manufacturing companies, one must look beyond price to their overall equipment strength, quality control system, and engineering support capabilities.

- Customized services and large-scale production are not opposed, and excellent partners can simultaneously handle both through flexible systems.

- Engaging professional manufacturers such as JS Precision in the Design for Manufacturing (DFM) stage helps mitigate risks, ensure cost-effectiveness, and complete the project work at a faster pace.

- Your success hinges upon having a manufacturing partner who can effectively coordinate cutting-edge gear machining process, a strict standard of quality, and your unique requirements.

Why Trust This Guide? A Detailed Explanation Of JS Precision Gear Hobbing Services

Based on JS Precision's many years of gear machining know-how, this guide is a valuable resource for clients in the premium industry of automotive, aerospace, and medical applications.

As one of technology driven gear manufacturing companies, we hold ISO 9001:2015 quality management system certification to ensure that every process meets rigorous quality requirements.

Our gear hobbing services support 50+ types of gear materials and involve modules from 0.2 to 10. In the last three years, we accomplished more than 300 high-accuracy projects with a customer repurchase rate of 85% and an average on-time delivery rate of 99.2%.

In the last three years, we accomplished more than 300 projects of high accuracy for our clients across the world with an average on-time delivery rate of 99.2% and a customer repurchase rate of 85%.

We have the case of resolving the noise and efficiency issues of a transmission for a high-end new energy vehicle manufacturer through the precision gear hobbing technique and DFM optimization, which involved less than 3dB gear meshing noise, an improvement of 1.5% efficiency, and increased mass production yields from 97.5% to 99.8%.

These tangible results demonstrate our ability to solve core pain points for our clients.

If you are looking for a reliable gear hobbing services provider, JS Precision's professional capabilities, rigorous quality control, and extensive industry experience are trustworthy. Want to directly verify our technical strength? Contact our engineers to obtain a free gear machining feasibility analysis report and see how we can support your project.

What Is Precision Gear Hobbing? The Core Of Modern Gear Machining

The gear machining process has undergone decades of innovation, and precision gear hobbing has become the mainstream efficient method, achieving high precision and high production capacity through continuous cutting with rolling cutters, making it the preferred choice for medium to large-scale production.

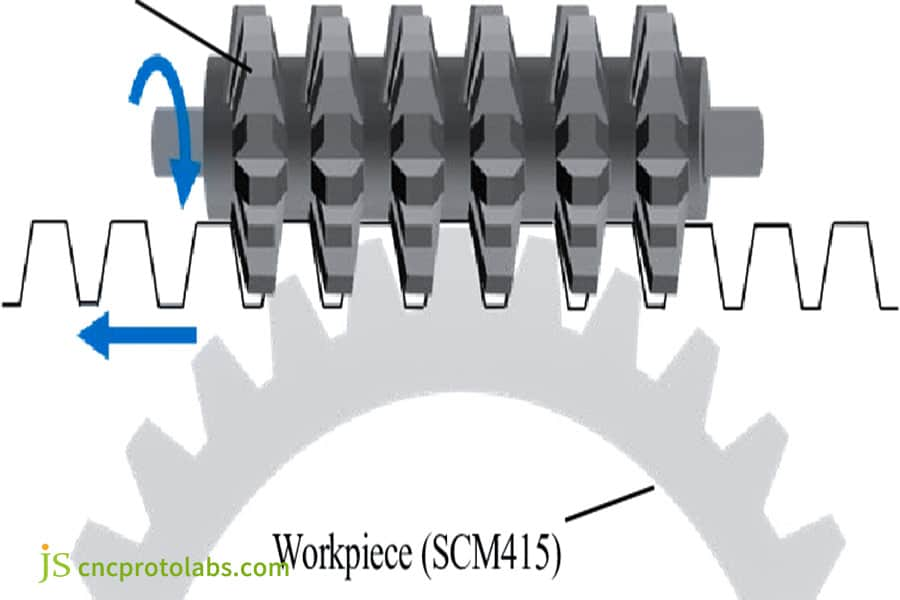

Gear hobbing principle: How is continuous meshing accomplished in gear hobbing?

The gear hobbing process relies upon the principle of non-stop meshing between the gear hobbing cutter and workpieces. It revolves and cuts at a fixed ratio in collaboration with the workpieces.

The process does not involve repeated positioning, therefore, it is more efficient than other intermittent machining processes. JS Precision can adjust the cutting parameters depending on the required accuracy.

Gear hobbing vs. gear shaping/milling: Why does it dominate medium- to high-volume gear manufacturing?

Gear hobbing offers significant advantages over other processes and is suitable for medium to large-volume production:

| Process Type | Production Efficiency | Machining Accuracy | Applicable Batch Size | Cost Control |

| Gear Hobbing | High (Continuous Cutting) | ISO 5-8 | Medium to Large Batch | Low (Unit Cost Decreases with Batch Size) |

| Shaping | Medium (Intermittent Cutting) | ISO 6-9 | Small Batch | Medium (Suitable for Complex Tooth Profiles) |

| Milling | Low (Single Tooth Cutting) | ISO 7-10 | Single Piece/Small Batch | High (Long Processing Cycle) |

Gear Hobbing Process Breakdown

The entire gear hobbing process requires rigorous actions for ensuring quality:

- Raw Material Preparation: Choosing appropriate materials and processing them with heat to improve functionality.

- Hob Selection & Installation: Choosing the hob based on gear parameters & installing it accurately on a gear hobbing machine.

- Blank machining: CNC turning produces precise blanks.

- Gear Hobbing: Based on the program and observation with simultaneous adjustment.

- CNC Programming: The process of entering parameters to regulate operations of machine tools.

- Precision Inspection: Inspects key parameters such as tooth profile and pitch.

- Deburring and Cleaning: Removes impurities to ensure purity of surface.

- Post-processing: Heat treatment or grinding if necessary.

JS Precision has been actively engaged in gear hobbing solutions for several decades, with an optimum process in place for the precise machining of complex gear types with high accuracy.Want to know how our gear machining process fits your product? Submit your gear drawings to our engineering team to receive a free process optimization solution.

How Does a Modern Gear Hobbing Machine Guarantee Unmatched Precision?

A high-quality gear hobbing machine is the hardware basis for Precision gear hobbing. In JS Precision, the company imports the highest quality machines from Germany and Japan, ensuring high precision requirements are met.

In-Depth Analysis of the Key Elements

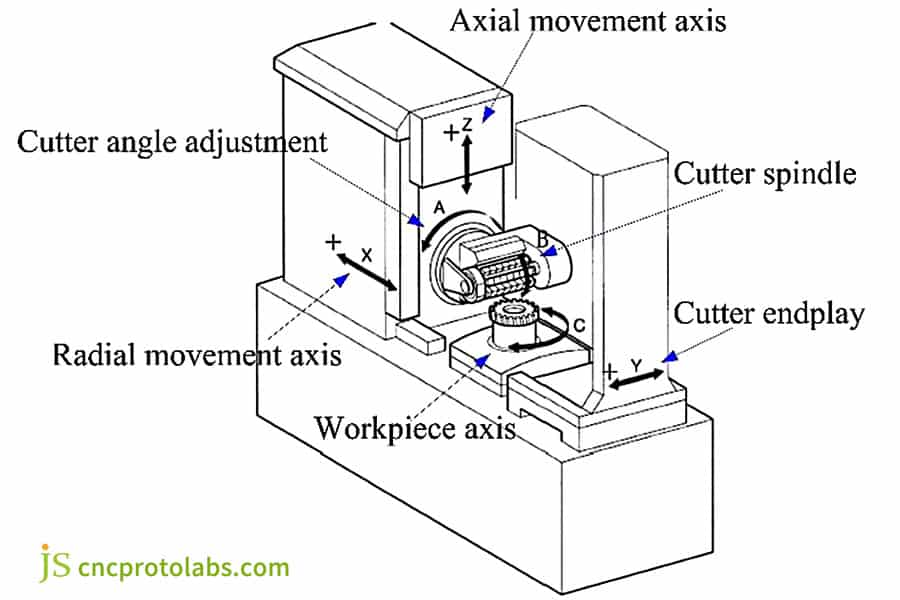

Precision in gear hobbing machines is achieved through the collaboration of essential components:

- CNC System: Siemens/Fanuc brand with highly accurate axis movement with error compensation functionality.

- Spindle: Bounce error<± 1 μ m, ensuring stable rotation.

- Tool Spindle: High rigidity for minimal cutting vibration.

- Worm Gear Pair: Hardened and ground process, transmission error <0.5µm.

Five-Axis Linkage and Automation: Conquering Difficult Gear Shaping and Unmanned Production What is five-axis linkage

JS Precision's five-axis linkage gear hobbing machine possesses the capability to process complicated gear shaping with a shaping tolerance of ±5μm. In addition, there is an automatic production line with a robot arm and an automatic tool setter. Accordingly, it supports unmanned production. The processing efficiency has been increased by 40%.

Precision Foundation Machine Rigidity, Thermal Stability, and Repeatability

A gear hobbing machine's precision is determined by three major factors:

- Rigidity: High quality cast iron bed, surpassing standards by 20%.

- Thermal Stability: The temperature control system maintains a temperature of ± 1 ℃ to reduce thermal deformation.

- Repeatability: Up to ±2μm.

The gear hobbing machine of JS Precision allows for online detection and compensation systems, meaning it can automatically detect dimensions and compensate for errors as it manufactures products that meet precision standards.

Why Are Gear Hobbing Tolerances The Benchmark Of Your Gear's Performance?

Gear hobbing tolerances directly determine the efficiency, noise, and lifespan of gear transmission. High end applications have strict requirements for them, and JS Precision can accurately ensure that products meet the standards.

Key Tolerances Described

Core Tolerances and Control Standards:

- Tooth profile error (fHα): Precision gears ≤4μm.

- Tooth direction error (fHβ): ≤3µm ensures equal loading.

- Radial runout (Fr): ≤5μm ensures concentricity.

- Cumulative pitch error (Fp): Precision gears ≤ 8μm.

From Numbers to Experience: How Do Tolerances Affect End Applications?

Gear hobbing tolerances greatly affect the end-user experience because:

- Noise level: The noise level can be lowered by 3-5dB. The circuit meets low noise specifications.

- Transmission efficiency: As tolerancing becomes more accurate, transmission efficiency gets improved by 1-2%, thereby increasing the range of the vehicle.

- Fatigue life: Uniform load extends the life by 20-30%.

Application Scenario Benchmark

Different scenarios have different requirements for gear hobbing tolerances:

| Application Scenario | Precision Grade (ISO/AGMA) | Key Tolerance Requirements | JS Precision Solution |

| Automotive Automatic Transmissions | ISO 5-6/AGMA 10-12 | fHα≤3μm, Fp≤6μm | Five-axis linkage gear hobbing + SPC control |

| Industrial General Gears | ISO 7-8/AGMA 6-9 | fHα≤6μm, Fp≤10μm | High-precision gear hobbing + online inspection |

| Aerospace Gears | ISO 4-5/AGMA 12-14 | fHα≤2μm, Fp≤4μm | Customized process + multi-dimensional inspection |

Case Study: JS Precision Overcomes Mass Production Challenges For Two-Speed Electric Drive Gears In High-End Electric Vehicles

Challenge

The trial production of a two speed electric drive gearbox by a certain new energy vehicle company encountered problems: meshing noise of 72dB (exceeding 2dB), transmission efficiency of 97.2% (not reaching 98.5%), and mass production yield of 97.5%, resulting in high costs and delivery delays.

JS Precision Solution:

1. DFM Analysis & Optimization of Tooth Profile Modification Parameters:

By inputting relevant data from the gear measurement center and acoustic simulation results, the engineering team performed a series of DFM analyses.

Besides, they found that most of the problems exist in gear tooth profiles & directions being unreasonably designed. In accordance with the computed results, the optimum parameters of tooth profile modification (with modification amount ±5μm) have been pre-defined.

2. High-Precision Machining with Superhard Coated Tools and a Five-Axis Linkage Gear Hobbing Machine:

By importing the five-axis linkage gear hobber for our technological center, high-precision machining with superhard coated tools was enabled to be customized for gear materials to be machined with the five-axis linkage gear hobber.

3. Full Process Accuracy Detection:

SPC control regulation of real-time on the whole process, emphasizing monitoring critical tolerances, such as tooth profile error (fHα ≤ 4μm), and accumulated pitch error (Fp ≤ 6μm). The gears shall meet requirements of American Gear Manufacturers Association (AGMA) Level 13. Online setting inspection station will reject defective products online.

Results:

Key outcomes obtained post-implementation: Noise level reduced to 69dB, efficiency increased to 98.7%, yield of 99.8% obtained, unit cost of 15% decreased (which translates to a saving of $200,000 each year), and the delivery cycle cut down by 20%, enabling earlier launch of new products.

Customer Testimonial: "JS Precision's customized solutions accurately solve the core pain points of our electric drive gearboxes, with noise and efficiency indicators far exceeding expectations. The quality stability during mass production provides a key guarantee for the launch of our new products and is a long-term trusted strategic partner."

This case fully demonstrates JS Precision's ability to solve the complex challenges of mass-producing high-precision gears. Does your gear project face similar problems? Contact us to share your specific needs, and our team will customize a solution for you.

Can Custom Gear Hobbing Services Realize Your Complex & Prototype Designs?

Complex gear manufacturing or small-batch prototype gear reproduction requires high flexibility as well as technical knowledge. JS Precision custom gear hobbing services offer a one-stop solution for prototype and small-batch productions.

Custom Complex Gears: Meeting the Challenges of Special Needs

Complex customizations include specific material machining, exotic tooth profiles, micro-modules gears representation, among other customizations. The key quantitative machining parameters related to customized requirements are shown in the table provided below.

| Customization Need Type | Module Range (mm) | Tooth Count Range | Tooth Width Range (mm) | Material Hardness (HRC) | Modification Tolerance (μm) | Prototype Delivery Time (days) | Prototype Delivery Time (days) |

| Micro-module Gear Customization | 0.2-0.8 | 12-50 | 2-8 | 28-42 | ±3-±5 | 7-10 | 300-500 |

| Special Material Gear Customization | 0.5-5 | 15-80 | 5-30 | 35-62 | ±4-±6 | 10-14 | 200-400 |

| Extreme Tooth Profile Gear Customization | 0.6-3 | 20-60 | 8-25 | 32-58 | ±2-±4 | 14-20 | 150-250 |

| Thin-walled Gear Customization | 0.8-2.5 | 18-45 | 3-15 | 30-45 | ±3-±5 | 12-16 | 250-350 |

| Customized Composite Gears | 0.6-3 | 16-55 | 8-25 | 35-55 | ±2-±3 | 16-22 | 100-200 |

The above-mentioned customization parameters can also be met by JS Precision. It maintains a group of skilled technical staff and advanced machinery that overcomes processing difficulties effectively for ensuring accuracy and quality in customized gears.

Process Innovation: Breaking Through Customization Bottlenecks

To fulfill their requirement for custom gear hobbing services provision, we address the limitation for customization in the following three core fields of innovation:

- Customized Cutting Tools: Hobs are designed for specific tooth profiles.

- Cutting Optimization: Parameter adjustment for different materials/specifications optimizes for reduced wear and increased accuracy.

- Hybrid Processes: Gear hobbing and grinding for surface finish precision.

Design for Manufacturability: The Value of DFM Intervention

The benefits DFM promotes early stage interventions in manufacturing. We support carrying out one trial production based on a prototype within 2-3 weeks. You will be provided with a free DFM report and quotation within 48 hours after uploading your drawings.

How To Scale High-Volume Gear Hobbing Without Compromising Quality?

The production of gears on a mass production basis with quality is an issue in the industry. JS Precision uses automation, lean production, and quality management to enable an efficient approach to mass production.

Consistency Challenges: Tool Life and Dimensional Drift

In high volume gear hobbing, tool wear and dimensional drift are key to quality, and we accurately respond by monitoring tool life in real-time and adjusting SPC parameters.

Automation and Lean Manufacturing: Driving Cost Reduction and Efficiency Improvement

Our high volume gear hobbing system achieves cost savings and productivity improvements based on automation (efficiency improvement by 50%), MES system, and lean production.

Supply Chain Resilience: Ensuring Stable Delivery

Creating Uninterrupted Flow in A successful supply chain is essential for mass production. We have built long-term contracts with our major suppliers and also established a safety stock. The monthly production volume of our standard gears is 1 million units, and our delivery performance for large volume shipments is over 99%.

Looking for a reliable high volume gear hobbing partner? Contact us for a free mass production cost estimate and learn how we can help you achieve efficient, high-quality, and cost-effective gear production.

Who Should Be Your Ideal Gear Manufacturing Partner? An Evaluation Framework

Choosing the right gear manufacturing companies can be a critical determinant of success in the project. The evaluation can extend beyond the cost criteria based on the overall capacity.

Specialized vs General-Purpose Firms: Key Differences in Core Competencies

There is a significant difference between professional gear manufacturing companies and general factories:

- Technical Expertise: Starting from their background in the gear industry.

- Equipment Investment: Equipped with specialized high-end equipment such as gear hobbing machines.

- Extensive Experience: Has experience in handling production problems efficiently, thus removing all possible threats.

- Strict Quality Control: Full process testing and traceability to ensure consistency.

Five Key Evaluation Dimensions: Complete Partnership Value Appraisal

The five key factors that must be evaluated in regard to finding a potential manufacturing partner for gears are:

- Equipment Level: It includes advanced equipment like gear hobbing machine.

- Technical Team: Experience / Technical Support Capabilities.

- Service Capabilities: One stop full cycle support.

- Industry Experience: Accumulation of corresponding field projects.

- Quality Certifications: International standards such as IATF 16949:2016.

Needs Matching: Finding the Right Partner

Different project needs require different partners:

- Rapid Prototyping: Select a partner with high flexibility and efficient processes.

- High-Precision Prototypes: Find a partner with strong custom gear hobbing services and fast delivery.

- Mass Production Projects: Engage a partner with a mature high volume gear hobbing system.

FAQs

Q1: What is the highest precision level achievable through gear hobbing?

Ultra-precision levels of ISO class 5 or AGMA class 14 are achieved in gear hobbing, thanks to world-class machines and optimized processes. The critical tolerance, namely profile error of teeth, remains ≤2 micron limits, thus meeting high-precision requirements of high-end applications.

Q2: What is the typical lead time for gear hobbing?

Lead time would depend on the type of gears ordered based on batch size and the level of complexity. Orders for prototypes would require 2-3 weeks for small batch sizes, while for larger batch sizes, the time required would be 4-6 weeks for production orders.

Q3: What gear materials can you process?

In our gear hobbing services, a range of gear materials including different types of alloy steel, stainless steel, titanium alloys, powder metallurgy materials, and engineering plastics like POM are supported. We have an abundance of material processing knowledge and process know-how.

Q4: What are the minimum and maximum machining module ranges?

We provide gear hobbing services ranging from micro-modules of 0.2 to macro-modules of 10, catering to the processing requirement of micro-precision gears and up to macro-industrial gears with respect to the use requirement in most industries.

Q5: How do you ensure consistency in mass production?

In automated production lines, we limit human interference, integrate online inspection systems for real-time monitoring of sizes, and make use of statistical process control in analyzing data trends. Life management for tools is carefully done to ensure consistency in mass production hobbing.

Q6: Are the start-up costs for prototype development and small-batch production high?

JS Precision provides flexible collaboration opportunities for prototype manufacturing, small-batch production, more, via process improvement, resource sharing, in order to cut start-up costs, so as to help customers with prototype prototyping in very low quantities, including just one piece.

Q7: How do you handle gear deformation during heat treatment?

Our early DFM designs are optimized to provide reasonable machining allowances. For heat treatment processes, we emphasize appropriate processes. In gear manufacturing processes, we use a composite process of "gear hobbing-heat treatment-hard turning/grinding" to properly manage heat treatment deformation.

Q8: What is your minimum order quantity (MOQ)?

In matters concerning prototyping as well as custom orders, we do not have any minimum order quantity. For mass production orders, one may negotiate a minimum order quantity based on their specifications.

Summary

Precise gear hobbing is the foundation of high-quality gears, the precision of gear hobbing can directly lead to success or failure in the end product. If it is customized prototypes or bulk manufacturing, it is important to select the right partner for gear manufacturing.

JS Precision boasts advanced gear hobbing technology, strict quality control measures, and flexible services to turn designs into quality products. JS Precision is your best choice from design for manufacturing analysis to mass production delivery.

Your next high-precision gear project deserves the most professional support. Contact JS Precision immediately and let our engineering team provide you with customized gear hobbing services, transforming precision craftsmanship into a competitive advantage for products and driving project success together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com