Pinion machining is an important part in industrial devices.

In the transmission mechanism, the pinion bears the entire responsibility for the success or failure of power transmission. A minor mistake in tooth profile results in noise, vibration, and sometimes early failure of the system, while its excellence in precision provides silky-smooth, noiseless operation with much-extended life.

Whether it's the common spur gear and pinion pairing or the rack and pinion gear system converting rotary to linear motion, the quality of the pinion gear is the cornerstone of performance. JS Precision understands that the art of pinion machining goes far beyond basic replication of the tooth profile in material, precision manufacturing, and heat treatment.

Key Answer Summary

| Core Consideration Dimensions | Technical Challenges and Solutions | JS Precision's Value-Added Services |

| Accuracy and Performance | Tooth profile error, tooth surface smoothness, and heat treatment deformation are the core challenges. We use processes such as Spin Pinion Machining, CNC gear scraping, and grinding to ensure quality. | Provide one-stop optimization from material selection, DFM analysis to heat treatment process to ensure tooth profile accuracy and durability. |

| Design Points | Clarify the role differences between pinion vs gear (small gears are usually more prone to wear), pay attention to the pairing parameters of spur gear and pinion, and consider the meshing characteristics of rack and pinion. | Our engineers participate in design reviews, optimizing parameters to improve efficiency, reduce noise, and extend lifespan. |

| Cost and Delivery Time | Pinion Machining Cost is influenced by materials, precision, heat treatment, and batch size. Small batches can be optimized through standardized processes and intelligent scheduling. | We help you find the best balance between cost and performance while ensuring quality through process innovation such as Spin Pinion Machining and transparent pricing. |

Why Trust This Guide? JS Pinion Machining Practical experience

Before getting into the specific technical details regarding pinion machining, one might ask, why is this guide reliable? The answer lies in JS Precision's practical experience in gear machining over the years.

Precision pinion machining has been the concentration of our company since its inception, with the completion of more than 5,000 different projects for over 10 industries like automotive, robotics, and medical devices. Steel spin pinion precision machining projects take up about 35% of our total projects.

For instance, we machined 0.8 module pinions for an industrial robot manufacturer. With the optimization of the scraping process and heat treatment procedures, we were able to control the cumulative pitch error within 0.005 mm.

This precision not only far exceeds the ISO 7 level required by the customer, but also reflects our deep understanding and application of the best practices outlined by the American Gear Manufacturers Association (AGMA) in the "Precision Gear Manufacturing Guidelines".

Moreover, we are familiar with the machining characteristics of various alloy steels such as 4140 and 8620. It enables us to shorten the production cycle from the industry average of 6 weeks to 3 weeks in case of small-batch orders (up to 50 pieces) for customized jobs.

This handbook is a collection of practical case studies, process parameters, and problem-solving solutions. Each suggestion herein has been verified in actual production, so you may refer to it with full confidence.

If your project needs Steel Spin Pinion Precision Machining services or requires more information concerning related case studies, then feel free to contact JS Precision for one-on-one technical support.

What Are the Hidden Challenges In Precision Pinion Machining?

After understanding the reliability of the guide, let's break down the easily overlooked challenges in Pinion Machining, which directly affect the effectiveness of gear machining. Beyond conventional milling, the challenge of Pinion Machining begins with gaining control over the microscopic world.

The ultimate pursuit of tooth profile and tooth direction

The core problems are tooth profile, cumulative pitch error, and helix accuracy. Micrometer-level deviations can cause noise and vibration. For example, a customer's pinion had excessive noise due to a 0.02mm tooth profile error, exceeding the ISO Class 6 standard.

Steel Spin Pinions, because of their high material hardness, are even more difficult to control in terms of tooth direction accuracy, requiring optimized toolpaths.

Why Does Surface Finish Determine Lifespan?

The surface finish of the tooth is directly related to the oil film formation process. In case it exceeds Ra 1.6μm, direct metal-to-metal contact and accelerated pitting corrosion are possible. Once, one customer's pinion incurred pitting corrosion after running for only 300 hours because of a substandard surface finish. After we remachined it to Ra 0.4μm, its lifespan well exceeded 5000 h.

The Heat Treatment: Balancing Hardness and Dimensional Stability

While carburizing and quenching are good for improving hardness and wear resistance, these methods easily lead to distortion, especially in steel spin pinions. We use a controlled atmosphere carburizing furnace to reduce distortion, with a temperature fluctuation of ±5℃. Following this is gear grinding to ensure both hardness and precision meet standards.

Should you have any problem in pinion machining such as heat treatment deformation or surface finish, please do not hesitate to contact JS Precision for a customized gear machining solution based on the characteristics of the part.

How To Ensure The Tooth Profile Accuracy And Smoothness Of Pinion Machining?

Precision comes from advanced technology and rigid control. In order to guarantee the tooth profile accuracy and surface finish for pinion machining, there are several stages that have to be taken into account, from machining to inspection.

Spin Pinion Machining - Redefining Continuous Cutting

Processes like tooth scraping have involvement of the tool and workpiece continuously, hence offering 30%-50% higher efficiency compared to conventional gear shaping and hobbing. The error in the tooth profile is ≤0.005mm and Ra as low as 0.8μm. We achieved accuracy at ISO 6 level and improved efficiency by 40% for customers in automotive transmission.

The Final Touch: Grinding and Honing for Superfinish

Grinding is very important for finishing, and it plays an indispensable role when accuracy to the ISO 5-6 level or a mirror finish is required. We apply high-precision gear grinding machines fitted with diamond grinding wheels to achieve Ra 0.2μm and cumulative tooth pitch error ≤0.003mm, meeting low-noise requirements of medical devices.

Our Complete Quality Monitoring System

Utilize the gear measurement center and CMM to inspect the material before and after processing. During the process, sample the tooth profile and pitch for verification. The defect rate in the steel spin pinion machining project is ≤0.1%.

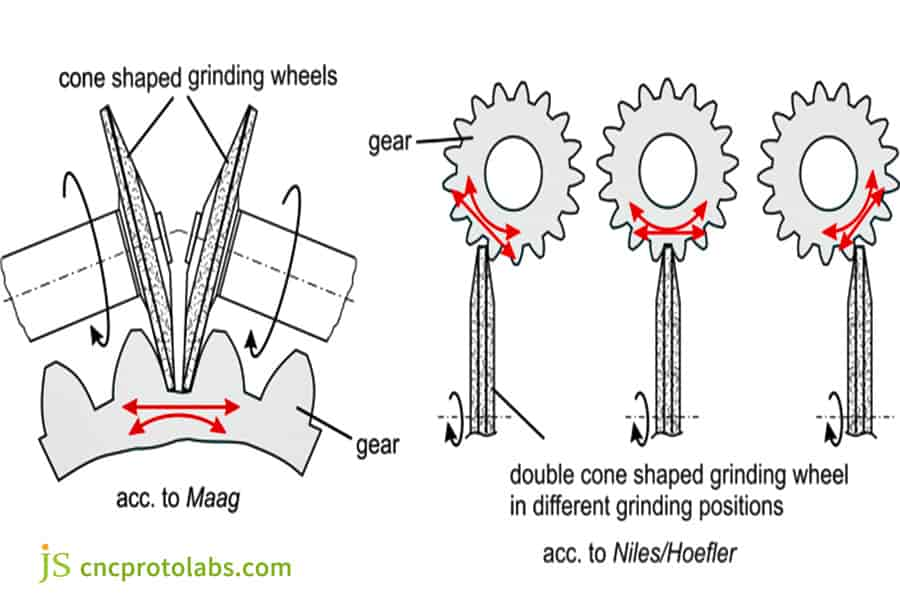

Figure 1: Gear grinding.Grinding is the key to precision machining.

Pinion Vs Gear: A Designer's Guide To Roles And Responsibilities

A clear understanding of the difference between pinion vs gear is the first step in optimizing transmission design. Although they are in the category of gear machining, their design and use are very different.

| Comparison Things | Pinion | Gear |

| Number of Teeth | Usually fewer, 10-20 teeth. | Usually more, 30-100 teeth. |

| Cyclic Stress | Higher, higher rotational frequency. | Lower, lower rotational frequency. |

| Material Requirements | High-strength alloy steel (e.g., 8620). | Conventional alloy steel (e.g., 4140). |

| Failure Risk | Higher - prone to pitting, tooth fracture. | Lower - slower wear. |

| Design Focus | Strength of the tooth root, hardness of the surface. | Load-bearing capacity in general. |

Why is the pinion typically the design focus?

The pinion has fewer teeth and higher rotational frequency, with up to 2-3 times that of the large gear in the same system, with more cyclic stress and over 50% more wear. Higher grade material and heat treatment is required to extend its lifespan.

Size Matters: How to Find the Optimal Transmission Ratio and Center Distance?

Calculate gear ratio (transmission ratio) based on the rotational speed and torque. Then, from the formula "Center distance = (Number of teeth on the pinion + Number of teeth on the large gear) × Module ÷ 2", calculate the center distance. For example, when the gear ratio is 1: 3, module is 2, the number of teeth for the pinion is 15, for gear is 45, and the center distance is 60mm.

When is it necessary to use a special pinion?

- Helical pinions are suitable for high-load, smooth transmissions, such as in automotive gearboxes.

- Bevel pinions are suitable for intersecting shaft transmissions, such as the steering of machine tools.

- Worm pinions are suitable for high reduction ratio occasions, such as elevator lifting.

If you are not sure how to specify the type of pinion in your design, or need to compare the particular parameters of the pinion vs gear, please contact JS Precision. Our engineers will provide professional design advice for you.

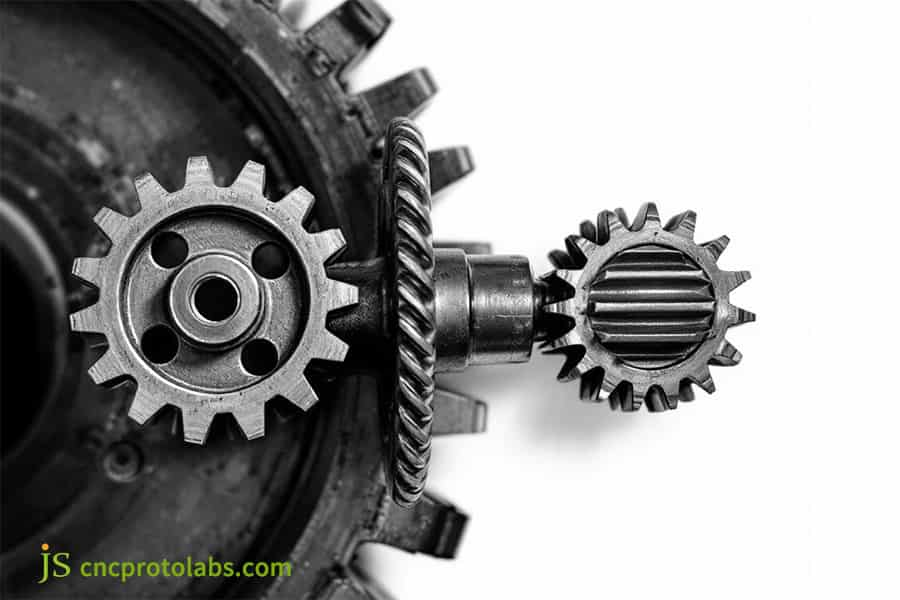

Figure 2: Pinion vs gear. They have some key differences in functionality, size and shape, number of teeth, speed, and application.

Why Is Spin Pinion Machining A Game-Changer For Modern Gear Production?

This section shows the advanced technology JS Precision boasts. In modern gear machining, Spin Pinion Machining is revolutionizing the industry with environmentally friendly, efficient, and flexible advantages, especially that of steel spin pinion precision machining.

Dry Machining and High Efficiency:

Without the need for cutting fluid, the cost of waste disposal for cutting fluid can be saved at $1000-$2000 dollars per month, while simultaneously reducing processing time by 20%-30%. We have processed many batches of steel spin pinions for new energy companies, raising daily output from 50 to 70 pieces.

Flexibility in Small Batch Production:

Fast changeover and flexible programming, switching between different pinions takes only 1-2 hours (compared to 4-6 hours with traditional processes). We completed the production of 30 different specifications of steel spin pinions within 5 days.

Chip Control and Tool Life:

Continuous cutting provides excellent chip breaking and longer tool life, extending tool life by over 50% compared to conventional hobbing, and reducing unit cost from $2 to $1.30.

If your company has small-batch steel spin pinion precision machining needs or wants to reduce costs through the spin pinion machining, please contact JS Precision. We will develop a customized production solution for you.

Designing For Harmony: Key Considerations For Spur Gear And Pinion Pairs

Successful design relies upon achieving perfect meshing. In the design of spur gear and pinion pairs, several parameters are to be attended to, while rack and pinion gear systems also have their particular design considerations.

Selection of Pressure Angle and Module: The Basis of Power Transmission

The selection of pressure angle and modulus directly affects the bearing capacity, noise, and size of spur gear and pinion.

There are two commonly used pressure angles: 20° (high load-bearing capacity, suitable for engineering machinery) and 14.5° (stable meshing, low noise, suitable for precision equipment).

The module determines the gear size. The larger the module is, the greater the load-bearing capacity will be. Taking module 3 as an example, the tooth thickness increased by 50%, and the load-bearing capacity increased by more than 40% compared with the teeth of module 2.

So in further steps, we are supposed to choose parameters based on customers' needs for ensuring stable power transmission.

The Art of Profile Shift: Avoiding Undercut and Optimizing Strength

Profile shift is widely used in spur gear and pinion pairings to avoid undercutting and optimize strength.

When the pinion has fewer than 17 teeth, the standard design is prone to undercut-excessive cutting at the tooth root reduces strength-which can be avoided by increasing the tooth root thickness in a positive profile shift design.

Simultaneously, the profile shift can balance the bending strength of the two gears, for instance, positive profile shift on the pinion and negative profile shift on the gear can make the root stress of both gears converge.

In one design for a machine tool customer, the profile shift increased service life for the pinion by 30%.

Backlash Control: The Delicate Balance Between Smoothness and Precision

In the rack and pinion gear transmission system, backlash control is very important. The transmission accuracy and impact noise are generated due to the inappropriate amount of backlash, represented by the meshing tooth surfaces.

Backlash controls are done in three ways: the value set according to a particular scenario during the design phase, such as in precision transmission using 0.01-0.03mm, adjusting the cutting tool in machining for maintaining the accuracy in tooth thickness, and fine-tuning the center distance during assembly.

If you encounter parameter selection difficulties during spur gear and pinion or rack and pinion gear design, please don't hesitate to contact JS Precision for detailed design solutions and support in calculating parameters.

What Truly Drives Pinion Machining Cost?

We build trust with our customers by providing transparent cost breakdown analyses. There are three major factors that determine pinion machining cost: material, precision requirements, and post-processing. Knowing them will help you better control the cost.

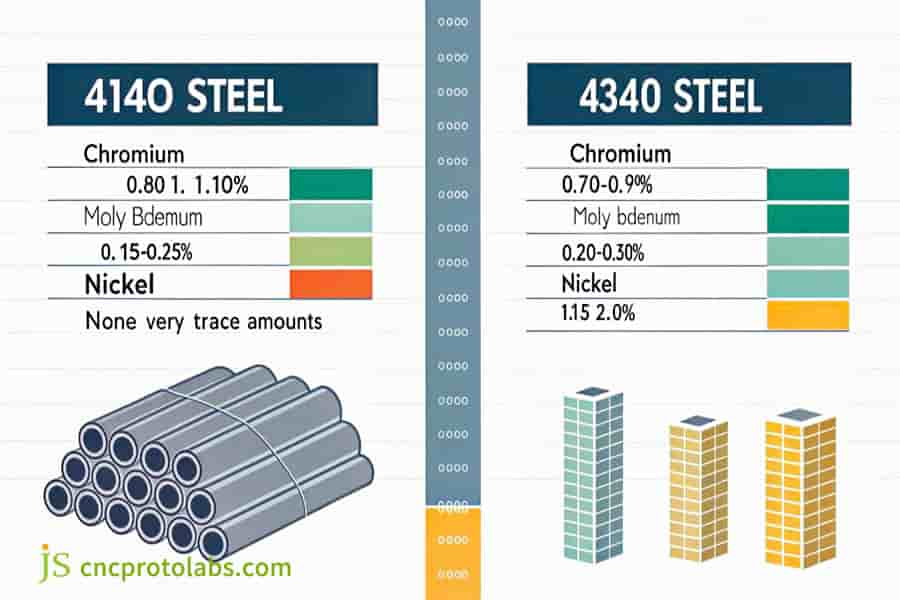

Material Grade and Machinability: Cost-Effectiveness Trade-offs from 4140 to 8620

| Material Type | Price/ton (USD) | Machinability | Heat Treatment Performance | Applicable Scenarios |

| 4140 | 1200-1500 | Good | Medium | General Load Pinion Machining. |

| 4340 | 1800-2200 | Medium | Excellent | High Load, High Strength Requirements. |

| 8620 | 1800-2200 | Good | Excellent | Precision Pinion Machining Requiring Carburizing and Quenching. |

Material grade and machinability are both basic factors in pinion machining costs. We will promote cost-effective materials according to customer needs.

The Tolerance Tightrope: Why does increased precision lead to exponential cost increases?

Therefore, the cost increases are all about precision requirements.

Increasing the quality from ISO 8 to 6 drastically raises the costs: ISO 8 relies on gear hobbing at a cost of $10-15 per piece, ISO 7 involves gear hobbing + semi-finish grinding for $18-25, while ISO 6 involves gear hobbing + heat treatment + grinding, which costs $30-45.

Greater precision also increases testing costs, the testing time for ISO 6 is 3-4 times that of ISO 8.

The Hidden Cost of Heat Treatment and Finishing

Many times, heat treatment and finishing processes are considered 'hidden' costs - such as carburizing and quenching, ranging from $5-10 per piece depending on the size of the part, a shot peening for improving tooth root strength at $2-3 per piece, and phosphating to add rust resistance at $1-2 per piece.

While adding cost, these will greatly improve the overall performance and life span for the pinion. We will offer a complete breakdown to our clients in order for them to understand where total quality management adds value.

Figure 3: 4140 and 4340 steel cost composition

Optimizing For Agile Manufacturing: Streamlining Lead Times And Pricing For Custom Orders

The section addresses efficiency and price-related concerns about small-batch, customized orders. In pinion machining, processes and workflows can be optimized such that lead times for small batches are effectively short while keeping costs at low levels.

Leveraging Standardized Tooling and Processes: Balancing Speed and Cost

We reduce the setup time and lower the start-up cost for small batches by using a standard tool library and mature process parameters.

A standard tool library with modules of 0.5-10 eliminates the need to make a custom tool for regular pinions, saving 3-5 days, by inputting mature parameters into the system, new orders require only minor adjustments, reducing setup time from 2 days to half a day.

We once processed 20 module 3 pinions for a client and reduced the cycle time from 10 days to 7 days while lowering the start-up cost by 20%.

Digital Prototyping & Virtual DFM: Solving All Problems Before Production

All of our quotes are backed by digital DFM work, at no additional cost, to help predict and avoid machining problems. Once a client provides drawings, digital prototypes are created via 3D modeling, machining is simulated, and design issues are identified such as a tooth root fillet that is too small or a mismatch between bore diameter and tooth count.

A customer's recent pinion tooth root fillet of 0.1mm was susceptible to stress concentration. We recommended increasing it to 0.3mm to avoid rework, saving 5 days and $2000 in costs.

Flexible Production Scheduling for Urgent Needs

We reserve the fast-track production channel for key customers. Urgent delivery for any quantity can be supported, without compromising quality. Given the urgent orders of the customers, we give priority to production scheduling:

A customer needed 15 urgent pinions and wanted delivery in 3 days. We turned on the fast track and completed the order in 2.5 days to minimize the losses brought about by downtime. The fast track only adds a 10%-15% rush fee to the regular price, offering excellent value.

Case Study: From 95dB To 68dB—Endowing High-Speed Robot Joints With "Silent" Gears

The case study represents a classic example of JS Precision's work on Steel Spin Pinion Precision Machining, solving difficult problems regarding pinion machining, and allows for referring to how spur gear and pinion pairing can be optimized.

Customer Dilemma

In the test of a new articulated arm from a high-end industrial robot manufacturer, noise levels reached as high as 95dB, far in excess of the standard 75dB for high-end machines. As such, it did not meet the quiet operation requirements of medical, electronics, and other applications.

The pinion gears showed pitting corrosion on the tooth surface after 500 hours of load testing, hence they had a lifespan of only 800 hours instead of 3000 hours as expected, impacting product competitiveness.

Fundamental Analysis

By using a gear-measuring center and roughness tester for the inspection of an existing pinion, we found the following three core problems:

- The tooth profile accuracy was only ISO 8, whereas ISO 6 was called for with a tooth profile error of 0.02 mm.

- Tooth surface Ra was 1.6 μm, which is too rough to form a stable oil film.

- Uneven heat treatment temperature control resulted in a difference of 0.2 mm in the hardened layer between the teeth, and inadequate hardness in some places accelerated the wear.

JS Precision Solution

1. Material Upgrade: Vacuum-melted 8620 steel is recommended since it has 40% higher purity over the customer-supplied 4140 steel, which reduces the risk of deformation and pitting during heat treatment.

2. Precision Machining: Use Steel Spin Pinion Precision Machining for rough machining to ensure tooth surface consistency and leave even allowance for precision machining.

3. Optimized Heat Treatment: controlled atmosphere carburizing furnace is used, and furnace temperature fluctuation is controlled within ±5 ℃. The hardening layer depth is controlled in real time to ensure the uniformity is within 0.05mm and reaches a hardness of HRC58-62.

4. Ultimate Refinement: Combining high-precision gear grinding with diamond wheels raises the accuracy of spur gear and pinion considerably to ISO 5, with a total cumulative pitch error ≤0.003 mm and tooth surface finish Ra 0.4μm.

Our Achievements

Customer 2000-hour load testing indicates that the noise of the robot joint is maintained at 68dB, meeting high-end quiet operation requirements, no pitting wear on the tooth surface appears, and the lifespan is expected to be over 5000 hours, which exceeded expectations by 1.7 times, helping customers launch high-end robot products and capture the niche market.

Figure 4: Industrial robot articulated arm small gear

FAQs

Q1: What are the most common failure modes of pinion machining?

Tooth surface pitting and root fracture are the most common failure modes in Pinion Machining.Pitting and tooth root breakage. Pitting is caused by contact fatigue on the tooth surface, while tooth breakage comes from the bending fatigue overload in the tooth root, both related to machining accuracy.

Q2: Under what circumstances is grinding necessary for pinion machining?

In cases when the accuracy of the pinion machining is higher than ISO 7 class, tooth surface hardness is higher than HRC 45, or very high operational smoothness and noiselessness are required, grinding should be used.

Q3: Does spin pinion machining replace grinding?

Spin pinion machining alone cannot replace grinding. The most efficient semi-finishing/finishing process is by spin pinion machining, but a higher accuracy and surface finish are possible by grinding. Selection of either process will depend upon the quality requirement.

Q4: What are the special design features of the pinion gear in a rack and pinion gear system?

In designing a pinion in rack and pinion gear systems, tooth root strength should be improved to resist meshing impact, considering the improvement of wear resistance on the tooth surface. Deep carburizing and quenching are usually necessary.

Q5: What is the smallest module pinion you normally deal with?

JS Precision commonly undertakes orders for pinion machining of modules from 0.5 to 10. In addition, special machining processes are required for the micro-gears with modules less than 0.5.

Q6: How long does it usually take to make small batches, say 50 pieces with customization and pinions?

Since the different processes take different times, the general cycle for machining of the pinion for small-batch orders of 50 pieces takes 2-4 weeks. These can be expedited with expedited service.

Q7: What are the surface treatments that you apply for rust and wear resistance?

The surface treatment in pinion machining includes blackening, phosphating, zinc plating, nickel plating, and DLC to satisfy the requirements for rust prevention and wear resistance in various environments.

Q8: Why choose JS Precision instead of other gear machining plants?

As for why JS Precision was chosen, we focus on high-precision, small-batch customized pinion machining and provide end-to-end services and advanced processes, delivering technical solutions instead of parts.

Summary

The quality of the pinion in power transmission stands for the upper limit of performance of the whole system. It's the art of shaping metals, but all in all, it's a final pursuit of precision, durability, and efficiency.

The need to grope in a fog of technology for precision pinion machining in the pursuit of tight tolerances and customized production is not there. Instead, JS Precision could balance precision, cost, and delivery time by tending to your needs with rich practical experience, advanced processes like spin pinion machining, and end-to-end quality control.

Critical components should not be a bottleneck in your whole project. Please submit your design challenges to us now!

Please go to JS Precision's official website, upload your gear drawings or technical requirements, and get comprehensive feedback within 24 hours, including detailed process plans, transparent quotations, and professional DFM analysis. Let us be your most reliable transmission component manufacturing partner!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com