The gear manufacturing cost is a major concern of equipment procurement and budgeting for industries. In cases like auto transmission and robot joints, the accuracy and quality of gears are directly related to equipment performance. Nevertheless, gear manufacturing cost composition is intricate and may frequently mask project considerations.

This article will help you clear the cost fog and systematically analyze the deep composition of gear manufacturing cost to the technical cost of implementing 1 micron tolerance gear manufacturing cost, providing a clear methodology.

This article will aid you in selecting the right process, getting quotes, creating a cost understanding system, and maximizing your investment opportunity for custom gear manufacturing projects.

Core Answer Summary

| Core Question | Key Answer | Value |

| How is cost composed? | The cost comprises aspects such as material requirements, man hours, precision, and customization needs. | It is essential that a comprehensive cost view be developed. |

| How to choose the optimal process? | Processes should be assigned based on the batch size and complexities. | All the mentioned processes could potentially pose some risk of process mismatch. |

| How to obtain an accurate quote? | Specify technical and business requirements and decode details given by quote details. | Acquire skills in investigating inquiries for evaluating worth. |

Key Takeaways

- Precision costs increase exponentially: Higher accuracy levels, such as a tolerance difference of ±0.01mm to ±0.001mm, can lead to a multi-fold increase in costs due to the difficulties faced in the working conditions of the gear cutting machine.

- Early Collaboration drives the cost baseline: Adding a DFM (Design For Manufacturing) analysis as part of the custom gear manufacturing design process can remove unnecessary expenses and maximize up to 20% of cost savings.

- Batch size determines the technology selection: For prototyping based on the small-batch product, CNC gear machining is appropriate, and for mass production, either powder metallurgy or casting should be selected for the lowest cost.

- Total cost thinking is better than unit price thinking: A professional CNC machining quote should detail all costs, helping you focus on the comprehensive value and risks behind gear machining services cost.

Why Trust This Guide? A Cost Analysis Of JS Precision Gear Manufacturing

JS Precision has been extensively involved within the gear machining industry for the past 15 years and is an expert in custom gear manufacturing and precise gear cutting. JS Precision has served more than 500 customers and accomplished more than 1000 complex gear orders.

In order to deliver precision to our customers, we own an array of high-precision gear cutting machines that include German gear grinding machines and Japanese Tsudakoma gear hobbing machines. In addition to this, we also own an entire quality control system adhering to the ISO 1328 norm.

Reliable information proves the validity of our professionalism. According to AGMA 9005-E02, for every 2-level increase in gear accuracy, the average manufacturing cost increases by 60% -120%, which is highly consistent with the data accumulated from our years of projects.

A European robotics customer, through our process optimization and DFM analysis, was able to achieve a gear manufacturing cost reduction of 40% without compromising AGMA level 11 accuracy.

Our guide does not stack theories, but only provides cost optimization methods and process selection logic that have been verified through practical experience. Whether you need small-batch prototyping or mass production, whether you prioritize standard precision or 1 micron tolerance gear manufacturing cost, you can find a solution tailored to your needs here.

Want to verify our cost optimization capabilities? Submit your gear drawings or technical requirements to JS Precision, and our engineering team will provide you with a free preliminary cost assessment and process suggestions, allowing you to intuitively experience the value of professional custom gear manufacturing services.

What Really Makes Up Your Gear Manufacturing Cost?

Cost structure knowledge is the most important basis of optimization. In addition to the cost of materials, the hidden cost, such as work time and precision, has an important impact, and gear machining efficiency directly affects the cost.

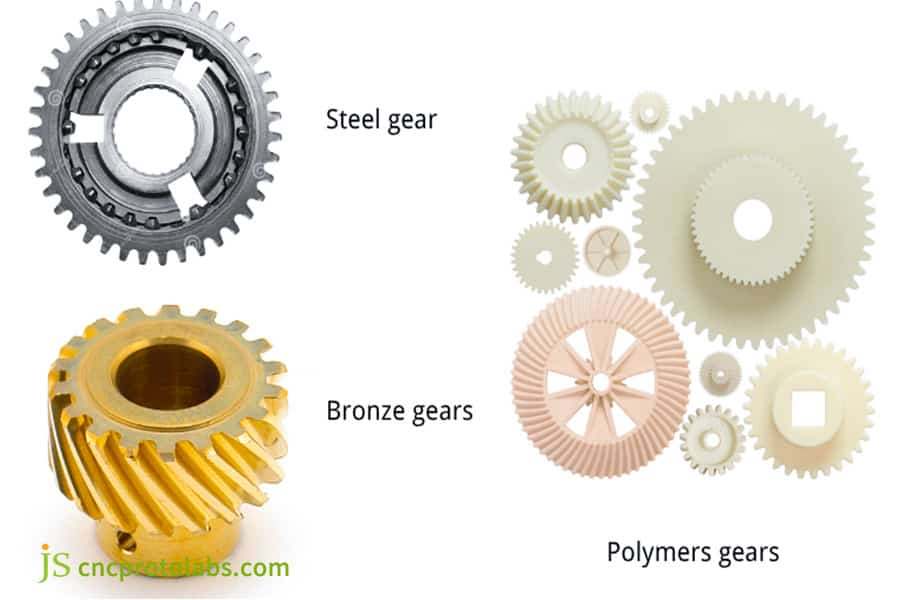

Material Costs: More Than Just Unit Price

Material choice is a direct source of differences in cost and performance. There are major differences among materials regarding cost, workability, and usage, as indicated in the following table:

| Material Type | Unit Price (USD/kg) | Hardness (HRC) | Machinability (1-10) | Tool Wear Rate | Applicable Scenarios |

| 4140 Pre-hardened Steel | 3.2-4.5 | 28-32 | 7 | 1.0 | General Machinery, Gearboxes |

| 8620 Carburized Steel | 4.8-6.2 | 58-62 | 6 | 1.3 | High-strength Transmission Components |

| 6061 Aluminum Alloy | 2.5-3.8 | 10-15 | 9 | 0.7 | Lightweight, Low-Load Equipment |

| POM Plastic | 5.5-7.0 | 8-12 | 8 | 0.5 | Low-Noise, Corrosion-Resistant Scenarios |

Machinability directly affects cost. For example, when machining 8620 carburized steel, tool wear is 30% faster, efficiency decreases by 20%-30%, indirectly increasing machining service costs.

Process Time: Machine Time is Money

Process time accounts for a very high percentage of costs, machine time directly translates into cost. Different processes have significantly different processing efficiencies:

| Process | Teeth Per Minute | Applicable Type | Precision Grade | Single Piece Time | Hourly Rate (USD) |

| Hobbing | 15-30 | Spur/Helical Gears | AGMA 8-10 | 8-12 minutes | 80-120 |

| Shaping | 8-15 | Internal/Multi-Gears | AGMA 7-9 | 15-20 minutes | 100-150 |

| Gear Grinding | 3-8 | High-Precision Gears | AGMA 11-13 | 25-40 minutes | 200-300 |

| Honing | 2-5 | Ultra-Precision Gears | AGMA 12-14 | 45-60 minutes | 300-400 |

High-precision gears require secondary finishing, such as those from AGMA Grade 12 gears require hobbing followed by grinding, increasing labor time by 2-3 times and significantly raising costs.

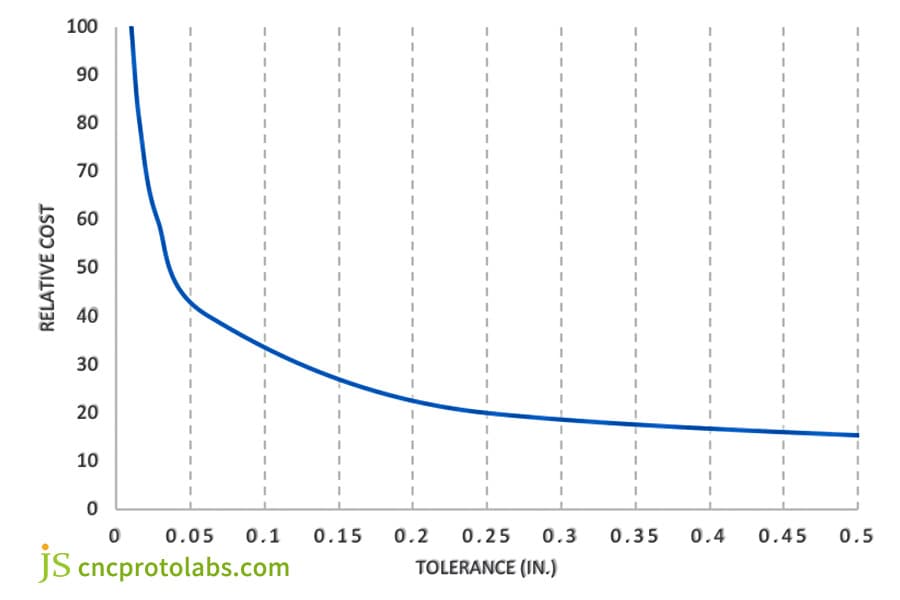

Design and Precision: The Silent Cost Amplifier

Precision is one of the major cost drivers. Higher precision, as per the AGMA/ISO standards, incurs higher costs, and the graph follows the pattern of exponential growth.

An increase in the precision of the gear, from 10 to 12, as per the ISO 1328 standard, incurs 80-120% higher costs, and the 1-micron tolerance system mandates the requirement of the highest level of equipment and entails exceedingly high costs for the procurement and running of the equipment.

Figure 1 Material selection will significantly affect the cost of gear quotation.

Why Does a 1 Micron Tolerance Increase Your Gear Manufacturing Costs?

1 micron tolerance gear manufacturing cost is high, as it exceeds the limits of conventional manufacturing and requires extreme requirements for equipment, environment, and materials. Therefore, it is necessary to rationally evaluate the investment value.

The Exponential Curve of Precision and Cost

The relationship between tolerance and cost is exponential, and not linear:

- ± 0.025mm to ± 0.005mm, with a cost increase of 50% -80%.

- ± 0.005mm to ± 0.001mm, with an additional cost increase of 100% -150%.

This surge in cost stems from extreme investments in three areas:

- Equipment: It needs a very accurate gear machining center, which costs millions of US dollars for each machine.

- Cutting tools: CBN super-hard cutting tools, which are more expensive by 5 to 10 times in relation to common cutting tools.

- Environment: Costs for a temperature-controlled workshop per square meter per year for maintenance: $500-800.

The Technological Barrier to Achieving 1 Micrometer Tolerance

Production of 1-micrometer tolerance would also pose additional technological hurdles, adding costs:

- Deep cryogenic treatment of materials to eliminate stress, increasing processing costs by 15% -20%.

- Live tracking of processing variables results in rising expenses by $30-50 an hour.

- The total inspection time is 30-60 minutes for each article, and there is heavy depreciation of inspection equipment.

When to Pay for Ultimate Precision?

In applications such as satellites and high-end medical equipment, 1-micron precision is indispensable, its reliability value far outweighs the additional cost.

Figure 2 Tolerance is usually inversely proportional to manufacturing cost. The stricter the tolerance, the higher the price, and vice versa.

How To Control Costs In Custom Gear Manufacturing?

Custom gear production needs to strike a balance between individualization and expenses. Expense management remains possible through optimization, collaborative manufacturing, and the batch method.

Define 'Core Customization' and 'Edge Requirements'

Core and peripheral requirements: Emphasis on essential features and alleviating non-critical factors:

- Core Customization: The critical performance items such as nonstandard tooth profiles and customized material must be guaranteed.

- Peripheral Requirements: Non-Critical Tolerancing and excessive surface finish smoothness can be relaxed.

One of our optimizations enabled a customer to achieve a surface finish on non-mating surfaces, reducing Ra 0.8µm to 1.6µm, thus resulting in a 10% reduction in the costs of machining services.

DFM: Golden Rule for Cooperative Design with Manufacturers

DFM is the key to cost reduction for customized gears, and incorporating manufacturer recommendations during the design phase can significantly reduce machining difficulty:

- Optimizing the radius of undercuts will help eliminate tool chipping problems and achieve a 15% increase in efficiency.

- Optimum uniformity of wall thickness removes deformation and costs of rework.

- It simplifies designs and thus removes complex details. This facilitates fast coding and machining.

Applying DFM principles can optimize the total cost of custom gear manufacturing by an average of 15%-20%.

Optimizing Unit Costs by Batch Effects

Small-batch production can benefit the economy of scale in the following ways:

- Consolidating orders helps in reducing equipment changeover and cutting unit labor costs.

- Modular design allows commonality of components and minimizes the need for specialty tooling.

- Long-term interaction cements price levels, as volatility is reduced in markets.

Want a customized cost optimization solution for custom gear manufacturing? Download the free "DFM Design Guide" from JS Precision now, or contact our engineering team to inform us of your customization needs and budget. We will tailor a cost-reduction solution for you.

How To Choose The Right Gear Manufacturing Methods For Cost & Performance?

The selection of appropriate gear manufacturing methods is fundamental for the balance between cost and performance. This has to do with comprehensive judgment on batch size, precision, and complexity. Equipment performance defines processing quality.

CNC Gear Machining: The Cost and Value of Flexibility

CNC gear machining is suitable for small-batch and customized needs. The core feature of it includes:

- Advantages: include no high mold costs, flexible design, able to machine complex tooth profiles, and precision up to AGMA 10-12.

- Cost: Material utilization rate 60%-80%, high cost per piece, suitable for batches of 10-500 pieces.

- Equipment: JS Precision uses Japanese and German equipment, while applying the systems provided by Siemens to ensure precision and efficiency.

Forming Processes (Powder Metallurgy/Precision Forging): Low Cost Tools for Mass Production

Powder metallurgy and precision forging have provided cost-cutting tools for manufacturing gears en masse.

- Advantages: Material utilization rate ≥95%, high efficiency, unit cost 30%-50% lower than CNC.

- Cost: High investment in mold, suitable for batches over 100,000 pieces per year.

- Limitations: Low design freedom, precision only AGMA 8-10 level.

Additive Manufacturing: Breaking Through Geometric Limitations in Cost

Additive manufacturing is suitable for customizing gears in special scenarios, with core features:

- Benefits: Capable of carrying out complex production, short prototyping cycle, does not need special tooling.

- Cost: Materials cost 3-5 times more, post-processing, batch size of 1 to 50 units.

- Scenarios: R&D, emergency spare parts, light-weight structures.

Want to determine the most suitable gear manufacturing methods for your project? Tell JS Precision your batch requirements, precision requirements, and gear structure. Our process engineers will provide you with free process selection analysis and cost comparison to help you make the optimal decision.

What Information Do You Need To Provide For a Precise CNC Machining Quote?

Accurate quotes are essential to cost control. Ambiguous specifications are commonly associated with errors, whereas having all the specifications correct helps to insure that the quotation is accurate and can be evaluated to control cost.

Technical Data Package: Clearly Define Requirements

The technical data package is the basis of the quotation and must be complete and accurate, including the following:

- 2D/3D Drawings: Annotate dimensional tolerances, tooth profiles, roughness, etc.

- Material Specifications: Grade, heat treatment, hardness requirements.

- Quality Standards: Industry standards and testing requirements.

- Extra-Requirements: Surface treatment, Dynamic balancing, and others, which influence the gear machining services cost.

Commercial Terms: Set an Expected Framework

Clarify business requirements, assist suppliers in matching optimal production lines, and reduce quotation deviations:

- Batch Size: The first item and annual demand are known, and it fixes the production process.

- Delivery Time: 10% to 30% extra for rush delivery.

- Packaging & Logistics: The requirements include those for rust resistance and shock resistance.

Decoding the Quotation: Understanding the True Cost Structure

The structure professional quotes demand detailed costs to enable the making of an assessment regarding reasonableness. The vital information to be provided is as follows:

| Cost Item | Composition | Percentage (%) | Optimization Potential (%) | Influencing Factors | Reference Unit Price |

| Raw Material Costs | Purchase Price + 3%-5% Loss | 30-45 | 5-10 | Material, Loss Rate | 2.5-7.0 USD/kg |

| Processing Costs | Labor Costs + Equipment Depreciation | 25-40 | 10-15 | Process, Efficiency | 80-400 USD/hour |

| Heat Treatment Costs | Carburizing, Quenching, etc. | 10-20 | 5-8 | Process, Batch | 5-20 USD/piece |

| Tooling Costs | Design and Manufacturing Costs | 5-10 | 10-20 | Customization, Reusability | 500-5000 USD/set |

| Management Fees and Profits | Operating Costs + Reasonable Profit | 8-15 | 2-5 | Cooperation Model, Batch | Calculated Based on Total Cost |

Need a quick and precise gear machining services cost quote? And understand the breakdown of the quote? Just send your technical specification and business requirements under the mention "Precise Quote," and the team of engineers at JS Precision will prepare a detailed quote for you within 24 hours, and assist you in analyzing the cost-saving points of the quote for no charge.

Figure 3 The drawings contain almost all the information required for gear manufacturers to quote, such as gear geometry specifications, part numbers, and version numbers.

Case Study: From Dependence In Germany To Precision In China: JS Precision Reduces Gearbox Costs By 40% For European Robot Customers

Small batch, high-precision custom gear manufacturing often faces the dilemma of high cost and long delivery time. We company has found a solution to this problem for its European clients.

Problem: Cost Challenges of Small Batch, High-Mixture Production Lines

A collaborative robotics company in Europe needed to buy several types of precision planetary gears in small batches, ranging from 100 to 500 pieces per type. The original German supplier had a high gear machining services cost, with an average cost of $120 per gear and an average lead time of 12 weeks.

This affected the gear development time and competitiveness in the marketplace. In addition, the customer required a high degree of precision in the gear, classified in the AGMA class 11, which involved high transmission.

JS Precision's Solution: Systematic Process Refactoring

While trying to solve customer pain points, JS Precision enhances certain process, design, and supply aspects of:

1.Process Reselection:

Abandoning the high mold cost forming process and adopting the Japanese Tsuda Koma gear hobbing machine for CNC gear machining, combined with domestically produced high rigidity gear cutting machine for hard turning/grinding composite processing, not only ensures AGMA 11 level accuracy, but also reduces tooling costs for small-scale production.

2.DFM Optimization:

Engineers suggested increasing three non-critical tolerance limits from ±0.005mm to ±0.01mm and replacing European Standard Steel with Chinese Standard Pre-Hardening Steel 4140, which led to a reduction of 15% material cost with no effect on functionality.

3.Supply Chain Integration:

Leverage the localized supply chain, one-stop solution for the entire process of bar procurement, processing, heat treatment, and complete inspection, and reduce the production cycle.

Results: Win-Win Solution on Cost, Efficiency, and Quality

After systematic optimization, the project has achieved significant results:

- The comprehensive gear manufacturing cost has been reduced to $72 per piece, a year-on-year decrease of 40%, saving customers over $200000 in costs annually.

- The delivery time has been shortened to 6 weeks, which is 50% faster than the original supplier and meets the customer's demand for rapid product iteration.

- The gear accuracy has been tested by a third-party and has consistently reached AGMA level 11. The transmission noise and service life are better than the original product standards.

Facing similar precision gear machining with small lots? Click to see more industry-specific case studies made possible by JS Precision. Or contact us to tell us about the challenges in your project so we can devise a cost-cutting solution with our winning formula.

Figure 4 Planetary Gears for Robotic Applications

FAQs

Q1: Which of the gear manufacturing processes is the most economical for small batches?

CNC gear machining. It saves the high expenses of molds involved and offers high flexibility to cater to small-batch customized demands. Being a favorite process during prototyping and small-scale custom gear manufacturing due to cost and precision management, it is great.

Q2: What is specifically referred to by the gear precision grade in the quote?

This is a total rating of errors such as tooth profile, tooth direction, and pitch based, generally on ISO or AGMA standards. The higher the rating is-which means a smaller number-the greater the machining difficulty and, therefore, the higher the 1 micron tolerance gear manufacturing cost.

Q3: What factors have the greatest impact on gear machining service cost?

Material hardness, gear precision, tooth surface roughness requirements, and production volume are the four core factors. Of these, cost is exponentially influenced more and more by precision requirements and therefore, should be watched closely.

Q4: Why are there such large differences in CNC machining quotes from different suppliers for the same drawings?

The differences lie in process paths, equipment, material sourcing, and quality control requirements. Witness, for example, whether a gear grinding operation is involved and whether imported or local gear cutting machine are employed, and all these factors impact costs directly.

Q5: What is the largest/smallest module gear that JS Precision can machine?

The CNC gear processing abilities in JS Precision cover gears in modules ranging from 0.5 to 10 and diameters ranging from 5 mm to 800 mm.

Q6: Do you provide gear assembly services?

Yes. JS Precision covers the whole spectrum of gear machining, including gear processing, shaft and housing production, as well as precision assembly, to provide the best possible matching performance and stability of the transmission unit.

Q7: How do you ensure consistency in mass production of gears?

We use key parameter monitoring in real-time via Statistical Process Control, and we have inspection equipment for sampling or complete inspection to enable process parameter optimization to ensure quality in mass production.

Q8: If my design needs modification, will it affect the quote and delivery time?

Design changes are usual too. JS Precision offers flexible design change service support in assessing the impact of design changes on the CNC machining quote and delivery times, and in the change solution implementation process.

Summary

Gear machining cost is an intricate problem of engineering, related to the type of gears, raw material, processes, precision, and customization. Process selection plays an extremely important role in gear machining to ensure cost savings and optimal results.

At JS Precision, we, with our expertise in CNC gear machining, advanced gear cutting machine, and DFM optimization solutions, encourage you to go beyond per-piece gear machining services cost and explore the true value of gear machining cost. It could be customization, mass production, standard precision, or extreme tolerance – we will be with you.

Act today and let expertise work for you!

If you are having problems with the cost, accuracy, or delivery time for your gear parts, please send us gear designs and specifications. Our engineering team will provide you with a detailed CNC machining quote that includes DFM recommendations and demonstrate how we can help you optimize gear manufacturing cost and gain a competitive advantage in the market.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com