Precision CNC milling is how manufacturers produce parts that standard machining cannot handle. A titanium alloy part for medical implants with tolerances of ±0.005mm. An aluminum prototype that needs to go from CAD file to functional part in 48 hours. A thin-wall aerospace component that requires zero clamping errors across multiple surfaces. These are real manufacturing problems that require precision CNC milling.

At JS Precision, we've solved these problems for 2000+ customers over 18 years. This guide covers what precision CNC milling is, how it works, what materials work best, how to optimize costs, and when to use it instead of 3D printing. We break down the technology based on actual manufacturing experience, not theory.

We are going to break down the technology in layman's terms and illustrate its value with real-life examples to help you really understand the core logic of precision CNC milling.

Core Answer Summary

| Core Technology | Key Capabilities/Precision | Typical Application Scenarios | Core Value |

| High-Precision CNC Milling | Tolerance control up to ±0.005mm, 5-axis simultaneous clamping. | Medical implants, aerospace components, optical platforms. | Achieve complex geometries and ensure consistency in mass production. |

| Material Machining Range | Covers aluminum alloys, stainless steel, titanium alloys, PEEK, etc. | Flexible material selection based on strength, corrosion resistance, and high-temperature resistance requirements. | Achieve optimal balance between cost, performance, and machinability. |

| JS Precision Advantages | 18 years of experience, 2000+ customer cases, 5-axis equipment cluster. | Provides full-process services from DFM analysis and intelligent programming to online quality inspection. | Possesses industry standard certifications in aerospace, medical, and other fields, providing one-stop solutions. |

| Digital Workflow | Seamless CAD/CAM integration, virtual simulation pre-visualization, real-time compensation. | Rapid prototyping development, small-batch customized production. | Shortened delivery cycle (quote in as little as 1 hour), reduced overall costs. |

Overcoming High-Precision Machining? JS Precision CNC Milling Guide

In the field of precision CNC milling, experience is never an abstract thing but is accumulated through countless specific parts and breakthroughs in process technology. JS Precision has been deeply involved in this field for 18 years, serving more than 2000 clients across industries characterized by high precision requirements: aerospace, medical, optics, semiconductors.

We have handled medical catheters made of titanium alloy with only a diameter of 3mm (tolerance controlled within ±0.005mm) and have also finished aerospace structural components of aluminum alloy 1.2 meters long. Flatness was 0.02mm/m. We have prevented thin-walled vibration problems in satellite projects of startups and mass-produced surgical instruments meeting the standards of ISO 13485 for large medical companies.

These experiences have taught us that high-precision machining is not just a competition of equipment but comprehensive control over details, including material properties, toolpaths, and ambient temperature.

This guide is a distillation of that experience. From basic principles, the latest trends, cost optimization, and case studies-every perspective flows from our real manufacturing practice. Whether you are having problems with part precision, delivery time, or material selection, this practical guide will help you find clear direction.

With years of experience in CNC milling, JS Precision can handle various complex machining needs with great accuracy. For any custom machined parts needs, don't hesitate to contact us for prompt response and professional solutions.

What Is Precision CNC Milling? A Key Process For Achieving Complex Designs

What is Precision CNC Milling?

Precision CNC milling is much more than just "computer numerical control" machining but a thorough digital manufacturing ecosystem. At its heart, this design-driven system incorporates CAD software, CAM systems, high-precision machine tools, and quality inspection equipment that help transform conceptual 3D models into physical parts, meeting strict tolerance requirements.

Its core value lies in achieving complex geometries impossible with traditional machining methods, while maintaining consistency in mass production, which makes precision CNC milling indispensable for everything from aerospace parts to precision molds.

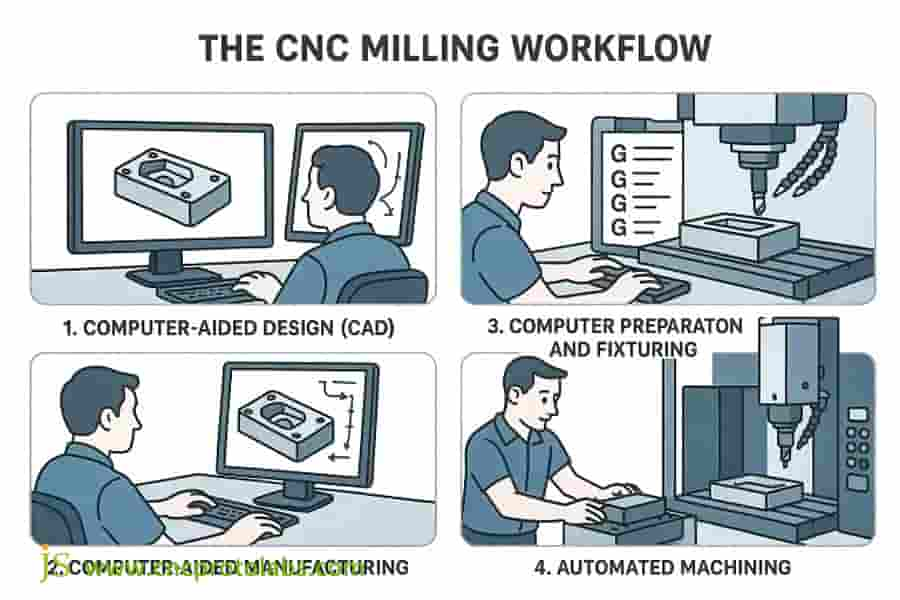

Precision CNC Milling Workflow

With the Precision CNC milling workflow, all the steps are connected and will affect the final result:

- Firstly, the customer supplies a 3D CAD model-the "blueprint" for machining.

- Then, the model is analyzed by engineers using the CAM program to develop toolpath generation, the so-called G-code, using parameters such as material hardness and tool rotational speed.

- Then, the numerical control milling machine will start multi-axis linkage according to the G-code, with a rotating tool cutting material from the blank with high precision, removing extra material.

- Finally, after online quality inspection, the CNC machined parts perfectly matching the design are obtained.

Unique Perspective of JS Precision: We see every CNC machine tool as a data-driven paintbrush and the material as a canvas. Our engineers are the combination of an artist and a programmer, they know how to make toolpaths more efficient and can anticipate what kind of deformations may happen during machining to ensure precision in every cut.

With JS Precision's precision CNC machining services, we can effectively take your designs and turn them into high-quality CNC machined parts, providing full control from design to finished product for peace of mind.

Figure 1: A collection of high-precision CNC milling parts made from aluminum and stainless steel, used in aerospace and medical industries.

The Manufacturing Process Revealed: How Your Custom Machined Parts Come Into Being

After understanding the basic concepts of precision CNC milling, you probably would want to know what steps a custom machined part goes through from design to finished product. The manufacturing process at JS Precision is therefore constructed around the core principles of "precision" and "efficiency," divided into four key stages:

Step 1: Deep Design Collaboration

Our engineers will work with you on Design for Manufacturability, DFM. For example, if the part has deep cavities, we recommend increasing the fillet radius to avoid tool vibration. If lightweighting is required, we recommend adding weight-reducing holes in non-stress areas, which improves part strength, reduces costs, and shortens delivery time.

Step 2: Intelligent Programming and Simulation

We use advanced CAM software for preparing toolpaths and strategies, like using helical cutters to reduce the impact on stainless steel machining and selecting high-speed shallow cuts to avoid deformation of thin-wall parts.

At the same time, we perform virtual environment machining simulation to analyze collision risks in advance and ensure error-free actual machining.

Step 3: Precision Setup and Multi-Axis Machining

We are equipped with 5-axis CNC machining that enables machining of all surfaces of a part in one setup. For example, parts with inclined holes and irregular curved surfaces require three setups on a 3-axis machine, but only one setup on a 5-axis machine, thus reducing time, minimizing errors, and ensuring geometric tolerances.

Step 4: Online Quality Inspection from end-to-end

All of our machine tools are equipped with on-machine probes and laser tool setters: the probes measure dimensions automatically and compare them with design values after critical processes, the laser tool setter detects tool wear and automatically compensates for exceeding thresholds, hence the controllable whole process of precision CNC machining services.

JS Precision focuses on custom CNC milling, striving for excellence in every aspect from design collaboration to final quality inspection. If you need customized parts, please feel free to contact us and we will provide you with a clear processing plan and time schedule.

Figure 2: Infographic illustrating the four key steps in the precision CNC milling process at JS Precision: from CAD design to final inspection.

The Art Of Materials: Choosing The Perfect Material For Your Custom Machined Parts

Different materials directly influence the performance, cost, and difficulty of machining custom machined parts. Material selection is one of the most important steps in ensuring the success of a project.

The following is an analysis of the common processing materials and their characteristics in JS Precision:

The Metal Kingdom

Because of the need for strength and stability, metallic materials are widely used in precision CNC milling. We have compiled a comparison of several commonly used metals:

| Material | Core Characteristics | Typical Applications | Processing Difficulty |

| Aluminum Alloy | Lightweight (Density 2.7g/cm³), moderate strength. | Prototyping, aerospace parts, cases. | Low |

| Stainless Steel | Strong corrosion resistance, high strength. | Medical equipment, food machinery. | Medium |

| Titanium Alloy | High specific strength, resistance to high and low temperatures. | Aerospace, medical implants. | High |

| Invar | Ultra-low coefficient of thermal expansion ≤1.5×10⁻⁶/℃. | precision optical platforms. | High |

| Molybdenum Copper Alloy | High thermal conductivity, low expansion. | Semiconductor heat dissipation components. | High |

Engineering Plastics and Composite Materials

Engineering plastics and composite materials have unique lightweighting and corrosion resistance advantages that make them appropriate for the following applications:

| Material | Core Characteristics | Typical Applications |

| PEEK | High temperature resistance (Continuous Operating Temperature 260℃), chemical corrosion resistance. | Oilfield components, medical devices. |

| ULTEM | Good flame retardancy - UL94 V-0, high strength. | Electronic casings (housings) Aerospace interiors. |

| Carbon Fiber Composite Materials | Lightweight (density 1.6g/cm³), high-strength. | Racing Car Parts, Drone Frames. |

JS' Professional Advice:

We provide a material selection guide according to the project needs. For instance, if rapid prototype manufacturing is required, then aluminum alloy could be the most economic solution, if working in high-temperature surroundings, PEEK would be a better option.

With the experience we have, our main objective is to look for an optimum balance between cost, performance, manufacturability, and delivery time.

Figure 3: CNC milling is used on many materials, some of the most commonly used materials include wood,metal,glass,plastic.

Accelerator For Prototype Development: How To Optimize The Cost Of CNC Milling For Prototypes

Cost control is important during the development of prototypes but not at the expense of functionality. JS Precision has summarized several proven cost optimization methods to help you advance your CNC milling for prototypes projects in the most efficient way.

The Mindset of "Designing for Prototypes"

The core of prototyping is to validate functionality, not to pursue perfect details. Simplifying the non-critical features without affecting core functionality can reduce the cost significantly.

For example, replacing strict corner clearing (internal corner radius ≥ 0.5mm) with rounded corners can reduce wear and tear on tools and save programming time, changing deep holes into through holes avoids vibration problems from using long tools.

Shared Clamping and Intelligent Layout

Intelligent layout of multiple prototype parts on the same material sheet maximizes material utilization.

For instance, on a 300×300mm aluminum alloy sheet, the material utilization rate of one processed 100×100mm part is about 11%, while the layout of four identical parts increases the utilization rate to about 44%, which can reduce the material cost per part by more than 50% after distribution.

Meanwhile, encourage the usage of standard-specification profiles or pre-machined parts in prototypes, such as using a standard round bar instead of a customized blank to reduce custom CNC milling workload.

Cost Benefit Analysis of 3D Printing

Not all prototypes are suitable for CNC milling. We objectively compared the applicable scenarios for the two processes:

| Scene | CNC Milling for Prototypes Advantages | 3D Printing Advantages |

| High Material Strength Requirements | Approaching the performance of mass-produced materials, suitable for mechanical testing. | Low material strength. |

| High Precision Requirements | More stable tolerance control. | Poorer surface roughness. |

| Small Size Complex Structure | Suitable for metal materials, with lower cost. | Suitable for plastic, faster molding. |

| >=5 Pieces Batch Size | Unit cost goes down with increased batch size. | Unit cost remains basically unchanged. |

JS Precision has extensive experience in CNC milling for prototypes and helps customers control costs by optimizing their design and layout. Just submit your prototype requirements, and we'll be happy to provide a solution complete with cost optimization suggestions within 24 hours.

Looking To The Future: Disruptive Trends In Precision CNC Milling

Precision CNC milling is fast iterating, and these cutting-edge trends are bound to redefine the possibilities of manufacturing:

1. Artificial Intelligence and Adaptive Processing

Machine tools collect cutting force, temperature, and other data in real time through sensors, and AI algorithms automatically adjust rotational speed and feed rate. When encountering material impurities, the system immediately reduces speed to prevent tool breakage, achieving an accuracy of ±0.002mm and extending tool life by more than 30%.

2. Digital Twins and End-to-End Digitalization

Simulating the temperature deformation and tool wear by creating a "digital twin" synchronized with the physical machine tool in the virtual world is possible. The parameters can be optimized in advance by engineers to achieve predictive maintenance, even zero downtime.

3. Mixed Additive and Subtractive Manufacturing

By integrating 3D printing and CNC milling on the same machine, one can achieve both rapid material deposition and precision, this allows manufacturing of internal cooling channels and lightweight lattice structure parts impossible with traditional manufacturing methods.

4. Sustainability and "Green Milling"

Optimize tool path to reduce cutting time by 50% and lower energy consumption. Replace traditional mineral oil with plant-based coolant to reduce pollution. Establish a chip recycling system with an aluminum alloy recovery rate of over 95%, promoting sustainable development of the manufacturing industry.

Choosing JS Precision: Six Reasons To Unlock Superior Precision CNC Machining Services

Why are more and more customers choosing JS Precision's precision CNC machining services? That comes from our comprehensive advantages in technology, service, and philosophy.

1.Technologically Advanced Equipment Group:

Equipped with high-end Swiss and German machine tools ranging from 3-axis to 5-axis CNC turning centers, capable of handling features from 0.1mm in size up to 2-meter-long parts.

2.Full Material Certification Capability:

All materials are supplied with original manufacturer material certification, traceable to batch lots, to very high standards for such demanding industries as medical and aerospace, so our customers can be confident in the reliability of their custom machined parts.

3.Seamless Digital Experience:

This includes features such as instant quoting through the online uploading of 3D files, real-time order progress tracking, delivery documentation management, and a transparent, efficient process that keeps you up-to-date on project dynamics.

4.Interdisciplinary Engineering Team:

Our team understands machining processes and has a better understanding of industry requirements such as aerospace (NASA standards), medical (FDA requirements), and optics (Ra ≤ 0.02 μ m), providing solutions for ultra machining itself.

5.One-Stop Post-Processing Services:

We can provide a full range of surface treatments, including anodizing, electroplating, sandblasting, and laser marking to avoid troubles brought by multiple suppliers and shorten the whole delivery cycle.

6.Customer Success as Our Goal:

We think of ourselves as an extension of your R&D and production team by considering cost optimization and lead time reduction proactively. Your success is our ultimate value proposition.

JS Precision is committed to providing exceptional precision CNC machining services, comprehensively meeting your needs from equipment to our team. No matter how big or small a project is, we will go all out and look forward to becoming your long-term partner.

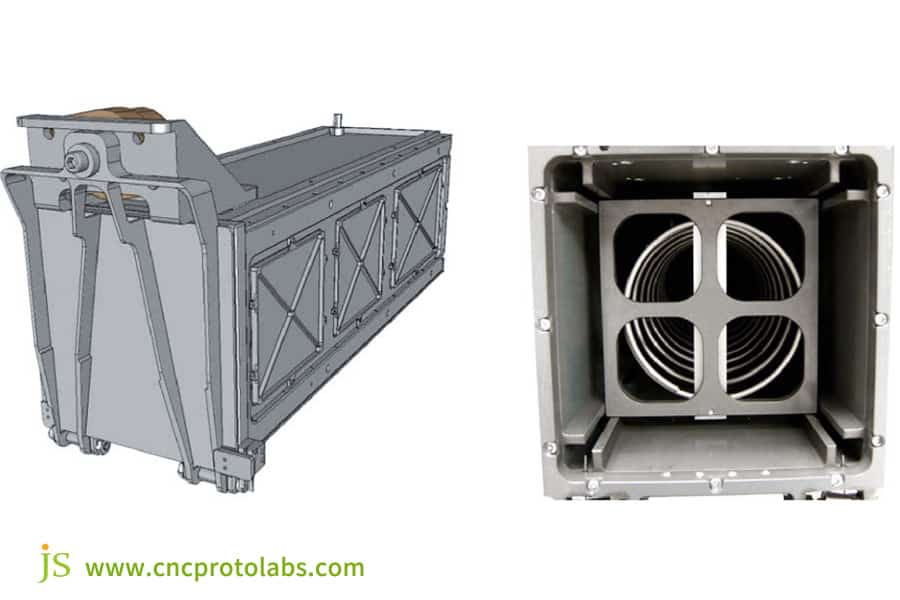

Case Study: How JS Precision Overcame The Challenge Of Thin-Wall Machining For Satellite Attitude Control Components

Customer Challenge

An aerospace startup needed to manufacture a core component for a satellite attitude control system. This component, made of high-strength aluminum alloy (7075-T6), has a maximum size of 350mm but includes multiple 0.8mm thick thin walls and a 50mm deep cavity. The surface profile of the irregular curved surface must be ≤0.02mm.

More importantly, the weight of the part should be controlled within 250g, and the dynamic balance error cannot exceed 0.005g・cm—requirements that traditional 3D printing cannot meet in terms of structural strength, while ordinary machining cannot meet geometric tolerance requirements due to multiple clamping operations causing errors.

The Solution From JS Precision

To deal with these issues, a three-pronged core approach was taken:

1. Collaborative Design Optimization: We used topology optimization software with the client's design team to plan material distribution, adding honeycomb-shaped weight-reducing holes in non-stress areas to reduce weight while enhancing rigidity, adjusted three internal sharp corners that were difficult to machine from R0.1mm to R0.5mm to ensure no vibration upon tool entry.

2. 5-Axis Linkage Strategy: Within one setup, all machining was completed using a German DMG MORI 5-axis machine tool.We designed a dedicated vacuum fixture to hold the parts in place and prevent deformation of thin walls. Afterwards, we applied a high-speed spindle of 40,000 rpm with ultra-fine grain carbide tools for shallow cuts and rapid traverse to reduce the effect of the cutting force.

3. Micro Milling and Online Compensation: Finishing with 0.4mm micro cutting tools for 0.3mm micro features on curved edges. During processing, the machine probe measures key dimensions every 30 minutes, and the system automatically compensates for tool wear (with an accuracy of 0.001mm).

Achievements and Value

The final delivered part weighs only 212g, 15% lighter than the weight called for by the design; The result of the dynamic balance test is 0.0035g · cm, which is 30% higher than expected.

From confirmation of design to delivery, it took only 12 days in total. That allowed direct usage of the part for assembly for the customer and ensured the satellite project was launched as scheduled. This case also earned industry recognition of our technical strength in the high-end custom CNC milling field.

Figure 4: Close-up of a complex thin-wall aluminum alloy component for satellite attitude control, machined with high-precision 5-axis CNC milling.

FAQs: Everything You Need To Know About Precision CNC Milling

Q1: How long does it usually take to get a quote from the time drawings are provided?

With our online platform, if the parts are made from standard materials by conventional processes, you will get a detailed quote, including material, process, and delivery time, within 1 hour of uploading your 3D file.

Q2: What is the highest machining tolerance you can guarantee?

For conventional machining, there would be a tolerance promise of ±0.025mm depending on machinery and material, while for projects with high-stringent requirements, special process control, including temperature-controlled workshops and dedicated fixtures, could even reach ±0.01mm.

Q3: What are the differences in processing difficulty and cost between aluminum alloy, stainless steel, and titanium alloy?

Among them, the easiest machining is for aluminum alloys with low tool wear and the lowest cost. Stainless steel has high hardness and results in faster tool wear, its cost is around 40% higher than for aluminum alloys. Because of the poor thermal conductivity, high cutting temperatures, extremely high requirement for tools and processes, titanium alloys are 3 to 5 times more expensive than aluminum alloys.

Q4: What are the particular advantages that 5-axis CNC milling has over 3-axis?

The most essential benefit of 5-axis is in the reduction of clamping times: all surface features of the part can be machined in one clamping. This improves productivity by more than 50% and avoids datum conversion mistakes because of multiple clampings. Thus, undercuts and complex-curved surface machining beyond the capability of 3-axis machining become possible.

Q5: Does my prototype need further surface treatment? Any recommendations?

Whether the prototype needs surface treatment depends on the application. For example, anodizing can enhance the wear and corrosion resistance of aluminum alloys, while passivation can enhance the rust prevention of stainless steel, and sand blasting provides a uniform matte surface, suitable for outside parts.

Q6: How can you reduce material waste while doing CNC machining?

Optimizing the layout of parts on the material plate using intelligent nesting software can achieve a utilization rate of over 85%, at the same time, using pre-machined blanks as much as possible-in a shape as close to that of the part-can reduce source waste, particularly effective for expensive materials like titanium alloys.

Q7: How do you handle and protect my confidential design files?

We will sign strict confidentiality agreements with all clients. Design files are stored only on the local encrypted server, which is accessible only by the project-related engineers. If you request to do so after machining, these will be permanently deleted for information security.

Q8: How would you facilitate part cooling and lubrication during machining?

We will choose the appropriate coolant based on the material: emulsion for processing aluminum alloys, extreme pressure cutting fluid for stainless steel, and specialized coolant for titanium alloys. Meanwhile, high-pressure internal cooling technology-up to 70 bar-is employed to deliver coolants right at the point of cutting with high precision, which guarantees both machining quality and tool life.

Summary

Profound and dynamic, the world of Precision CNC milling holds within it many elements of both science and art. We at JS Precision blend these qualities by delivering not only high-quality CNC machined parts to you but also a smooth, firm, and insightful collaboration journey.

Whether your project is a prototype in the conceptual stage or a complex custom-machined part about to enter mass production, we are ready.

Take the first step today in bringing your ideas to life!

Check JS Precision website, upload your 3D CAD file, and get a detailed quote with DFM feedback in 1 hour. Let us be your most trusted partner in manufacturing. Break the limits of manufacturing and realize more possibilities.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com