For product design, engineers and designers basically have a fundamental question: "release" solid objects from material, or "build" them in layers out of material?

This is the exact philosophical dilemma between subtractive manufacturing (precise CNC machining) and additive manufacturing (3D printing). They're both fantastic digital manufacturing technologies, but they possess very distinct capabilities.Choosing the right process means less cost, faster speeds, and better products, do it wrong and it is budget and time disaster.

This guide will guide you through carefully balancing the pros and cons of each technique along key parameters such as accuracy, cost, and material to arrive at the optimal decision for your project. This guide is based on real cases and data of CNC machining services.

Core Answer Summary

| Comparative Dimensions | Precision CNC Machining | 3D Printing |

| Key Philosophy | Subtractive Manufacturing: Removing material from a solid blank | Additive Manufacturing: Building a part by adding material layer by layer. |

| Dimensional Accuracy | Very precise (up to ±0.025mm or better) | High Isotropy (typically ±0.1mm - 0.5mm), Can vary based on orientation and heat shrinking. |

| Material Range and Properties | Extremely broad, covering metals, plastics, and composites, Isotropic, 100% density, and mechanical properties identical to forged parts. | High and special grade of metal powders, photosensitive resins, and engineering plastics specifically developed for printing, may exhibit anisotropy and internal porosity. |

| Low-Batch Cost | Low tooling costs but per-part material/labor costs are high, economical batch sizes are tens to hundreds of parts. | No tooling cost, relatively fixed cost per part, best suited for very low batch sizes (1-10 parts) and complex structures. |

| Design Freedom | Limited access to tooling, making it difficult to machine internal cavities and interlocking components. | Essentially limitless possibilities, with ease of topology optimization, lattice structures, and embedded assembly. |

| Post-processing Requirements | Typically require surface treatments such as deburring, sandblasting, and anodizing. | Support removal, cleaning, curing (resin), heat treating (metal), and surface polishing are generally always required. |

Why Is It Reliable? From JS Precision's Real-World Project Experience

To determine the reliability of a process comparison guide, the key is to see whether or not it has practical project experience behind it.

With more than 5,000 manufacturing projects for various industries like aerospace, medical, and automotive shipped since the company was founded eight years ago, JS Precision, as a professional CNC machining service company, accumulated tremendous experience in precision CNC machining and 3D printing applications.

In the field of aerospace, we utilize precision CNC machining technology to guarantee dimension tolerances in ±0.005mm for titanium alloy structure parts. We have already shipped over 2,000 CNC machining parts, which passed NASA's rigorous quality testing with flying colors.

In the medical industry, we offer custom CNC machining manufacturing services to meet the precise requirements of surgical instrument parts, a surface roughness of Ra 0.02μm, and achieved ISO 13485 medical quality system certification.

This tutorial, based on our own experience on real-world projects, discusses the basic differences between the two processes and why you would pick between them so you can completely trust the content.

JS Precision's precision CNC machining service relies on rich practical experience. Simply send us your part requirements, and we'll provide you with a solution within 24 hours, and deliver fast compliant CNC machining parts to your project.

The Micron War: Who Wins In Dimensional Accuracy

Having established the authority of this guide, we now focus on the core difference—dimensional precision. Micron-level errors can have direct impact on part performance and therefore ranks as the most common basis of comparison between 3D printing and precision CNC machining.

CNC Machining vs. 3D Printing Accuracy Comparison

| Process Type | Accuracy Range | Key Influencing Factors | Applicable Scenarios |

| CNC Machining | ±0.001-±0.01mm | Machine Tool Mechanical Structure, Tool Rigidity, Feedback System. | Accuracy High-Precision Fittings, Seals. |

| 3D Printing | ±0.1-±0.5mm | Layer Thickness, Material Shrinkage, Thermal Deformation, Equipment Calibration. | Functional Prototypes, Non-Precision Structural Parts. |

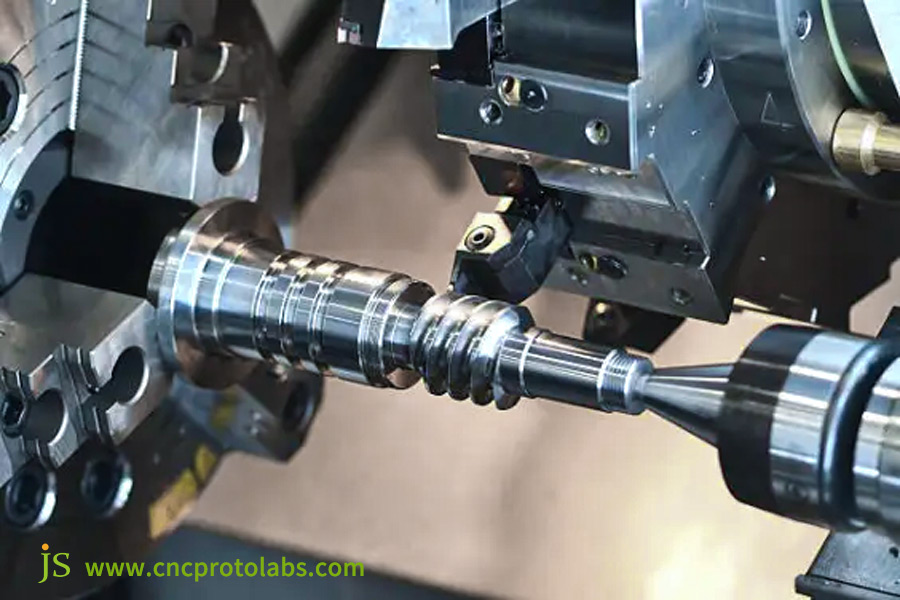

CNC Machining: Reliability and Ultimate Accuracy

CNC precision comes from rigid tools, rigid fixtures, and a live feedback system. Deviation can be adjusted in real time, and accuracy is guaranteed by stable equipment performance. Parts are isotropic, with consistent X/Y/Z axis precision. For example, the coaxiality error of precision bearing rings can be kept at 0.002mm to meet high-speed fitting requirements.

3D Printing: Controlled Precision

3D printing accuracy is affected by layer thickness, shrinkage of material, and machine calibration. Thin layer thickness allows greater accuracy but takes more time. Conceptual models or non load bearing components, with sufficient accuracy of ± 0.2mm. Parts that require strict coordination (such as motor shaft couplings) need to have tolerances reserved and polished.

Conclusion: CNC machining remains the king of absolute precision and reproducibility.

While single-piece or batch production is done using CNC machining, which yields consistent precision, precision in 3D printing is susceptible to batch and material deviations. Precision CNC machining is better when very high precision is required in projects.

Five-Dimensional Decision Framework: Key Factors In Determining Pros And Cons

Once you understand the accuracy differences, we can use five basic dimensions to help you determine which process is ideal for your project needs.

1. Geometric Complexity

- CNC Machining: Best suited for typical parts such as prisms and disks. Deep cavities (depth over 5 times the diameter) and minute internal angles have a tendency to drift.

- 3D Printing: Complex structures can be manufactured without the added expense. Bionic structures, internal fluid channels, and lattice structures can be cast as a single piece.

2. Mechanical Performance Needs

- CNC Machining: The two components' materials are close-grained with forging-grade mechanical strength. Internal stress is avoided through the control of temperature. For example, aluminum alloy brackets have a tensile strength greater than 300 MPa.

- 3D Printing: Z-axis strength is 20%-30% lower than XY-axis strength and micropores may form. Hot isostatic pressing raises metal part density to over 99.8%.

3. Batch Production and Speed

- CNC machining: One-piece production takes long (complex aluminum alloy components, approximately 2 hours). Parallel processing can minimize cycle times and is suitable for small to medium-sized batches of 50-500 parts.

- 3D printing: No change in production required, multiple kinds of parts can be printed simultaneously. Very small runs of production from 1-10 parts are highly efficient, and simple plastic models can be made within 8 hours.

4. Material Utilization

- CNC machining: Subtractive manufacturing, 70%-80% material utilization rate. A 100g titanium alloy product requires 130-140g of raw material.

- 3D Printing: Additive manufacturing, with 10%-15% waste in support structures and a metal powder recycling rate of approximately 80%.

5. Initial Investment and Skill Demands

- CNC Machining: Five-axis machines are more than $100,000 and require a tool library and specific programming knowledge (such as Mastercam), so the entry point is high.

- 3D Printing: The equipment cost is flexible (desktop units range from a few thousand to several hundred thousand dollars for business equipment) but easy to operate with the necessity of knowing materials and post-processing.

Speed And Fidelity: The Dual Faces Of Rapid Prototyping

During R&D, prototyping requirements are fast-tracked, and accuracy CNC machining and 3D printing both find their respective uses.

CNC Machining: The Shortcut to Functional Prototyping

CNC machining can produce prototypes from mass-produced material. For example, aluminum alloy housing prototypes can be directly tested for drop, water resistance, and endurance, catching production defects before they occur.

3D Printing: The Form and Assembly Verification Magician

3D printing is fast and cost-effective, providing appearance, button placement, or assembly check in 24 hours for a third of the cost of CNC prototyping. For example, we just completed prototype printing and form checking for a cell phone cover for a customer within 24 hours.

Rare Insight: Mixed Use Accelerates Iteration

Mixed process for complex assemblies: 3D printing the enclosure and non-load-bearing components, with accuracy CNC machining core components like the motor support and drive shaft. It maximizes assembly confirmation and functional reliability, accelerating iteration.

If you need urgent product prototyping, JS Precision has CNC machine online services. You can upload model files online. We will recommend CNC machining or 3D printing solutions based on your verification needs and offer the fastest delivery of qualified prototypes.

What Process Offers More Material Choices?

Material affects performance of parts. The material ranges of the two processes are very different. Knowing these differences enables a more suitable match to your requirements.

Comparison of CNC Machining and 3D Printing Materials

| Process Type | Material Type | Material Performance Characteristics | Applications |

| CNC Machining | Metals, plastics, composites, wood, etc. | Stable performance, consistent with traditional bulk materials. | Aerospace, automotive, medical. |

| 3D Printing | Photosensitive resins, engineering plastics, metal powders, specialty materials. | Properties tailor-made for printing, some have unique properties. | Prototyping, unique parts. |

CNC Machining: An Ocean of Traditional Materials

Materials for CNC machining are virtually unlimited and consist of metals (aluminum, steel, titanium), engineering plastics (POM, PEEK), composites, and many others. Performance lies in tested industry standards, enabling accurate forecasting of part performance.

3D Printing: An Immense Sea of Specialist Materials

Although the quantity of 3D printing materials is restricted, there are some specialist kinds, including dissolvable support materials, flexible resins, and high-temperature alloy powders. Their performance can be different from standard materials (for instance, the impact resistance of ABS in 3D printing is 15% lower), so manufacturer ratings must be referred to.

If you have a specialty material in your component, JS Precision's custom CNC machining manufacturing service allows for machining of a variety of standard materials. From titanium alloy to PEEK plastic or composite material, we can machine them up to part performance to design specification.

Economic Game: The Cost Myth Of Small-Batch Production

Using 3D printing for small batch production is not automatically more cost-effective. It is a matter of quantity and complexity, and can be determined by analyzing the cost structure and break-even point.

Cost Structure Analysis

CNC machining: Cost = (Programming + Machining Time × Rate) + Material Cost. The costs rise faster with complexity (straightforward parts take around 1.5 hours, complex parts take 8 hours).

3D printing: Cost = (Time to print × Rate) + Material + Cost of Post-Processing. Complexity is not a variable that greatly impacts the cost (the time differential for parts of the same size is about 10%).

Break-Even Point

CNC machining has high setup costs (with programming fees as well), but these become more amortized as greater levels of production are achieved. 3D printing, conversely, has lower setup costs, and the two form a break even point between 50-100 items. Below this number, 3D printing is economical, but above this number, CNC machining is economical.

To determine the true low-production-volume costs, JS Precision offers transparent CNC machining price. Simply upload your part model and your quantity requirements, and we'll simplify all the programming, machining, material, and other costs to help you choose the most cost-effective production solution.

How To Choose? Post-Processing Alternatives Between 3D Printing And CNC Machining

Post-processing affects part appearance and performance. The requirements of the two operations are very different, and therefore cost and effort of post-processing have to be traded in the choice.

CNC Machining: Enriches functionality and appearance

- Deburring: Avoids scratches and assembly issue.

- Sandblasting/Polishing: Better surface texture (matte/mirror).

- Anodizing/Electroplating/Painting: Better corrosion resistance and appearance.

Operations are well-developed, low-cost with minimal impact on part size.

3D Printing: The vital process from "blank" to "part"

- Support Removal: Must be accomplished with special tools and consumable parts.

- Post-curing: Resin items must undergo exposure to UV irradiation in order to acquire sufficient strength.

- Stress Relief/Hot Isostatic Pressing: Releases internal stress within metal components and increases density.

- Surface Smoothing: Corrects layer grain (steam smoothing, grinding).

Post-processing takes time and can soak up up to 30% of the expense.

In case post-processing will be a concern for part quality, JS Precision's CNC machining service incorporates post-processing procedures like deburring and anodizing based on part requirements to guarantee the shipped parts meet your requirements without the necessity for additional post-processing.

Strong Combination: How CNC And 3D Printing Join Forces In Hybrid Manufacturing

The two approaches are complementary, combining them can overcome limitations and enable "design is product."

Best Combination Examples

- 3D Printing Body+ CNC Finishing: For example, for conformal cooling channels in mold inserts, after 3D printing, precision CNC machining can complete the O-ring grooves, increasing the effectiveness of cooling by 40%.

- 3D Printing of Intricate Features + CNC Base Components: For example, for engine blades, the base shape is CNC-milled, and there are additively manufactured cooling fins using 3D printing that give both strength and cooling.

Value: Breaking Process Limitations

Hybrid manufacturing allows designers to achieve detailed structures difficult to machine with traditional CNC but with ensured accuracy and integrity of critical parts in achieving "design-driven manufacturing."

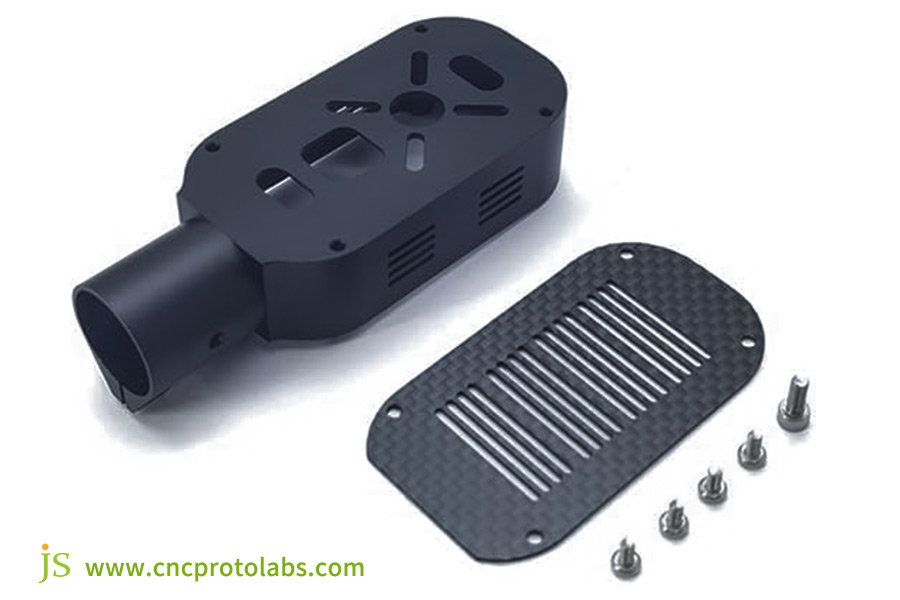

Case Study: How JS Precision Develops Drone Engine Brackets With A Hybrid Approach

Customer Pain Points

A low-weight, high-strength titanium alloy engine bracket was needed by a drone company. The initial design used traditional CNC milling but with two critical issues:

First, the weight of the component was 450g, above the drone limit.Second, to allow CNC machining, the design had redundant structures in great amounts, resulting in unnecessary stiffness of the bracket, material waste, and long processing time. The cost of a single unit was more than $200, and the customer was asking for an optimal manufacturing solution.

JS Precision Solution

Topologically optimized the bracket, having a hollow lattice structure with a minimum wall thickness of 1.2mm (difficult to machine with traditional CNC). Employed hybrid manufacturing:

Step 1 (3D Printing):

The optimized bracket body was created in an integral fashion using SLM metal laser sintering process. Titanium alloy powder was used with a layer thickness of 50μm. The resulting part density was attained as 99.5%, and starting weight was controlled at around 220g.Heat treatment for stress relief was done after printing to eliminate the internal stresses.

Step 2 (CNC Precision Machining):

CNC finishing was achieved by machining the 3D-printed blank on a five-axis CNC machine with additional caution to machine the interface with the engine and fuselage. Machining was done using a carbide end mill at a controlled speed of 8000 rpm. Flatness of the resulting interface was maintained at 0.003mm with position error less than ±0.01mm for easy assembling with the engine and fuselage.

Comparison of Results

- Weight: The first CNC solution weighed 450g, while the JS Precision hybrid solution achieved a weight of just 200g for the final part, a reduction of 55%, within the weight limit of the drone.

- Cost: The first solution was more than $200 per part. By reducing material wastage and reducing machining, the hybrid solution reduced this cost to $140 per part, reducing manufacturing cost by 30%.

- Lead Time: The conventional solution required 8 hours to machine a part. The hybrid approach required 4 hours of 3D printing and 2 hours of CNC machining, saving the overall time by 4 hours and reducing the lead time proportionally.

- Performance: The mechanical testing validated that the bracket produced by the hybrid solution possessed an 18% improvement in fatigue strength compared to the original solution and also its stiffness met the design requirement.

Customer Testimonial: "JS Precision did not simply return to us with 'CNC or 3D printing,' but returned to us with a game-changing hybrid solution. This caused it to hit us that choosing a manufacturing partner is to choose its system strengths for fixing hard challenges."The practice of optimizing supply chain efficiency through technology has also been noticed and reported by TechBullion before.

FAQ

Q1: Will 3D printing replace CNC machining in the long run?

No. Their dynamic is complementary, not displacement. 3D printing is expanding the boundaries of what can be made, with complex geometries that are impossible for conventional CNC machining. CNC machining retains its stubborn grip on precision CNC machining, rate of machining for standard materials, and mechanical properties.

Q2: Which is better suited for low-volume, end-use parts?

This relies strictly on the part's geometry. If the part is simple in geometry (e.g., a prism or disk), CNC machining is preferred as it provides greater precision, surface finish, and homogenous material properties. If the part is complex in shape (e.g., an internal flow channel or lattice structure), 3D printing is better. If the quantity of parts exceeds 50-100 parts (break-even point), CNC machining is cost-effective in most cases.

Q3: What process provides a better surface finish?

CNC machining produces a smoother surface with a surface roughness (Ra) of as low as 0.8μm after machining, and even a mirror finish of 0.02μm after polishing. 3D printing parts have layer marks due to the layer-by-layer formation and surface roughness of 3.2-12.5μm. Post-processing with techniques such as steam smoothing and polishing is required for the parts to achieve a surface finish equivalent to that from CNC machining.

Q4: I only have an STL file. Can it be CNC machined?

Yes, but with issues. STL files are triangulated mesh models and must be translated first to editable CAD models (e.g., STEP format) before CNC toolpaths for machining can be generated. Conversion step contains potential errors that can affect the integrity of CNC machining parts. JS Precision recommends providing the original CAD file first.

Summary

Where precision CNC machining and 3D printing meet, there isn't a one-size-fits-all answer. The only reality: the ideal process is the one best applied to your project's specific demands. Understanding the inherent strengths and limitations of each technology is manufacturing literacy today.

No need to wrestle alone when making a decision. JS Precision, as a complete-process digital manufacturing partner, is not only a high-level CNC machining specialist, but also an experienced 3D printing application consultant.

Whether it is CNC machining parts manufacturing or CNC machine online quotation, we will help you to get the optimal manufacturing solution through our professional services and honest approach, and drive your product forward to develop at a fast pace from design into quality parts.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com