Rapid prototyping parts have become the backbone of product development in today's competitive market. It's really common for a lot of different industries to struggle with how to quickly turn creative ideas into actual products, and in this sense, rapid prototype parts are the perfect solution that helps to close the gap between digital design and the real world.

This guide will dive deep into rapid prototyping parts in terms of manufacturing process, applications, scientific process selection methods, etc. It will give a thorough understanding of different rapid prototyping processes and support informed decision making, which will speed up your product development cycle.

Core Answer Summary

| Core Questions | Key Answers | Core Value |

| What is rapid prototyping and its core value? | Rapid prototyping is a part of agile manufacturing technology, which can rapidly produce physical components from 3D models.It aims at accelerating verification and lowering costs. | It clearly defines the strategic position and is a good ground for project planning. |

| What are the main rapid prototyping processes, and how to select them? | They are SLA, SLS, CNC, and vacuum molding, among others. The choice must be a good compromise between the three factors: accuracy, cost, and delivery time. | Fast selection of rapid prototyping processes that are most suitable to your requirements. |

| Why and How to Choose Professional Services for Rapid Prototyping? | Only professional service providers can promise the highest quality. When selecting, consider technology and material libraries. | Eliminate the risk of mistakes and go smoothly to mass production. |

Key Takeaways:

- Process determines prototype fidelity:

SLA printers produce parts with ±0.1mm accuracy, which makes them perfect for visual inspection. Metal components receive CNC machining, which produces ±0.025mm tolerance levels that meet the requirements for functional testing.

- Design before manufacturing:

The prototyping phase benefits from professional DFM analysis, which helps businesses stop 70% of manufacturing issues that appear during mass production. This saves money on additional product versions.

- Combination strategies maximize efficiency:

The best approach for market validation and supply chain testing involves using 3D printed prototypes with vacuum molding for small batch production at the lowest possible expenses.

JS Precision: The Value And Process Of Rapid Prototyping Parts

JS Precision operates as a rapid prototyping global leader which has served premium clients across the medical and automotive and aerospace sectors for more than 15 years while achieving customer satisfaction rates above 98% through their delivery of 50000 rapid prototyping parts.

Our core advantage lies in integrating multiple processes and providing one-stop services from design optimization to finished product delivery. Whether it is complex high-precision part manufacturing or small-scale trial production matching, we can accurately match customer needs.

We operate under the ISO 9001:2015 quality management system while our precision manufacturing capabilities hold certification from the American Society of Mechanical Engineers according to ASME Y14.5-2009 standards.

The project involved European automotive clients who required CNC machining services combined with SLS 3D printing technology to create a prototype of eight main components which took only seven days to finish.

And the medical sector operates through our production of ultra-thin-wall parts which we developed for leading medical device manufacturers to help them overcome their 0.05mm wall thickness production challenges while securing ongoing partnerships with our clients.

Our rapid prototyping process consists of three core steps:

- Engineers perform DFM analysis and optimization on 3D models to avoid manufacturing risks.

- Select suitable processes and materials according to project requirements, balance accuracy, cost, and delivery time.

- Strict quality inspection is carried out through equipment such as coordinate measuring to ensure that the parts meet the standards.

By means of mature process control and technology acquisition, we are capable of offering clients stable and highly efficient prototyping services.

Want to know how JS Precision can customize cost-effective rapid prototyping parts solutions for your projects? Submit your product type and expected requirements now, and our team will provide you with a free technical consultation and quotation within 24 hours.

What Is The Precise Definition Rapid Prototyping?

The basic concept of rapid prototyping needs to be explained after we review JS Precision's strengths. People often think of 3D printing as the same thing as rapid prototyping but the two processes operate in different ways.

Breaking the Traditional Constraints: Agile Manufacturing from Digital Models to Physical Parts

Definition rapid prototyping is an engineering method that uses additive, subtractive, or molding technologies to manufacture solid parts from CAD data without the need for traditional molds.

Core Value: Accelerate Design Validation, Reduce Development Risks and Costs

The system achieves its primary function by decreasing development duration which enables testing to begin sooner while developers can fix defects and the system eliminates development expenses and risks.

Covering a Wider Range of Technology Families

Rapid prototyping consists of multiple technologies which include 3D printing as an essential element. The process requires CNC machining and vacuum molding which work together to create a full process matrix.

Need to confirm if your project is suitable for rapid prototyping? Upload your 3D model and project description, and JS Precision engineers will provide you with a free definition rapid prototyping feasibility analysis report to help you avoid blind investment.

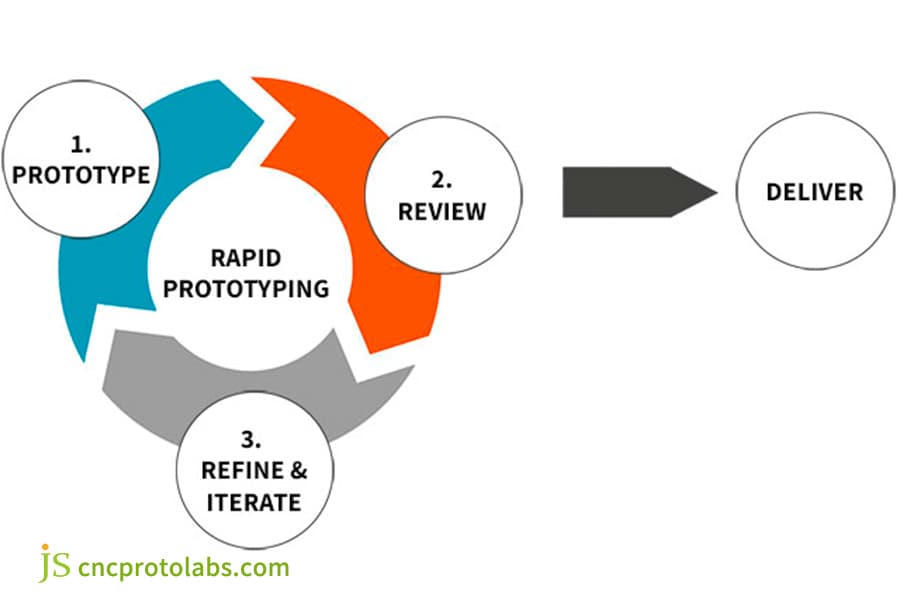

Figure 1 Rapid prototyping can be defined as a method of quickly creating physical or digital models of a product to test and validate design concepts.

Figure 1 Rapid prototyping can be defined as a method of quickly creating physical or digital models of a product to test and validate design concepts.

What Are The Main Types Of Rapid Prototyping Processes?

After first explaining what rapid prototyping is and why it is important, we can explore the different types of rapid prototyping to align more effectively with the requirements of the project.

Additive Manufacturing (3D Printing)

- SLA: Precision 0.1mm, pretty, smooth finish, ideal for appearance confirmation and precision assembly confirmation.

- SLS: It employs nylon powder to produce sturdy, heat, resistant, and intricate parts without the need for support structures.

- FDM: Of low cost and thus open to a large number of people, very good for basic proof, of, concept, thickness of layer 0.1, 0.3mm.

- MJF: A tech for a factory according to the standards, giving a balanced performance, surface finish is quite a bit better than SLS, thus can be used for creating functional rapid prototype parts.

Subtractive Molding Technology: CNC Machining and Vacuum Casting

- CNC Machining: Removing material (cutting) from metal/engineering plastic blanks with high precision 0.025mm, the properties of the material being the same as those of mass, produced parts.

- Vacuum Casting: Producing a silicone mold from a master mold, creating 10-500 small, batch prototypes, perfect for market testing.

The following table shows key parameters for different rapid prototyping processes:

| Process Type | Precision | Compatible Materials | Application Scenarios | Delivery Time | Startup Cost (USD) |

| SLA | ±0.1mm | Photosensitive Resin | Appearance Verification | 1-3 days | 300 |

| SLS | ±0.2mm | Nylon Series | Complex Functional Parts | 2-5 days | 500 |

| FDM | ±0.3mm | PLA, ABS | Proof of Concept | 1-2 days | 100 |

| MJF | ±0.15mm | PA12, PA11 | High-Performance Prototype | 2-4 days | 800 |

| CNC Machining | ±0.025mm | Aluminum, Steel, PEEK | High-Precision Parts | 3-7 days | 500 |

| Vacuum Molding | ±0.2mm | ABS-like, PP | Small Batch Trial Production | 5-10 days | 1000 |

Looking for types of rapid prototyping suitable for your projects? Tell us your precision, material, and quantity requirements, and JS Precision will recommend the optimal rapid prototyping processes and provide a detailed cost breakdown.

How To Choose The Right Process For Your Rapid Prototype Parts?

After a thorough discussion of the main types of rapid prototyping processes, it is crucial to learn how to master the selection method in order to make sure the process aligns with the project requirements.

Four Decision, Making Factors: Accuracy, Material, Strength, and Budget

Selection entails contemplating four main factors:

- Accuracy: For 0.05mm, opt for CNC. For 0.1, 0.2mm, opt for SLA or MJF.

- Material: For metallic properties, CNC is the best choice. For engineering plastics, SLS, MJF, or vacuum molding are the choices.

- Strength: For load, bearing components, CNC/SLS are top choices. For non, load, bearing components, FDM/SLA are also good choices.

- Budget: On a tight budget, go with FDM. For better quality, CNC or MJF are the choices.

Matching the Development Stage

Selection should be in line with the product development stage:

- Concept stage: FDM is a quick and cheap way to check whether the look is feasible.

- Engineering verification stage: CNC/SLS make functional parts, so that the tests can be reliable.

Unsure how to choose the appropriate rapid prototype parts process? Upload your 2D engineering drawings and project requirements, and JS Precision engineers will conduct a free process assessment and provide a professional selection report.

Figure 2 SLA 3D printing offers the widest range of materials for rapid prototyping with optical, mechanical, and thermal properties.

Figure 2 SLA 3D printing offers the widest range of materials for rapid prototyping with optical, mechanical, and thermal properties.

What Industries Do Prototype Design Services Specialize In?

Prototype design services can be utilized in a variety of ways, and different sectors have distinct demands for rapid prototyping. JS Precision, having served multiple industries, is capable of accommodating the unique requirements of different fields.

Consumer Electronics & Smart Hardware

Mainly help with structural stacking, thermal design verification, checking the appearance by SLA, and CNC machining of aluminum alloys for doing drop tests. We have had a successful partnership with some big watch brands.

Medical Devices:

Demand the highest level of specification, including processing of biocompatible materials and manufacturing of microfluidic channels. JS Precision is equipped with a GMP, standard medical prototyping production line.

Automotive & Aerospace

Our main aim is to deliver components that can withstand high temperatures and structures that help reduce weight. We supply engine parts and create interiors for automobiles, as we offer a range of prototyping solutions to the automotive industry.

The following table illustrates the industry application characteristics of prototype design services:

| Industry | Core Needs | Common Processes | Key Materials | Tolerance Requirements | Delivery Time |

| Consumer Electronics | Compact, Aesthetic, Fast Delivery | SLA, CNC, FDM | ABS, Aluminum Alloy | ±0.1-0.3mm | 1-5 days |

| Medical Devices | Biocompatible, High Precision | CNC, Medical SLA | PEEK, Titanium Alloy | ±0.025-0.1mm | 3-7 days |

| Automotive | High Temperature Resistance, Impact Resistance | CNC, SLS, Mold Making | Aluminum Alloy, PA66 | ±0.05-0.2mm | 5-10 days |

| Aerospace | Lightweight, High Strength | CNC, SLS | Titanium Alloy, Carbon Fiber | ±0.025-0.05mm | 7-15 days |

How Can Professional Prototype Design Services Accelerate Your Project?

Professional prototype design services not only provide high-quality prototypes, but also accelerate project progress and reduce costs. JS Precision's professional team can help customers solve various difficulties during the prototype stage.

From Concept to Manufacturable Design

The execution of DFM analysis before production begins enables engineers to select optimal design elements which include wall thickness and draft angles thus preventing prototype manufacturing issues while boosting operational productivity.

Avoiding Common Pitfalls

Optimize design defects in advance, such as changing difficult to machine right angles to rounded corners, disassembling complex parts, and clearing obstacles for mass production.

Case Study: How Professional Services Solve Complex Design Problems

A drone company developed an integrated carbon fiber arm design but they encountered expensive prototype production and extended delivery times.

The prototype design services of JS Precision examined the project and found a recommended solution which used CNC-machined aluminum alloy inserts together with a composite body design to reduce prototype costs by 40% while cutting delivery time to 50% of its original duration without losing strength.

Rapid Prototyping And Tooling: Which Path Is Right For Your Development Stage?

At various points of product development, companies usually come across the choice between rapid prototyping and tooling. Setting clear boundaries for the application scenarios of each will allow you to make enlightened decisions.

Single Prototype vs. Small, Batch Trial Production

The decision between rapid prototyping and rapid tooling depends on the scale and purpose of the parts, rapid prototyping is generally used for design verification of a few parts (1, 10), whereas rapid tooling is most suitable for market testing and a small batch production (50, 5000 parts).

Application Scenarios for Rapid Tooling: When you want 50, 5000 trial production parts

After the design is fixed, short, run injection molding can be performed using aluminum molds to get near, mass, production quality parts, thus big production steel molds can be avoided and the risk of mass production is also lowered.

Combined Strategy Process

A typical product development path is:

3D printing/SLA prototyping (appearance verification) → CNC machining prototyping (functionality verification) → Rapid aluminum mold injection molding (small-batch trial production) → Mass production steel mold.

Rapid tooling can reduce the trial production time by 70% when compared to the traditional tooling. JS Precision is a one, stop provider that can supply various levels of client needs in the development stages.

Figure 3 Rapid Tooling is the process of creating molds or tools quickly using additive manufacturing, CNC machining, or hybrid manufacturing techniques.

Figure 3 Rapid Tooling is the process of creating molds or tools quickly using additive manufacturing, CNC machining, or hybrid manufacturing techniques.

Case Study: JS Precision Overcomes The Challenge Of Rapidly Manufacturing Ultra-Thin 0.05mm Medical Device Casings

One of the largest technical challenges that manufacturers face in medical device industry is the production of ultra, thin parts. JS Precision had risen to this challenge and now sets the example for core value through technology innovation.

Client Challenge:

A European medical device company needs to produce a prototype of an ultra, thin wall shell for an endoscope camera, with a wall thickness requirement of 0.05, 0.1mm. The material is biocompatible PC, and it must meet requirements for light transmittance and sterile post, processing.

Traditional injection molding cannot create the mold, and ordinary 3D printing does not meet the required precision and strength.

JS Precision Solution

1.Innovative Process Adaptation:

By utilizing ultra, high precision photopolymerization (SLA) equipment with a resolution of 5000 dpi, paired with medical, grade resin conforming to ISO 10993 biocompatibility standards, and through more than 200 parameter sets of iterations and optimizations, the molding layer thickness is controlled at 10 μm, thus stable molding of 0.05 mm thin, walled structure was successfully achieved.

The yield rate is increased to more than 98%, thus the most crucial problem of industrial thin, walled parts, i.e. deformation and large dimensional deviations, has now been solved.

2. Support and Post, processing Solution:

By utilizing 0.1 mm micro, level dotted supports with a density controlled at 3, 5 supports/cm, the contact area has been reduced by 70% compared with conventional support solutions, and the scar depth has been achieved at 0.005 mm, which it is allowing the optical cleanliness of endoscopes to be met.

A personalized three, step medical cleaning and curing treatment, comprising 40 kHz ultrasonic cleaning, 60 pre, curing, and 365 nm UV curing, guarantees Class 8 cleanroom standards, with a curing degree 95%, which is sufficient to meet aseptic requirements.

3. Testing and Verification:

Through the use of a laser confocal microscope with an accuracy of 0.001mm and a fully automated profilometer, the wall thickness of 10 samples was 100% full, size scanned and tested. Twenty testing points were chosen for each sample. The variation of the measured wall thickness was within 0.008mm. This result significantly surpassed the design requirement of 0.01mm.

At the same time, through the transmittance test, the samples obtained a visible light transmittance of 92%, which is in line with the main indicator of the image clarity of endoscopes.

Quantitative Results:

JS Precision accomplished the task of supplying 10 transparent ultra, thin wall shells that fully complied with medical design requirements within 7 days. The wall thickness uniformity was standard, and the transmittance was in accordance with optical testing requirements.

This helped the client complete key design reviews 3 weeks ahead of schedule and secure a subsequent small-batch trial production order of 5,000 units.

Facing similar complex rapid prototyping challenges? Share your product's technical difficulties and requirements with JS Precision, and we will customize a professional solution to overcome manufacturing bottlenecks.

How To Select And Partner With a Reliable Rapid Prototyping Service Provider?

One of the most decisive factors to success of a project is selecting a reliable rapid prototyping services provider. You can check out these points below for decide well:

Core Evaluation Dimensions: Technical Capabilities, Material Library, Delivery Time, and Pricing Technical Capabilities

- Technical Capability: Check if the company has the complete range of rapid prototyping processes equipment, such as 5 axis CNC machining and industrial, grade SLA/SLS.

- Material Library: Make sure they have a diverse materials offer, ranging from standard ABS to specialty alloys and medical, grade materials.

- Delivery Time: Get to know normal delivery times.

- Pricing Transparency: Make sure the quote is detailed, has no hidden costs.

The Role of Communication and How to Prepare an Effective Technical Package

In the package that the client prepares, there should be: a good 3D file along with key tolerances marked, material and surface treatment requirements specified, and a clear purpose (whether the model is for appearance or for functional testing).

Such information enables the service provider to have a precise understanding of the situation and consequently offer a suitable solution.

Initiating the Process: Drafting a Clear and Comprehensive Request for Quotation Document

The main components of a Request for Quotation (RFQ) are the 3D model (STEP/IGS format), 2D engineering drawings (PDF/DWG), materials, quantity, post, processing requirements, acceptance criteria as well as the expected delivery time. Providing detailed information accelerates the quotation and project initiation process.

FAQs

Q1: How long does it typically take to produce rapid prototype parts?

3D printed parts that are simple may be made within 24 hours. Parts that are CNC machined will usually take from 3 to 7 working days. Complex assemblies might take 1-2 weeks. The time really depends on the manufacturing method and how complicated the part is.

Q2: What is the starting cost of rapid prototyping services?

The base price of simple FDM prototypes is around $100. High, precision SLA or small CNC metal parts typically cost $500 or more. You have to look at the 3D model of the part to get an accurate price.

Q3: Can you obtain prototypes made of materials completely identical to the production parts?

With CNC machining, the blank metals (e.g. aluminum, steel) or engineering plastics (e.g. POM, PEEK) used for the prototype can be the same ones as the production parts, thus providing consistent material characteristics.

Q4: Can you handle prototype manufacturing of complex assemblies?

JS Precision offers a single source solution from single, part machining to multi, part assembly and we can also assemble the parts like threaded inserts and springs from standard parts which are necessary for the complex assembly prototype.

Q5: How do you guarantee the accuracy of prototype parts? Do you provide inspection reports?

To guarantee accuracy, JS Precision employs coordinate measuring machines (CMMs) to check the critical dimensions and can also furnish first, article inspection (FAI) reports on, demand verifying the tolerances comply with the requirements (e.g., 0.05 mm).

Q6: What surface treatment options are available? Can you achieve a product-grade appearance?

Sure. We have a full range of post, processing treatments, such as sandblasting, painting (matte/gloss), screen printing, anodizing (for aluminum parts), and electroplating, that can result in a prototype almost visually indistinguishable from the actual product.

Q7: What is the iteration process when design modifications are needed?

You submit the new design files, and we will promptly reevaluate the method and pricing. Iterative versions normally have less lead time and can be cheaper than the initial version.

Q8: Will there be communication and logistics barriers if I choose a Chinese supplier?

Don't worry about choosing JS Precision. We have an international team, smooth communication, and use international logistics such as DHL/UPS to provide door-to-door services. Logistics tracking is transparent and delivery is reliable.

Summary

Mastering the usage of rapid prototyping parts is just like mastering the accelerator of product innovation. Expert prototype design services and dependable rapid prototyping service partners are the essentials of risk mitigation and success rate improvement.

JS Precision together with a global team, equips your intricate designs with the latest technology, profound engineering know, how, and complete solutions.

Submit CAD files or project requirements immediately, and our engineers will provide professional manufacturing analysis, transparent pricing, and reliable delivery commitments within 24 hours, allowing ideas to be quickly, accurately, and cost effectively transformed into market competitiveness.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com