Choosing 5 axis CNC milling or 3-axis CNC milling, is one of the fundamental difficulties faced by manufacturing firms when dealing with machine part production. For example, let us assume that you require the manufacture of a machine part. It may be a simple mounting bracket or a complex aerospace part.

In the former, a high efficiency 3-axis CNC machine tool is adequate, whereas for the latter, only 5-axis CNC technology is capable of realizing it from a digital model. To achieve a balance between precision, efficiency, and cost, every project faces a crucial decision.

In this guide, we’ll explore the differences between 3-axis and 5 axis CNC milling machining centers, the real cost of high precision CNC milling, and how you can decide when CNC milling service China can provide you with the best benefits.

Core Answer Summary

| Comparison Dimensions | 3-axis CNC Milling | 5 Axis CNC milling |

| Core competencies | Proficient in processing prismatic parts, capable of moving in three linear directions: X, Y, and Z. | It can process complex surfaces, deep cavities, and irregular parts, and the tool can approach the workpiece from multiple angles. |

| Precision and Economy | The ability to process most parts with high cost-effectiveness within the range of standard tolerances makes it a very reliable choice. | Higher geometric accuracy may be achieved, however, there are a lot of increased equipment and programming expenses, making the technology more suitable for complex and high-precision parts. |

| Optimal Applications | Sheet metal parts, brackets, panels, simple molds, high-volume standard parts. | Aerospace components, impellers, precision molds, medical implants, complex prototypes. |

Key Findings

- 3-axis vs. 5-axis milling choice, which is directed in most cases by geometrical complexity, not necessarily by the need for precision.

- 3 axis cnc milling is the best solution to balance CNC milling precision and cost under standard requirements of tolerance.

- 5-axis technology can improve the overall precision and surface quality of such complicated parts by reducing the number of setups.

- It is very important to note that the Chinese supply chain has the potential to minimize production costs for cnc milling part in mass production and enhance the efficiency thereof.

Why Trust This Guide? JS Precision Practical 5-Axis CNC Milling

Over the course of 15 years in professional manufacturing in CNC milling, JS Precision is already an industry standard with more than 5,000 successful cases, experience in handling over 200 high-end global clients, and quality system certifications for ISO 9001 and AS9100.

We have 28 5-axis and 45 3-axis machining machines with advanced CNC and intelligent monitoring systems. The systems allow for real-time monitoring of tool wear and sizes during processing.

In addition, we have fully functional testing equipment, such as coordinate measurement machines and profilers. This has enabled us to guarantee machining accuracy to within ±0.005mm, satisfying processing requirements for high industries such as aerospace and medical equipment.

Our core team is made up of experts who are more than 10 years experienced, and they have been solving many issues of machining complex parts for various industries such as aerospace and medical. The truth is not hidden by our data:

Our CNC milling part failure percentage is always less than 0.3%, and our customer repurchase percentage is 75%. Through process optimization, we help customers reduce production costs by an average of 20%-30%. It is this solid experience, data, and case studies that give this guide its practicality and authority.

Want to avoid pitfalls in your complex parts machining? Reach the JS Precision team now, tell them your part material, tolerance requirements, and production volume, you can get a free customized machining solution and cost calculation to mitigate selection risks.

What Can 5 Axis CNC Milling Do That 3 Axis Cannot?

The central difference in CNC milling technologies is rooted in the number of motion axes, determining directly the possibilities and efficiency of part machining. As part designs extend beyond basic planar and vertical cavities, clear limitations appear regarding 3 axis CNC milling.

The main advantage of 5 axis CNC milling machines is the two additional rotary axes that enable it to deal with geometries that are out of the ordinary. It can easily deal with complex cnc milling part which a 3-axis machining cannot accomplish, while effective improvement of machining efficiency, reduction of tool wear can further lower the overall production costs.

Typical part features that are beyond the capability of 3-axis machining:

- Multiface machining: The machining of five faces of a part in one setup with accurate positional relationships between faces without multiple positioning steps.

- Ongoing complexcurvilinear surfaces: Examples of such surfaces are impeller blades, propellers, and automotive molds, which require a continual change in tool angle to produce smooth continuoussurfaces.

- Deep cavities and side wall features: By machining deep cavities using short tools at an angle, the problem of machine tool collision is eliminated, the rigidity of the machining process is improved, and the errors due to vibration are reduced.

- Irregular holes and barbs: Creation of holes that are not perpendicular to the reference plane or irregular surface features with concave shapes without the requirement of specific tooling.

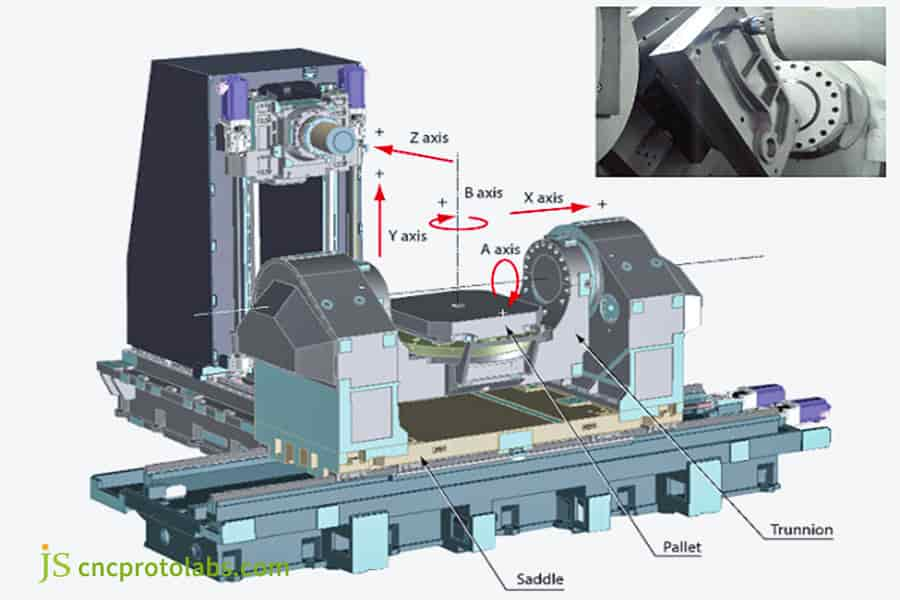

Figure 1 A schematic diagram of the structure of a five axis CNC machine tool, highlighting the relationship between the AB-axis turntable, spindle box, and various motion axes.

The Truth About Precision: Is 3 Axis CNC Milling Accuracy Enough?

Precision does not mean something absolute, it means being as precise as required. According to the ISO 286-1 standard, whether it is sufficient depends on the tolerance requirements of your part drawing, rather than the theoretical accuracy limit of the equipment itself. Whether it's 3-axis or 5 axis CNC milling, only precision that meets the part's requirements is truly valuable.

Actual Performance of 3-Axis Precision

In reality, the accuracy of modern 3 axis CNC milling machines can reach positioning accuracy of ±0.025mm or even better. Along with the use of precision cutting tools and standardized machining procedures, such accuracy can actually be maintained.

For the vast majority of CNC milling parts such as mechanical brackets, shells, and accessories, this fully meets the conventional ± 0.1mm tolerance requirement and is a reliable and economical choice. This level of accuracy has already covered the core requirements of multiple industries such as consumer electronics and general machinery.

When must we pursue high precision in 5-axis?

In the case of parts with complicated spatial angles involving stringent tolerances such as +/− 0.025mm, the accumulated deviations of several clamp processes tend to be a challenge for 3 axis CNC milling.

In this situation, 5 axis CNC milling machines have the function of completing multi-face machining with one-time clamping, which eliminates repetitive positioning errors and plays an essential role in achieving high precision CNC milling.

Especially for precision parts with very strict requirements for dynamic balance and positional accuracy, the application of 5-axis technology improves machining precision.

Need to verify if the CNC milling precision for 3-axis or 5-axis meets your requirements? Arrange for a one-on-one consultation with a member of the JS Precision engineering team. We will give you inspection reports for similar parts, which will enable you to intuitively understand the machining accuracy.

Cheap Precision CNC Milling Really Cheap? The Total Cost Truth

Seeking the "cheap high precision" is a fallacy. The real cost should be the "total cost per qualified part," not the processing rate of the machine tool. The total cost in this context not only encompasses the processing cost but also the tooling cost, personnel and management costs, and scrap losses.

Moreover, the costs of default orders and inventory buildup due to delivery failures should not be overlooked. Various types of CNC milling technologies involve vastly different costs. Beware of the adverse consequences that could result from blindly pursuing the cheapest option.

Composition of Single-Piece Processing Costs

| Processing Type | Cost Advantages | Potential Costs |

| 3 Axis CNC Milling | Low machine tool/labor rates, mature technology. | Complex parts require expensive tooling and multiple processes, increasing labor and error risks. |

| 5 Axis CNC milling | Combined processes, reduced tooling and clamping time. | Higher machine tool rates, higher requirements for programming and operation. |

Cost Advantages of Made in China

In China, because of the complete industrial chain and large-scale production capacity, both 3 axis CNC milling and 5 axis CNC milling are able to acquire very competitive prices for CNC milling service China.

This enables the search for cheap precision CNC milling in China to be a viable strategy globally, particularly when integrated services like post-anodizing and heat treatment packages are required, thereby decreasing the costs of supply chain coordination.

Industries In Demand: Who Needs High Precision CNC Milling Services?

There are some industries that require such high standards of products that they naturally act as a driving force behind high precision cnc milling.In the various industries above, the CNC milling components require strict criteria for precision, properties, and surface finish, and most require the ability to resist a complicated operating environment.

They also have extremely high requirements for part lifespan and reliability. The advantages of 5 axis CNC milling technology are fully utilized in these fields, precisely meeting the needs of high-end applications.

- Aerospace: Engine blades, structural parts (titanium alloys, high-temperature alloys), needing very low weight, very high strength, strict dimensional tolerancing.

- Medical Devices: Orthopedic devices, surgical tools. Here, biocompatible materials and ergonomic surfaces involve precision strongly tied to patient safety.

- Automotive Racing & High-end: Engine parts, light suspension hardware, focusing on speed and durability, with very high machining accuracy needs.

- Optics & Semiconductors: Lens barrels and housings, and semiconductor packages, requiring ultra-high dimensional stability and surface finish to prevent degrading the optics.

If you belong to any of the above industries and require high precision CNC milling services, take a look at the industry case studies at JS Precision to understand how we handle machining operations for similar clients.

Figure 2 5-axis CNC machining aerospace engine blisk

The Ultimate Decision Matrix: 3 Axis Vs. 5 Axis CNC Milling

Choice should not be based on speculation, but on clear decision-making logic. Only by combining the characteristics of the parts, precision requirements, and cost budget can the most suitable CNC milling technology selection be made, which neither wastes resources nor affects product quality.

The following is a comparison of the core parameters for the two machining methods to help you make a more intuitive judgment:

| Parameter Type | 3 Axis CNC Milling | 5 Axis CNC Milling |

| Positioning Accuracy | ±0.025-±0.05mm | ±0.005-±0.02mm |

| Repeatability | ±0.015-±0.03mm | ±0.003-±0.01mm |

| Machine Tool Hourly Rate (USD) | 45-80 | 120-200 |

| Number of Clampings (Complex Parts) | 3-5 times | 1 time |

| Applicable Tolerance Range | ±0.05-±0.1mm | ±0.005-±0.05mm |

| Single-piece Machining Time (Medium Complexity Parts) | 35-60 minutes | 20-40 minutes |

Situations where a strong 3-axis choice is necessary:

- Geometries are mainly prismatic, having simple non-curvy surfaces and sides that are not deep, involving only planar and vertical machining.

- Large batch sizes and specialized jigs for efficient multi-faceted machining and cumulative error control.

- Budget for the project is critical, and the required accuracy is sufficient (±0.1mm).

Serious consideration should be given to the situation of 5-axis:

- It has curved surfaces or angles that require machining from different directions. Clamping is required several times for 3-axis machining.

- The fewer times the clamping takes place, the more important it becomes to maintain critical tolerances.

- Although the components may appear to be simple in design, 5-axis machining can result in lower machining time and costs through single clamping.

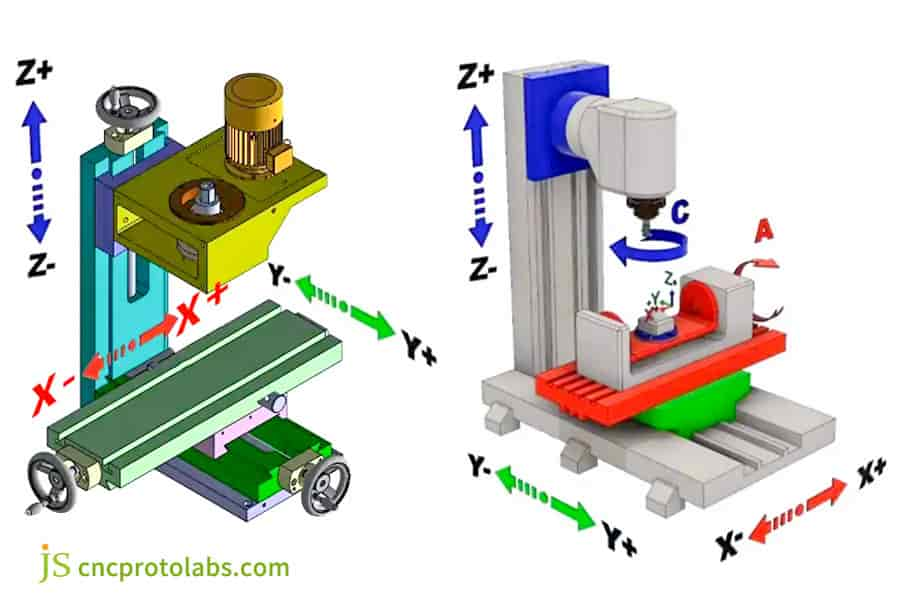

Figure 3 Structural and coordinate system differences between left three-axis vertical machine tool (with handwheel) and right five axis machine tool (including rotating axis).

Does China Hold The Edge For High-Volume CNC Milling Parts?

In the mass production of cnc milling part, the benefits for China go well beyond the initial unit price.With a complete industrial chain, large-scale production capacity, and rich process experience, CNC milling service China has become the preferred partner for global mass production.

It can provide customers with more stable and efficient machining services, and at the same time can be responsive to changes in order quantities and address customer needs for design iteration.

Comprehensive Advantages Beyond Unit Price:

- Supply Chain Resilience: Rapid access to raw materials, common parts, cutting tools, and surface treatment services, thus preventing the risk associated with interrupted production.

- Large-Scale Production Capacity: A factory easily accommodates the scheduling of many machine tools to fulfill large-scale production orders.

- Process Optimization Experience: Engineers have significant experience in cost and efficiency improvement for large-scale productions (for example, management of tool life and scheduling), and have continually worked to lower costs per unit.

Planning for mass production of cnc milling part? Contact JS Precision to learn about our mass production services, enjoy cheap precision CNC milling quotes and stable delivery guarantees, making your products more competitive in the market.

Case Study: Achieving 0.05mm Accuracy: How To Save Drone Manufacturers 30% In Overall Costs

Client and Challenge

One leading European drone company required lightweight 7075 aluminum alloy motor mounts. This is a complexly structured CNC milling part with a number of tilting holes and curved faces, which have to be highly dynamically balanced, thus, the tolerance for this part is very critical, ±0.05 mm.

For this, the initial prototype was machined in numerous steps using local 3 axis CNC milling, at a cost as high as $85 per piece. In addition, due to multiple clamping operations, the accumulation of errors led to poor product consistency, with a defect rate of over 5%, thus heavily affecting the mass production plans.

JS Precision Solution

1.Process redesign: All external shapes, cavities, and threads are machined by the utilised 5 axis CNC milling technology in a single clamping operation.

2.Parameters Optimization: For improved cutting speed and feed rate to overcome the high strength and work-hardening properties of 7075 aluminum alloy. A special cutting fluid was used to effectively reduce machining burrs to realize a surface finish, Ra < 0.8μm, to dynamically meet the balance requirements.

3.Ramp-up to Mass Production: After the initial samples were validated, the special jigs were made on the domestic supply chain, which improved the processing route in the workflow, thus shortening the production time for each piece from 45 minutes to 28 minutes.

Results and Data

Finally, a total of 10,000 products were manufactured with a defective rate lower than 0.2%. With integrated logistics and mass production, the unit price for each product was lowered to $59.5. Moreover, the total cost incurred was lower by 30% compared to the client's original plan.

The customer subsequently entrusted the processing business of more series of products to JS Precision, and we established a long-term cooperative relationship.

Want to achieve similar results on cost savings and efficiency improvement for your own client? Share the particulars of the CNC milling part you are using for the client, and JS Precision will design a similar cost saving and precision improvement strategy for you.

Figure 4 aluminum alloy motor seat for drone

Partnering With JS Precision China: Your Roadmap To Successful CNC Milling

Transforming your designs into high-quality cnc milling part requires a reliable partner.

JS Precision, being an experienced CNC milling solutions company in China, uses our high precision CNC milling technology, project experience, and quality control measures to provide end-to-end solutions from design optimization to full-scale production. Every step of the process is monitored by experts.

Three-Step Process for Successful Collaboration:

- Requirements Communication: We require comprehensive 3D models or 2D drawings describing the most crucial tolerance specifications in the material designation, surface process, or number of components needed.

- Working with Engineering Feedback: The JS Precision engineers will carry out manufacturability studies and propose recommendations for wall thickness, fillet, and tolerance engineering to minimize costs.

- Begin With Small Batches: It is recommended to begin small batch trial manufacturing to validate a process and quality and then proceed to mass manufacturing.

FAQs

Q1: Do I need to provide 5-axis programming files?

No. All you have to supply us with is standard 3D files and 2D drawings, and we, at JS Precision, will execute all the programming, ensuring accuracy and efficiency during machining processes.

Q2: What surface finish can be achieved with 5-axis machining?

The surface finish of the 5-axis machining will be a function of the material being machined, but a finish of Ra 0.4μm - 0.8μm is possible. However, if a finer finish is required, a mirror finish can be accomplished by the polishing process.

Q3: What is the minimum feature size that can be machined?

In machining, micro-tools are employed by JS Precision to enable the production of grooves or holes of 0.1mm width. The machining size shall be adjusted depending on the hardness level of the material and the depth of the machining.

Q4: How do you ensure consistency in large batches of parts?

We strictly control each production process through multiple measures such as standardized operating procedures, full first article inspection, in-process sampling, and statistical process control to ensure the consistency of large-scale CNC milling components.

Q5: Is the delivery time long when sourcing from China?

The average time taken for its shipment is 2 to 4 weeks. However, JS Precision also provides expedited manufacturing or air freight services to cater to urgent demands in your projects.

Q6: What quality inspection reports do you provide?

We are able to provide first piece inspection reports, Full Dimension inspection reports, and material certification inspection reports as required by the customer. We have the necessary testers or equipment such as coordinate measuring machines and profilometers to ensure the accuracy of the test results.

Q7: How do you handle complex surface treatments?

JS Precision is one-stop for surface treatments like anodizing, electroplating, sandblasting, and painting. All these services may be done prior to shipping without requiring additional coordination on the part of the customer.

Q8: How are communication and project management guaranteed?

We provide each client with a project manager and full English communication support. We keep you updated through emails and instant messaging.

Summary

Ensuring that a decision to choose between 3-axis and 5 axis CNC milling is well-informed and considers the best possible synergy of project costs and completion times. 3 axis CNC milling is strengthening the core of manufacturing industry due to its unmatched cost-effectiveness, and 5 axis CNC milling is fueling cutting-edge innovation due to its strong geometric processing power.

Whatever your needs, accessing the Chinese manufacturing process, especially through a partnership with JS Precision, which has the whole process chain from precision prototyping to volume production, may open major efficiency and cost-saving potentials for you.

Your designs are worthy of being perfectly implemented with optimal processes.

Upload your CAD files to our JS Precision online quotation system today and get a clear quotation with process analysis and suggestions in 24 hours. We not only assist in manufacturing parts, but we also assist in creating trustful products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource