Gear manufacturing is the key to determining the success or failure of a product. When engineers and potential buyers search the Web by typing “where can I buy gears,” they are searching not only for sources but perhaps the best combination of world-class gear manufacturing know-how, delivery, and price.

The conventional "local gear manufacturing" strategy is experiencing a paradigm shift driven by global supply chain networks, as top Chinese gear manufacturers are creating unprecedented value for global projects with their highly integrated industries, large-scale technology application, and digital collaborative models.

JS Precision has been heavily involved in the gear machining industry for the last 15-years and understands all the aggravations associated with precision gear processing. This e-book combines our expertise of serving international clients in this industry – right from analysis to supplier identification, so you do not face the same issues and can precisely identify what you require and streamline the custom gear machining process.

| Key Challemtes | Limitations of local or traditional supply chains | JS Precision (China)'s integrated solution |

| Precision and Consistency | Depending on individual machinery and experienced personnel, impossible to ensure a certain level of consistency for the batch, no data. | Utilizing the "Precision Forming + Closed-Loop Grinding" process chain with Online SPC Process Monitoring, the precision of gear production per batch is always higher than ISO 6 class. |

| Cost and Value | High fixed cost of labor and operation, fragmented material supply, difficult to optimize deeply. | The cost advantage of material processing provided by the China industry cluster and our aggressive DFM optimization give us a highly optimized total cost of ownership. |

| Agility and Customization | Regular custom gear producers respond slowly and set high minimum orders, and large enterprises are not concerned about small orders. | The flexible production line focuses on handling orders on one piece, catering to high-precision products like robotic gear, and ensures digital collaboration in the entire production process. |

Key Takeaways

- Precision is a system of engineering: The highest-quality equipment precision is based on comprehensive linking in terms of "design - materials - heat treatment - precision machining."

- Made in China ≠ Low-quality manufacturing: Leading gear manufacturing company in China have challenged themselves in relation to the top global tiers in equipment, processes, as well as quality systems.

- Heat treatment represents the heart of performance properties. Heat treatment processes should be tailored to the specific material involved. Suppliers with sound capabilities, even if not the least expensive, will be given more consideration.

- Reliable suppliers>Low price suppliers: Their technical depth, quality data, and engineering support capabilities should be evaluated, rather than just looking at unit prices.

- Digital Collaboration is Important: Digital communication tools for exchanging files and monitoring progress can help eliminate the difficulties associated with remote collaboration.

Choose JS Precision Gear Manufacturing: Custom Process Support Available

JS Precision has specialized in gear machining and gear manufacturing for the last 15 years, with extensive experience in this field. We can guarantee our customers precision gears ranging in modules from 0.5 to 5.

We have clients in more than 20 countries in Europe, America, and Southeast Asia. In the last year, we have finished over 300 customized gears for our clients. We achieved shorter delivery terms of 65% for a robot company in Silicon Valley and achieved an accuracy level of ISO 5 for a medical equipment company.

Our machining accuracy fully complies with the international standard ISO 1328-1:2013 "Precision Requirements for Cylindrical Gears Part 1: Tolerances for Pitch, Profile, and Orientation", which specifies the tolerance specifications for core parameters of high-end gears.

This guide is the accumulation of our countless project experiences, and every suggestion has been verified through practical experience. You can completely trust it.

Want a personalized gear machining solution? You can now submit your gear module, material, and quantities to get a free gear machining process evaluation in 48 hours from JS Precision engineers to avoid processing risks.

What Core Technologies Define Modern Precision Gear Manufacturing?

Precision gear production is a system of interconnected engineering processes. The technology cycle of the core directly influences improvements in gear production accuracy and efficiency at all steps of gear manufacturing process.

From formation to finished product: The development of hobbing, shaping, and shaving technologies.

The old hobbing and shaping methods are inefficient and produce poor tooth surface finish and quality. The shaving technique, with continuous cutting, provides better tooth surface finish and accuracy in tooth profile.

| Processing Method | Advantages | Disadvantages | Appropriate Situations |

| Gear Hobbing | Relatively low in cost, high versatility | Medium accuracy of teeth' surface, average efficiency | Coarse Cutting. Low to Medium accuracy gears |

| Gear Shaping | Suitable for internal gear cutting | Not very efficient, particularly for large-scale manufacturing | Special profiles and small-scale manufacturing |

| Gear Shaving | High surface qualities in teeth, High efficiency | Higher machinery cost | Semi-finishing/finishing of medium to high precision gears |

The Kings of Finishing: Form Grinding and Worm Wheel Grinding

- Form Grinding: High accuracy, precise control of tooth profile error, appropriate for small series production and hard surface processing, relatively low efficiency.

- Worm Wheel Grinding: Continuous grinding, 3-5 times more efficient than form grinding, appropriate for large-scale precision manufacturing.

Measurement is Control: Gear Measurement Center and Process Monitoring

Quality control cannot rely solely on final testing, the entire process of gear machining requires precise measurement. We use a gear measurement center to generate full error color maps, providing data support for process optimization, and online SPC real-time monitoring of production to ensure batch consistency.

Want to check if the design of your equipment is suitable for the most optimal processing method? Please provide information on the parameters of the tooth profile you need, and the JS Precision company will give you a diagnosis and the most appropriate processing method that will increase the efficiency of the gear manufacturing.

Figure 1 The design and manufacture of gears can take many paths, such as continuous generating grinding which utilizes threaded wheels, which remain in constant contact with the developing gear tooth structure.

Why Is Heat Treatment The Most Critical Phase In The Gear Manufacturing Process?

Heat treatment is the "soul" of gear manufacturing process, determining the strength, hardness, and durability of the gear. It is necessary to use the right method to optimize the functionality of the gear.

The King of Surface Hardening Techniques: Carburizing and Quenching

Carburizing and quenching processes enable the gear to have a “hard outside, tough inside” structure with a hardness of HRC 58−62 and excellent core toughness suitable for high contact pressure conditions like robot gear processing, though with high deformation control requirements.

Low Deformation Methods: Nitriding & Induction Hardening

- Nitriding Method: Low deformation, enhanced wear-resistance, and corrosion-resistance, hardening depth 0.1-0.5mm. Mostly used for precision transmission gears.

- Induction Hardening: Fast heating, high efficiency, controllable deformation, adjustable hardening layer depth, and suitability for certain tooth profiles and large module gears.

Our Controlled Atmosphere Heat Treatment System

We strictly follow the process requirements of ASTM A890-18 “Standard Specification for Castings, Duplex Stainless Steel” in the heat treatment of stainless steel gear components. We employ controlled atmosphere multipurpose furnaces to accurately control carbon potential and temperature. We create customized process curves depending on material properties and traceability of processes performed.

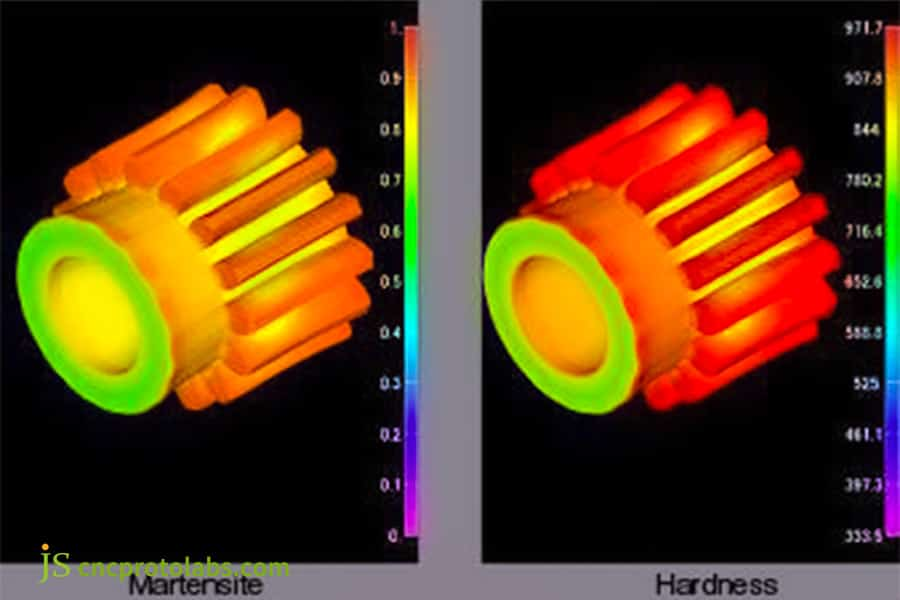

Figure 2 By changing the physical, chemical, and metallurgical properties of gears, heat treatment can optimize or even extend the service life of gears.

The Global Value Proposition: What Drives The Cost Advantage Of a Leading Gear Manufacturing Company In China?

As a leading gear manufacturing company in China, our cost advantage does not come from low price competition, but from the multiple empowerment of industrial chain, technology application, and management efficiency.

Multiplier Effect of Industrial Chain Clusters

We are in a professional manufacturing cluster, which is equipped with affiliated enterprises like steel, tool, and heat treatment enterprises. This ensures that we are able to easily access raw materials, ensure joint processing, and share costs of equipment maintenance and R&D, which cannot be done by isolated factories.

Democratization and Scaled Application of Technology

China's huge market stimulates the extensive application of high-end processing devices. Our imported CNC gear grinding machines and measurement centers enjoy the benefit of lower costs through bulk procurement, while the qualified technical maintenance team cuts the processing time, thus reducing the unit cost of the technologies.

Efficiency Revolution Triggered by Digitalization & Automation

Via the use of the ERP/MES, we are able to integrate orders and scheduling. The main processes include the use of automated loading and unloading systems, which reduce the use of human labor and improve the efficiency of production.

How To Vet a Custom Gear Manufacturer For True Precision And Reliability?

When selecting a custom gear manufacturer, don’t simply consider marketing speak, you have to assess them rigorously through three aspects: process, data, and collaboration enablements.

“How” instead of “Can”: Analyze Process Details

World-class manufacturers should also be able to describe their process flow. You may ask, "For a 42CrMo steel gear with a module of 2, how do you perform finishing, and what is your gear profile error control?"

Request Data, Not Promises: Review Historical Quality Records

Oral promises are unreliable. Demand inspection report data (including error curve graphs), material certificates, and heat treatment data for similar projects in order to assess the accuracy of the processing.

Assess the Depth of Engineering Collaboration: DFM is the Touchstone

Designers from professional manufacturers can offer design optimization advice even before sending quotes, gear profile modifications or material recommendations for instance. The amount of detailed feedback in DFM indicates the amount of technical enthusiasm they exhibit.

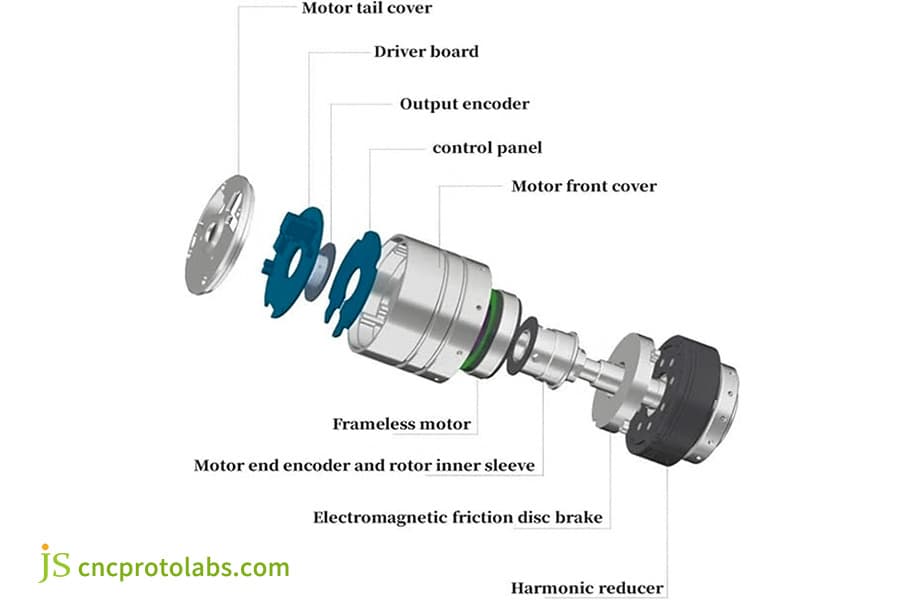

How Is Gear Manufacturing For Robotic Applications Engineered For Peak Performance?

Gear manufacturing for robotic is a high-end gear manufacturing technology that demands extremely high precision, light weights, and a long product lifetime. Every step requires precise control.

Ultra-Precision Gear Grinding and Profile Modification: Designed for Noiselessness and Smooth Running Characteristics

The noise and vibration level of robotic joints are of ultra-high standards. Our company adopts ultra-precision gear grinding technology, which adjusts the tooth profile and direction, compensating for deformation due to loads, and thus provides noise at a level below 45dB, completely satisfying robotic requirements.

Practical Implementation of Materials Science: Starting with High-Quality Alloy Steel to Sintered Metal

- Harmonic reducers flexible gears are made from specialized precipitation-hardening stainless steel that is strong and resilient.

- The gears used in a robotic arm are made of powder metallurgy materials to provide strength and be lightweight, which are 30% lighter than other gears made of metal.

Comprehensive Failure Analysis and Life Testing Support

We assist clients in conducting tooth contact analysis (TCA), predicting meshing forces, providing limited life testing services, and providing data support for robot system integration to ensure stable gear operation.

Need custom gears for your robots? Then supply your robot model, your desired loading, as well as the gear expected life, and JS Precision will become your one-stop-shop from material choice through process improvement so that gear manufacturing for robotic will become more precise.

Figure 3 High-Performance Worm and Spur Gear Set for Robotic Hand Actuation

Conquering Corrosion And Hardness: What Are The Unique Challenges In Machining Stainless Gears?

The processing of stainless gears is a difficult point in gear manufacturing, and its material properties bring many challenges to the processing, which need to be addressed in a targeted manner.

Work Hardening: Every cut makes the task harder.

Austenitic stainless steels like 304 are known to undergo "work hardening" in the cutting process. This results in a hardened layer that can be up to 30%-50% harder than the rest of the material. This will cause high tool wear. We use a "low-stress" cutting approach based on our control of speed and feed rates.

Tool Sticking and Chip Removal Issues Due to High Toughness

Stainless steel is very hard and tough and results in chipping that cannot break and tends to curl around the tool. We use professional chipping tools with PCD and 150 bar high pressure coolants to remove chipping and cool the tool.

Corrosion Resistance Retention: A Balance between Heat Treatment and Post-Treatment

Tempering martensitic stainless steel gear materials like 440C is required after quenching, or it may affect their corrosion resistance. To overcome this challenge, a method has been proposed to determine the tempering process that not only increases their hardness (HRC 55-58) but also their corrosion resistance.

Do you require machining of your stainless steel gears? Just give us the details regarding the type of stainless steel, the tolerance level, and the working conditions, and JS Precision will prepare a customized machining plan for you to overcome the challenges involved with stainless steel and to ensure your stainless gears function with high precision.

Where Can I Buy Gears For Prototypes And Small Batches With Speed And Certainty?

When it comes to prototypes and short-run gear requirements, “where can I buy gears” is much less about “gear manufacturing near me” and more about selecting a supplier that is ready to respond and commit to quality.

"Near Me" Gets a New Definition: Proximity and Responsiveness Online

Modern forms of communication and logistics have overcome geographical limitations. We have engineering support online 24/7. Our online platform connects easily with your needs. From the moment you inquire to the moment you are quoted, it takes just 4 hours. This is significantly shorter than the industry standard.

One-Stop Online Platform: An Experience Spanning Inquiry to Delivery

Our online platform enables the digitization of the entire process, right from the uploading of the drawings and the filling of the requirements to obtain an initial quote to the viewing of the progress of the work and downloading of the reports.

Flexible Manufacturing Unit for Prototypes

We have a special line for prototypes and small-series products. With the help of standardized modules and rapid changeover systems, we have cut the lead time for small-series orders (less than 100 units) to 2-4 weeks, which is 50% shorter than the industry average.

From 8 Weeks To 19 Days: How a US Robotics Startup Scaled With Chinese Gear Manufacturing

Customer Bottleneck:

A robotics start-up company in Silicon Valley was facing the following problem:

The base harmonic reducer gear sets for the new collaborative robot joints had a production time of 8 weeks and a price of $200 per set from a custom gear manufacturer in US who customized the gears. They were unable to meet the conditions for heat treatment deformation and most suppliers were not ready to accommodate an order for just 20 prototype gear sets.

JS Precision Solution:

JS Precision accepted this challenge.

- We accomplished this task of reviewing the drawings within 48 hours through our online platform, and suggestions for DFM of gear profile parameters were made to ease gear grinding.

- Simultaneously, we launched our flexible small-batch production line and made progress in the procurement of materials and the preparation of tools

- In the case of the special precipitation-hardenable stainless steel material used in our project, "vacuum heat treatment + deep Cryogenic treatment" was applied in combination to restrict deformation to 0.005mm.

- Afterward, using CNC gear shaping and grinding machines with online measurement ensures gear accuracy in accordance with requirements.

Final Successful Outcome:

Orders were confirmed, and the delivery in California took only 19 days. The equipment accuracy level met the standards of ISO 5, and the cost per unit was $80, which is 60% lower than what the US company estimated. The customer was able to conduct prototype testing, and the product reached the marketplace 4 months ahead of schedule.

Do you also require small-batch-produced gears, high-precision gears? Please call our service hotline and describe your technical difficulties and requirements for delivery. JS Precision will work up a customized solution for you to echo this success story.

Figure 4 Robot joint harmonic reducer gear set

FAQs

Q1: What is the smallest module gear you can produce?

Precision gear processing is possible if their module is 0.5 or higher. For smaller modules, their processing has to be assessed according to design requirements. The company also has micro gear processing facilities to cater to special demands.

Q2: How to choose between plastic gears and metal gears?

Plastic gears are appropriate for lightly loaded and low-speed transmission systems and are distinguished by such characteristics as noiselessness, lightness, corrosion resistance, and low costs, metal gears are strong and heat-resistant and are appropriate for highly loaded transmission work requiring high accuracy.

Q3: How to provide gear drawings or technical requirements?

We propose supplying detailed 2D drawings in PDF/DWG, which have to outline all data regarding the complete tooth profile, tolerances, material, and heat treatment. 3D files in STEP format may serve as additional references.

Q4: What is the normal delivery time and cost from China?

Air freight has a delivery period of 3-7 days, while sea freight has a delivery period of 20-35 days. The cost will depend on the weight and size of the products. Door-to-door (DDP) service quotes are given, and there will be all transportation costs and taxes involved.

Q5: Can there be gear matching and assembly assistance?

Yes, we can. All you have to provide us with is the gear center distance and the assembly requirements, and we can accurately mate the pinion and the gear. Then, either the press fit or simple assembly can reliably mesh the components.

Q6: Is there a minimum order quantity (MOQ) for small batch orders?

Currently, we do not have specific requirements on our minimum order quantity, including single-item prototyping and small batch production. We strongly feel that today’s small batch prototyping has good potential to be developed for future mass production collaboration.

Q7: What is the usual lead time on a customer gear order?

Normally, for customized gears produced using standard materials, the processing lead time will be 3 to 5 weeks for orders involving less than 100 pieces. However, this will be negotiated based on the complexity involved in the gears. We also provide expedited services to accommodate urgent customer needs.

Q8: In my design, confidentiality is a must, how do you ensure that?

We will enter into a binding non-disclosure agreement (NDA) with our clients. Project-related documents are maintained within an encrypted environment, and we have provided intensive training to all employees necessary to prevent leaking of the design information.

Summary

The key to gear manufacturing is accuracy and reliability. If you have difficulty finding a reliable partner, you may go on a detour when it comes to custom gear processing. JS Precision is a reliable gear processing service provider that focuses on efficient and accurate gear processing.

It's high time to remodel your outlook regarding a "gear manufacturer supplier."

Begin your precision gear project today! Simply go to the JS Precision website and upload your gear designs or technical specifications. You will receive a thorough "Gear Manufacturability Report"and clear quote within 24 hours. Together, we can breathe a strong and robust "heart" into your machine.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com