How to make gears? As the core component of mechanical transmission, the manufacturing quality of gears directly influences the stability, efficiency, and service life of equipment.

Is it cost-effective mass production by powder metallurgy, or precision hobbing and grinding to meet the demanding requirement of the robotic joint? Professional and practical guidance about gear manufacturing could always help you avoid some pitfalls.

The following article will be a guide on manufacturing gears. It will spell out, point by point, the path of creation from concept sketch to finished product and will help explain why choosing a partner like JS Precision takes a gear project from "feasible" to "excellent".

Core Answers Summary

| Core Question | Technical Path and Choices | Value Provided by JS Precision |

| How are gears manufactured, and which method is right for me? | From cost-effective powder metallurgy to high-precision cutting, the method depends on batch size, material, and precision. | We provide comprehensive consulting from design to production, matching you with the most cost-effective gear manufacturing process. |

| How to Achieve Customized and High-precision Manufacturing? | The custom gear manufacturing process is rigorous, precision gear cutting services are the core, and post-processing ensures performance. | One-stop precision gear manufacturing services integrate precision cutting, heat treatment, precision grinding, and inspection in its structure to ensure excellent gears. |

| How to choose a supplier for specific fields (like robotics)? | Gear manufacturing of robotics requires an extremely low backlash and must be of high wear resistance and lightweight, which challenges the comprehensive capability of a supplier. | As a professional spur gear supplier and the manufacturer of complex gears, we have mature experience with proprietary technology in serving the robotics industry. |

Key Takeaways

- Design First: Accurately designed gears are the first step in successful gears. Clearly defining application scenarios, load, and precision requirements is the first step.

- Process Dictates Cost and Performance: Understanding a few manufacturing methods for gears, such as cutting, forming, and powder metallurgy, along with their respective cost structures, is key to informed decision-making.

- High precision means systematic engineering: The right precision gear manufacturing services do much more than cut and involve entire processes: heat treatment, finishing, and strict inspection.

- Special Materials and Applications Call for Specialists: Whether it be the fictional "how to make netherite gear" or real-world robotic gear, special needs call for suppliers that have deeply knowledgeable material and process experience.

JS Precision Experience | Practical Tips On Gear Manufacturing

For 15 years, JS Precision has been deeply involved in the field of gear machining. Our quality management system strictly follows the requirements of the International Organization for Standardization (ISO) ISO 9001:2015 quality management system, which lays a solid foundation for us to provide stable and reliable gear manufacturing services.

We provide all kinds of gear manufacturing solutions for more than 3000 customers from 12 industries such as aerospace, robotics, automotive parts, medical equipment, and having over 5000 customized gear projects.

Our experience ranges from miniature instrument gears with a module of 0.1 to large transmission gears with a module of 10. We are able to process more than 20 materials and have achieved mass production breakthroughs with high accuracy from DIN 7 to DIN 4, noise reduction of 15dB. Maintaining over 99.5% yield rate for standard gears at 100,000 pieces batch.

This tutorial on how to make gears summarizes our practical experience of more than a thousand projects, and every suggestion was checked in production.

Want to use our experience in gear machining to avoid pitfalls? Just tell us about your project requirements, and JS Precision will present you with a free, industry-specific process evaluation report that focuses on the core points of "how to make gears" in order to help you mitigate processing risks in advance.

How To Make Gears? Choosing The Most Cost-Effective Path

There's more than one way to manufacture gears, and the choice depends on budget, production volume, materials, and performance requirements. This is a core decision point in "how to make gears."

Forming Method: The economical choice for large-scale production

The forming method forms the tooth profile directly by molds, including powder metallurgy, precision casting, and die forging processes. It has extremely low cost and high efficiency in mass production and is suitable for standard gears with an annual output of more than 100,000 pieces and DIN 8 accuracy or lower.

The disadvantage is high mold development cost and uneconomical in small batches, and lower tooth profile accuracy.

Cutting Method: King of precision and flexibility

The cutting method is the core of achieving high precision and customization in "how to make gears," including hobbing, shaping, CNC milling, shaving, and grinding processes.

Gear hobbing/shaping is suitable for mass production of gears with DIN 6-8 accuracy grades, while CNC milling is suitable for small-batch customization.

Gear shaving/grinding can improve accuracy to DIN 3-5 grades and is an essential process for special gears such as those used in "how to make netherite gear," requiring no mold costs and capable of handling complex tooth profiles.

Additive Manufacturing: A New Frontier for Complex Structures and Rapid Prototyping

3D printing is an emerging approach to "how to make gears," which suits prototype verification and small batches of complex structure parts such as gears with built-in cooling channels. It can rapidly convert drawings and shorten the R&D cycle.

However, the strength and wear resistance of the materials are worse than in traditional processes. Efficiency is low, and it is not suitable for mass production. Further post-processing will be required to achieve the desired accuracy.

| Manufacturing Method | Single Mold/Equipment Cost (USD) | Unit Cost (10,000 units batch, USD) | Applicable Accuracy Level | Applicable Production Volume | Core Advantages |

| Powder Metallurgy | 5000-15000 | 1.2-3.5 | DIN 8-10 | 100,000+ units | Low cost, high efficiency |

| CNC Gear Hobbing + Grinding | 1000-3000 | 8-25 | DIN 3-6 | 100-10,000 units | High precision, flexible |

| 3D Printing | 0-500 | 50-200 | DIN 10-12 | 1-100 units | Rapid prototyping, complex shapes |

Cost Difference Table for Gears of Different Accuracy Levels

| Accuracy Level (DIN) | Processing Technology Combination | Unit Cost (1000 units batch, USD) | Cost Premium Compared to Basic Level | Applicable Scenarios |

| Level 10 (Basic) | Powder Metallurgy / Ordinary Milling | 1.5-4.0 | 0% | Ordinary home appliances, simple transmissions |

| Level 7 (Medium) | Gear Hobbing + Heat Treatment | 5.0-12.0 | 233%-200% | General machinery, ordinary motors |

| Level 5 (High Precision) | Gear Hobbing + Carburizing and Quenching + Honing | 18.0-35.0 | 1100%-775% | Automotive transmissions, industrial robots |

| Level 4 (Ultra-precision) | Gear Hobbing + Carburizing and Quenching + Grinding | 30.0-60.0 | 1900%-1400% | Collaborative robots, aerospace equipment |

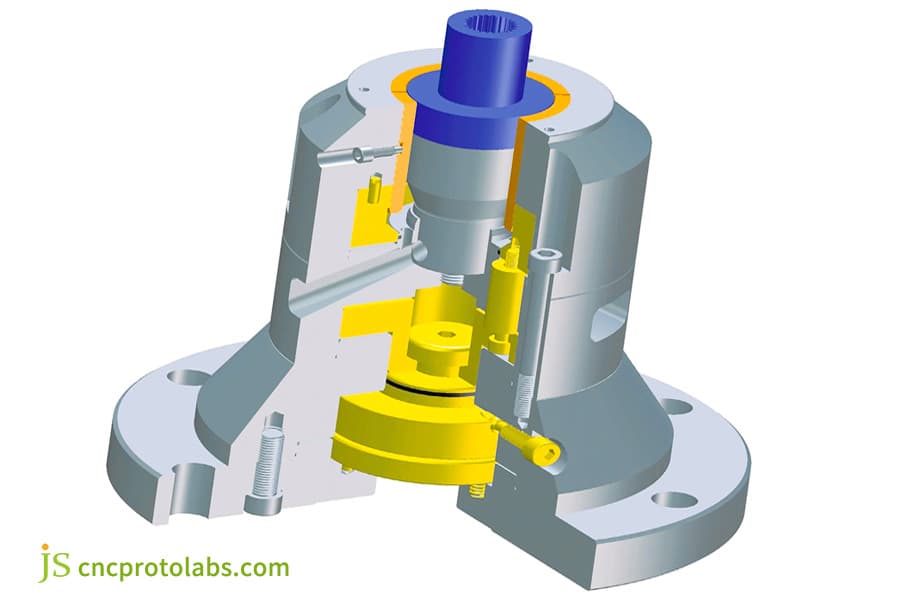

Figure 1:Gear forming is a gear machining process mainly used in situations where gear size correction is not possible.

From Drawing To Physical Product: Unveiling The Full Workflow Of Custom Gear Manufacturing

From drawings to finished products, customized gear manufacturing requires strict control over every step, especially in the gear profile machining stage. The control of key parameters must strictly follow the relevant provisions of ISO 1328-1:2013 cylindrical gear accuracy standard. This is the cornerstone of ensuring smooth gear meshing, low noise, and long service life.

In our precision gear cutting services, engineers review drawings based on this standard and conduct full-size inspections using gear measuring centers after machining to ensure that the output results fully meet design expectations.

Phase 1: Collaborative Design and Engineering Review

When designing gears, we work in cooperation with the manufacturers. JS Precision engineers review drawings, check the rationality of gear tooth parameters, and the compatibility of materials and processes, they conduct manufacturability analysis and give optimization suggestions to avoid cost increases due to improper design.

Phase 2: Precision Machining and Core Forming

The core process deals with gear tooth machining by precision gear cutting services:

- Material Preparation: Buying raw materials and pre-processing to enhance the performance of machining.

- Rough Machining: To machine the datum surfaces, inner holes, and end faces to ensure positioning accuracy.

- Gear Tooth Cutting: Choose hobbing, shaping, or CNC milling according to precision required in the work.

Phase 3: Post-processing and Perfect Acceptance

JS Precision provides a complete set of precision gear manufacturing services, including heat treatment, precision machining, and cleaning. Detect key parameters through the gear measurement center and deliver a complete quality report.

Custom Gear Manufacturing Lot Price Gradient Table

| Batch (PCS) | Module 2 Steel Gear Price (USD) | Mold/Programming Amortization Cost (USD) | Total Cost(USD) | Delivery Time |

| 1 (Prototype) | 120.00 | 800 | 920.00 | 7-10 days |

| 50 | 35.00 | 800 | 2550.00 | 10-15 days |

| 500 | 18.00 | 800 | 9800.00 | 15-20 days |

| 1000 | 12.00 | 800 | 12800.00 | 20-25 days |

Are you designing gears or embarking on a custom gear manufacturing project? Schedule a free design review with a JS Precision engineer to mitigate process risks and make precision gear cutting services more efficient and cost-effective.

Material Limit Challenge: Cost And Process Discussion Of How To Make Netherite Gear

Level gears made of "netherite alloy" embody the ultimate in strength, wear resistance, and light weight, which is the essential meaning of how to make netherite gear. Most of them have special material ingredients and advanced processes, accompanied by cost premiums.

Deconstructing "Netherite": A Metaphor from Gaming to Engineering

"How to make netheritage gear" is essentially the application of special materials in extreme working conditions, which in real life involves high-strength alloy steel, titanium alloys, Inconel alloys, and DLC coated materials suitable for aerospace and high-end robotics, among other fields.

The Cost and Process Premium of Special Materials

Reasons for High Costs:

- Procurement cost: Special materials are 3~10 times more expensive than ordinary carbon steel, the price of titanium alloy can reach $80-120/kg.

- Processing difficulty: Highly hard, fast tool wear, thus specialized tools are needed, which generally has a low processing efficiency.

- Sophisticated heat treatment: carburization, quenching, and nitriding, which all raise the cost of production.

Value Trade-off: When to Invest in "Top-Tier Equipment"

In applications like gear manufacturing for robotics, jet aircraft engines, which need to support loads that are exceptional, ordinary materials are inadequate. "Netherite"-grade gears reduce long-term maintenance costs, hence justifying the investment.

Finding Experts: In What Way Can One Find Really Reliable Precision Gear Cutting Services?

The very foundation of selecting a supplier is to assess their hardware capabilities, technical experiences, and quality system. These are the fundamental guarantees for precision gear cutting services.

Equipment List and Technical Capability Audit

Equipment is the hardware foundation. A reliable supplier needs CNC gear hobbing machines, gear shaping machines, gear grinding machines, and gear measuring centers. Import equipment, JS Precision owns the best DIN 4 precision to complete all procedures in its production chain independently without any risks involved with outsourcing.

Process Knowledge and Case Experience

Evaluate the experience of the engineering team in tooth profile design, heat treatment deformation control, and view successful cases. The average working experience of JS Precision engineers is over 8 years, they can solve various technical problems quickly.

Quality System and Certification

Confirm that ISO 9001 and IATF 16949 are certified. Specify whether full test reports can be provided for every batch of gears. JS Precision has passed both certifications and set up a full-process traceability system. It can provide every batch of gears with detailed test reports.

Would you like to get the equipment list and quality system documents? Contact customer service to get a free quality inspection manual and case study by mentioning "precision gear cutting services inquiry" for quickly identifying reliable suppliers.

What Are The Major Post-Processing Techniques Involved In Precision Gear Manufacturing Services?

Basically, it is a process to which gears undergo to enhance their performance. The following key processes are included in precision gear manufacturing:

Heat Treatment: The "tempering" that gives gears their soul

The core processes include carburizing and quenching (to improve surface hardness and withstand high loads), nitriding treatment (wear and corrosion resistance, minimal deformation), and quenching and tempering treatment (to balance strength and toughness), significantly improving the service life of gears.

Precision Machining: The "grinding" for quietness and precision

The gear grinding improves the accuracy to DIN 3-5 and the surface roughness will be reduced. In addition, the gear honing removes burrs, improves meshing performance, and reduces noise by 3-5dB. This is a necessary process for high-precision gears.

Surface Treatment and Lubrication Preparation

Phosphating treatment allows the prevention of rust, zinc/nickel-chromium plating offers the improvement in corrosion resistance, while Teflon coating provides self-lubrication. Applications decide the choice of process.

Figure 2:Heat treatment will form a hard hardening layer on the surface of the gear, enhancing its wear resistance while maintaining the toughness of its internal core material.

Spur Gear Supplying: What Are The Possibilities With a Good Spur Gear Supplier?

A good spur gear supplier needs to have three major capabilities: stock availability, comprehensive coverage, and customized services, catering to different scenarios.

Extensive Stock and Fast Delivery Capability

Module, tooth count, material, and bore size variations of standard spur gears are kept in stock by JS Precision. We can ship in 24-72 hours for urgent replacements and prototype verification to avoid equipment downtime.

Full Material and Specification Coverage

Materials range from plastics to metals, and specifications from tiny instrument gears to large transmission gears, with modules from 0.1-10mm and tooth counts from 10-200 teeth, suitable for various application scenarios.

Seamless Transition from Standard Parts to Custom Parts

We support custom gear manufacturing, completing design optimization and production quickly according to drawings. Whether it is modifying standard parameters or designing from scratch, we are capable of quicker delivery.

How to get a list of standard spur gear stock: Contact customer service and mention "spur gear supplier inquiry" to receive a detailed list including specifications, materials, prices, and inventory. Besides, enjoy priority scheduling for customized services.

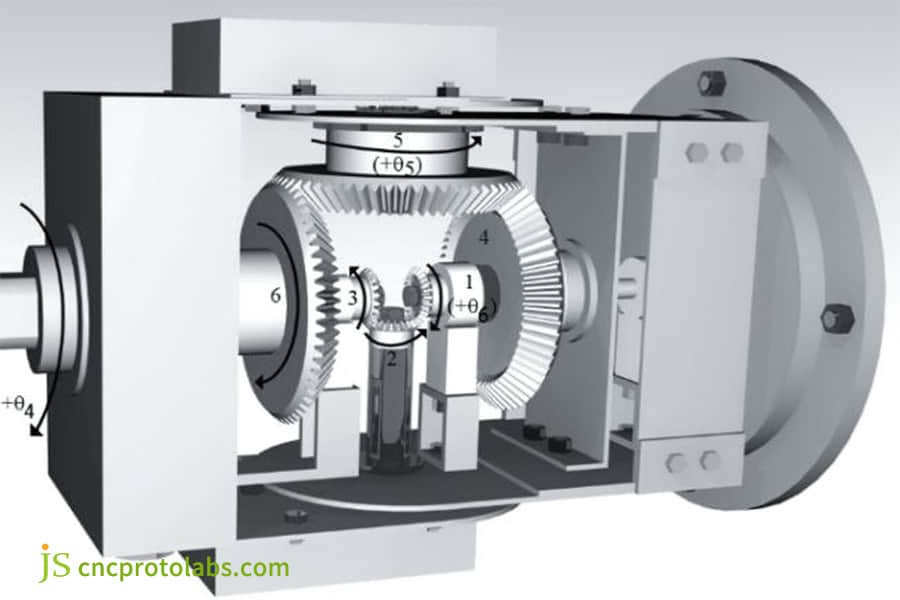

Giving Life To Robotic Arms: What Makes Gear Manufacturing For Robotics Unique?

Gear manufacturing in robotics, therefore, needs an extreme balance considering precision, lightweight design, and noise control to meet the peculiar requirements of robots.

Extreme Precision, Ultra-Low Backlash Requirements

Robot joints need DIN 4-5 grade precision and backlash within 0.1-0.3mm. Precision gear cutting services combined with precision gear grinding are needed. JS Precision can keep achieving this standard.

Lightweight, high power density, long service life

Using light and high-strength materials, hollow structure design, and coatings for wear resistance, the weight is reduced on the premise of ensuring stability under frequently changing working conditions of start, stop, and variable loads.

Noise Control and Smooth Transmission

By modifying the tooth profile, improving the precision grade, and using special lubricant, transmission noise is controlled below 55dB, which fully meets the demand of human-robot collaboration.

Figure 3:Gears are the fundamental components of robot joints, capable of achieving smooth and precise motion.

2-Level Precision Improvement, 15db Noise Reduction: JS Precision Helps Collaborative Robot Joint Gears Achieve Mass Production

Background

A rising European collaborative robot company was going to launch its second-generation product. The core requirement was to make the joints lighter, quieter, and more precise.

Previously, the prototype gears used by the company reached 70dB in noise testing and showed tooth surface wear after 1000 hours of life testing, with precision dropping to DIN 7 grade, failing to meet mass production requirements. They approached us, hoping we could solve these problems.

Challenges

A helical gear pair with module 2 and 30 teeth was to be fabricated within the compact joint space. Some of the specific requirements placed on this were:

- Precision to DIN 5 grade, noise in transmission below 60dB, weight not to exceed 200g, and a mass production yield rate over 99%.

- Furthermore, the material should balance strength and light weight, and deformation after heat treatment should be controlled within 0.01mm.

JS Precision Solution

1. Design Optimization and Process Planning:

Our engineers are involved in fine-tuning the design gears, a crowned tooth profile design was suggested to reduce meshing impact. In order to reduce the weight while improving the wear resistance, high-strength aluminum alloy with DLC coating was adopted.

A complete precision gear manufacturing service was developed, including "CNC gear hobbing -> carburizing and quenching -> precision gear grinding -> coating treatment".

2. Precision Machining & Process Control:

Imported five-axis linkage gear grinding machines were utilized for precision finishing of gear profiles, and the processing parameters of each process were controlled in a very rigid way.

During the heat treatment process, special fixture was applied to minimize deformation, it introduced SPC statistical process control into production, detecting key dimensions in real time to guarantee the consistency for every batch of gears.

3. Full test & data analysis:

The key parameters were inspected by a gear measuring center, 100% tooth profile, tooth direction, tooth pitch, and radial runout, detailed inspection reports were given to customers, CPK analysis was also done to prove the process capability meets requirements of mass production.

Results

The final delivered gear pair reached a stable accuracy of DIN 4, higher than the customer requirement of DIN 5. Measured transmission noise was reduced to 55dB, weight control was at 185g, and mass production yield rate was over 99.5%.

It is under such condition that the customer successfully launched a new generation of robots to market, with its quiet performance and operational stability widely praised in the industry, market share rising by 15% within six months.

Want to learn more about robot gears or gear manufacturing cases in other industries? Contact JS Precision now and mention "Case Study" for a free complete case report, learning how to realize product upgrade by means of process optimization.

Figure 4:Robot joint gear

The First Step Is Simple: How To Obtain Accurate Online Gear Manufacturing Quotes?

An accurate quote is very important to initiate the project, and a detailed online gear manufacturing quote can effectively control the budget.

Key Essential Core Information Checklist: This will ensure that accurate quotes are provided, including complete gear drawings, material specification, heat treatment requirements, accuracy level, and target quantity.

Additional information that is optional but can optimize the quotation: Application scenarios, load conditions, and expected lifespan information is useful and will help the engineers provide more cost-effective process and material suggestions.

JS Precision's Fast Quotation Process: After submitting your inquiry, our engineers will review your requirements within 24 hours and provide a formal quotation containing process analysis, material details, pricing, etc., within 3-5 business days. The quotation can be adjusted and optimized according to your needs.

FAQs

Q1: How to choose between plastic and metal gears?

- Plastic gears are lightweight, corrosion-resistant, self-lubricating, and low-cost, suitable for light loads, low speeds, or applications requiring quiet operation.

- Metal gears possess excellent strength, abrasion resistance, and resistance to high temperatures, and are used in high-load and high-precision transmissions.

Q2: What do gear accuracy grades represent?

The accuracy grades reflect the quantization of the range of various gear errors allowed, such as tooth profile, pitch, runout, etc. The smaller the number of grades, the higher the accuracy, the higher the difficulty and cost of manufacturing, the smoother the transmission, and the lower the noise, which is suitable for high-end precision equipment.

Q3: What is the MOQ of the small batch customized gears?

JS Precision supports very low minimum order quantities down to single-piece prototype production. We leverage the flexibility of technologies like CNC machining, specializing in small-batch, multi-variety custom gear manufacturing to meet personalized customer needs.

Q4: How long does it take from receiving drawings to receiving samples?

The delivery time of prototype samples is usually within 5-15 business days for gears made from conventional materials with medium complexity. In some cases, with special materials or complicated processes, the delivery time will be longer until the design complexity and production schedule are met accordingly.

Q5: What gear inspection equipment do you use?

With advanced gear measuring centers, hardness testers, roughness testers, and many other inspection facilities, we do a comprehensive inspection on all key parameters including tooth profile, tooth direction, pitch, and runout for all products, while visual inspection reports are also generated.

Q6: How to prevent gear corrosion?

According to the use environment, choose a method to prevent corrosion. Some common methods used in industries are the use of stainless steel material for gears, galvanizing or nickel-chromium plating on their surface, blackening treatment, phosphoric acid treatment, and smearing with antirust oil or painting special paint on it.

Q7: What particular information am I supposed to provide in the drawings?

Please provide a full gear tooth parameter list including module/diametral pitch, pressure angle, helix angle, etc., then include all of the dimensions and tolerances, accuracy grade requirements, material specifications, heat treatment, and surface treatment requirements. This will be sure the gears manufactured will meet your requirements.

Q8: How to start a gear project collaboration?

Please access JS Precision and provide drawings of your gears, together with your requirements via the "Get a Quote" channel. Our engineers will proactively get in contact with you to discuss process solutions, price details, and establish efficient professional cooperation.

Summary

How to make gears? The answer is never unique, it all depends on your needs, budget, and application scenario. Be it a custom prototype or high-precision mass production of parts, a partner who can integrate design, precision machining, and post-processing capabilities becomes vital.

JS Precision is just such a partner. From online quick quotes to performance verification, we provide end-to-end solutions in precision gear manufacturing and are unusually well-placed to meet the demands of challenging fields like robotics.

Upload drawings of your gear or requirements today, and our team of engineers will in 24 hours offer professional analysis and a clearly transparent solution that will have you reliably implementing your ingenious design.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com