There is a titanium alloy drive shaft in a heart pacemaker, which has only a diameter of 0.8mm and needs a positioning accuracy of 5 micrometers. On the other hand, there is the cycloidal wheel embedded in the RV reducer of an industrial robot, whose contour error requirement has to be controlled within 3 micrometers.

Modern precision CNC turning technology is progressively knocking down one barrier after another in manufacturing that was previously thought impossible to achieve.

This article will delve into how this technology enables complex shaft components to move from design drawings to perfect physical objects, helping you find reliable machining paths. Through this mature precision CNC turning technology system, various difficult shaft component machining needs can be met.

Core Answer Summary

| Comparison Dimensions | Traditional Lathe Machining | Modern Precision CNC Turning |

| Accuracy Capability | ± 0.1mm tolerance range. | ±0.005mm or even higher. |

| Complexity | Simple stepped shafts. | Complex curved surfaces, irregular contours, and micro-features. |

| Consistency Guarantee | Relies on operator skill. | Fully digital control, zero batch-to-batch variation. |

| Material Adaptability | Ordinary steel, aluminum. | Titanium alloys, high-temperature alloys, and composite materials. |

| Core Value | Removing material. | Creating precision value. |

Machining Shafts Of High Difficulty: The Strength Of JS Precision Turning

Many difficult problems in precision shaft part machining depend on experience for their solution, and JS Precision has been particularly experienced in this. With over 15 years of experience in the domain of precision CNC turning, JS Precision serves customers from all industries or application areas, including medical, aerospace, and automotive.

For instance, JS Precision has also machined Inconel shafts for an aerospace client with 15 mm diameter and 120 mm length, reaching 1.2μm roundness. They have also machined 316 stainless steel sensor shafts for a Client manufacturing automotive electronics, with a diameter of 5 mm and a length of 80 mm, reaching a surface roughness of Ra 0.4μm.

The above are only a few of the many successful projects undertaken by JS Precision. They can handle shafts from 0.5mm to 300mm diameter, encompassing various difficult-to-machine materials such as titanium alloys, stainless steel, and aluminum alloys.

This guide is a summary of the years of practical experience from JS Precision. Every suggestion and method has been verified in actual production, so its professionalism and practicality can be absolutely trusted.

JS Precision has vast experience in precision CNC turning and therefore can handle shafts made of a wide variety of tough-to-machine materials. If you have any needs, just send the part drawings, and we will quickly offer you a detailed quote and initiate a time-efficient machining process.

The Core Advantages Of Precision CNC Turning Parts

CNC turning is preferred in the manufacture of complex shaft parts due to the following core advantages:

- Extreme precision and repeatability: Controlled by the CNC system, working in accordance with the preset digital blueprint eliminates human errors. Be it the first or 100th, each CNC turning parts precisely fitting the blueprint for batch precision requirements.

- Amazing Production Efficiency: Preset programs make it possible for CNC lathes to handle 24/7 constant production, with very limited manpower needed on the site. Suitable for big-volume orders, the bigger the production volume, the bigger the unit cost advantage.

- Unmatched Sophistication: Drilling, milling, and tapping functions are integrated with today's milling and turning centers to offer "one-time setup, complete machining," totally releasing parts from design constraints.

- Superior Surface Quality: The optimized cutting parameters and finishing toolpaths enable the parts to reach near-polished surfaces directly, hence reducing further grinding processes.

Following is the comparison of CNC Turning with conventional turning to demonstrate visually the advantages:

| Comparison Items | Traditional Turning | CNC Turning |

| Precision Control | Manual operation, error 0.05-0.1mm | CNC control, error 0.001-0.005mm |

| Production Efficiency | Frequent adjustments are required, resulting in low batch efficiency. | 24/7 uninterrupted production, 3-5 times more efficient than traditional methods. |

| Surface Quality | Roughness Ra 1.6-3.2μm | Roughness can reach Ra 0.4μm, some reaching Ra 0.1μm. |

| Complex Feature Machining | Difficult to integrate multiple features Multiple clampings are required. | Multiple complex features are machined in a single clamping operation. |

This efficient processing mode enables each batch of CNC turning parts to maintain stable quality, fully adapting to the stringent requirements of high-end manufacturing.

If you need high-quality CNC turning parts, the Precision CNC Turning service offered by JS Precision is your best choice. We can fully utilize our technical advantages for you and provide efficient production. After placing your order, we will promptly feed back the production progress for you, so that you can wait with peace of mind.

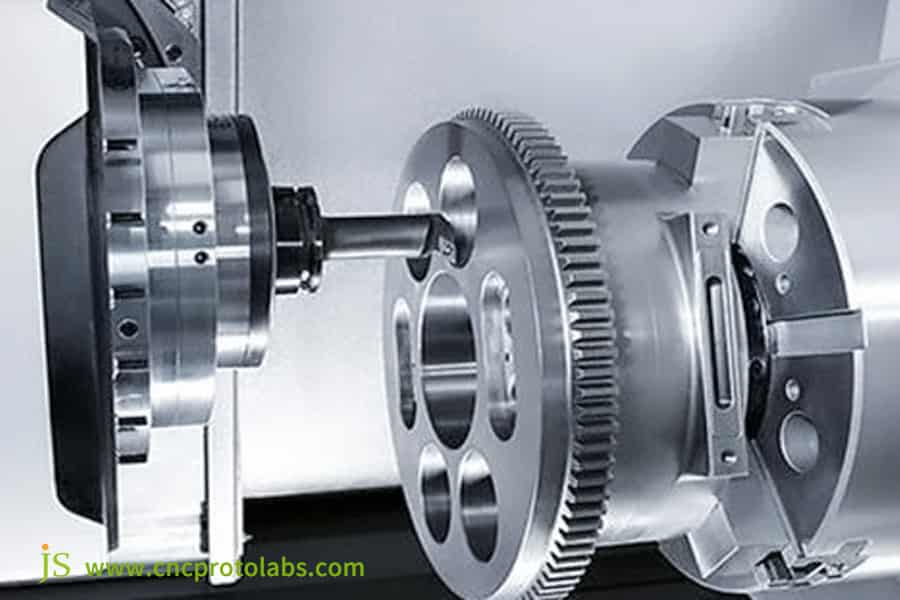

Figure 1: The CNC turning process involves securing the raw material onto the lathe, where it is rotated while a single-point cutting tool moves parallel to the axis of rotation, shaping the material accordingly.

What Makes Tooling Critical In CNC Precision Turning

In CNC precision turning, the tool determines machining accuracy, efficiency, and quality. The essential factors to consider are:

Material-Specific Design: Tools designed according to work material properties. For example, titanium alloys require tools that bear high hardness and high-temperature resistance, whereas for aluminum alloys, tools should bear performance in chip removal, hence, their micro-geometric parameters are different.

Extreme Rigidity System: Based on high-precision clamping systems like a heat shrink tool holder, after cooling, the heated tool holder will firmly clamp and repress the micro-vibrations during high speeds, thus improving the accuracy of machining.

Micro-Chip Breaking Control: Precision in the groove design ensures that chip breaking occurs within set parameters during micron-level cutting, without entanglement of either tool or work, for smooth machining.

Intelligent Monitoring & Management: In-process and real-time tool wear monitoring, lifetime prediction, and timely replacement before quality deterioration occur to secure machining stability and uniform part quality.

JS Precision places much emphasis on tool selection and management in CNC precision turning, using optimum tools paired with parts made from various different materials. By choosing our service, you will enjoy a smooth and efficient machining experience. We can quickly develop a tooling solution once receiving your requirements.

Figure 2: High-quality cutting tools are critical to achieving precision in CNC turning.

How To Design Advanced Workholding For Complex CNC Turned Parts

Machining of complex CNC turned parts requires advanced tooling in order to maintain accuracy. Key design methods include the following:

- Unified Datum Principle: The method of establishing a stable datum with the six-point positioning rule can reduce datum conversion errors, ensuring the positional accuracy of the machining features.

- Thin-Wall Deformation Control: Hydraulically expanded mandrel uniformly applies radial pressure, deformation < 5μm. Hydraulic expansion conforms to the inner wall of the part, preventing localized deformation.

- Vibration Anti-Vibration Solution for Slender Shafts: Real-time changes in vibration conditions allow an immediate adjustment in support stiffness of a magnetorheological intelligent tool holder. The variation in the viscosity of magnetorheological fluid controls the vibration and thus manages the machining accuracy.

- Customized Irregularly Shaped Parts: Topology-optimized design of dedicated chucks perfectly fits the surface of irregularly shaped parts, ensuring reliable clamping and preventing machining displacement.

The following table reflects various tooling solutions with their applicable scenarios and effects:

| Tooling Solution | Applicable Part Type | Deformation Control Effect | Advantages |

| Hydraulic expansion mandrel | Thin-walled cylindrical parts | Deformation < 5μm | Uniform pressure, stable clamping. |

| Magnetorheological Intelligent Tool Holder | Slender shaft parts: L/D>10 | Effective in suppressing vibration, increases accuracy by 20%. | Real-time adjustability adapts to different machining stages. |

| Topology Optimized Dedicated Chuck | Irregularly shaped parts | Clamping error < 3μm | Fits perfectly to the part shape, high reliability. |

These designs can effectively solve the clamping problem in CNC turned parts machining and provide stable support for high-precision machining of complex parts.

Advanced tooling for complex CNC turned parts can be designed by JS Precision to ensure machining accuracy. If you have any special requirements for part machining, like irregular shapes or thin walls, please don't hesitate to contact us, we can customize a dedicated tooling solution for you and enable fast production once the order is placed.

Conquering The Challenge: Precision CNC Turning Titanium

Challenges and Solutions for Precision CNC Turning Titanium:

- Thermal Management Challenges: With the low thermal conductivity of the titanium alloy, there could be thermal accumulation while cutting. High-pressure coolant is directly injected into the cutting zone to rapidly dissipate heat or control the temperature for dimensional stability.

- Work hardening control: Optimum cutting parameters with lower speeds and appropriate feed rates are used based on characteristics of the titanium alloy to minimize surface work hardening and tool wear.

- Chemical Reactivity Management: Titanium alloys tend to react readily with the cutting tools at high temperatures. Special tools, such as ultra-fine grain cemented carbide tools, have been selected to resist this chemical reaction for increasing the tool's life.

- Compensating for Elastic Deformation: The elastic modulus of titanium alloys is small and is easily deformed. During the design, pre-set compensation quantities are added. Values for deformation will be calculated based on simulations and experience. Adjustments will be performed during programming.

These targeted solutions effectively solve the machining difficulties of precision CNC turning titanium and provide the possibility for mass production of titanium alloy shaft parts.

How We Optimize The CNC Turning Process For Complex Shafts

Optimizing the CNC turning process is key to improving the machining quality of complicated shaft parts. JS Precision optimizes the process in the following ways:

1. Digital Start:

Upon receiving the 3D model of the part, technicians will analyze the data to come up with reasonable machining benchmarks. Meanwhile, there is a comprehensive design for manufacturability review to see if the structure of the part will meet the requirements for machining. Any problem found should be adjusted and communicated back to the client promptly.

2. Intelligent Programming:

In the CAM programming process, it not only generates precise toolpaths but also runs collision checks to avoid collisions between tools and machine tools, fixtures, or parts. Besides, the cutting parameters are optimized based on part material and machining requirements, which guarantees the highest efficiency in machining under the premise of ensuring machining quality.

3. Lean Manufacturing Process:

- Roughing: This process follows a large depth of cut and high feed rate to remove excess material on the work surface, this is for the subsequent machining.

- Semi-finishing: According to the requirements of finishing, the machining allowance for the parts is kept uniform in order to avoid errors during finishing because of an uneven allowance.

- Finishing: With brand-new cutting tools, a machining method of small depth of cut, high speed, and slow feed is employed to make certain that the parts achieve the final dimensional accuracy and surface finish.

4. Online Inspection:

During the machining process, with the help of a probe, the key dimensions of the parts are measured automatically. If some dimension deviation is detected, the system compensates for tool wear in real time so that each part's dimension accuracy can be met.

This complete CNC turning process optimization solution can significantly improve the machining qualification rate of complex shaft parts and shorten the production cycle.

Figure 3: CNC precision turning is fully automated, with adjustable speeds for enhanced accuracy, eliminating the need for manual shaping.

JS Precision Case Study: Precision Turning Of A Titanium Alloy Driveshaft For A Miniature Medical Robot

Customer Requirements

A medical equipment company requested a Ti alloy (Ti-6Al-4V) driveshaft for a surgical robot. The part is only 3mm in diameter and 50mm in length.

Besides the fact that it is small in size, the part also requires multiple miniature threads with different leads, one eccentric cam, and a 15mm deep hole to reduce its weight. Its general roundness should be less than 2μm, and the surface roughness should reach Ra 0.4μm. The first lot of 100 pieces shall be delivered within two weeks.

Core Challenges

- First, titanium alloy as a material is hard to machine and work hardens easily, along with heat accumulation during cutting. This very small part needs even more increased control over the cutting parameters.

- The workpiece is slender, with a large length-to-diameter ratio of 16.7, so it easily deforms and vibrates under cutting forces, affecting the machining accuracy.

- Besides, this part is characterized by an array of complicated features, where a minimum thread lead is 0.5mm and an eccentricity for the eccentric cam is 0.3mm. It is extremely difficult to maintain the relative position accuracy among all the machining features fabricated within one clamping.

- Finally, the length-to-diameter ratio of the weight-reducing deep hole reaches 5, which makes chip removal difficult during drilling and easily leads to rough hole walls or drill bit breakage.

Precision Solution from JS Precision

For all these issues, JS Precision has a comprehensive solution.

Tooling: A miniature hydraulic expansion mandrel is designed and fabricated, with the length of its clamping section strictly controlled at 8mm for providing enough clamping force to hold the part firmly but without over-positioning.

Equipment Selection: Using a Swiss type longitudinal cutting lathe, whose spindle is of high precision and the tool post is powered, enabling all outer diameter turning, thread machining, eccentric milling, and deep hole drilling to be produced in one clamping operation. Thereby, the clamping error could be reduced.

Tools and Cooling: Adopting micro hard alloy cutting tools optimized for titanium alloys, with specially treated cutting edges for improved cutting sharpness, are employed. A high-pressure coolant system of 70 bar ensures smooth chip removal and controls the generation of cutting heat effectively.

Quality inspection: A high-resolution vision inspection system is integrated into the machining process to perform 100% on-machine inspection for part critical dimensions and surface quality, allowing timely detection and adjustment of problems.

Results and Value

With all of the above solutions, JS Precision delivered the first batch of 100 pieces within 12 days, two days in advance of the customer's required lead time. The delivered parts conformed entirely to drawings: roundness controlled within 1.5μm, and a surface roughness of Ra 0.3μm, well beyond the customer expectations.

The customer received core components that can be directly assembled without further processing, which saved precious time for the successful launch of their high-end medical devices and built a good foundation for the two sides in long-term cooperation.

JS Precision efficiently solves the machining challenges of precision CNC turned parts, taking a specific miniature medical robot drive shaft as an example. If you have more complex parts that require machining, please contact us and provide your drawings to obtain a solution. We will deliver quickly after your order is placed.

Figure 4: Titanium alloy (Ti-6Al-4V) drive shaft

How To Identify A Qualified Precision Turned Parts Manufacturer?

Choosing a qualified precision turned parts manufacturer requires multi-dimensional evaluation to make sure it will answer your machining requirements:

Technical Capability Matrix: Includes advanced equipment, process database, and technical team. Advanced equipment is the foundation of precision, a comprehensive process library provides mature solutions, and a professional team solves technical challenges.

Depth of Quality System: Certification to ISO 9001 does not replace the strict systems required by IATF 16949, nor does it provide standardized records of quality inspection in the whole value chain from raw materials to finished goods.

Accumulation of Industrial Experience: Various industries differ significantly in the requirements for components. Favor manufacturers who already have successful cases in the target industry-e.g., medical or aerospace-since they understand the needs in detail for that particular industry.

Mechanism for Continuous Improvement: A big data-based closed-loop process optimization system needs to be established. Data analysis is to be used to optimize processes and promote quality and efficiency.

The JS Advantage: Your Partner For Complex Precision CNC Turned Parts

As a company specializing in the machining of precision CNC turned parts, JS Precision has many core advantages to make it a reliant partner:

Technical depth:

High-precision workshops of JS Precision are equipped with high-performance, advanced hardware such as Swiss-type longitudinal lathes and high-precision testing equipment. We have established an abundant knowledge base regarding processes entailing difficult-to-machine materials like titanium alloys and Inconel, and complex geometries.

In the case of Inconel parts, for instance, a set of exclusive cutting parameters and cooling solutions have been developed that can effectively improve machining efficiency and quality.

Quality Commitment:

JS Precision considers "zero defect" as a realizable target and has implemented a full-process quality control system. Starting with the procurement of raw materials, each batch is checked by testing the performance and composition. During the process, real-time online inspection for every dimension is performed, and before leaving the factory, every part is checked in detail for dimension and appearance.

Cooperation model:

JS Precision can participate in project development as early as possible to provide customers with free DFM consultation. From the drawings of the parts, we would analyze the difficulties in the process, give optimization suggestions, and assist customers in reducing the cost of processing and shortening the development cycle.

Reliable Delivery:

JS Precision deeply understands the importance of delivery time to clients. Through scientific supply chain management and production planning, we ensure on-time delivery.

We rationally arrange the production sequence according to the order status of the product, track raw material procurement and production progress in real time, and promptly communicate with clients in case of special circumstances to jointly find solutions.

FAQs

Q1: What surface roughness can be achieved through precision turning?

The general precision turning process of JS Precision can achieve a surface roughness of Ra 0.4μm. After subsequent processes, such as roll forming, the surface roughness can reach Ra 0.1μm or even better for a mirror finish, to meet most high-precision requirements.

Q2: What are the main advantages of precision turning compared to grinding?

Precision turning is able to make complex shapes in one setup, with higher efficiency and the same mirror finish. It is also particularly suitable for integrating multiple processes, reducing equipment changeovers, ensuring higher geometric tolerances, and lowering machining costs.

Q3: What size CNC turned parts can you handle?

JS Precision equipment is competent to process the CNC turned parts in diameter from 0.5mm to 300mm. Thus, it is able to provide precision machining services either for micro parts or large parts.

Q4: What are the differences in parameters when turning different stainless steel grades, for example, 303 versus 316?

303 stainless contains sulfur and is easy to cut, JS Precision will utilize a higher feed rate. The 316 stainless steel is tougher and the tools need to be sharper with lower speeds and high-pressure coolant to ensure chip breaking and surface quality.

Q5: Is precision turning suitable for small-batch prototyping?

Precision turning is very suitable for small-batch prototyping since the CNC turning does not require any special molds. Prototypes can be quickly produced after programming to meet the needs of iterative verification and small- and medium-sized batch production, saving time and cost.

Q6: What materials do you support?

JS Precision supports precision turning for various kinds of metals, including aluminum, stainless steel, titanium, copper, alloy steel, and some engineering plastics like PEEK and Delrin. Applicable materials could be recommended based on requirements.

Q7: Do sharp edges of turned parts require chamfering? How would one treat them?

Chamfering of sharp edges on machined parts is important because a sharp edge may act as a point of stress concentration, besides being hazardous. JS Precision applies programmable toolpath control to chamfer or passivate all sharp edges accurately and reliably.

Q8: How long does it take from an inquiry to receiving a quote?

JS Precision promises a clear and transparent preliminary quote for standard parts with complete drawings within 2 hours, and for complex parts, quotes would be provided after communicating with customers within 4 hours.

Summary

Precision CNC turning is the cornerstone of modern manufacturing, perfectly balancing the ultimate material performance with precise digital control. Distinguishing among technically proficient and more experienced partners will prove to be a decisive factor in the success of your critical parts.

As a reliable precision turned parts manufacturer, JS Precision will help in design optimization, full-service from design to delivery of finished products, overcome several challenges that come up while machining complex shaft parts.

Upload your part drawings now for a professional manufacturing feasibility analysis and competitive quote. Let us work together in creating a model of excellence in precision manufacturing.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com