Reliable CNC turning and milling services are pivotal for project success.

While a titanium alloy joint implant smaller than a finger tip must have a mirrorsmooth surface and strength higher than human bone, a complex thermal management system housing in an aluminum alloy for a next-generation electric vehicle must have a complicated network of fluid channels internally and a precise mounting interface externally.

These are not from two different factories, but represent the wide domain covered by modern CNC turning and milling services.

I understand the challenges that you face in selection, processes, and quality control as a senior engineer at JS Precision. This guide will reveal how to master this core technology of precision manufacturing, ensuring that every part-from a single prototype to millions of units produced-perfectly matches your design ambitions.

Figure 1:Show the process of CNC turning.

Core Answer Table

| Key Considerations | Core Technology Strategy | Unique Value Offered by JS Precision |

| Service Provider Selection and Capability Matching | Evaluate equipment breadth (multi axis), process depth (turning milling composite), and quality system. | We are a one-stop supplier that provides end-to-end CNC turning and milling services, from 3-axis to 5-axis, and from prototypes to scale a million pieces. |

| Achieving Precision and Quality | Control the core variables of the CNC turning process: machine tools, cutting tools, parameters, and cooling. | Based on high-rigidity equipment, a strict process database, and SPC control, we will ensure micron-level consistency for precision turned parts. |

| Optimizing Efficiency and Cost | Design dedicated process and supply chains for high volume precision turned parts. | Large-scale production, value engineering analysis, and localized rapid response together allow us to achieve optimal total cost for high volume CNC machining projects. |

Key Takeaways:

- Choosing partners is more important than comparing prices: An excellent CNC turning and milling service provider should be able to provide Manufacturing Design (DFM) support, which is the cornerstone of project success.

- Precision is a System Product: The whole quality of the CNC turning process depends on the synergy between machine tools, cutting tools, processes, and materials rather than any single factor.

- Axis-Count Liberation Design: Five-axis CNC milling services can complete the most complex machining in a single setup. That itself is the key to improving accuracy while shortening lead times.

- Materials define the limits of performance: From medical-grade PEEK to high-strength titanium alloys, material selection directly defines the application ceiling of precision turned parts.

- Mass production is a profession: Manufacturing of high volume precision turned parts needs a different approach from prototyping. The key issues are cycle time and stability.

JS Precision: CNC Turning And Milling Services For Complex Parts Manufacturing

During the 15 years since our founding, JS Precision has deeply focused on CNC turning and milling services, including complex precision parts customizations and mass production.

We have served five high-requirement industries including medical, aerospace, automotive, electronics, and industrial equipment, completed over 100,000 projects and manufactured over 500 million precision turned parts.

We are equipped with more than 50 sets of advanced machining facilities, including dual-spindle milling and turning centers and five-axis machining centers from world-famous brands like DMG MORI and Haas, which can meet all the needs ranging from simple turning to five-sided machining. The tolerance control is consistently within ±0.005mm.

We have completed five-axis machining of Ti6Al4V titanium alloy parts for aerospace clients and completed mass production of millions of stainless steel precision pump cores for the medical industry. We also have acquired various authoritative certifications such as ISO9001 and ISO13485.

The guide is an epitome of our team's practical experience after handling more than 10,000 complex projects. The key points it offers from prototype to mass production are a guarantee you can completely trust.

Want to know how JS Precision's CNC turning and milling services can adapt to your complex part requirements? Just submit your part drawings and machining requirements, and we will provide a free quotation with a tailored process solution along with case studies of similar projects executed in the past for your reference.

What Are The Core Dimensions For Selecting Excellent CNC Turning And Milling Services?

In selecting CNC turning and milling services, a comprehensive evaluation in three dimensions is needed: technology, quality, and collaboration. This will be the direct determinant of the precision of parts, stability in delivery, and long-term value in cooperation.

Depth and Breadth of Technical Capabilities:

True strength lies in having a diversified portfolio of equipment. JS Precision possesses a full-range array of CNC machine tools, from three to five-axis ones, including multi-axis milling and turning systems covering machining requirements for everything from simple shafts to complex curved surface pieces, the best international brands in the industry supply all this equipment.

Reliability of the Quality Assurance System:

Reliable CNC turning and milling services depend essentially on comprehensive quality control processes. We are ISO9001- and ISO13485-certified, carrying out first-piece inspection, real-time process monitoring, and CMM measurement reports upon final delivery to ensure the consistency and traceability of parts without batch quality issues.

Engineering Support and Collaboration Capabilities:

A quality service provider should participate in the design phase. The JS Precision engineering team offers professional DFM analysis, providing the optimization of part structure, tolerances, and material selection for the improvement of manufacturability and cost reduction to avoid defects during subsequent machining.

Figure 2:When choosing CNC machining services, consider whether the supplier has professional knowledge in innovative CNC technology and a skilled team of mechanics.

What Variables Dominate The Quality Of Your CNC Turning Process?

Several key variables dictate the quality of the CNC turning process. In fact, overlooking any of the steps involved might result in either dimensional deviations or mediocre surface finishes. All these variable parameters need critical accurate control to make superior-quality precision turned parts.

The Inherent Capabilities of Machine Tools:

Machine tools constitute the very foundation of the whole CNC turning process. The rigidity of the spindle, the accuracy of the guideway, thermal stability, and the CNC system itself set the upper limit of precision.

JS Precision machine tool controls spindle run-out within 0.002mm. With high-precision guideways and a competitive CNC system, it offsets vibration and thermal deformation to assure stable precision turned parts.

The "Dance" of Tools and Processes:

Matching the tool to the cut path parameters is at the heart of the CNC turning process. The tool material and coating match the workpiece material, while the appropriate cutting speed, feed rate, and depth of cut are determined through testing to produce the best surface finish within efficiency.

The Hidden Influences of Materials and Cooling:

In the progress of adjusting machining strategy, different materials have quite different cutting characteristics. Therefore, with the most careful selection and application method, coolants serve to reduce the temperature during cutting, remove chips, prevent workpiece deformation and tool wear, and ensure the dimensional stability and surface integrity of precision turned parts.

Concerned about potential quality issues in your CNC turning process? Simply upload part drawings and note "Process Diagnosis," and we will analyze, without charge, the key variables that have the greatest impact on the quality of precision turned parts-targeted process optimization solutions help mitigate machining risks.

Figure 3:The manufacturing of precision turning parts is a product of the perfect combination of equipment, processes, materials, technology, and many other factors.

Three Axis, Four Axis, Or Five Axis? Match The Best CNC Milling Service For Your Project

Different part structures and machining requirements call for a match with proper CNC milling services. Choosing the right machining method can maximize efficiency, reduce costs, and ensure quality.

Three-axis machining: the cornerstone of versatility and economy

3-axis machining is the most common CNC milling service, which can be used to machine most plate-shaped and block-shaped parts for their 2.5D contours and cavities. It is easy to operate and economical, thus, it is the first choice for people who require versatility and economy.

Four-Axis Machining: Unlocking Creativity Around Cylindrical Perimeters

Four-axis machining includes the rotary axis in addition to the axes X, Y, and Z, making it more flexible. It is suitable for machining features on the side faces of cylinders, such as grooves, holes, or cams, or carving continuous contours to reduce clamping and improve efficiency and accuracy.

Five-Axis Simultaneous Machining: The Ultimate Solution for Complex Surfaces

Five-axis simultaneous machining is the most high-end CNC milling service that integrates five axes moving simultaneously, while one time clamping can form parts such as complicated special surface, impeller, and medical implant, avoiding several clamping operations to reduce errors and greatly improving accuracy and efficiency.

Not sure which kind of CNC milling service is the one that suits your project? Just tell us the geometric features, precision requirements, and production volume of the parts, and our engineers will conduct a free process assessment to recommend the most cost-effective machining solution for you, so that you can find a proper balance between efficiency and cost.

From Drawings To Reality: Which Materials Can Achieve The Highest Precision Turned Parts Requirements?

Material variety directly influences the performances, difficulty in processing, and cost of precision turned parts. Therefore, appropriate materials must be selected according to the application scenario of parts and requirements to manufacture high-precision parts.

Metallic Material Family

The most common metallic materials used in precision turned parts are aerospace, aluminum alloys such as 7075, stainless steels such as 304/316, tool steel, titanium alloy Ti6Al4V, and high-temperature alloys such as Inconel. 7075 Aluminum alloy is lightweight and high strength, stainless steel is corrosion-resistant, titanium alloys have good biocompatibility, and high-temperature alloys are resistant to extreme environments.

Nonmetal and Advanced Material

High-performance engineering plastic (PEEK, ULTEM), composite material and special ceramics are the important choices, too. PEEK has good heat resistance and biocompatibility, ULTEM has high strength and chemical resistance, the composite materials have light weight and high strength, special ceramics have high hardness and good wear resistance, all needing specialized processes.

From Laboratory To Production Line: Strategic Transformation Of High Volume Precision Turned Parts Production

From prototype to high volume precision turned parts mass production, a comprehensive strategic transformation in process, quality control, supply chain, and other aspects is required to achieve stable and efficient mass production.

Process Consolidation and Optimization

The prototype processes are very flexible, however, mass production requires standardized processes. We consolidate the effective processes, optimize the cutting parameters, design dedicated fixtures, and adopt multi-spindle lathes to simplify the complex processes into a cycle-based production flow that improves efficiency and reduces unit costs.

A Paradigm Shift in Quality Control

High volume CNC machining requires a paradigm shift from full inspection to SPC-based sampling inspection for quality control. We establish a predictive quality monitoring system for real-time collection of data on machining, its fluctuation trend analysis, and early warnings for problematic possibilities, thus assuring the long-term stability of high volume precision turned parts.

Supply Chain and Logistics Collaboration

The supply chain requires extremely high demands in providing high volume precision turned parts. We establish a just-in-time production and VMI model, sign a long-term agreement with raw material suppliers to ensure supply, optimize logistics solutions, and deliver precisely according to customer production plans.

How To Optimize The Cost-Effectiveness Of High Volume CNC Machining Projects?

Cost control is of the essence in this high volume CNC machining project. Comprehensive optimization from design, process, and cost perspectives will make the product much more cost-effective while ensuring that the quality remains the same.

Value Engineering at the Design Level:

Without affecting functionality, our engineers work closely with customers to significantly enhance machining efficiency and reduce cost using minor design modifications like standardized fillets, relaxed non-critical tolerances, and simplified complex structures.

Lean Production Processes:

Lean manufacturing eliminates waste and improves the efficiency of high volume CNC machining. We isolate and remove ineffective processes such as waiting, handling, and over-processing by introducing automated loading and unloading, central scheduling, and enhancing overall equipment utilization.

Total Cost of Ownership Perspective:

Cost optimization can't be confined to just the processing cost per piece, it has to look at the total cost of ownership inclusive of logistics, inventory, and quality risk. We provide optimal overall solutions by optimizing the supply chain, implementing VMI, and enhancing quality stability.

48-Hour Response, 35% Cost Reduction: JS Precision Helps Medical Companies Stabilize Million-Unit Precision Pump Core Production

Background:

A top European medical equipment company has an annual demand of millions of precision turned parts for its core product, stainless steel precision pump cores.

These parts are core drug delivery components in medical devices. Due to increased costs and geographical factors, the original European supplier had a delivery delay rate of 15%, impacting the customer's production severely.

Challenges:

Part tolerance ±0.008mm, surface roughness Ra0.4, needs aseptic cleaning and packaging, zero-defect quality, cost optimization, and smooth supply chain transition with no interruptions to production.

JS Precision Solution:

1.The key breakthrough lies in process reengineering.

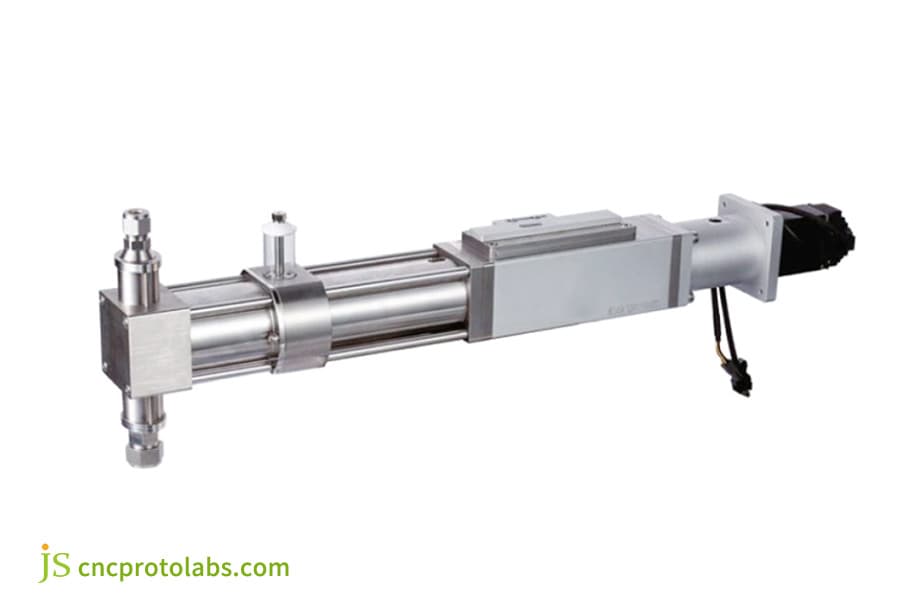

The engineering team of JS Precision reengineered the original "single-piece turning + multi-pass milling" process through DFM analysis into one-clamp operation using an imported DMG MORI twin-spindle turning-milling center with 50% more cycle time by reducing clamping errors.

2.Mass production system deployment assures stability.

A dedicated production line was configured for the project by integrating automatic inspection and real-time SPC monitoring, establishing a VMI inventory model, and setting up an inventory point near the customer's Asian assembly center for precise weekly delivery.

3.Localized emergency response clears up worries.

Based on the advantages of the local supply chain in China, the emergency channel for tool and auxiliary material replenishment was set up and a professional project team with bilingual service members was established to support the weekly video conference and to give responses to technical inquiries within 48 hours.

Results:

Achieve mass production ramp up within 6 months, reduce unit costs by 35%, deliver on time rate of 99.8%, pass rate of 100%, and fully comply with the requirements of ISO 13485:2016 medical device quality management system standard. The customer successfully minimized their supply chain risks in the Asian region and is now planning to transfer more high volume precision turned parts production to JS Precision.

Do you have a mass production need for millions of high volume precision turned parts? Please call our hotline now. Please tell us your part requirements and production plan, and we will provide a free mass production feasibility analysis and cost quote to help you reduce costs and increase efficiency.

Figure 4:precision metering pump

Why Is CNC Milling Services Near Me Your Strategic Advantage In China?

In this respect, choosing CNC milling services near me in China-in particular, partnering with JS Precision-can bring the following strategic advantages to your globally-oriented business. These are reflected not only in higher-level communication, agility, and depth of collaboration but also far beyond simple cost advantages.

Seamless Communication & Synchronous Development

By choosing JS Precision, you have a zero-time-difference engineering team at the heart of your Asia-Pacific supply chain. Work hours overlap with major global markets to support real-time calls, drawing revisions, and video conferencing. Rapid responses are enabled for both prototyping and mass production stages for efficient and accurate iterations.

Ultimate agility located at the center of the manufacturing ecosystem

China is the global manufacturing hub. Locally cultivating the supply chain, JS Precision sources raw materials and accessories rapidly. Sample delivery is 30% faster than in Europe and America, therefore enabling a rapid response to increased orders and process adjustments, hence unparalleled flexibility.

Deep Collaboration Partner Beyond Suppliers

Understanding international standards and the compliance requirements of the industries, we provide transparent bilingual project management, regular progress updates, proactive manufacturing optimization suggestions to reduce costs and enhance efficiency in the process.

Are you in need of effective CNC milling services near me? Fill in your project's requirements and contact, and we will assign an account manager to you right away while offering you free Chinese supply chain solutions to help enhance the competitiveness of your business.

FAQs

Q1: What is the minimum order quantity?

We don't have a rigid MOQ. From one prototype sample to millions of units in mass production, we support every order, whether you're at the project development or mass production stage.

Q2: Should the method of assembly or surface treatment be supported simultaneously with providing CNC machining?

Yes, we are a one-stop service. Besides CNC milling and turning, we cover surface treatments including anodizing, electroplating, sandblasting, and passivation, as well as the assembly of parts and customized packaging services to greatly simplify your supply chain management.

Q3: Is 5-axis machining always more expensive than 3-axis machining?

Not necessarily. Complex curved surfaces and multi-process part jobs may use 5-axis machining, thereby reducing setups with process combination to be more economical. We will be suggesting the most cost-effective CNC milling service solution for your part geometry and production quantity.

Q4: With mass production, how would you ensure absolute consistency of parts?

By using high-precision machine tools, standard operating procedures for every operation, periodic planning of tool replacements, and a stern SPC system that will monitor the production process in real time, we can ensure long-term, high volume precision turned parts consistency.

Q5: How long will it take from inquiry to receiving a quote?

In cases of standard needs where a drawing is clear and the specifications are well-defined, we usually give a preliminary quotation within 24 hours. For parts that involve complex structures requiring process evaluation, quote time is 1-2 business days, ensuring accuracy.

Q6: What is the shortest time for delivering prototypes?

Simple prototype parts can be delivered within 3-5 business days after your drawings and confirmation of order are received. For urgent projects, we open a fast track, allocate resources for priority production, and shorten the delivery time.

Q7: How do you protect my design intellectual property?

With clients, we will sign a strict confidentiality agreement, encrypt and manage the drawings and technical data of clients, isolate different clients' projects physically and in production systems to ensure your design intellectual property is safe during the whole process.

Q8: What is the quality problem handling process?

We follow the 8D problem-solving approach. We first isolate the problematic product to avoid further escalation of the impact, then organize a professional team for root cause analysis. Quickly implement corrective and preventative measures, and submit a complete report to the client, ensuring the problem is closed.

Conclusion

Basically, the manufacturing of precision parts is a hard nut to crack, finding an appropriate balance between accuracy, efficiency, and cost, in which reliable CNC turning and milling services are crucial.

JS Precision is your strategic extension in China. Advanced CNC turning and milling technology, along with seamless international project collaboration, ensures that your designs are realized efficiently and precisely right from the blueprint to mass production.

Take immediate action and experience professional response from the core area of precision manufacturing:

Send us your part drawings or requirements, and get a professional manufacturing feasibility analysis along with a competitive quote within 24 hours. Contact JS Precision today to make precision manufacturing easier and more reliable.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource