CNC turning parts require careful machining plan planning before design finalization.When your design is complete and you are ready to machine it using advanced CNC machinery, one of the most important questions you will need to answer is which machining option is best—'rotary turning' or 'milling'?

Choosing the right process path and partner for a seemingly simple shaft or sleeve component not only ensures excellent precision and smoothness, but also achieves dual optimization of cost and delivery time. When searching for CNC turning components manufacturers, are you limited to local options and overlooking the more competitive expertise in the global supply chain?

This article will make an organized analysis of the design principles and process selection rationale of CNC turned parts, so as to explore how JS Precision, with the advantages of turning expertise that roots deeply in China, turning precision technology equivalent to that of Europe and America, and quick response of Chinese manufacturing, has become your best partner to manufacture CNC turning components.

Core Answer Summary

| Decision Dimensions | Common Pitfalls | JS Precision Solutions |

| Process Definition | Mixing up turning and milling, taking inefficient milling solutions for some rotating parts, which highly increases costs. | Precisely identify features of rotary parts, focus on the most efficient CNC turning, and integrate the turning-milling composite process for complex features. |

| Design & Cost | We offer the most in-depth DFM analysis that optimizes part structure, tolerances, and material selection, control costs, and reduce risks early on. | We offer the most in-depth DFM analysis that optimizes part structure, tolerances, and material selection, control costs, and reduce risks early on. |

| Supplier Selection | Comparing only unit prices ignores technical capabilities, quality systems, and protection of intellectual property and overall project support. | We offer the best in transparent pricing, rigorous quality documentation, a robust IP protection policy, and full-cycle engineering support. |

Key Takeaways:

- CNC turning is the most efficient and economical preferred process for rotating parts, ensuring accuracy while controlling costs in mass production.

- Communicating with the manufacturer on DFM before finalizing the drawings will avoid more than 80% of design flaws and cost pitfalls, maximizing project value.

- Mill-turning in a single operation balances accuracy, efficiency, and cost for rotating parts of irregular shapes, making the process very apt for complex CNC turning components.

- Excellent CNC turning component manufacturers not only provide machining services but also create long-term value through technological enhancements and risk management.

JS Precision: High-Performance, Cost-Effective Custom CNC Turning Parts

CNC turning is at the heart of precision manufacturing. JS Precision has been deeply involved for 15 years with a commitment to delivering high-performance and competitive price custom CNC turning parts to clients worldwide.

We have served more than 500 customers from aerospace and medical industries and have completed over 1000 projects that were in fact pretty complex. For example, we have optimized micro-shaft parts for medical clients to achieve the targets: stable batch tolerance at ±0.005mm and a defect rate of less than 0.1%.

Core Benefits:

- We have 20 Swiss-type Swiss-type lathes and multi-axis milling & turning centers, up to Φ0.5m~Φ300mm machining range.

- We have a dedicated process database for more than 10 commonly used materials like Aluminum, Stainless Steels, and Titanium alloys for immediately matching the best machining solution.

- Equipped with high-precision inspection equipment, such as coordinate measuring machines and roundness testers, this company realizes quality control ranging from the first piece to mass production.

Also, according to the ISO 13485:2016 standard, one of the characteristics of precision manufacturing is end-to-end quality control.

Leveraging our extensive industry experience, we not only manufacture according to drawings but also proactively provide DFM optimization suggestions. We once helped a client refactor a part that originally required multi-stage milling into a CNC turning part-based machining solution, directly reducing production costs by 42% and shortening the delivery cycle by 65%.

Need a customized CNC turning parts optimization solution? Contact JS Precision engineers, submit your requirements, and you'll receive a free ISO standard DFM report and accurate quote to help your project get started.

What Truly Constitutes a Precision CNC Turning Part?

What most individuals may know if they were to ask about CNC turning parts would be "rotational machining." But true precision in CNC turning part involves a significant synergistic relationship among geometry, machining capabilities, material, and precision control.

Common Geometric Characteristics: Preferred Conditions for Turning

The defining feature of the CNC turning components is that the dominant geometric feature is created through rotational movement. This sets the CNC turning part apart from other components.

- Basic geometric elements: cylinders, cones, end surfaces, threads, etc. can be effectively manufactured by spindle rotation and tool motion.

- Typical parts: shafts, pins, sleeves, rings, flanges, etc. These are the most desirable features in the parts that involve CNC turning as the machining process.

Machining capability limits - from micro to complex

Modern CNC turning machines are constantly improving and extending the machining capability limits of CNC turning part from micro to complex.

- Scale: from Φ0.5mm microscopic shafts (e.g., the shaft part of the medical product of the guidewire) to Φ300mm large flanges with a maximum machining length of 1000mm.

- Complex machining: Machining kits with power tool holders, as well as Y-axis and other functions, make it possible to perform secondary machining operations like milling and drilling. This helps finish complex cnc turning components in a single operation.

Material compatibility and accuracy benchmarks

Material selection and precision control directly determine the performance and cost of CNC turning part.

- Material Properties: Aluminum has good machinability with ease of cutting and surface finishing, stainless steel has poor machinability with difficulty in cutting, brass has good machinability with precision thread cutting, titanium has temperature-dependent machinability.

- Accuracy Standards: Manufacturing tolerances of ±0.01mm and Ra of 0.8µm are standard, but special requirements can be achieved within ±0.005mm and Ra of 0.4µm, according to ASME Y14.5-2009.

Figure 1 Precision turning parts refer to parts manufactured through CNC turning technology, where raw materials rotate on a lathe to create objects that are symmetrical around the axis of rotation.

From Blueprint To Reality: Optimizing Your CNC Turning Part Design For Manufacturability

World-class manufacturing requires world-class designs. DFM (Design for Manufacturability) serves as a link between designs and reality. Moderate DFM optimization can ensure the equivalent functionality of CNC turning components, decrease costs, and reduce delivery time—this sums up the JS Precision philosophy.

Thin-Wall Parts Design:Balance between rigidity and weight

Thin walled CNC turning parts are widely used but prone to vibration and deformation, requiring collaborative design and process optimization.

- Structural Design: Use stiffeners and rounded corners to enhance stiffness and eliminate parasitic vibrations in thin-walled sections.

- Process Strategy: Machining process with roughing and finishing steps, optimizing cutting parameters for minimizing the effect of cutting forces.

Deformation Avoidance: Stress and Thermal Management

Turning parts with CNC machinery involves complex tasks in dealing with stress and temperature during deformation processes.

- Stress Management: Stress-reduction blanks and symmetric cuts that prevent stress concentration.

- Thermal Deformation Control: Precise spraying of coolants, optimization of cutting parameters, and reasonable process interval arrangement for cooling.

Tolerance Marking: Accurate Transfer of Requirement and Cost Controlling

The tolerance marking impacts machining difficulties and expenses. The proper marking following the ISO 8015:2011 tolerance guidelines will prevent unnecessary expenses.

- Hierarchical Marking: Differentiating between critical and non-critical tolerances by function reduces costs and inspection burden.

- Geometric Tolerances: Emphasizing roundness and coaxiality, ensuring compliance through precise clamping and calibration.

Need to improve the manufacturability of CNC turning part? Contact JS Precision with the note "DFM optimization." Our engineers will review drawings free of charge and provide professional advice to reduce costs and increase efficiency during the design phase.

Milling Vs. Turning: A Strategic Guide To Selecting The Right Process For Your CNC Turning Components

Customers often hesitate about the choice between CNC turning and milling, as the two are not in opposition and the key is to match the characteristics and requirements of the parts. Clarify the process selection logic for CNC turning components to balance cost and accuracy.

Key Signals for Favoring Turning

Components that have the following qualities will make CNC turning the best option:

- There are over 60% of features that are rotating bodies (cylinders, threads) and can be finished through spindle rotation.

- High tolerance levels in rotational surface characteristics such as Concentricity and Cylindricity.

- Mass production, seeking maximal efficiency and cost advantages.

Application Scenarios of Mill-Turn Composite/Sequential Machining Operations

The parts that have exceeded the limits of the turning operation require a versatile approach between composite processes/sequentially machining described as follows:

- A composite process is defined as the operation of Applicable Situations: The primary component is a rotational component with non-rotational details like eccentric holes and key ways.

- Solution Comparison: For small batches, "turning + subsequent milling" is an option (low cost), for large batches, mill-turn composite machining is preferred (fewer clamping, high precision, high efficiency).

Process Selection Decision Table

| Decision Questions | Choose Turning | Choose Mill-Turn Composite Machining | Choose Milling |

| Is the main body of the part a rotating body? | Yes | Yes | No |

| Is the proportion of non-rotational features less than 40%? | Yes | No | |

| Is extremely high concentricity accuracy required? | Yes | Yes | No |

| Is the batch size large? | Yes | Yes |

Need to quickly determine the optimal process for CNC turning components? Provide JS Precision with the part features, precision, and batch size to obtain accurate process suggestions and cost calculations, avoiding selection errors.

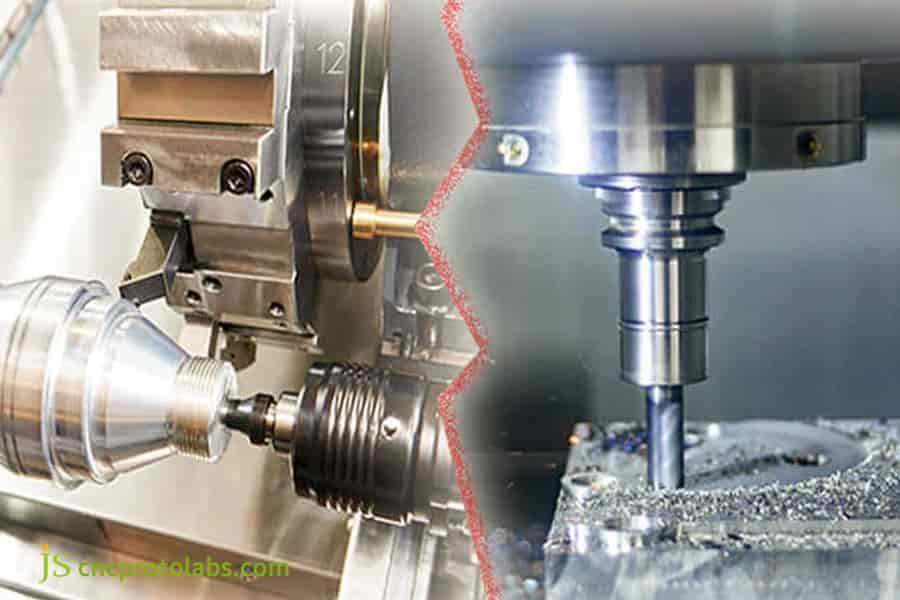

Figure 2:Comparison diagram of CNC turning and vertical milling machining

Critical Factors In Choosing Among CNC Turning Components Manufacturers

When choosing CNC turning components manufacturers, price is not the core, and technical capabilities, quality systems, and service levels determine the success or failure of cooperation. Effective suppliers can contribute toward solving machining problems, reducing risks associated with projects, and adding value.

Information Technology Capability Assessment: Equipment & Team

Capability in technology is a basic source of competitiveness. It needs to be assessed from two different fields:

- Equipment Configuration: Does it have multi-axis turning centers, milling and turning combined machines, and precision testing equipment (coordinate measuring machines, roundness testing machines, etc.)?

- Team Professionalism: Does the manufacturing company possess the capability to deliver DFM comments and suggestions regarding process improvements to their customers?

Quality & IP Protection: Requirements of a Successful Collaboration

Quality assurance and safeguarding of intellectual properties form the foundation of a successful joint effort.

- Quality Control: Are there full procedures in place covering the first article inspection, the product manufacture, and the final inspection at the manufacturer?

- IP Protection: Is the company protecting their IP using an NDA or encryption of data?

Communication and Support: Efficient Cooperation Guarantee

Efficient communication, along with transparency, improves effective collaboration:

- Response Efficiency: Is the communication timely and can the production progress be visualized and tracked?

- Additional Services: Do additional services such as material procurements and surface treatment offered by the company help simplify its supply chains?

Inside a Leading CNC Turning Components Factory: The JS Precision Advantage

As a leading CNC turning components factory, JS Precision prides themselves with the motive or motto that can be summarized as follows: “Precision, Efficiency, and Reliability” to form an ecosystem where customized machining services exceed the expectation of the client.

The Core Manufacturing Ecosystem: Focusing on Precision Machining of Rotary Components

There is an emphasis in the manufacturing environment on the exact machining of rotary parts, which offers some professional advantages:

- Equipment Configuration: The 20 Swiss-type Swiss-type Swiss-type turning machines with milling/turning centers with automatic loading and unloading are characterized by high effectiveness for mass production of high-precision complicated CNC turning parts.

- Process Support: Comprehensive and updated database of processes for different materials, library of tools and fixtures to respond to requirements.

Digital Project Workflow: Smoothening the Transition from Inquiry to Execution

Digital tools that make processes simpler and more efficient:

- Online Collaboration: Upload your 3D files and get initial analysis + DFM suggestions and quotes by our engineers.

- Progress Visualization: Real-time monitoring of order milestones right from your project dashboard – no confirmations needed.

Sustainable Manufacturing: Where Efficiency and Environment Meet

Balancing Production Efficiency with Environmental Protection:

- Energy Saving: Intelligent scheduling and optimization in tool management will save energy and reduce consumption.

- Environmental Protection: The coolant circulation system will recycle and repurpose the coolant, and there will be no pollution.

Do you want to experience the leading CNC turning components factory service? JS Precision provides a one-stop solution for submitting part requirements, covering the entire process from design to delivery, saving time and effort.

Case Study: 42% Cost Reduction Achieved: Transforming a Milled Bracket Into An Optimized CNC Turning Part

Background:

A customer needed an aluminum alloy connector, whose design originally included being manufactured as a mill part from square stock.However, the deficiencies of the current solution included:

Low usage rate of the material to be less than 30%, hence large waste of material, total machining of the product requiring only four clampings, thus low production efficiency and large coaxial tolerance error of only 0.1mm, and high unit cost of mass production of about $50, which was not affordable by the customer.

JS Precision’s DFM Intervention

JS Precision was given the requirement, and our engineers analyzed the part drawings and application circumstance. We found that as the part has functional surfaces that can be produced by rotation, it was completely convertible into a CNC turning part.

The part had some holes that needed to be drilled, but given that the part was very small and drilling would require a high precision process, the designers decided to convert the part into a CNC turned part to enable the company to manufacture the part.

According to this, we offered a targeted optimization solution:

- The raw material became round bar stock manufactured through CNC turning, along with a few milling operations using power tools.

- Optimize mounting interface of parts to make it adequate for turning logic.

- Unifying of machining datum is by adding various features that were finished by milling to the turning operations.

Result

The optimized solution turned out to be extremely successful, since it optimized the material use from less than 30% to 85%, reduced the machining time by 65%, and reduced the number of clamping tasks to one. The accuracy of the coaxiality of the important axis was also optimized by 50% to 0.05mm, which allowed better stability in part assembly performance.

During mass production, the unit cost was reduced to $29, resulting in a direct 42% decrease in total cost and extremely high customer satisfaction. This is just another benefit that solves the cost-related problems faced by the customers and further enhances the performance of the components, increasing the customers' product competitiveness.

Do you want your CNC turning parts to also achieve cost reduction and efficiency improvement? View JS Precision's complete case library to learn more about industry solutions, and submit your part information. We will customize an exclusive optimization solution for you, unlocking the dual advantages of cost and accuracy.

Figure 3 CNC turning of aluminum alloy connectors

Partnering Across Borders: Streamlining Collaboration With Your CNC Turning Components Manufacturer In China

Collaborating with a Chinese CNC turning components manufacturer can enjoy cost efficiency advantages, but distance communication is a concern. JS Precision makes cross-border cooperation simple, transparent, and reliable through standardized processes and digital tools.

The Perfect Request for Quotation Package - “Accelerate Project Start-up”

Clear and complete inquiry information can improve the accuracy and efficiency of the quotation process. It is necessary to prepare:

- Technical Documentation: Technical Specifications The 2D detailed drawings and 3D models, which clearly define dimensions and tolerances.

- Special Requirements: Material, quantity of production, surface treatment and test requirements.

- Annotation Suggestions: Critical and non-critical dimensions should be clearly differentiated from one another in an annotation, without strict tolerances.

Digital Technology: Realising a Transparent Production Process

The customer portal from JS Precision offers a complete view of collaboration worldwide.

- Collaboration Platform: file transfer, communication, and version management, important processes are transparent.

- Document Delivery: First article inspection reports and shipment inspection reports are automatically generated to ensure traceability for quality.

Building Partnerships through Trust

JS Precision is committed to long-term partnerships rather than one-time transactions:

- Tiered Collaboration: Quality and engineering support throughout the production cycle, from Prototype to Production Volume.

- Extended Services: Enabling services such as material procurement, surface finishes, and assembling processes in order to make managing the supply chain easy.

Your Next Step: Initiating a Precision CNC Turning Parts Project With Js Precision

As an end result of the elaborate information introduced above, I believe that you now have gained sufficient understanding on CNC turning parts processes, design optimization, and collaboration. It’s high time that you turned your design concept into a quality product.

As a seasoned supplier of CNC turned components, JS Precision brings rich expertise, advanced technology, and a widespread service network to support you in your endeavors.

Upload the part drawings immediately to the JS Precision real-time quotation page to obtain a transparent competitive quotation, while triggering the senior engineer DFM preliminary review. Looking forward to optimizing the design with you and embarking on a journey of efficient, precise, and mutual trust cooperation.

FAQs

Q1: What are the maximum and minimum diameters that can be turned in a CNC turning process?

The machining we can undertake ranges from 0.5mm-diameter micro-shafts to 300mm sized disk-like objects. The exact capabilities we have regarding the dimensions, material, and tolerance of the objects will depend on your information. However, if you need a specific size, let us know when enquiring so we can ascertain whether we can machine. Our machining is based on normal machining practice.

Q2: What is the difference between processing of aluminum parts and stainless steel parts?

The main points of difference in machining ease, efficiency, and cost are as follows: Aluminum components have ease of cutting, high speeds, easy surface finish, and low cost. whereas stainless steel components have strong material properties, low machining speeds, large cutting forces, demand high tool qualities, and involve higher machining times and machining costs.

Q3: How do turned parts produced in large numbers achieve consistency?

Clamping errors are minimized through automation of loading and unloading, constant analysis of tool wear through online detection probes, and mitigation of dimension differences, together with periodic analysis through SPC, of machining errors. These multiple measures ensure consistency in mass-produced turned parts.

Q4: What are some common surface treatments of turned parts?

Common surface treatments are selected based on materials and scenarios, and aluminum parts are commonly anodized to enhance corrosion resistance and aesthetics; Stainless steel is often passivated/nickel plated for rust prevention, as well as chrome plating, blackening, polishing, sandblasting, etc. to enhance wear resistance or decorative properties.

Q5: To what precision can the thread turning process be carried out?

The tolerance levels guaranteed by thread turning are consistently ISO 6H/6g or better. For thread cutting, we employ professional cutting tools, ensuring accurate parameters, and inspect using either go/no-go inspection or thread scanning. This is followed by inspection reports that will ensure accuracy.

Q6: How long will it take from the inquiry to the receipt of the prototype?

The time required from the time of inquiry to the receipt of the prototype depends on the complexity of the ordered piece. If it is a simple piece made from CNC turning, it will be delivered in 5 to 7 business days after the confirmation of the order. But for a complex piece made from a specialty material, it will take 10 to 15 business days.

Q7: How do I protect my design from leaking or from theft?

We sign strict NDA agreements with our clients to clarify confidentiality obligations. Our clients' files are stored on encrypted servers and access permissions are restricted. We regularly conduct employee confidentiality training to ensure that our designs are not leaked or stolen from all aspects of our systems and processes.

Q8: Can you carry out inspections in line with the standards of our company?

We can inspect according to your company's enterprise standards. At the beginning of cooperation, we will provide inspection standards or control plans. Our quality team will study and adjust the inspection process and judgment standards to ensure that the results meet the requirements and provide inspection records.

Summary

How to choose the CNC turning parts processing method is never just a technical problem, as it involves comprehensively judging the processing precision, expense, and other capabilities.

JS Precision is dedicated to being your trusted partner in precision turning with our professional technology, reliable quality, and service to ensure every design is efficiently realized and every collaboration reaches a win-win effect.

It is about time you used your blueprints to your advantage.

Please visit the JS Precision website today, upload your drawings of the part, and get an accurate quote with expert analysis from the DFM process. Together, we will find the best way to make each critical part of your CNC turning project and give your creative process the head start it needs to succeed in the industry.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com