Custom CNC turning parts are the core carrier for achieving rapid and precise transformation from design blueprints to physical products in modern manufacturing.

Whether you need a unique prototype or are looking for reliable OEM production partners for the next generation of products, precision CNC turning technology can provide critical support for the manufacturing of such parts.

This guide will explore every aspect of custom CNC turning parts and how expert OEM CNC turning services translate blue prints into reality and how you can easily gain free and transparent CNC turning quote estimates.

When going for JS Precision, it means selecting a strategic manufacturing partner who is in China and is characterized by the highest precision, fast respondability, and high cost-effectiveness.

Core Answer Summary

| Core Questions | Key Answers | Value for You |

| Custom CNC Turning | It can perform precise cutting on a rotating workpiece with CNC lathes and manage to achieve customized machining according to drawings, ensuring the accuracy to be ±0.005mm. | Clearly defining technical boundaries to seek out the best solution for shafts, sleeves, and flanges. |

| OEM Service Operation Mode | From design to providing full-process managed services, including DFM optimization, programming, production, quality inspection, etc. | It offers one-stop design-to-delivery support and reduces management and supply chain risks. |

| Choose Professional Service Provider | Provide high-precision, low-cost, fast delivery, and seamless scalability from small batches to mass production. | Ensure part quality, accelerate time-to-market, optimize costs, and focus on core business. |

| Get Accurate Quotation | Upload 3D drawings and the system instantaneously provides an open, transparent quotation, based on materials, tolerances, and other factors. | Drastically reduce the barriers to inquiry and facilitate rapid completion of project feasibility and cost planning. |

Key Takeaways:

- Precision Defines Performance: The precision of special quality custom CNC turning parts is measured in micrometers (µm).

- Collaboration Creates Value: True CNC turning OEM service starts with pre-production Design for Manufacturability (DFM) collaborations in order to optimize costs and timelines.

- Transparency Drives Trust: The cnc turning quote needs to be open to derive transparency. In other words, it needs to include cost details.

- Scalability Without Sacrificing Flexibility: Good suppliers must be able to work with prototypes as well as produce tens of thousands of pieces, thus lending to ultimate flexibility in the custom CNC turning services.

Why Choose JS Precision For Custom CNC Turning Parts?

As a company with 15 years of experience in CNC precision manufacturing, JS Precision's core competitiveness stems from its relentless pursuit of excellence in technology, quality, and service. This is also the key to gaining the trust of more than 500 high-end clients worldwide. In the field of custom CNC turning parts, our strength lies in three core dimensions:

First, our strong technological capability. More than 40 units of high-class CNC machines from Mikron of Switzerland and Mazak from Japan have been introduced. 5-axis milling and turning centers amount to 30% of these.

This enables us to finish several machining processes, such as turning, milling, drilling, and boring, within only one setting for complicated parts and control the cumulated error within ±0.005mm.

Second, our quality system ensures quality. All processes firmly follow ISO9001:2015 and AS9100D certification standards of the aerospace industry. Precision testing equipment includes Zeiss coordinate measuring machines, surface roughness testers, and so on. The first-piece full-dimensional check-up pass rate reaches 100%, and batch production is at an incessant 99.8% pass rate.

And finally, there’s the experience of accumulating experience itself. We have created over 10 million customer-specific parts in industries like aerospace, medical devices, and automotive. We managed to optimize the production of the gearbox shaft to save 30% on cost and 40% on delivery time for a new energy vehicle company.

Want to check our capabilities? Just send us your drawings now, and our JS Precision engineers will offer you a FREE DFM analysis and an accurate quote for custom CNC turning parts, showing you our strongest competitiveness.

What Are Custom CNC Turning Parts And How Are They Made?

CNC turning is the key process for the production of rotationally symmetric parts. Custom CNC turning parts are digitalized with high precision based on special drawings made by the customers. These parts are widely used in the production of shafts, sleeves, and other parts for the precision equipment.

Core Definition: Accurate conversion of digital into physical form

Custom CNC turning parts pertain to the production of precision parts made completely in accordance with the customer’s 3D drawings or specifications, using a CNC lathe to rotate and process the workpiece. Their core characteristic is rotational symmetry. Common products include shafts, sleeves, flanges, and other structural components.

Analysis of Turning and Milling-Turn Composite Technology

- Traditional CNC Turning: Turning of rotary features like external diameters and internal holes of the part. In this operation, the part rotates and the cutting tool is stationary.

- Milling Turn Composite Machining: Simultaneous movement of the work piece and cutting tool, enabling combination of several processes in a single clamping, thus reducing errors in clamping and increasing efficiency in production of complex parts.

Technical Depth: JS Precision's Core Capability Parameters

| Technical Indicators | Specific Values | Application Scenarios |

| Dimensional Accuracy | ±0.005mm (±5µm) | Aerospace sensors, medical implant components |

| Minimum Machinable Hole Diameter | 0.3mm | Minimum Machinable Hole Diameter |

| Surface Finish | Ra 0.4µm | Hydraulic valves, sealing contact surfaces |

| Roundness Tolerance | ≤0.002mm | High-speed rotating shafts, bearing sleeves |

| Material Compatibility | 20+ types including aluminum alloy, stainless steel, titanium alloy. | General-purpose for multiple industries, customized for special working conditions. |

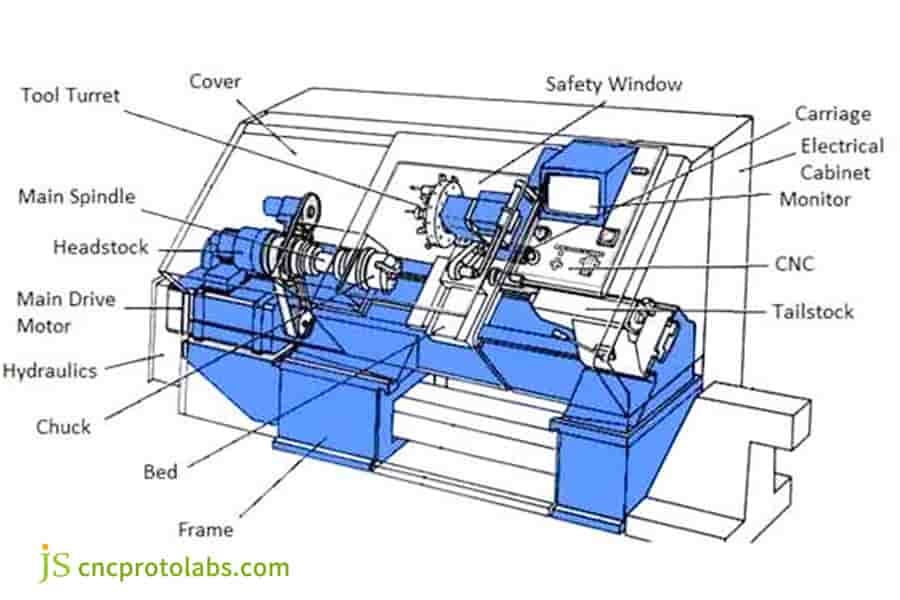

Figure 1 The Components of a Turning Lathe. CNC turning works by rotating a workpiece on a spindle while a cutting tool removes material to create the desired shape.

Figure 1 The Components of a Turning Lathe. CNC turning works by rotating a workpiece on a spindle while a cutting tool removes material to create the desired shape.

How Can OEM CNC Turning Services Bring Your Designs To Life?

The OEM CNC turning services go beyond the process of machining based on the drawings, rather, they symbolize the co-creation process based on the entire process chain, from design to delivery.

JS Precision, as an extended manufacturing team for customers, makes complex precision manufacturing simple and controllable through a digital and standardized service system.

Beyond Machining: Your OEM Partner as an Extended Manufacturing Team

JS Precision, under the OEM collaboration model, takes the whole process of process planning, production, and logistics as our responsibility. Engineers intervene in the process of design development, offering expert advice to the client to help them concentrate on their main R&D business.

A Digital Closed Loop from Concept to Finished Product

1. DFM Collaboration: Performs manufacturability analysis for CAD data within 24 hours, offering tolerance and structure optimization recommendations to minimize costs.

2. CAM Programming and Simulation: Produces tool paths and performs simulation of machining with commercial software while excluding collision and overcuts.

3. Precision Execution & Monitoring: High precision machining on high-end CNC machines with real-time monitoring by an IoT setup for process control & stability.

Quality Embedded in Every Step

We established a multi-level quality inspection system, and all processes adhere to ISO 9001:2015 and AS9100D standards in quality:

- First Article Inspection: Inspection involving a complete dimension with a coordinate measuring machine, along with issue of a report.

- In-Process Inspections: 5% sampling inspection. Full inspection of critical dimensions for timely correction.

- Outgoing Inspection: Products are inspected before delivery based on appearance, size, and performance.

Are you searching for a complete OEM solutions provider? Upload your 3D designs, and JS Precision will offer you complete OEM CNC turning services from design to delivery with the result that the R&D cycles are significantly decreased along with the supply chain management costs.

Why Opt For Professional Custom CNC Turning Services?

Selecting custom CNC turning services is a fundamental choice of optimal precision, efficiency, and cost. JS Precision provides customers with three fundamental values by virtue of technological advancements and optimization of processes:

Precision and Consistency: The Core Guarantee of Product Performance

That is the essence of the performance guarantee of the product. Even the micron level of precision is directly related to the reliability and performance of the equipment. JS Precision, using high rigidity machines and temperature-controlled workshops, provides consistent parts for batches, ensuring the dimension tolerance level of precision with an error of ≤0.01mm.

Two-Handed Advantage of Cost Effectiveness and Speed

- Cost Optimization: By process integration, mass purchasing, and optimized production planning, cost benefits can now be realized for small batch orders.

- Fast Delivery: Standard deliveries take 5-10 working days, while 72-hour fast delivery is available. Rapid prototyping lines facilitate R&D cycles.

Flexible Production from Prototype to Mass Production

| Order Size | Delivery Time (Regular Materials) | Delivery Time (Special Materials) | Cost Advantage | Typical Material Examples |

| 1-10 pieces (Prototype) | 3-5 days | 5-7 days | No programming or fixture fees, 40% reduction in prototype verification costs | Aluminum Alloy 6061, Stainless Steel 304 |

| 10-1000 pieces (Small Batch) | 5-10 days | 8-12 days | 5%-10% discount on bulk material purchases, 15% cost reduction through process optimization | Aluminum Alloy 7075, Stainless Steel 316, Brass H62 |

| 1000-50000 pieces (Large Batch) | 10-20 days | 15-25 days | 30%+ cost reduction through process optimization, 15%-20% discount on bulk material purchases, significantly reduced unit cost | Aluminum Alloy 6061, Stainless Steel 316, Titanium Alloy TC4 |

| 50000 pieces and above (Very Large Batch) | 20-30 days | 25-35 days | Customized production lines reduce costs by 40%+, with long-term material price guarantees through cooperation. | 6061 aluminum alloy, 45# carbon steel, and 304 stainless steel |

Looking for a combination of accuracy, affordability, and the faster turnaround time? Get in contact with the experts from the JS Precision engineering team today for your complimentary proposal for the total cost of ownership for your custom CNC turning services.

How To Get Your Instant And Accurate CNC Turning Quote Online?

CNC turning quote is the first step in the activation of projects. JS Precision simplifies the inquiry process, allowing customers to obtain accurate quotes within minutes without the need for tedious communication.

Get Your Instant Quote in Three Easy Steps

1. Prepare Materials: Provide 3D CAD models, which should support STEP, IGES, and X_T file formats, with material type, order quantity, delivery time information.

2. Apply Quotation request: Use the JS Precision quotation system and enter the required details while ensuring the parameter details entered correctly.

3.Receive Quotation: By utilizing the artificial intelligence algorithms and the process database, the system is capable of automatically generating a rough cnc turning quote with respect to the pricing information, process evaluation, and delivery plans, which can be accomplished in a matter of minutes.

Understanding Your Quote: Transparent Cost Breakdown

| Cost Breakdown | Influencing Factors | Example Comparison (100-piece order) | Optimization Suggestions |

| Material Costs | Material Type, Specifications, Loss Rate | Aluminum Alloy 6061: $500. Stainless Steel 316: $1200. Titanium Alloy TC4: $2000 | Low-cost alternatives can be used for non-critical parts. |

| Machining Costs | Process Complexity, Tolerance Grade, Machining Time | 2-Axis Turning: $800. 5-Axis Milling and Turning: $1500 | Simplify non-critical features and relax non-core tolerances. |

| Post-Processing Costs | Surface Treatment Type, Accuracy Requirements, Coating Thickness | Anodizing: $300. Nickel Plating: $600 | Choose the most cost-effective solution based on the application scenario. |

| Quality Inspection Costs | Inspection Items, Report Requirements, Inspection Accuracy | Routine Inspection: $100. Full-size FAI Report: $300 | Mass production can reduce inspection frequency. |

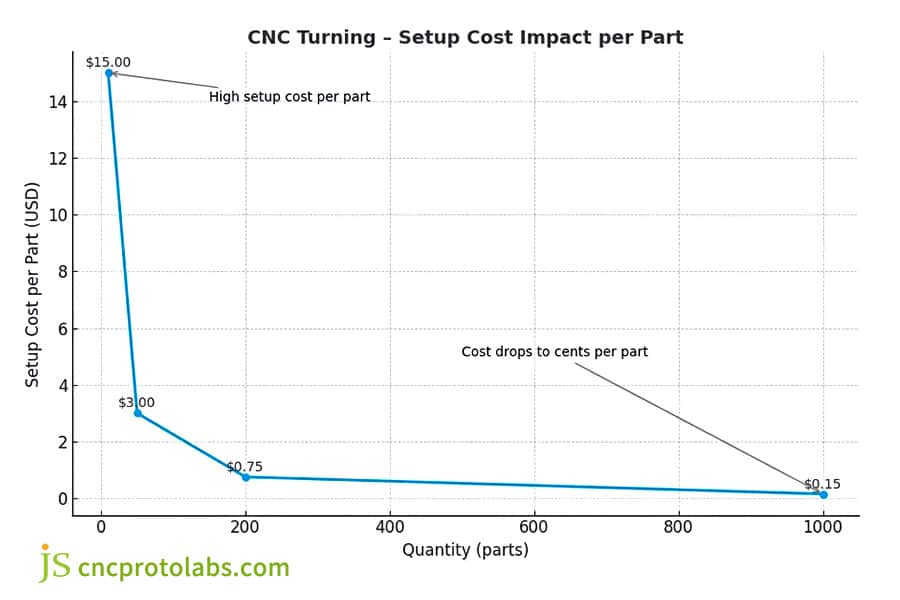

Figure 2 Graph showing cost per part curve as quantity increases.The single piece cost of CNC turning projects will significantly decrease with the increase of order quantity.

Figure 2 Graph showing cost per part curve as quantity increases.The single piece cost of CNC turning projects will significantly decrease with the increase of order quantity.

Who Needs a CNC Turning OEM Partner And Where Are They Used?

CNC turning OEM services are used across a wide range of industries that have high demands on part precision, reliability, and delivery time. Customers of JS Precision are located worldwide, covering the following core areas:

- Aerospace & Defense-as required: AS9100 certifications, high-temperature alloy machining, and applied in components like landing gear, engine shafts, sensor casings, etc.

- Medical Devices: Requires the use of biocompatible material, such as titanium alloy or PEEK, and usually sterile cleanliness. It could be fabricated for parts in surgical instruments, implant accessories, and diagnostic equipment.

- Automotive & New Energy: Its products include engine, transmission, and electric drive system parts. These require high strength, high wear resistance, and mass production capability.

- Industrial Automation & Robotics: Precision components for lead screws, couplings, and joint components require high rigidity, long-term positioning accuracy.

- High-Performance Consumer Electronics: Pursuing the ultimate in looks and dimensions, utilized in audio components, structural parts of optical equipment, and connectors.

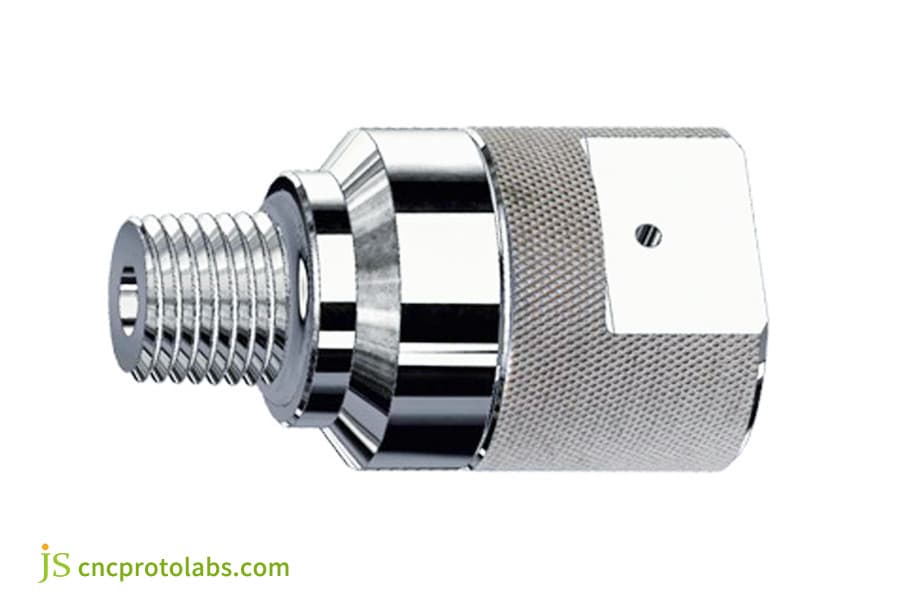

Figure 3 Different CNC turning machining components.CNC turning machining supports a wide range of industries and everyday products.

Figure 3 Different CNC turning machining components.CNC turning machining supports a wide range of industries and everyday products.

Case Study: 72 Hour Battle, How JS Precision Delivers Aerospace Grade Sensor Housings

Challenge: A Nearly Impossible Mission

A world-famous drone manufacturer had a pressing demand for a set of titanium alloy (TC4) sensor housings that could meet the following three key challenges:

- Complex shape: presence of deep holes and thin walls.

- High accuracy: overall shape ≤0.02mm, surface roughness of the internal cavity <0.8µm.

- Fast delivery cycle: preparation of the first batch of samples in 5 working days at most, to be applied in the first flight test.

JS Precision's Response: A Victory of Technology and Collaboration

1.Rapid Response: Immediately upon receiving this request, JS Precision set into motion their emergency response plan by assessing DFM within 2 hours and making suggestions for optimizations, which included adding ribs for reinforcement of thin-walled areas for effective control of machining deformations.

2.Process Innovation: On the Mazak Japanese 5-axis mill/turning center, the machining process could be done in one fixture, eliminating mistakes due to secondary fixtures, while internal cooling tools were designed for deep-drilled holes, utilizing the high frequency chip removal technique to create a smooth, burr-free hole finish.

3.Parallel Quality Inspection: In parallel to production, the quality team works on designing inspection fixtures and CMM inspection programs, as well as performing full-dimensional inspection right after parts are produced.

Results: Delivery Exceeding Expectations

Finally, from the confirmation of the order to the delivery of the initial shipment of parts to the customer, a mere 72 hours were achieved. The customer received all the parts with 100% satisfaction for critical dimensions, and the curvature accuracy was ≤0.015mm, which surpassed customer satisfaction.

The customer successfully conducted the flight test and signed an effective long-term strategic cooperation contract for an annual purchase of 50,000 pieces.

Urgent processing tasks which have to be completed right away? Please contact the JS Precision service hotline. We will make the most of our 72-hour processing skill and provide high-quality CNC turning OEM parts for you so as not to affect the project deadline and make the most of the market opportunities for your success.

Figure 4 CNC machining of drone sensor housing

Figure 4 CNC machining of drone sensor housing

What Truly Determines Your CNC Turning Parts Quotes?

CNC turning parts quotes are not simply a combination of materials and labor hours, and their hidden dimensions determine costs. Understanding these can help to accurately control costs.

Hidden Dimensions Affecting Final Cost

- Exponential Cost of Extreme Tolerances:The tolerance has been increased from ± 0.05mm to ± 0.01mm, requiring precision machine tools, slow processing, and high-frequency testing, which may increase the cost by 3-5 times.

- Material Machinability: Various materials have varying high cutting difficulty. Taking an example, hard steel machining (HRC 50+) demands CBN tools, which are very costly as compared to aluminum materials.

- Quality Assurance Level: There are additional costs associated with requiring a full-size inspection report (FAI) or a 'Mill Certificate' or third-party inspection.

Value Created by JS Precision for Customers

Our role is in optimizing total cost of ownership with expert technology in form of relaxing tolerances in non-critical components, material substitution with easily machinable material, and machining turn and mill parts to save the cost of assembling different parts together.

Want to optimize your quote costs? Upload your drawings and mark key tolerances. JS Precision will provide you with CNC turning parts quotes optimization suggestions to reduce costs and enhance product competitiveness without affecting performance.

FAQs

Q1: What materials are best suited for CNC turning?

The CNC turning services at JS Precision can turn different materials that include aluminum alloys, stainless steel, carbon steel, and brass. It can also turn titanium alloys, nickel superalloys, and engineering plastics that include PEEK.

Q2: What is the tightest tolerance I can achieve?

JS Precision’s tolerance level for standard products is ±0.01mm. However, in specific material conditions for critical dimensions, tolerance levels of ±0.005mm may be achieved, which meets the requirements of high-precision equipment.

Q3: What is the minimum order quantity (MOQ)?

JS Precision accepts orders of 1 piece for custom components, as well as for prototypes, without a minimum quantity limit. For both individual product testing of prototypes, as well as large-scale production, we have stable service and quality.

Q4: How long does it take from quotation to receiving samples?

Simple custom CNC turning parts may take 1-2 weeks for the first sample, while complex parts involve process development and debugging, which takes 2-4 weeks. Fast track service reduces the period to 72 hours.

Q5: How do you ensure consistency in mass production?

JS Precision maintains dimension stability and quality consistency during mass production by their standardized working processes, Statistical Process Control, tool compensation, and machine servicing along with inspections performed during and upon completion of a process, called first-piece inspection.

Q6: What if design issues are discovered during processing?

We will immediately suspend processing and contact you as soon as possible with professional modification advice and effective solutions. The production delivery will only proceed with your written confirmation and will prevent unnecessary loss of production value.

Q7: Are there price discounts for mass production?

Yes. With higher order quantities, the programming and fixtures cost will be shared, so it will be significantly economical. Price discounts for mass production orders will be up to 30%. Please refer to our engineers for more ideas on this topic.

Q8: How are shipping and logistics arranged?

JS Precision offers door-to-door logistics for delivery from China to global locations. According to your time and cost constraints, you can select global express delivery, which involves DHL and UPS, and air and sea transport for the safe delivery of your parts.

Summary

In today’s highly competitive market, having a trustworthy, accurate, and responsive manufacturing partner is invaluable. Custom CNC turning parts are not merely ordinary mechanical parts, but the very backbone of your success, and specialized CNC turning OEM services are the vital key to unlocking success in the market.

Choosing JS Precision means choosing the confidence to implement precise design, worry free collaboration throughout the process, and cost-effective solutions. Upload your 3D drawings today and get a clear, transparent, real-time cnc turning quote. Let the JS Precision engineering team evaluate and optimize your project for success on your next project.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com