OEM CNC turning parts constitute the main precision pieces in automotive braking systems, which mainly influence safety and performance. Are you sure that your brake system parts supplier is reliable?

Generic type parts or non-specialized machining frequently end up as performance bottlenecks and even safety hazards.

This article will discuss the manufacturing of top-quality custom brake components by using professional OEM CNC turning parts and precision CNC machining automotive processes, thus uncovering the main reason for selecting a professional precision CNC turning company.

Quick Overview of Core Answers

| Core Questions | Key Answers | Value for You |

| How to make sure brake components are totally safe and consistent? | Stick to CNC turning OEM standards, allowing complete traceability of materials, processes, and testing, and be superior to aftermarket parts. | Know the safety and reliability benefits of OEM-level manufacturing and set quality standards. |

| How to get super accuracy and strength even in complicated brake parts? | Combine multi-axis CNC turning and mill-turning technologies with composite to how key components are machined with great precision thus the sealing and structural integrity are guaranteed. | Explain the main technological road of high-performance brake components and get the process, performance coupling idea. |

| How to pick the most dependable machining partner for custom projects? | Check the industry certifications, technical capabilities, and engineering support thoroughly, and choose the companies who are the specialists of precision CNC machining automotive. | Obtain a hands-on approach for choosing high-end CNC turning process suppliers. |

Key Takeaways:

- No Compromises on Safety: It is crucial that the OEM CNC turning parts for brake systems are totally traceable, a small deviation at any point might cause dangerous consequences.

- Accuracy is the Key to Efficiency: The roundness of the caliper piston should be ≤0.003mm, thus, it directly influences the brake feeling and the sealing, which is a must be for precision CNC turning.

- Process Issues: It involves choosing aluminum alloys or high-temperature alloys and CNC machining of intricate internal oil channels and cooling fins, which cannot be done with generic parts.

- Partners Are the Best Asset: Seasoned precision CNC turning company is capable of reducing design costs by 20% and speeding up the time-to-market through the DFM optimization.

Why Trust This Article? JS Precision’s Authority In Automotive CNC Machining

This article is based on JS Precision's 15 years of work in automotive precision CNC machining. As a brake components precision CNC turning company, apart from being IATF 16949:2016 certified, we are also AS9100 Rev D aerospace-grade certified, which allows us to apply aerospace standards to automotive brake components.

JS Precision is skilled in CNC turning technology and offers OEM CNC turning parts customization services to 50+ OEMs and racing brands worldwide. We have supplied 1000+ core brake components, covering all categories like calipers, pistons, and wheel flanges, with a machining accuracy of as much as 0.003mm.

We have developed a wide range of innovations for the manufacturing processes of metal brake components in areas such as deformation, free machining of aluminum alloy brake components and integrated machining of complex hydraulic systems.

Our company has more than 20 multi-axis milling and turning machines, each fitted with an online measurement probe and a tool breakage detection system. We have implemented a fully traceable quality control system that covers everything from the inspection of incoming materials to the full-dimensional inspection of the finished products.

As for brake system components, we have established a CNC turning process parameter library that allows us to precisely address component performance issues at high temperature and high-pressure conditions.

JS Precision's engineering team offers full-process DFM support from design to mass production in personalized services. We have assisted several clients in obtaining more than 15% weight reduction and 25% brake component processing cost reduction.

Our know-how and successful cases are the main support of this article, so that each process analysis and selection recommendation are in line with real production requirements and truly solve clients' problems in brake component processing.

Want to obtain JS Precision's CNC machining process manual for automotive brake components and gain a deeper understanding of OEM CNC turning parts processing standards? Contact a JS Precision engineering consultant immediately and mention "brake process" to receive it for free, along with one-on-one technical support.

Why Are OEM CNC Turning Parts Critical For Brake System Safety And Reliability?

The braking system stays at the core of automotive safety and OEM CNC turning parts will directly influence the reliability of brakes. It is essential to opt for standard CNC turning OEM parts instead of generic components to lower the risk of safety. This significance is manifested in three aspects: materials, performance, and cost.

The Basis of Material Consistency and Structural Integrity

Complete material traceability is one of the fundamental requirements for CNC turning OEM. In manufacturing CNC turning OEM parts, JS Precision carries out mechanical property testing on every batch, starting from the original manufacturer certification of 6061-T6 and 7075-T651 bar stocks.

During the processing, stress release is strictly enforced to make sure that the components' structural integrity is maintained. Various brake parts are subjected to very different working conditions and thus, the properties of the materials must be exactly in line with each other.

Below are the commonly used brake component machining materials and their core performance parameters from JS Precision:

| Material Type | Tensile Strength (MPa) | Hardness (HRC) | Density (g/cm³) | High Temperature Resistance (°C) | Applicable Components |

| 6061-T6 | 310 | 90-95HRB | 2.7 | 204 | Caliper body, brake bracket |

| 7075-T651 | 572 | 15-18HRC | 2.8 | 180 | Caliper piston, high-performance brake shaft |

| 304 Stainless Steel | 515 | ≤201HB | 7.93 | 870 | Brake hose connector, flange |

| Inconel718 | 1241 | 38-40HRC | 8.19 | 650 | Brake components for ultra-high temperature conditions |

| Cast Iron HT250 | 250 | 180-220HB | 7.2 | 400 | Brake Discs & Drums |

Precise and judicious selection of materials is essentially the starting point for the safe and dependable OEM CNC turning parts. JS Precision is capable of suggesting the best materials and granting original equipment manufacturer (OEM) certification that is in line with your component's working environment.

Performance Guarantee Exceeding Aftermarket Standards

The critical dimensional tolerances of parts produced through CNC turning OEM at JS Precision are controlled within ±0.01mm, which is a lot better than the ±0.05mm of general-purpose parts. After a number of load cycles tests, their fatigue life is 30%-50% higher than general-purpose parts, thereby they are quite capable of frequent braking wear.

Lowering System Risks and Running Costs

Using cheap brake parts may cause problems such as seal failures, vehicle recalls, etc., which would result in the losses that far exceed the investment in the purchase of qualified OEM CNC turning parts. JS Precision has the ability to keep the component defect rate at less than 0.05%, which will massively cut down on the costs of maintenance and recalls.

Want to check if your current brake components meet OEM CNC turning parts standards? Contact JS Precision now, submit your component drawings, and you'll receive a free tolerance and performance evaluation report, as well as information on CNC turning OEM quality improvement solutions.

How Does The CNC Turning Process Prevent Deformation In High-Speed Brake Machining?

Brake components are typically constructed from light weight aluminum alloys, and such materials can easily be deformed under the cutting forces and heat generated during the high-speed CNC turning brake machining. JS Precision, professional CNC turning process suppliers, can successfully address this issue by triple controlling process, tooling, and parameters.

Machining Sequence and Stress Control

To ensure the release of internal material stress step by step, JS Precision implements a multi-stage process of "roughing, stress release, semi-finishing, aging-finishing". With the aid of stress testing after semi-finishing and high-temperature aging after roughing, the component deformation is effectively prevented

Advanced Tooling and Dynamic Balancing Technology

In machining thin, walled caliper bodies, JS Precision hydraulically expands the mandrel and uses specially designed soft jaws to ensure uniform clamping. Together with the dynamic balancing technology of the machine tool spindle, this eliminates cutting vibration, guarantees uniform wall thickness, and keeps the tolerance within ±0.05mm.

Based on the machining requirements of core brake components, the following are the CNC turning core tolerance standards for brake components followed by JS Precision:

Brake Component CNC Turning Core Tolerance Standard Table

| Component Name | Diameter Tolerance (mm) | Roundness Tolerance (mm) | Surface Roughness Ra (μm) | Position Tolerance (mm) |

| Caliper Piston | ±0.005 | ≤0.003 | ≤0.4 | ±0.01 |

| Brake Disc Mounting Surface | ±0.01 | ≤0.008 | ≤0.8 | ±0.02 |

| Wheel Hub Flange | ±0.01 | ≤0.006 | ≤0.6 | ±0.015 |

| Caliper Body Hydraulic Passage | ±0.015 | ≤0.01 | ≤1.0 | ±0.02 |

| Brake Master Cylinder Spindle | ±0.003 | ≤0.002 | ≤0.2 | ±0.005 |

These stringent tolerance standards are achieved through the aforementioned anti-deformation process and are the core of precision CNC turning's guarantee of brake component performance.

Want to learn about anti-deformation CNC turning process solutions designed for your brake components? Tell JS Precision about the materials and structure of your components, and our engineers will customize a custom CNC turning brake machining process for you free of charge, mitigating the risk of deformation.

What Does Precision CNC Machining Automotive Mean Under As9100 Standards?

Precision CNC machining automotive refers to a very accurate CNC machining process applied to automobiles. The implementation of the AS9100 aerospace-grade standard entails its requirements being a lot higher than those of regular automotive machining.

The essence is in strict process control and documentation management, which give even greater assurance for brake components.

Documentation and Process Control Beyond ISO

AS9100 stipulates that each and every step of precision CNC machining automotive be documented and auditable. JS Precision completely follows this rule when it comes to the production of brake components, generating detailed machining records so that each piece can be traced.

First Article Inspection and Statistical Process Control (SPC)

JS Precision makes it FAI reporting compulsory in precision CNC machining automotive brake components. During mass production, SPC is employed to continuously monitor key features and thus ensure minimum deviation in accuracy.

Figure 1: An exploded diagram of a car, with various internal and external components separated and color-coded to illustrate the complexity of parts manufactured through precision CNC machining.

Figure 1: An exploded diagram of a car, with various internal and external components separated and color-coded to illustrate the complexity of parts manufactured through precision CNC machining.

Where Does Precision CNC Turning Make The Biggest Difference In Brake Components?

Precision CNC turning is the core process of brake component processing, and its accuracy directly determines the performance of key components such as caliper piston and caliper body. The flexible CNC turning applications can achieve integrated processing of high-performance components.

In, depth Analysis of Key Components: Caliper Piston and Body

The caliper piston with roundness controlled to ≤0.003mm and surface finish measured at Ra ≤0.4μm by precision CNC turning is very important to stay within the proper sealing ring fit.

Using multi-axis technology, caliper body with its complicated hydraulic matchmaking and bridge positions is performing single clamping operation finishing through CNC turning applications ensuring concentrically.

Solutions for High-Performance Demands

To manufacture high-performance racing brake components, JS Precision combines precision CNC turning and CNC milling to machine 7075-T651 aluminum alloy one-piece calipers, producing integrated machining of the hydraulic circuitry and the hollowed, out sections, leading to a weight reduction of 15% and better heat dissipation.

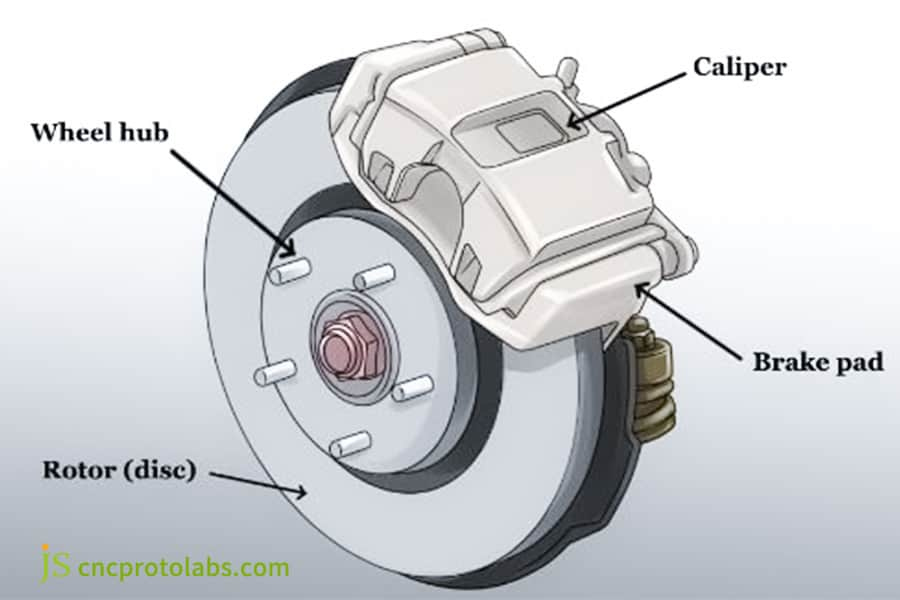

Figure 2: A labeled diagram showing the components of an automotive disc brake system, including the rotor, caliper, brake pad, and wheel hub.

Figure 2: A labeled diagram showing the components of an automotive disc brake system, including the rotor, caliper, brake pad, and wheel hub.

How Can CNC Turning Applications Solve Unique Custom Brake Challenges?

The demand for customized brake components is increasing day by day, and the flexibility and process diversity of CNC turning applications can perfectly solve customization challenges such as small batches and modifications, providing efficient and accurate processing solutions.

Flexibility in Customization and Small Batch Production

Quick changeover between CNC programming is a main benefit to JS Precision. The company can promptly debug programs and start production of a single prototype to hundreds of customized parts at a fraction of the cost, with the same precision as OEM CNC turning parts.

Functional Innovation through Integrated Design

Relying on the combination of turning and milling technology, JS Precision can integrate the separated piston and retaining ring for processing, reducing assembly steps, reducing weight, and completely eliminating the risk of oil leakage.

Rapid Iteration and Testing Verification

JS Precision can rapidly generate CNC programs from the 3D models of the brake components and produce functional prototypes for testing within 72 hours, thus significantly shortening the time to market.

JS Precision Case Study: 18% Weight Reduction & 25% Cost Saving For Eu Motorsport Brake Caliper

Challenge

A prototype of a new one-piece four-piston caliper from a European motorsport brand showed stress concentration and microcracks when tested on a bench. Additionally, the fabrication cost of one unit was $850, which was considered too high. So, they requested technical support from JS Precision.

Solutions

1.DFM Optimization:

JS Precision's engineering team went DFM optimizing the caliper prototype's design when they got involved. Through usage of topology load analysis software, and while still ensuring the rigidity of the caliper's key stress areas, we made a lightweight hollow design for non-load-bearing areas.

Also, we regulated the turning radius of the internal oil passages by changing the corners from right angles to rounded ones thus, reducing the resistance of the fluid and stress concentration at the same time.

2.Process Innovation:

Composite CNC turning developed from five axis milling and turning was employed instead of traditional multi-process machining.This not only assures the positional accuracy of all oil passages and the mounting surfaces of the caliper but also, avoids errors due to the change of multiple clamping operations.

TiCN-coated carbide tools were also chosen along with cutting parameters being adjusted to enhance the turning efficiency of the 7075-T651 aluminum alloy.

3.Supply Chain Optimization:

We advised and certified the use of aerospace-grade aluminum alloy materials with performance comparable to that of the customers original imported materials but with lower procurement costs, and that is how the customer cut down on material costs.

Results

The caliper was optimized for a weight reduction of 18%. A decrease in stiffness was not allowed so the caliper was able to withstand a pressure of 100, 000 pulses without failure.

Furthermore, the unit cost of a caliper was brought down to $637 (a 25% reduction), and the time from design freeze to first sample delivery was only 4 weeks. In short, the customer was able to get racing certification and start mass production with the help of these initiatives.

Want to achieve both weight reduction and cost reduction in your brake components? Contact JS Precision's engineering team now, submit your component design, and receive free DFM optimization analysis to accurately calculate weight reduction and cost reduction potential.

Figure 3: A close-up of a high-performance monobloc brake caliper marked "PERFORMANCE MACHINE" and "RACE SERIES", used in motorsport applications.

Figure 3: A close-up of a high-performance monobloc brake caliper marked "PERFORMANCE MACHINE" and "RACE SERIES", used in motorsport applications.

What Should You Look For In a Precision CNC Turning Company For Automotive Parts?

Finding the most suitable precision CNC turning company plays a significant role in ensuring that the high-performance brake components meet the expected standard, their expertise, advanced equipment, and engineering support will ultimately dictate whether the project will be a success or a failure.

Essential Qualifications and Industry Experience

A reputable precision CNC turning company should have IATF 16949:2016 certification, case studies of brake component production that can be verified, and professional knowledge of processing various materials, thus allowing them to match the best materials and processes.

Technical Capabilities List

- Equipment: Should have a milling and turning center with Y axis and B axis plus an online inspection system.

- Process: Should be able to machine difficult-to-machine materials and have a specific CNC turning process parameter library for brake components, which can handle issues like deformation and complex hydraulic systems.

Engineering Support and Collaboration Capabilities

Leading CNC turning process suppliers will give a DFM report without being asked. JS Precision will give design change recommendations after 24 hours upon receipt of drawings, thus decreasing the difficulty and cost of precision CNC turning.

Want to obtain an accurate screening list of precision CNC turning company and quickly find suitable CNC turning process suppliers? Contact JS Precision now and mention "screening list" to receive it for free, plus one-on-one selection guidance.

FAQs

Q1: What are the common materials used in CNC machining for brake calipers?

The main materials for CNC machining brake calipers are high-strength aluminum alloys, largely 6061-T6 and 7075-T651. 6061-T6 offers a better balance of properties and is more machinable, while 7075-T651 has higher strength and is qualified for high-performance racing calipers.

Q2: What are the limits of deviation normally allowed for high-precision brake pistons?

The diameter tolerance of high-precision brake pistons needs to be within ±0.01mm, and the roundness specification should be ≤0.005mm to be perfectly compatible with the sealing ring and to avoid brake fluid leaking.

Q3: Is it possible to use CNC turning for the production of brake discs?

The brake disc base is of casting. CNC turning is a method for the finishing operations only, in which the friction surfaces and mounting surfaces are machined so that the face runout is ≤0.05mm thus braking stability is improved.

Q4: Is it necessary to meet certain minimum order quantities (MOQ) if ordering small batches of custom brake parts?

JS Precision promotes flexible manufacturing. There is no such strict high MOQ for small batch custom brake parts. We are capable of custom processing from a single prototype up to hundreds of pieces.

Q5: What is the typical delivery time from drawings to samples?

Usually, the initial sample for moderately complex brake components can be sent after 2-4 weeks from drawing and process confirmation. The delivery time for complicated integrated calipers will be changed according to the design.

Q6: How do you ensure consistency in mass production?

JS Precision can secure the quality of mass production by stabilized and standardized operations, SPC and process control, and full inspection of key dimensions, along with a process parameter library.

Q7: Can you provide material certifications and mechanical performance test reports?

Yes, material certifications from original manufacturers are provided for all brake components. At the same time, third-party mechanical performance test reports can be made available to customers upon request.

Q8: What is the process if my design needs modification to facilitate manufacturing?

JS Precision will issue a Design FM report within 24 hours after receiving the drawings, which will include an outline of design optimization suggestions and the impact on cost and performance, thereby enabling customers to make the process adjustments accordingly.

Summary

Safety and performance are the first to be considered when it comes to automotive braking.We can say that the OEM CNC turning parts highly contribute to the development of superlative braking systems.

At the same time, the precision CNC machining automotive processes guarantee the highest quality of parts.A professional precision CNC turning company even through a combination of design optimization, cost reduction, and weight reduction approach can achieve the desired results.

JS Precision, as a professional CNC turning process supplier, is your reliable partner for creating high-performance brake components with professional processes, complete qualifications, and rich case studies.

Don't hesitate to send your brake component drawings or requirements to JS Precision. Our engineering team will give you technical analysis, process solutions, and quotations in 24 hours to help you develop safer and more efficient brake components.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com