OEM CNC turning in the manufacturing division of labor is a primary process for making rotary components such as shafts, sleeves, and flanges. Precision, efficiency, and consistency make the process an important supporting function for original equipment manufacturers in innovation and the marketplace.

However, to cope with the challenges of the entire process, from prototype to mass production, are you seeking a trustworthy partner who not only offers you highly developed turning technology, including in-depth knowledge of the intention of the design, as well as the manufacturability (DFM) process, but also provides one-stop, customized solutions from material to end product?

This article will offer a comprehensive insights brief on the entire custom OEM turning process from Core Capabilities – Material Science – Machine Tools to Quality Assurance Systems to learn how you can integrate your designs through partnering with the leader like JS Precision to make qualitative & affordable custom CNC turning parts with the fastest time to market.

Key Answer Summary

| Decision Dimensions | Common Challenges | JS Precision's Integrated Value |

| Technology and Capabilities | Concerns about complex parts requiring multiple clamping operations affecting accuracy and efficiency, uncertainty about how to match the most suitable machine tool. | We offer complete solutions from simple lathes to multi-axis milling and turning centers, enabling complex OEM CNC turning parts to be completed in a single setup, ensuring precision and efficiency. |

| Materials and Costs | Limited or expensive material selection, difficulty in maintaining consistency during mass production. | We support a wide range of materials, from aluminum alloys to high-temperature alloys, and ensure batch consistency in OEM CNC turning machining and control total costs through rigorous process control and SPC statistics. |

| Technology and Capabilities | Lengthy and opaque quotation processes, slow supplier response and lack of engineering support. | We provide a digital, real-time quotation process and dedicated engineers for in-depth DFM collaboration, offering truly one-stop OEM CNC turning services that are transparent and efficient. |

Key Takeaways

- The essence of truth lies in the system: A uniform consistency of batches in the process, rather than simply superior machine tool performance, demands process control and SPC.

- DFM is a lever between cost and cycle: Collaboration between engineering and the manufacturer at a very early stage greatly reduces costs for custom CNC turning parts.

- Comprehensive advantage of one-stop service: When a customer chooses a supplier such as JS Precision, which has the capability of OEM large CNC turning services, it becomes easier for the customer's supply chain management because there will be a smooth transition from prototyping to production.

JS Precision's Experience: Precision Control Of OEM CNC Turning

As a professional producer that has accumulated 15 years of experience in the CNC turning industry, JS Precision has become a trusted partner in the OEM CNC turning market, accumulating over 5,000 successful cases and cooperating with premium clients from more than 30 countries around the world.

We have a total of 28 premium milling and turning centers, with 12 of these machines having five-axis functions. Equipped with a complete set of inspection equipment including coordinate measuring machines and roundness testers, we can reliably handle parts with diameters ranging from 0.5mm to 500mm.

On the healthcare side, we are able to provide the medical industry with ultra-high precision titanium alloy components for implant customers with a tolerance level of ±0.005mm.

On the aerospace side, we are able to ensure the dimensional stability of 100,000 aluminum alloy structural components with an SPC system and a defective level below 0.03%, meeting all the requirements of the aerospace quality management system standard AS9100.

The figures above represent our effort to get into the details of the process, from analyzing the material spectral composition to monitoring the process and finally inspecting the product dimensionally before it is shipped out.

Our comparative edge is not only our equipment and technology but also our engineering team’s Design for Manufacturing abilities. Our engineering staff, with an average experience level of over 8 years, are also capable of assessing improvement options during the quoting phase.

We have enabled a customer from the automotive sector cut production costs for custom CNC turned parts by a considerable 35% and deliver them 40% earlier.

Want to ensure your OEM CNC turning project avoids risks and achieves precise implementation? Contact JS Precision's sales team now, tell them your part requirements, and you'll receive a free, customized DFM analysis report and cost optimization plan.

OEM CNC Turning: Precision Manufacturing From Drawings To Batch Production

CNC turning is a mature technological field, hence OEM CNC turning is a prime outsourcing option for manufacturing, as it turns abstract ideas into real precision parts.

As for OEM partnerships, OEM CNC turning is a type of service that involves experienced manufacturers with CNC lathes for precision turning according to a complete set of technical specifications from the client.

It goes beyond processing based on supplied drawings to a very intense level of manufacturing outsourcing.

This is because the manufacturing company takes complete responsibility from process planning, programming, machining, to ensuring that the parts delivered on time are qualified, thereby giving its OEM clients time to concentrate on designs and markets.

The primary value for this service lies in translating the design intent of the client into thousands of identical precision components. Regardless of the type of project, involving prototype verification to mass production delivery, the OEM CNC turning services strike a balance between quality and efficiency.

What Metals Can Your OEM CNC Turning Project Utilize?

The performance starting point of OEM CNC turning parts begins with the material, and selecting the right material can greatly improve the performance of the parts. Excellent manufacturers should be able to handle a wide range of material systems to meet different application needs.

JS Precision's material systems are depicted in the table shown below:

| Material Category | Representative Model | Core Advantages | Typical Applications |

| Aluminum Alloy | 6061, 7075, 2024 | High strength-to-weight ratio, good machinability, corrosion resistance | Aerospace structural components, consumer electronics housings |

| Copper Alloy | Brass, Phosphor Bronze | Excellent electrical conductivity, strong thermal conductivity, good corrosion resistance | Electrical connectors, valve components |

| Stainless Steel | 303, 304, 316, 17-4PH | Strong corrosion resistance, high strength | Medical equipment, food machinery, marine parts |

| Alloy Steel | 4140, 4340 | High strength after heat treatment, good wear resistance | Heavy machinery, hydraulic components |

| Titanium Alloy | Grade 2, Grade 5 Ti-6Al-4V | Extremely high specific strength, good biocompatibility | Aerospace parts, medical implants |

| High Temperature Alloy | Inconel 718 | High temperature resistance, strong stress resistance | Turbine engines, extreme environment components |

Do not know how to select appropriate material for your application? You can consult JS Precision's material engineering experts about using conditions and requirements. In this way, you can acquire free advice for selecting appropriate material to help you achieve better usage requirements for OEM CNC turning parts performance.

Figure 1: Many types of metals and plastics can be used to produce turning parts.

Can Intricate Parts Be Finished In a Single Setup?

Production of complex OEM CNC turning machining parts has always presented a problem. With traditional multi-clamping, the process is not only inefficient but also error accumulation is a problem. However, with modern multi-axis milling and turning machines, the ability to make complex parts in one setup has become a reality.

Multi-Axis Milling and Turning Technology

Milling and turning centers with facilities such as Y-axis, C-axis, and sometimes B-axis are capable of performing turning, milling, drilling, tapping, eccentric machining, and even beveling in a single operation.

This implies that a component with side holes, slots, or irregular features may not need secondary clamping from blank to finish, thus achieving greatly increased accuracy (positional accuracy is readily safeguarded).

Driving Force: Advanced CAM and Simulation

Complex machining in one setup is not only a matter of hardware but also of advanced programming of CAM software and simulation of the machining process for optimal toolpaths and collision-free machining. It can even predict and eliminate machining deformation, reflecting high requirements in OEM CNC turning machining.

JS Precision, by using simulation technology in CAM, successfully solved the complex part machining challenge for many industries and improved accuracy while gaining great efficiency.

How Batch Precision Is Guaranteed In CNC Turning?

The consistency of the thousands of custom CNC turning parts in mass production could be the first concern for customers, which is considered to be the core value of OEM CNC turning machining. Stability and reliability of batch accuracy are guaranteed in JS Precision by three systematic methods.

Process Control and Statistical Process Control (SPC)

Regular spot checks are conducted on key dimensions during the production process, and data is entered into the SPC system to monitor in real-time whether the process is stable and whether there are any trends of variation. This allows the detection of potential issues prior to producing non-conforming batches of product.

Tool Management and Prediction of Lifespan

By monitoring wear in scientific tools and life management, tools are replaced before diminished performance results in dimensional drift due to wear. This is paramount for dimensional stability.

Standardized Operations and First Article Inspection (FAI)

Checklist and Form First-article inspection is strictly conducted before every lot, and a qualified first article is packaged as a "standard part." At the same time, all operators strictly conform to operating procedures to provide identical processing for each step.

Looking to ensure strong accuracy in a batch of custom CNC turning parts? Let JS Precision recognize your needs with our OEM CNC turning machining service. We will report SPC data findings throughout processing so that you can track the status of quality of processing in real time.

Figure 2: During batch CNC turning, the accuracy is often unsatisfactory.

What Is The Quotation Process For Custom CNC Turning Parts From Quote To Delivery?

A transparent and smooth process will be the best beginning of the cooperation in custom CNC turning parts. JS Precision has created a standardized quotation and production process, so the whole cooperation process will be transparent and controllable.

1.Inquiry: Customers supply the three-dimensional model as well as the two-dimensional views, the materials, tolerance levels, finish requirements, as well as the required quantities of the product ordered.

2. Engineering Review and Design for Manufacturing: The engineers at the manufacturing company carry out an analysis and optimization of the design, including corner optimization and tolerance optimization.

3. Quotation and Confirmation: After considering the reviewed plan, there would be a quotation for the materials, machining, and post-processing, among others. The order is then placed after confirmation between the two parties.

4. Production & Quality Control: Production, programming, material preparation, as well as machining, along with tight control procedures for in-process quality control (IPQC) and final quality control (FQC), take place.

5. Delivery and Support: After the product has been packaged, it will be dispatched in accordance with the delivery system agreed upon, and a comprehensive quality documentation package will also be offered.

Case Study: 30% Cost Savings And Half Delivery Time, Multi Axis Turning And Milling Composite Reshaping Of Hydraulic Valve Core

In the field of OEM CNC turning machining, there is ample value that can be generated by the combination of DFM optimization and technology. The project for a European hydraulic equipment customer’s stainless steel 316 valve core experienced a qualitative jump with JS Precision’s solution.

Challenge: Cost and Quality Bottlenecks Created through Welding Processes

Customer’s original design consisted of two parts: “turned body + welded flange.” In this process, three independent clamping steps were needed, and additional manual welding was involved.

This resulted in a value of 0.08mm for the concentricity variation in the φ20mm inner hole, which willfully met the 0.1mm specifications, with the entire production process taking almost a week from the four-week production cycle devoted to the process of welding and straightening, apart from adding to the material wastage and the manufacturing cost, which could be up to $85 per product.

Solution: Integrated Design and Multi-Axis Forming Technology

JS Precision engineers introduced an innovative solution for the Design for Manufacturing Concept (DFM), which considered the stress and fluids properties of the part simultaneously. The core goals for optimizing the design are:

- Structural Integration: Integrating the two-piece combination of "turning body + welding flange" into one structure so as to eliminate the problem of quality at the point of welding.

- Process Adaptation: Based on the multi-axis advantages of local advanced milling/turning machines through the optimization of the machining path for the operations.

- Flow Channel Optimization: Modification of the S-shaped flow channel from a segmented type to a continuous smooth surface.

By virtue of this design optimization, the final product is capable of undergoing milling directly through the accurate linkage between the Y-axis and the C-axis of the machine, thus eliminating all welding procedures with subsequent straightening.

Results

- Cost Reduction 30%: Save all welding, secondary clamping, and straightening costs. Improve material utilization by 15%. Unit cost is reduced to $59.5.

- 50% Lead Time Reduction: Compressing this production process in a short time, 4 weeks to 14 days, with machining time of only 32 hours.

- Value Added Quality Improvement: One-piece molding guarantees the stability of concentricity within 0.03mm, which reduces the pressure loss of a flow channel by 12% and prolongs the product life for more than 30%.

Want to save cost and enhance efficiency for your project of custom CNC turning parts? Check out the complete case library by JS Precision or contact us to share your pain points of the project to get a customized optimization solution.

Figure 3: 316 Stainless Steel Turning and Milling Processing CNC Machining Valve Core

Selecting The Right Partner: A Guide To Premium OEM CNC Turning Services

Choosing the right OEM CNC turning services, especially for OEM large CNC turning services, directly impacts the success of your project. Based on these three core dimensions, the selection of a partner can be done.

Assessing Technical Capabilities and Production Capacity

Analyze the list of machine tools that they have (machine tools for multi-axis milling and turning centers, large lathes), as well as testing equipment (coordinate-measuring machine and roundness tester). In cases involving high volumes, look into flexibility regarding production capacities and their ability to unload and load products automatically for a steady supply.

JS Precision has a production workshop with a size of 5,000 square meters, with a maximum annual production capacity of 2 million pieces, serving the demands for OEM large CNC turning.

Review Quality System and Engineering Support

Request to examine their quality certification (ISO 9001, IATF 16949) and quality control process documentations. More importantly, it needs to be evaluated whether their engineering group is equipped with proactive Design For Manufacturability analysis tools to offer expert advice on the improvement of the product cost during the quotation process.

Validate the SCM and Project Management

A reliable supplier must have a stable raw material supply chain, as well as established project management processes and communication methods (e.g., project managers, tracking tools on the Internet) which are imperative for the management of OEM large CNC turning services projects.

Looking for high-quality OEM CNC turning services? Fill out JS Precision's cooperation consultation form, noting your project scale and requirements. We will assign a dedicated person to provide you with customized solutions.

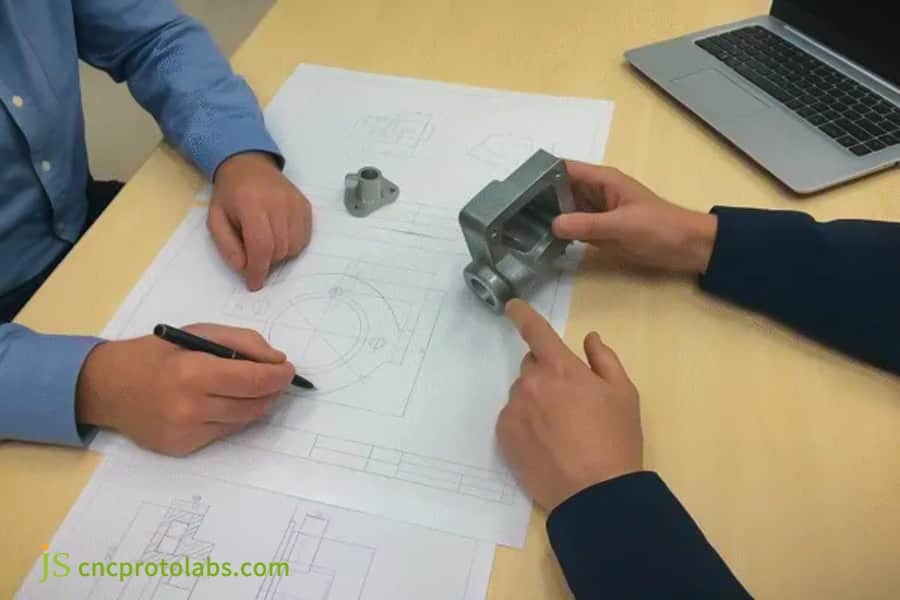

Figure 4: A professional CNC machining company should have strict quality control, clear communication, and profound material expertise.

FAQs

Q1: What is the largest turning part size you can process?

Large turned parts by OEM large CNC turning services at our company can be up to 500mm in diameter, and 1500mm in length. Material hardness and part structure may affect the size limit slightly. You can provide drawings for a precise assessment.

Q2: What surface roughness can you achieve?

In the case of standard precision turning processes, the surface roughness of our OEM CNC turning parts can be as good as Ra 0.8μm. Where high precision is required, subsequent processes like grinding can improve this to Ra 0.2μm or better to meet the requirements of most high-end applications.

Q3: What is the least tolerance you can ensure?

For standard OEM CNC turning machining projects, we can consistently guarantee a tolerance of ±0.01mm. While in the temperature-controlled workshop with some special processes, some precision parts can achieve ultra-high tolerance control at ±0.005mm.

Q4: How long does it usually take to get a quote?

For general questions regarding custom CNC turning parts with detailed drawings and requirements, we can usually provide you with a quote in 24 hours. However, if there are complex parts or special processes involved in manufacturing, we may require 48 hours to perform DFM analysis in order to provide you with an accurate quote.

Q5: Have you considered how you accomplish color matching in production (e.g., anodize)?

We employ standardized process tanks for our surface treatments, like anodizing. In production, color difference comparisons and film thickness verifications are periodically carried out, and samples of each production batch are stored to ensure that OEM CNC turned parts manufactured through mass production possess a consistent color and film thickness.

Q6: What is the difference in the sample price and mass production price?

There is a substantial price spread between the sample stage and mass production, primarily because the sample stage involves the amortization of one-time expenses such as the cost of fixture manufacture and programming. Such expenses are spread over mass production, which can result in a unit cost 30% to 60% lower than the sample cost, depending on the size of the batch produced.

Q7: What procedures do you have for incoming material quality control?

All the incoming raw material needs a material certificate. For the CNC turned parts for OEM projects, we undertake a spectral test as well as a mechanical property test for the raw material to ensure that the material has the correct material type and mechanical properties.

Q8: How are delivery delays considered?

We keep track of the production process through our ERP system in real time. As soon as the possibility of a delivery delay occurs, we inform the customer accordingly. When the delay is from our side, we will provide corresponding compensation according to the contract agreement.

Summary

In today's ever more competitive global market, selecting a qualified OEM CNC turning services partner is, in essence, a matter of selecting a business ally that can enhance engineering capacity, secure the value chain, as well as determine overall cost of ownership, which plays a critical role for product success.

JS Precision, as a precise manufacturing expert, adhering to the Chinese culture and benefiting the whole world, has a complete set of advanced equipment and technology from precise turning to OEM large CNC turning servises.

By having transparent processes, extensive engineering engagement, and a strong adherence to quality, we are assured that all custom CNC turning parts meet your specific expectations.

Take action now and experience the power of professional collaboration:

Upload your part drawings to the JS Precision website and not only will you instantly receive a quotation, but you’ll also have a chance to participate in a fruitful Design for Components (DFC) process with our team of experienced engineers to discuss the best way to optimize the design. We can turn your visions into a source of a competitive advantage in the market.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com