CNC turning services represent the very essence of the process by which precise rotating components are translated from design drawings to actual physical components.

In the realm of modern manufacturing, where efficiency and reliability are the highest goals, the quality of these components is the very benchmark by which the performance ceilings of a given product can be measured.

From implantable components with tolerances measured in millimeters to high-speed rotating sensor enclosures in new energy vehicles, these components have broad applicability to several high-end manufacturing fields.

This article will delve into an in-depth analysis of the entire value chain associated with precise turning components and reveal the means by which precise solutions that combine high accuracy with reliability can be efficiently obtained through professional customization services.

Core Answer Summary

| Key Considerations | Key Considerations | JS Precision Core Value |

| Understanding Service Value | Process Principles, Core Advantages, and the Necessity of Outsourcing. | Professional CNC turning services unlock customer productivity and provide technical expert support. |

| Achieving Custom Design | Seamless collaboration from design to production and the ability to process complex features. | Seamless integration with the customization process, providing DFM analysis to overcome the challenges of custom precision CNC turning parts. |

| Ensuring Long-Term Reliability | Materials science, protective surface treatment processes, and total lifecycle cost. | Significantly extending part life and reliability through collaborative design and specialized processes. |

| Advantages of Large-Scale Production | Advanced equipment clusters, standardized quality control systems, supply chain and cost control. | Large factories provide superior capacity, consistency, cost advantages, and delivery guarantees. |

Key Takeaways

- Professional outsourcing of CNC turning services is the best strategy for obtaining precision and cost-effective parts without investing heavily in assets.

- Protective precision CNC turning is the key to increasing the lifespan of parts under harsh working conditions and effectively reducing total maintenance costs.

- Selecting a large CNC turning services factory ensures the quality, cost, and delivery advantages of large-scale orders.

- Utilize CNC turning online quote system to quickly evaluate the feasibility of the project, which is the first step to initiating efficient collaboration.

Why Trust This Article? Because Of JS Precision's Experience In CNC Turning Services

JS Precision has 20 years of in-depth experience in the CNC turning industry, with a focus on technological innovation and service optimization in the CNC turning services sector.

We have served more than 500 premium clients worldwide, including major sectors like aerospace, medical, and new energy, and have completed more than 10,000 customized precision parts orders with a remarkably high passing rate of over 99.8% for ultra-complex parts.

Our R&D team includes more than 50 top engineers, with key members having over 15 years of experience in the industry and having developed several high-precision parts machining standards.

Our production workshop is equipped with more than 120 top-of-the-line CNC lathes and milling machines, including top international brands like DMG MORI and Mazak, to support full-scale production from prototype to mass production of millions of units.

The authoritative certifications are an important endorsement of our capabilities. Our company, JS Precision, is certified for the ISO 9001:2015 Quality Management System and AS9100 Aerospace Quality Management System and meets the FDA medical device manufacturing standards.

We have adopted the quality control measures for the entire manufacturing process in accordance with the ISO 13485:2016 Medical Device Quality Management System standard.

If you are looking for a reliable CNC turning services partner, contact a JS Precision technical consultant immediately. Tell them your part requirements to receive a free customized machining solution and cost assessment, allowing our professional team to help you mitigate production risks.

What Are CNC Turning Services And Why Are They Critical For Modern Manufacturing?

CNC turning is a core process in modern manufacturing, and CNC turning services provide efficient and accurate part processing solutions for various industries. Precision CNC turning services can meet various stringent quality requirements.

Definition and Core Advantages

CNC turning is a machining process using rotating workpieces and tool feeds to remove materials. Its fundamental advantages are:

- High Precision: Dimensional tolerance ±0.005mm, roundness error ≤0.0025mm.

- High Consistency: Standardizing the process to minimize errors in batch parts.

- Complex Machining: Can process multi-start threads, curved surface contours, etc.

- High Efficiency: Automation greatly improves production efficiency.

Typical Application Industries and Scenarios

CNC turning services cover many high-end industries, such as: aerospace high-strength fasteners,medical device implant interfaces,automotive engine sensor housings,new energy motor shafts, etc.

Why Choose Professional Services Instead of Building Your Own Capacity?

There are many benefits associated with using the professional CNC turning services provided by JS Precision, which include saving millions of dollars on investment and training, saving over 30% on product time-to-market, ensuring product quality through our mature system, and allowing clients to focus on their own business.

How Can You Navigate The Custom Precision CNC Turning Parts Process?

Customization is an important need in the present-day manufacturing process. Custom precision CNC turning parts services provide such customization, and JS Precision provides end-to-end customization services.

Customization Process from Design to Finished Product

- Requirements Analysis: Analysis of the functionality, performance, and usage of the parts.

- DFM Collaboration: Providing design inputs, optimizing design, and simplifying the process.

- Process Planning: Creating the best solution, including equipment and process parameters.

- Programming and Prototyping: Creating programs and prototypes, followed by prototype testing.

- Mass Production: Mass production after sample approval and process quality checks.

How to Prepare Technical Drawings and Specifications

Technical documentation is required, including key specifications such as key dimensions, tolerances, geometric tolerances, surface roughness, and material specifications.

Common Customization Requirement Examples

JS Precision provides complex custom precision CNC turning parts requirements, including requirements such as multiple start threads with pitch accuracy within ±0.003mm, ultra-thin walls with wall thickness less than 0.5mm, difficult-to-machine materials such as Inconel, composite machining involving milling and turning, and high cleanliness requirements for medical applications.

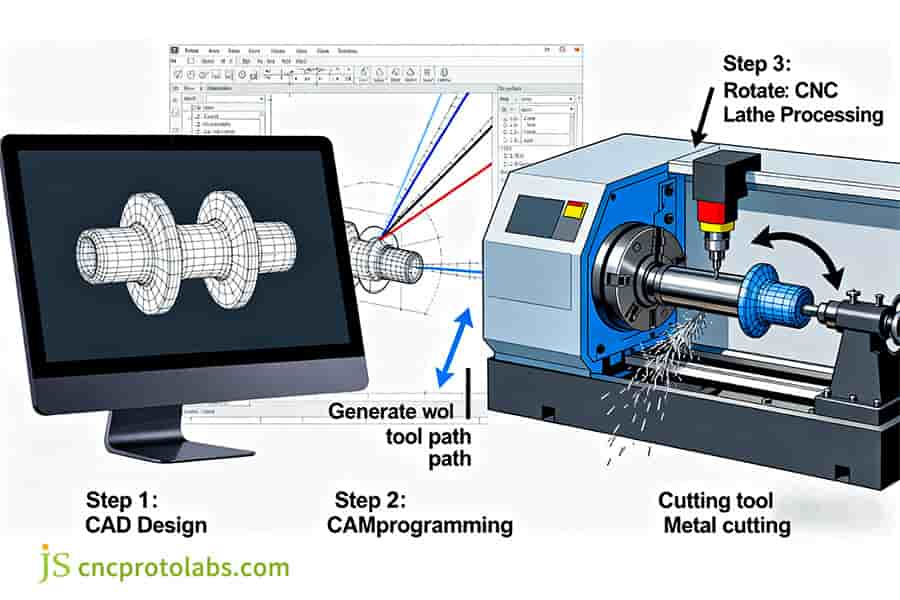

Figure 1 The Integrated CAD Workflow. Modern precision manufacturing relies on this digital thread, from 3D model design to automated toolpath generation and final machining.

Figure 1 The Integrated CAD Workflow. Modern precision manufacturing relies on this digital thread, from 3D model design to automated toolpath generation and final machining.

How Does Protective Precision CNC Turning Ensure Part Longevity?

Under severe working conditions, protective precision CNC turning ensures the lifespan of parts by using special processes and surface treatment.

Specific Technologies of Protective Machining

The specific technologies for protective precision CNC turning are: passivation treatment for enhanced corrosion resistance, nitriding treatment for enhanced hardness (HV 1000+), PVD coating for enhanced wear resistance and lubricity (HV 2000+), electropolishing, and Teflon coating to meet the needs of special industries.

Synergistic Effect of Material Selection and Surface Treatment

The performance of protective machining depends on the synergistic effect of materials and surface treatment. The following are examples:

| Application Scenarios | Substrate Selection | Surface Treatment Process | Protective Effect | Service Life Extension |

| Marine Equipment | 316L Stainless Steel | Passivation Treatment | Salt Spray Corrosion Resistance | 3+ times |

| Construction Machinery | Powder Metallurgy Steel | PVD Coating | Enhanced Wear Resistance | 4+ times |

| Medical Devices | Ti-6Al-4V Titanium Alloy | Electropolishing | Improved Biocompatibility | 2 times |

| High-Temperature Environments | Inconel 718 | Nitriding Treatment | High-Temperature Oxidation Resistance | 3 times |

Case Study: Protective Coatings Reduce Maintenance Costs by 30% on Hydraulic System Maintenance

Challenge: A construction machinery company's customer had hydraulic valve cores made of 42CrMo steel. The performance of the hydraulic valve cores had been compromised due to wear and tear after an average of 300 hours. The maintenance cost was as high as $150,000 per year.

JS Precision Solutions:

1. Material Upgrade: Changing the original material 42CrMo steel to a powder metallurgy steel, which is more wear- resistant and therefore improves the intrinsic performance of the substrate.

2. Protective Precision CNC Turning: Precision CNC turning of the dimensioned parts and then applying low, temperature PVD coating technology to deposit a high-hardness wear-resistant coating on the surface of the precision, turned parts.

3. Precision Guarantee: Use of precision testing instruments to ensure that the parts' accuracy is strictly controlled within 0.005mm after coating, as per the drawing requirements.

Results: The improved hydraulic valve core has an MTBF that has been surpassed 1200 hours, hence the maintenance costs have been reduced by 30%, and the equipment reliability and production efficiency have been increased by 25%.

If your parts face challenges related to wear resistance, corrosion resistance, or other protection issues, consider JS Precision's protective precision CNC turning service. Submit your part's operating conditions and requirements to receive a free, customized protection solution, extending part lifespan and reducing maintenance costs.

Figure 2 High precision hydraulic valve core

Figure 2 High precision hydraulic valve core

Why Does Choosing a Large CNC Turning Services Factory Matter?

Choosing a large CNC turning services factory is the key to ensuring stable supply and high quality. JS Precision possesses robust core competencies in large, scale manufacturing.

Large Capacity and Fast Delivery Capabilities

JS Precision houses more than 120 high-tech CNC machines such as 40% multi-axis composite machines. Automated production lines have 50% capacity increase, which means they can ship millions of components weekly and deliver prototypes within 3-5 working days.

Advanced Equipment and Standardized Quality Control System

By DMG MORI, Mazak, and robotic machines, standardized CNC turning process documents have been set up. SPC (Statistical Process Control) quality inspection is used at every step to ensure 100% first-piece acceptance and a batch defect rate of 0.2%.

How Big Factories Provide Better Costs and Stability

Group purchasing obtains a saving of 10%-15%, automation cuts down labor costs by 20%-30%, and a full process library diminishes trial, and, error losses. Besides, a well, developed supply chain guarantees a stable component supply.

Require large volume precision parts machining? By choosing JS Precision, a large CNC turning services factory, and providing us with your order quantity and requirements, you can get a more competitive price and ensure a stable supply, which will make your production plan more controllable.

Figure 3 A reliable precision CNC machining factory will establish strict quality control processes to ensure that every part produced meets or even exceeds customer expectations.

Figure 3 A reliable precision CNC machining factory will establish strict quality control processes to ensure that every part produced meets or even exceeds customer expectations.

What Materials Are Best For High-Strength Custom Precision CNC Turning Parts?

The performance of custom precision CNC turning parts largely depends on the material used. For high, strength parts that also consider factors like strength, toughness, corrosion resistance, and machinability, the choice of material is particularly crucial.

Here are some materials with properties that can be used to make high-strength custom precision CNC turning parts:

| Material Type | Represen-tative Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Yield Strength (MPa) | Main Advantages | Applicable Industries | Processing Difficulty |

| Titanium Alloy | Ti-6Al-4V | 900-1100 | 830-950 | 30-36 | High strength-to-weight ratio, good biocompatibility | Aerospace, Medical | Medium |

| Precipitation Hardening Stainless Steel | 17-4 PH | 860-1310 | 720-1180 | 30-45 | Heat-treatable, balanced corrosion resistance | Medical devices, Automotive | Lower |

| High Temperature Alloy | Inconel 718 | 1240-1400 | 1030-1240 | 40-45 | Maintains high strength under extreme temperatures | Aerospace, Energy | Higher |

| High Strength Aluminum Alloy | 7075 | 500-570 | 430-500 | 15-19 | Lightweight, good processing performance | Automotive, Electronics | Lower |

| Alloy Structural Steel | 42CrMo | 930-1080 | 780-900 | 28-32 | Good overall mechanical properties, moderate price. | General machinery and engineering machinery. | Medium grade. |

| Tool steel | H13 | 1800-2000 | 1600-1800 | 48-52 | High hardness, excellent wear resistance. | Molds and cutting tools. | High grade. |

JS Precision has extensive experience in processing high-strength materials and can provide the best material selection and processing technology combination recommendations based on your application scenarios and performance requirements.

How Are Vibrations Controlled In The CNC Turning Process For Flawless Surfaces?

Vibration is the main factor affecting surface smoothness and machining accuracy in the CNC turning process, especially for high-precision part machining. Effective vibration control is crucial. At JS Precision, it is ensured that the machining process is stable and accurate through multi-dimensional technical means.

Vibration Control Strategies:

1. Process Optimization: Experienced engineers use validated cutting parameters based on the characteristics of materials and structures of machined parts to avoid "chatter" phenomena that occur during machining.

2. Dynamic Stability Technology: The use of high-end machine tools with active damping systems or hydrostatic guideways makes it possible to identify and eliminate machine vibration during machining, thus increasing the rigidity of machine tools.

3. Tool and Fixture Strategy: The use of vibration-damping tool holders makes it possible to avoid tool vibration, meanwhile, it is possible to shorten the overhang length of the workpiece by designing workpiece fixtures with optimal rigidity.

4. Real-time Monitoring and Adjustment: The machining process is monitored in real time with vibration sensors. Once abnormal vibration is detected, parameters are adjusted to ensure machining stability.

With the above exhaustive steps, we are able to produce the mirror finish turned surfaces with Ra values less than 0.4μm in the CNC turning operation. The accuracy in the machining process meets the international standards for high-end manufacturing, as defined in the ISO 2808 standard for surface roughness.

Want perfect surface quality for your parts? Choose JS Precision's precision CNC turning services, tell us your surface roughness requirements, and we can optimize the CNC turning process to provide you with high-precision, high-surface-quality part machining services.

Figure 4 Dampers can absorb vibrations and eliminate vibrations, thereby achieving higher machining accuracy, better surface smoothness, and higher metal removal rates at critical machining depths.

Figure 4 Dampers can absorb vibrations and eliminate vibrations, thereby achieving higher machining accuracy, better surface smoothness, and higher metal removal rates at critical machining depths.

How Can You Get An Instant CNC Turning Online Quote Efficiently?

CNC turning online quote plays an important role in the efficiency of project evaluation. JS Precision simplifies the process and helps to quickly obtain CNC turning part quotes.

Online Quotation System User Guide:

- Log in to our online quotation system. No registration is required.

- Upload your 3D model in STEP or IGES format, or a 2D drawing.

- Enter your requirements, including materials, quantity, and finishing.

Key Factors Affecting Quotation:

Material cost and processability, part complexity and accuracy, order batch size, and post-processing process requirements.

How to Ensure Quotation Accuracy and Subsequent Communication:

Ensure that you are providing us with accurate drawings, communicating clearly about your requirements, including the finishing, and marking the order requirements. For complex projects, we will assess your requirements to ensure that there are no surprises.

Want to quickly get your CNC turning part quotes? Use JS Precision's CNC turning online quote system now. Upload your part drawings and requirements, and get a preliminary quote within minutes. Professional engineers will also provide cost optimization suggestions.

FAQs

Q1: What is the highest precision that CNC turning can achieve?

JS Precision uses high-end machines and precise techniques for machining. During the CNC turning process, accuracy is achieved within ±0.005mm, and roundness is achieved within 0.0025mm, thus fully satisfying the requirements of precision engineering applications.

Q2: What is your minimum order quantity (MOQ)?

At JS Precision, we are capable of serving all kinds of order quantity requirements, i.e., from one prototype piece to millions of pieces. There is no such restriction or limitation on the MOQ, thus fully satisfying all requirements at every stage of the product development process.

Q3: What is the typical lead time from quotation to delivery?

Delivery time is variable based on the type and quantity of the order. Delivery time for prototype pieces is as low as 3-5 business days, whereas for mass production, the delivery time is 2-6 weeks based on the quantity required.

Q4: How do you handle deformation of thin-walled parts during machining?

In order to solve the problem of deformation of thin-walled parts in the machining process, special fixtures are designed, and a step-by-step cutting process is adopted to reduce thermal deformation.

Q5: Can you provide mill-turn machining?

Yes, since JS Precision is equipped with a multi-axis milling and turning machine, it is able to perform all or almost all of the machining of custom precision CNC turning parts in a single operation, thus avoiding clamping errors and increasing machining accuracy of custom precision CNC turning parts.

Q6: What level of surface roughness can typically be achieved?

The conventional finish turning process is able to achieve a surface roughness of 0.8-1.6μm, whereas through optimized precision turning and polishing techniques, it is possible to achieve a mirror-like finish with a surface roughness of 0.2μm or less.

Q7: If my design may have manufacturability issues, can you provide advice?

Of course, since JS Precision also provides free DFM (Design for Manufacturability) analysis, which enables us to optimize the design of custom precision CNC turning parts, thus reducing machining costs and increasing product reliability.

Q8: How accurate are the instant online quotes?

The quotes given after acquiring clear drawings and complete technical specifications are very precise because complex components are immediately analyzed and verified by our experienced engineers to ensure that the CNC turning part quotes are correct with no hidden charges involved.

Summary

CNC turning services are the answer to linking precise design with high-performance products. The right expert is essential to linking precision, efficiency, and economy.

JS Precision, as a leading manufacturing solution provider, deeply integrates advanced CNC turning process knowledge, scalable production capabilities, and customer-centric services. Our new easy-to-use online quote system, CNC turning online quote, is intended to help you get started on projects efficiently and bring your ideas to market quickly.

Take Action Now: Upload your part drawings, get accurate CNC turning part quotes, and let JS Precision's expert team be your link to success with your next project.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com