CNC turning services are the basis of manufacturing rotationally symmetrical parts by shaping. It is not, however, the question of "whether it can be turned," but of flawless deliverability by means of "on-demand precision" and "zero defects."

When it comes to interpreting a design drawing and then forming lathe instructions, every process from programming strategy and multi-axis cooperation to material and quality closed loop is what makes or breaks the final part.

This article aims to take the global best practices for manufacturing as a yardstick to show how a professional CNC turning shop is making difficult customized CNC turning requirements into reality and analyze why the best manufacturing abilities in China have become a strategic alternative for global clients.

Core Answer Table

| Technical Aspects | Traditional Challenges | JS Precision's Solution |

| Design and Programming | The role of design intent reduces during transformation and is based on personal experience. | Digital twins and CAM simulation allow non-destructive transformation of designs from optimized CNC turning. |

| Complex Part Machining | Conventional lathes do not support features that are off-set, meaning these need secondary support. | CNC turning machining centers supporting multiple axes (milling/drilling) will provide a single-step processing of these features. |

| Quality Assurance | Relying on final sampling, defect detection lags behind. | The "online measurement real-time compensation" closed-loop system achieves process control and zero defect goals, ensuring the product quality of CNC turning shop. |

Key Takeaways:

- Digital Thread represents accuracy, lossless transfer from design to G-code is essential.

- Multi-axis turning machines with milling operations integrated are efficiency multipliers for turning complex rotary parts with eccentrics, holes, planes, and so on.

- Zero defect production requires real-time observation and compensation, and not after the product has been manufactured.

- Having a professional materials library and surface treatment system is closely related to the capability level of a CNC turning service provider.

- Automation not only improves the consistency of batches but is also central to minimizing costs.

JS Precision Experience: Implementing CNC Turning Services With On-Demand Precision

JS Precision has been actively engaged with the CNC turning industry for 15 years and has been able to cater to over 5,000 of its clients across 12 major industry verticals.

We were able to perform a customized CNC turning job for a prestigious European car parts manufacturer and reduce their defect rate from 3% all the way down to 0.5%. The importance of process control in ensuring consistency in products is clearly stated in ISO 9001:2015: “Control of process is essential to ensure consistency in products.”

We have processed more than 100,000 kinds of components, from simple bushing to complex high-functionality rotating component machining, from ordinary aluminum and stainless steel to difficult-to-cut titanium and high-temperature Inconel 718 materials, and formed experienced solutions for CNC turning services.

In just last year, we have accomplished more than 3,000 orders of customized CNC turning projects, of which multi-axis CNC turning machining projects occupied 45%, and maintained a customer repurchasing rate of 82%.

The following guide is built on our team's knowledge from many successful machining cases. All advice and strategies contained herein have been tested and true. If you are having issues with your precision, productivity, and/or costs associated with turning on your CNC machines, this guide can definitely help.

Want a customized solution for process optimization? Simply contact our engineers, share with them your part demands and difficulties, and they will provide you with free expert suggestions to reduce the number of detours in the process of CNC turning.

How To Execute Your Precision Blueprint For Customized CNC Turning?

Good CNC turning entails a proper understanding and non-destructive conversion of design intent, this is particularly true for customized CNC turning services. Design elements would have to be precisely applied for the piece to fit assembly specifications flawlessly.

Digital Twin And Virtual Debugging: Everything Before The Cut

We use advanced CAM software to create a "digital twin" of the machining process for comprehensive collision interference inspection, tool life estimation, and cutting force simulation.

This approach can identify potential issues before actual cutting, ensuring the safety and optimality of the program, avoiding workpiece scrap and equipment damage caused by program errors, and ensuring the accuracy of customized CNC turning.

Intelligent Process Database: Optimization beyond Experience

Our system recommends the best cutting parameters such as spindle speed, feed, and depth of cut based on extensive machining data accumulated from thousands of combinations of materials and tools. The parameters are a perfect balance between efficiency and quality, ensuring precise and efficient machining of CNC turning machining processes.

One-Way Door Between Drawings and Programs: Guaranteeing Lossless Information Passage

By using standard procedures for interpretation and modeling of drawings, we provide an assurance that every tolerance and geometric specification is properly translated into machine-code.

This is done under constant review by personnel, and there are no errors introduced by humans. The design blueprints are also replicated 1:1 as physical models through customized CNC turning.

Want your customized CNC Turning Project to be implemented? Submit your part drawings and technical specifications to get a free process feasibility study and quotation to ensure that all your designs are perfectly implemented.

Why Is Multi Axis CNC Turning Machining Capability The Watershed For Complex Parts?

When components become more complex than simple shafts, sleeves, and discs, including eccentrics and curved surfaces, conventional 2-axis turnings turn out to be inefficient. It is at this point that multi-axis CNC turning machining ability emerges as a primary criterion separating common suppliers from experts.

The value of precision thread machining tolerance specified in ASME B1.1-2019, which is also defined by ASME, highlights the significance of multi-axis machining in manufacturing complex features.

Mill-Turning Centers: The Paradigm Shift of Single

With powered turrets and Y-axis and C-axis machining capabilities, CNC turning machining centers have the ability to perforate, groove, tap, and even mill flat without dismantling the part.

This single setup technique will reduce the accumulative error that results from multiple setups necessary for machining the part to zero, thus improving the positional accuracy of the part and the benefits that come with CNC turning machining.

Backside Machining with Automation: Overcoming Secondary Clamping

Turning centers that have sub-spindles have an ability to take control and finish all the features of the other side of the workpiece automatically. This fully automated process of machining is very efficient for products that involve high concentricity on either side and enhance CNC turning efficiency of machine processing.

B-Axis Linkage. For Non-Circular Contours and Continuous Surface

High-end mill turning machines with B-axes are capable of changing angles continuously. It can easily process non circular sections like ellipses, cams, and simple free surfaces. This significantly expands the technical boundaries of CNC turning machining. It is no longer hard to process complicated parts.

How JS Precision's CNC Turning Service Can Handle The Challenges From Aluminum To High-Temperature Alloys

The capabilities of a premium CNC turning service supplier begin with its expertise and command over materials. The nature of different materials is diverse, and their processing also needs to be different.

| Material Type | Representative Material | Challenges in Machining | Solution by Core CNC Turning Servcies |

| Aluminum Alloys | 6061, 7075 | Tendencies to stick in the tool, susceptible to surface scratching | Uses sharp PCD tools, high pressure cooling, optimized high-speed machining parameters. |

| Stainless Steel/Alloy Steel | 304, 316, 4140 | Work hardening, sticking of tool material, poor removal of chips | Use of special tool shape, coating methods, programming of chip-breaking routines. |

| High-Temperature Alloys | Ti-6Al-4V, Inconel 718 | High cutting temperatures, high rates of tool wear | Low speed deep cutting, high-pressure cooling lubrication, specialized wear-resistant coating tool. |

King of Lightweighting: High-Speed Precision Turning of Aluminum Alloys

For aluminum alloys like 6061 and 7075, we use a high-speed turning method. This is made possible through sharp PCD tools, low cutting resistance, quick removal of cutting heat through a high-pressure cooling system, which prevents material adhesion and scratches.

The process results in a very high finish and very high dimensional stability and thus captures all demanding requirements of these sectors and would be one of the major factors for us in CNC turning services.

Rugged Challenge: Stainless Steel & High-Strength Alloy Steel

Machining 304/316 stainless steel and 4140 alloy steels is extremely challenging because of work hardening, tool sticking, and chip removal in CNC turning operations.

We overcome all of these difficulties in machining 304/316 stainless steel and 4140 alloy steels in our CNC turning process using specialized tooling, advanced coatings, and smart chip breaking programming in our CNC machines.

Extreme Applications:Titanium Alloys and Nickel-Based Superalloys

The machining of materials such as Ti-6Al-4V and Inconel 718 is extremely challenging due to high cutting temperatures and deformation of workpieces.

In order to effectively manage cutting heat and prevent deformations of machined workpieces and to demonstrate the expertise of CNC turning services, low-speed and heavy-cut machining processes combined with high pressure cooling and lubrication and special wear-resistant coated cutting tools are utilized.

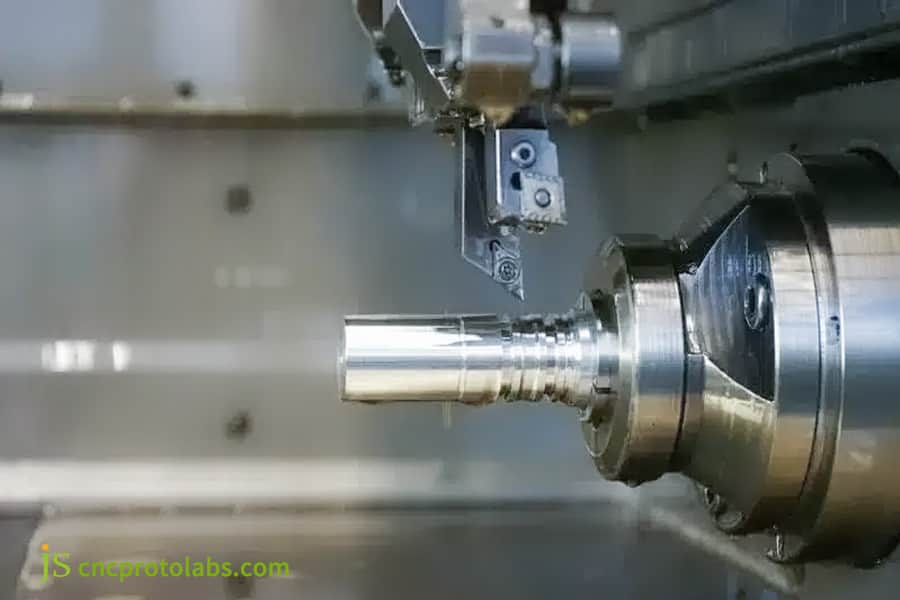

Figure 1 CNC Lathe Machining Aluminum Shaft

Zero Defect Commitment: How Is The Quality Loop Built For a Professional CNC Turning Shop

"Zero Defects" is more than just a motto, but rather an integrated quality culture and system within every cell of JS Precision’s professional CNC turning shop. At JS Precision, we make sure that all parts that are produced are of high quality through end-to-end quality control.

Intermachine Measurement: Real-Time Compensation and First-Article Inspection

Our lathes have integrated high precision probes, which enable us to measure critical dimensions right after or even during production. The system automatically provides feedback on deviation to our control system for compensation, which assures us that the first piece is qualified and prevents scrap production. This is an integral step to have zero defects on our CNC turning shop.

Statistical Process Control, the Basis of Predictive Quality Management

To ensure mass production, we use real-time SPC process monitoring for critical dimensions. Through abnormal trends of process data analyzed using control charts, we can take preventive measures before the production of scrap, ensuring the quality of CNC turning of products.

Full-Dimension Reporting and Traceability

Each order is provided with a comprehensive final inspection report in full dimension using a coordinate measuring machine. At the same time, we link information like material batches, process conditions, machine operators, and testing information, creating complete product traceability, giving you reassurance on the quality of CNC turning shop products.

Do you want to learn more about the quality control details of CNC turning shop?Now you can download our quality control manual in order to learn more about our full process of quality control, starting from material inspection through to delivering a product. Choose a reliable partner.

Figure 2 The true zero defect energy comes from multi-level inspection, which can prevent deviations from occurring at the source.

How Automation Empowers CNC Turning Services To Achieve High Consistency At Scale

Automation is therefore the connecting link between precise single-piece turning and mass production, and it is also the way and means to achieve consistency for the CNC turning service offered by JS Precision. By automation technology, we enhance productivity and assure quality of CNC turning products.

Robot Loading and Unloading: Achieving Unattended Production

Meanwhile, we have incorporated the usage of six-axis robots into our CNC turning service production line, allowing for automatic material loading, automatic unloading and sorting of the products.

However, using the automatic mode ensures 24-hour continuous production, reducing the cost per piece and the potential for human error due to manual control, thus improving the competitiveness of our CNC turning service.

Integrated manufacturing unit: series connection of turning and subsequent processes

We associate turning centers, deburring stations, and cleaning machines with automated tracks, thus creating a manufacturing cell. This way, intermediate steps in the manufacturing process will be reduced to a great extent, with consistent CNC turning results in all processes.

Adaptive Control System: Handling Tool Wear and Material Variations

To be precise, the CNC system adjusts automatically through its precise feed rate control, which is done through the assessment of spindle signals like spindle load. This hence helps to counteract tool wear and changes in hardness in materials to ensure that our CNC turning service is of good quality.

Have a production need for high precision parts on a mass production scale? Get in touch with our CNC turning service today to learn more about how automated production can benefit your production operations and improve your products' competitiveness in today's market.

Post Treatment And Surface Finishing Options Provided By Professional CNC Turning Services

CNC turned parts are purely semi-finished goods, expertise in post-processing adds value to CNC turning services. Proper post-processing techniques not only increase the aesthetic value of turned parts but also increase their functionality and longevity and play an indispensable role in the post-processing of CNC turning.

Deburring & Edge Refined: "Usable" to "Refined"

We use different methods for the process of deburring. These include vibratory grinding, magnetic grinding, thermal deburring, and manual deburring. It provides a burr-free edge that guarantees proper assembly and provides high-level assurance with respect to the entire CNC turning services process.

Functional Surface Finishes for Improved Performance and Longevity

The services that we provide also encompass a broad list of functional surface finishes such as hard anodizing on aluminum, zinc/nickel plating, QPQ salt bath nitriding finishes on steel, and physical/chemical vapor deposition. The finishes enhance wear-life, corrosion-resistance, and other physical properties of various items. In effect, they add value to CNC turning services.

Customer and Brand Requirements for Decorative Finishing

To serve the requirement of consumer electronics, high-end instruments, and other segments, mirror polishing, wire drawing, sandblasting, color anodizing, and laser marking services are also available.

These processes can endow parts with excellent appearance and brand identity, enhance the market competitiveness of products, and meet the personalized needs of customized CNC turning.

Figure 3 Aluminum CNC Turned Parts With Black Anodize

Case Study: Efficiency Improvement Of 285%, How Multi Axis Turning Reshapes The Manufacturing Process Of Hydraulic Valve Cores

In the engineering machinery industry, the production of high-quality CNC turning of the valve core of a stainless steel hydraulic valve was considered to be an issue.

The valve core has complex components with multiple radial cross holes at varied angles, end surface grooves, and precise threaded portions that demand high accuracy of dimensions and locations. Conventional manufacturing techniques cannot satisfy the CNC turning machining requirement of high precision.

Original Challenges and Components

The conventional procedure needs at least four setups between the 2-axis lathe machine, 3-axis milling machine, and drilling machine. This amounts to a total of 35 hours of machining time.

The procedure entails multiple setups, which is inefficient and further makes it challenging to ensure key precision standards such as coaxiality and perpendicularity of holes. This directly affects production schedules and costs of production for customers. The difference between conventional machining and professional turning is evident here.

JS Precision Solution

A complete reconstruction of the machining process has been accomplished, scrapping the conventional sequential machining method and using a 9-axis milling and turning machine with a Y-axis and a power turret for CNC turning machining.

With the outer diameter and end face of the main part turned, it becomes possible to directly machine and thread the workpiece using a power turret even without disassembling it.

At the same time, while processing the diameter of key sealing surfaces, we employ an in-machine probe for real-time measurement and automatic compensation to guarantee a strictly controlled tolerance of ±0.005mm, thus reflecting the advantages of customized CNC turning.

Results

The machining time for each piece was reduced from 35 hours to just 9 hours through this customized CNC turning solution, thereby realizing an efficiency gain of around 285%.

In particular, through applying a one-time clamping and forming CNC turning process, for example, hole perpendicularity and coaxiality, the relative positional accuracy of various features had reached an unprecedented high standard, therefore, the defective rate of the end product was reduced by 90%, and production cost and delivery time were also cut.

Are you also experiencing difficulties with low efficiency and accuracy in parts machining? Please upload your part drawings, and we will leverage the success from similar cases to renovate your CNC turning machining process, thereby creating a breakthrough in terms of efficiency and accuracy.

Figure 4 Precision CNC Turning Stainless Steel Hydraulic Valve Spool Sleeve

FAQs

Q1: To what degree of accuracy can your CNC turning milling service deliver?

When dealing with dimensions pertaining to standard sizes and within Φ50mm, our CNC turn service is capable of ensuring precision tolerance of + or – 0.01mm and roundness of 0.005mm.In case of specific precision needs, we can work towards achieving them by optimizing our processes as well.

Q2: Can non-circular sections be machined?

Non-circular cross-sections can be machined by us. From milling and turning centers with either C-axis and Y-axis turners or Swiss style lathe machines with powered turrets, along with precision synchronous control, non-circular cross-sections like polygons and ellipses can be machined by us on our CNC turning machines.

Q3: How can I obtain an instant quote for turned parts?

You may also upload your 2D graphics or 3D files using our quote service system. Be sure to include the type of material you want and the quantity. The process will quickly proceed to give you a transparent USD quote.

Q4: How can aluminum products be prevented from scratching and deforming during turning?

When machining aluminum components, we use aluminum alloy machining tools, and we control cutting forces and thermal deformation to prevent scratching of machined components through proper cutting conditions and use of proper fixtures, including flexible sleeves and proper cooling facilities.

Q5: What methods for deburring the turned edges of stainless steel would you recommend?

So, for stainless steel, we can make use of vibratory grinding accompanied by specialized abrasives or even electrolytic deburring. The process is very efficient in removing burrs without damaging precision edges and corners of the parts.

Q6: Are small batch orders (e.g., 50 units) accepted?

Yes, we accept small-batch orders. There is a special flexible production line in our company for small-batch, multi-variety customized CNC turning orders, which can conduct quick changes, meeting the requirements of various customers.

Q7: My design involves turning deep holes. Is there any restriction?

Turning holes that have a length-to-diameter ratio greater than 10 is a challenge we have expertise in. This is accomplished by the use of deep hole drilling and boring machines equipped with high pressure internal coolant systems and the necessary cutting tooling for turning holes having a length-to-diameter ratio greater than 20.

Q8: How long does it take to transport goods from China to Europe/North America?

From China to Europe/North America, air transport takes about 3-7 days, and sea transport takes about 25-35 days. We also offer one-stop logistics solutions and customs clearance services for smooth delivery of your shipment.

Summary

The main value of CNC turning services is rooted in its ability to translate design plans and blueprints into high-quality physical components. Investing in CNC turning services means investing in efficiency and reliability.

As long as you have CNC turning requirements, JS Precision can be your best choice to make all components proofed or tested for rigorous testing purposes and therefore introduce basic competitiveness to your products. Allow your next rotating part to undergo the transformation from "manufacturing" to "intelligent manufacturing."

Begin your defect-free teamwork today!

We ask that you please visit our JS Precision website and send in your turning part drawings. Our team of engineers will get back to you within 24 hours with a complete solution for you, encompassing route suggestions, tolerance analysis, and your price quote. Precision begins here.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com