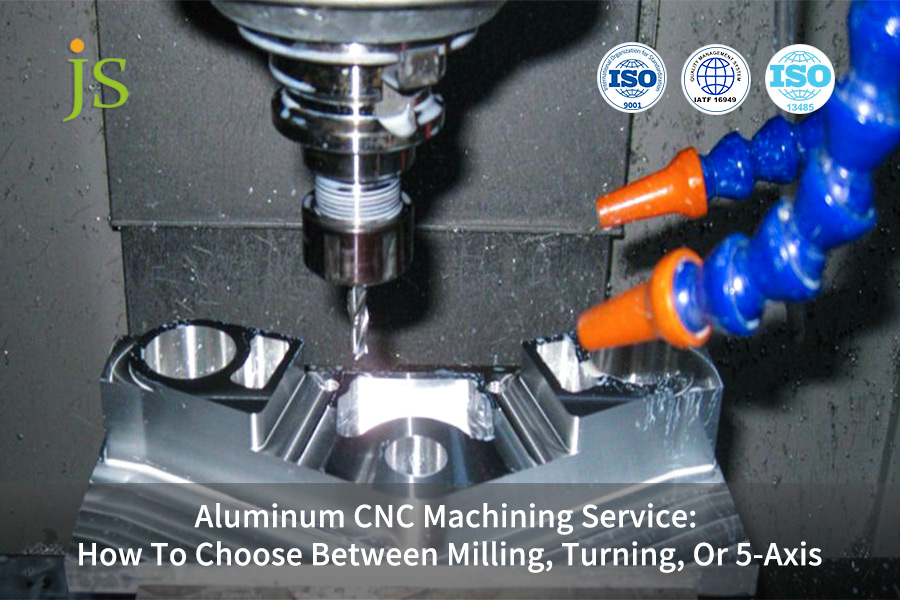

Aluminum CNC machining service is an essential core support service for industries such as aerospace, electronics, and automotive. As a designer with an aluminum alloy design, a critical consideration will greatly affect your performance, cost, and delivery time:

Should you go for CNC milling, CNC turning, or five-axis machining? Based on proper selection of machining technique, a complicated case of a housing can be produced in a single operation with aluminum CNC machining because of accuracy and efficiency, but incorrect selection can lead to complicated processing and higher costs.

In a global supply chain sense, when you conduct a search for "aluminum machining near me," have you thought of a better option than being constrained by your local geography?

This article will shed light on a framework for process selection for you and will make you understand why JS Precision, with Chinese advanced manufacturing technology, quick response, and cost-effectiveness, is the popular choice for global engineers in need of high-precision aluminum machining and customized aluminum parts.

Core Answer Table

| Decision Core | Pitfalls in Process Selection | The Integrated Solution by JS Precision |

| Process Matching | Selection by intuition or a single attribute (e.g., "looks like a rotating body"), resulting in poor processing efficiency. | Based on a geometric attribute knowledge base and AI analysis, our selection of the best combination of processes for your aluminum parts will achieve maximum processing efficiency and quality. |

| Cost Control |

Considering solely aluminum CNC machining quote on a per unit basis without taking into consideration the total cost of processes, tooling cost, and assumed scrap rate. | Our cost breakdown analysis is transparent with our goal of zero waste in design with DFM optimization for lowest total cost. |

| Precision and Collaboration | Assuming a remote collaboration can never finalize high-quality precision aluminum machining work and financial communication expenses are high. | Our company offers whole visual collaboration via a digital platform and guaranteed quality delivery of data, ensuring Chinese collaborations work with equal efficiency. |

Key Takeaways

- Five-axis machining is not a magic solution: For purely rotational bodies or simple prismatic workpieces, conventional turning or three-axis milling turns out to be more economical.

- "Single setup" is a very valuable process capability: five-axis technology greatly improves the total accuracy of complicated components such as concentricity accuracy and total lead time by reducing a series of datum transformations.

- The comprehensive advantages of Chinese manufacturing: Under the same technical standards, China's leading CNC machining parts suppliers have global competitiveness in terms of cost, supply chain response speed, and engineering support depth.

- Early collaboration determines success or failure: Discussions with the manufacturer concerning Design for Manufacturability (DFM) when inquiring about aluminum CNC machining quote can provide an invaluable chance to maximize cost savings and manufacturability.

- Accuracy is a function of the system: Where accuracy is a function of a system, this means it is not reliant on a single factor but a combination of factors such as machine tooling, cutters, strategy, or a quality control system.

Why Trust This Guide? JS Precision Team's Practical Experience In Aluminum CNC Machining

To make an informed decision on machining, you will need a good resource. JS Precision is a seasoned company with 15 years of experience in aluminum CNC machining. JS Precision CNC machining services include 12 main industries such as aerospace products, medical devices, and car electronics, with over 100,000 sets of precision aluminum parts machined.

Our aluminum alloy machining service strictly conforms to ASTM standards, which include ASTM B210/B210M-19a: "Standard Specification for Drawn Seamless Aluminum and Aluminum-Alloy Tubes," a standard quality norm in the global aluminum processing industry.

Examples of our work include delivery of 7075 aluminum alloy structural components in NASA-grade satellite projects, where we overcame deformation in deep cavity thin-wall components, and production of large quantities of aluminum parts in a production volume of 500,000 per year for automotive clients, in which we balanced cost with efficiency.

Through these practical applications, we have come across a number of issues including low efficiency in complex surface machining, cumulating tolerances above specifications in multi-step machining, and poor material usage, and have worked on resolving them accordingly.

Rather, this manual is based on practical experience gained with over 3000 customer requirements, and it will prove a very useful source of references no matter if you are a beginner in process selection or an old hand in this industry.

Want to check our practical capabilities? Please introduce your part industry and basic requirements, and JS Precision will provide you with case studies of successful projects in a similar aluminum CNC machining service for FREE, so you can browse our ideas and solutions to understand them intuitively.

How Do Modern Aluminum CNC Machining Services Conquer Complexity?

The machining of complicated aluminum components is an area which used to be a challenge in this sector, but current aluminum CNC machining service can undertake this with ease because of the upgrades in CNC machining technology with regards to multi-axis machining.

The Core Benefit of Five Axis Machining: Capability to Access Every Angle

In five-axis machine tools, two additional rotational axes are provided to the conventional three-axis configuration, which enables rotation to be performed on both workpiece and tool easily, allowing the tool to move towards any surface of workpiece at a suitable angle.

Therefore, negative angle cavities, deep cavities, and surface machining can be accomplished in a single setup without multiple clamping operations.

Turn-Milling: The Final Solution for Complex Rotational Parts

Turn/milling centers are CNC machines where turning and milling operations are performed in one machine, thus eliminating the need for interchanging workpieces from machine to machine.

Such machining centers do both machining of rotational parts and machining of irregular parts in a single machining cycle, which is suitable for non-standard aluminum parts such as shafts and discs.

Our "Digital Twin" Clamping Simulation

JS Precision employs specialized software to simulate the whole process of clamping and tool path during programming to recreate a machining environment in order to detect potential interference before the implementation of the solution and thus prevents time and money being wasted during implementation of the solution on site.

What Factors Most Influence Your Aluminum CNC Machining Quote?

While taking an aluminum CNC machining quote, differences in pricing arise based on the calculation of costs in the machining process, which is mainly affected by these three factors.

Geometric Complexity: The Direct Driver of Machining Time

Thin walls (<1mm), deep cavities (depth in excess of 3 times diameter), micro-features (-hole diameter <1mm), or large area complex surfaces make programming complicated, hence increasing machining time, thereby contributing to an increase in cost.

Cost of Material & Material Usage: Smart Manufacturing right from Material to Finished Product

Varieties of aluminum alloys cost differing amounts. The following table shows comparisons among different varieties of aluminum alloys that are in common usage:

| Aluminum Alloy Type | Machinability | Strength Scale | Price Limits (in USD/kg) | Use Cases |

| 6061 | Low | Medium | 2.5-3.5 | General structural parts, housings |

| 7075 | High | High | 5.0-7.0 | Aerial plane components |

Hidden Costs of Post-Processing and Quality Assurance

Surfaces finishes such as anodizing and sand blasting, and other quality control requirements such as full size reports and first article inspection, are all an essential part of the quotation and need to be transparent in front of clients in order to educate them on how the quotation is calculated.

Figure 1:Complex parts mean more processing time, more tool changes, and may even require more specialized equipment.

What Accuracy Can You Realistically Expect From A CNC Aluminum Parts Service?

For high-precision aluminum parts projects, it is vital to establish appropriate tolerance requirements. As a professional CNC aluminum part service company, JS Precision always pursues high-precision aluminum machining with clear standards.

Capability Range for Standard Machining

Under normal production circumstances, linear dimensional tolerance for medium scale components in a dimension of 50-500mm can be achieved to a accuracy of ±0.025 to ±0.05mm, hole diameter tolerance for small holes will be at the level of H7 (±0.015mm accuracy), and surface roughness will be Ra 1.6μm when machined conventionally, and Ra 0.8μm when machined precisely.

Such an accuracy level complies completely with the accuracy requirements for an H-class accuracy level in ISO 2768-1:1989 "Geometric Tolerancing Part 1: Tolerances for Linear and Angular Dimensions without Individual Tolerance Indications," a widely accepted standard in the production of medium-precision parts.

Key Factors Affecting Accuracy: Beyond Machine Tool Accuracy

Accuracy does not rely on machine tools alone. For instance, thermal expansion of aluminum alloys, tool wear, lack of work rigidity, and unreasonable fixture designs can all influence machining accuracy.

A Leap Forward in Geometric Tolerances: The Core Contribution of Five-Axis and Multi-Axis Technology

Five-axis machining can accomplish multi-surface machining in a single setup without relying on setups that include datum deviations, which can control positional tolerance to within ±0.02mm, thereby greatly improving parallelism and perpendicularity in key assembly.

Figure 2:An engineer measures the dimensions of machined parts during quality control inspections.

A Practical Framework For Choosing Milling, Turning, Or 5-Axis For Your Aluminum Parts

When presented with three processes, you can quickly find the optimal solution for your aluminum parts using this framework.

Typical Characteristics for Preferring Turning

- The basic part of a tooth is either cylindrical, conical, or disc-like.

- The main part elements revolve relative to the main axis: outer diameter, inner hole, groove for end face, threads.

- Examples: aluminum bolts, bushings, disc-shaped flanges.

- Advantages: Most cost-effective, fastest processing speed.

Typical Characteristics for Preferring Three-Axis/Five-Axis

- The part has a block or plate-like structure.

- Features planes, cavities, holes drilled into the solid model, and intricate non-rotationally.

- Three-axis milling: good for simple planes and cavities (like square aluminum boxes).

- Five-axis milling: used for continuous multi-directional curved surfaces or machining features with multiple angles, such as aviation special-shaped parts.

Processing Strategies for "Hybrid" Parts

Where there are elements with a rotating part and non-standard details, see below:

| Assessment Criterion | Sequential Processing Plan(Turning Main Body + Milling Irregular Features) | Turn-Milling Composite One Time Forming |

| Cost | Low capital requirement, adaptable for small batch production. | High capital requirement, but scale economies in mass production. |

| Delivery Time | Multiple equipment turnovers, longer cycle | One-time forming, shorter cycle |

| Accuracy | Multiple setups, larger cumulative tolerance | Single setup, higher accuracy |

Do you want to quickly determine the adaptation process for your aluminum parts? Upload your 3D model of your part and indicate your production volume, and JS Precision will give you a cost-free assessment and recommend which processing option is most suitable based on your requirements.

Figure 3:CNC turning is very suitable for machining cylindrical parts, such as shafts, spindles, and joints.

How Does 5-Axis Technology Elevate The Standards Of Precision Aluminum Machining?

Speaking strictly in terms of five-axis technology in precision aluminum machining, its application extends beyond machining intricate shapes in aluminum, rather, it boosts the standards of aluminum part processing in various dimensions.

A Qualitative Leap in Surface Finish: The Eternal Pursuit of the Optimal Cutting Angle

Five-axis technology holds the ideal cutting point of the tool, which prevents "overcutting" and "undercutting," providing a uniform surface finish on curved surfaces. Such technology meets the critical requirements for Aerospace and Optical components.

Improved Tool Life and Stability

Five-axis machine tools can overcome the problem of interference by means of tilting angles, ensuring shorter-cutting tool usage, reduced vibration, increased stability during cutting, a tool life of over 30% higher than before, and guaranteed processing quality.

Removing Error in Second Clamping: The Basis for Overall Accuracy

Single clamping can remove datum error in multiple clampings and hence provides a precise positional relationship among a variety of multifaceted features, which is the essence for precise part processing.

What Does The Production Journey Look Like With A Reliable Custom Aluminum Parts Manufacturer?

Collaboration with a custom aluminum parts manufacturer guarantees quality and efficiency through standardized processes at each production step.

Step One: In-depth DFM Collaboration and Engineering Confirmation

- Begin 3D engineering review upon receipt of drawings.

- Material selection: Recommendation of suitable grades of aluminum alloy depending on the operating environment.

- Process feasibility: The structure is optimised for process capability by reducing processing difficulties.

- Cost optimization: relax the tolerances that incur unnecessary costs.

- All suggestions are fully communicated and confirmed with the customer.

Step Two: Digital Production Preparation and First Article Verification

Plan the tool path using CAM software. Prepare suitable tools and fixtures, do a full-size inspection after first article processing, and start mass production after approval.

Step Three: Mass Production, Process Control, and Transparent Delivery

IPQC sets process inspection point during mass production. After the production is completed, the final inspection, surface treatment and customized packaging are made, with complete quality documentation delivered together with the goods.

Want to learn more about working with a custom aluminum parts manufacturer? Request our standardized production process manual for clear understanding from drawing submission to part delivery, making cooperation more reassuring.

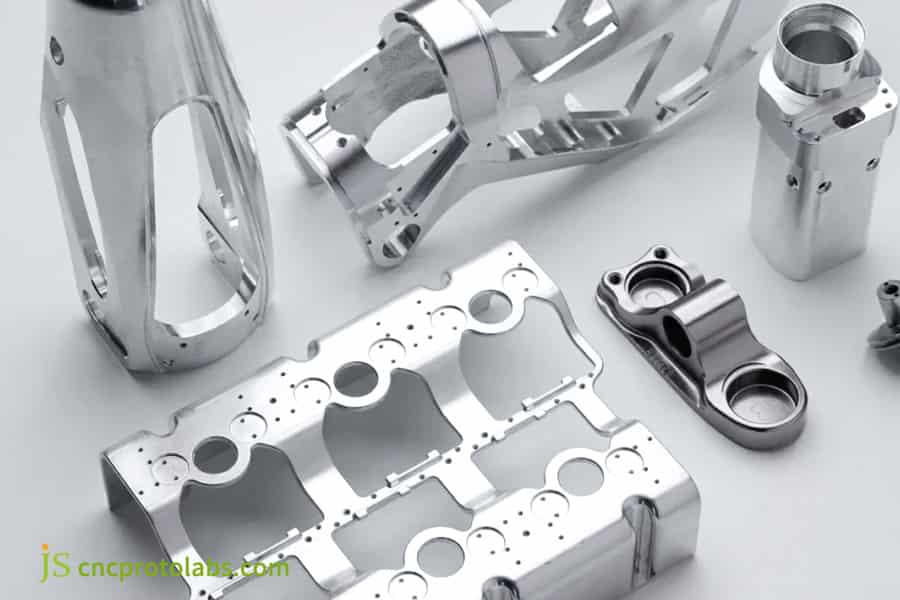

Costs Reduced By 68%: How Process Optimization Is Reshaping The Manufacturing Path Of Aerospace Brackets

In cnc aluminum parts service, there is tremendous value created from process optimization. JS Precision, as a professional custom aluminum parts manufacturer, has achieved significant breakthroughs for customers through process reengineering.

Original Design Challenges

A customer needed to produce an aluminum alloy 7075 bracket for a satellite payload. The original design was made up of 5 simple turned and milled parts assembled with screws. This design had several problems:

- Production cycle: 45 days, long lead time.

- Accuracies: more than ±0.1mm cumulative positional error.

- Overweight: 1.2kg exceeded project limits.

- Highly costly: Aluminum CNC machining quote reached $8000.

Analysis and optimization of the process performed by JS Precision

Based on these problems, the engineers at JS Precision immediately began comprehensive optimization.

In terms of DFM restructure, we proposed to integrate 5 pieces into a light, monolithic piece. Topology optimization software has generated a shape mainly consisting of rib structures, cutting down on excessive material while maintaining the strength.

The new design included multi-directional curved surfaces and deep cavities for process re-selection. Four setups would be required with traditional three-axis milling, we chose to use a five-axis machining center that would allow single-setup machining.

In terms of material and post-processing optimization, we chose 7075-T651 aluminum alloy, more suitable for five-axis high-speed machining, and set the hard anodizing for corrosion and wear resistance under the space environment.

Results

Part weight reduced by 42% to 0.696kg, with a 25% increase in stiffness, the total cost of manufacturing was reduced to $2560-a reduction of 68%, the lead time was shortened by 50% to 22 days, and positional tolerance was ±0.02mm, meeting aerospace requirements.

Want your parts to achieve cost reduction and efficiency improvement, too? Please submit your original part design plan and let JS Precision offer process optimization suggestions for free according to our experience in an aluminum CNC machining service to help you unlock cost and efficiency potential.

Figure 4:CNC Machined Custom Aluminum Brackets

How Can Global Clients Work Efficiently With A Distant CNC Machining Parts Supplier?

Many global customers are concerned about communication problems when cooperating with a remote CNC machining parts supplier. However, in the digital world, "aluminum fabrication near me" should be redefined as "a high-quality supplier with rapid response and smooth communication." JS Precision makes remote collaboration efficient and free of concerns.

Digital Project Portal: Your 24/7 Project Dashboard

One dedicated online customer platform supports file management, real-time progress tracking, and online communication across time zones. This breaks down geographical barriers and keeps you informed on the progress of your projects at all times.

Structured Communication and File Standards

A "perfect quotation package" should include: 3D models in STEP/IGES format, PDF drawings with tolerances, technical requirements, and target quantities to make sure everything is set up for efficient communication.

Building Trust Through Quality Data Flow

We create transparency in quality with automated First Article Inspection Reports (FAIR), visualization of key processes, and material batch number traceability, thus giving confidence to remote clients.

Want to enjoy seamless remote collaboration? Now call the Global Service Hotline or submit an inquiry on JS Precision's online platform. The account managers will immediately respond and help you get started at the earliest in the collaboration process of CNC machining parts supplier and help realize more convenient cross-border manufacturing.

FAQs

Q1: What are required documents for an online quotation of aluminum CNC machining?

Provide 3D models in STEP/IGES format and PDF drawings marked with tolerances if possible. Sketches are also good for inquiries, but the accuracy of the quote will be somewhat different, complete technical documents should be provided whenever possible.

Q2: What are the main differences between 6061 and 7075 aluminum alloys in terms of processing and performance?

6061 aluminum alloy is easy to machine, causes little tool wear, is weldable, and has medium strength. All that, in addition to being relatively inexpensive, makes it a good, general-purpose structural material, 7075 is very strong but difficult to machine and weld, so it should only be used in applications requiring a high level of structural strength.

Q3: Is five-axis machining necessarily more expensive than three-axis machining?

Not necessarily. Five-axis machining in complex parts could save multi-machine, multi-setups, specialized fixtures cost to shorten the processing cycle and may be lower than the total cost of multi-process three-axis machining. Its advantages are even more overwhelming in mass production.

Q4: What surface treatments are most common after aluminum part machining?

Anodizing is the most popular, offering various color options for ornamentation while hardening surface hardness and improving the resistance of wear and corrosion, and sand blasting is usually used to get the even matte texture and to improve the appearance of parts.

Q5: What is the minimum thickness of an aluminum feature that can be machined?

We can successfully machine aluminum alloy features, approximately 0.5mm wall thickness using appropriate process strategies and specialized tools. Features much thinner will need special fixtures and processes, their deformation risk should be assessed.

Q6: Do you take orders from prototyping to mass production?

Certainly. Our flexible production lines are capable of small batch prototyping, and the scaled production lines are able to efficiently handle mass production, with data continuity and quality consistency all along the process to meet every cycle need.

Q7: How do you ensure there is no damage to parts shipped from China during their transport?

We use customized shock-resistant packaging material, individually protect the precision surface, and reinforce large parts with wooden crates. Transportation insurance is bought to cover any losses. Years of international shipping experience enable us to effectively control the risk of damage.

Q8: What is the typical lead time for aluminum parts?

For parts of regular complexity, the lead time will be about 5-10 business days for prototypes and about 2-4 weeks for small batch production. The exact lead time will be specified in the aluminum CNC machining quote.

Summary

Choosing the right aluminum cnc machining service is never about "the more advanced, the better," but rather "the more suitable, the more efficient."

Turning is suitable for rotational parts, milling fits block structures, and five-axis machining specializes in high-precision complex parts. Based on 15 years of practical experience, JS Precision uses its professional capabilities to guide you through the optimal path from selection to delivery.

Stop hesitating over process selection or compromising due to high local quotes.

Get your unparalleled optimized solution today! Just go to the JS Precision website and upload your aluminum part design. You will get an instant and transparent aluminum CNC machining quote, but more importantly, our engineering team will prepare a "Process Selection and Cost Optimization Analysis Report". Let us work together to find the best way to realize your ideas.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com