CNC turning services constitute a main backbone in the production of parts through outsourced precision turning projects. If your project is looking for cutting parts through outsourced precision turning, do you often catch yourself wondering:

How to get reliable, accurate, efficient, and transparently priced CNC turning services suppliers fast from amidst tons of information? Uncertain pricing, worries about quality, and indefinite delivery times can significantly hamper the commencement of a project.

This article will directly address these core pain points and provide you with a clear decision-making path by answering key questions. It also shows that through JS Precision's integrated CNC turning online platform, one can get in a single stop both high quality precision CNC turning parts and competitive CNC turning parts quotes.

Key Answer Summary

| Customer Core Concerns | JS Precision Solution | Core Value Created |

| How to locate reliable suppliers who price their products transparently? | An all-in-one CNC turning online platform offers instant, transparent CNC turning parts quotes. | Free decision-making, fully controllable costs, and no more opaque pricing. |

| How to guarantee the precision and reliability of the parts? | In our capacity as a professional CNC turning parts manufacturer, we have invested in the latest CNC turning center and have implemented strict quality controls so that we can proudly state that our main focus is on delivering precision CNC turning parts. | Get micrometer level (like 0.005mm) accuracy guarantee, no more assembly failure and performance risks. |

| How to make a compromise between efficiency, cost, and complexity? | The optimized high speed CNC turning process and one-stop service, which extend the range of CNC turning services from simple shaft sleeves to complex composite parts. | Achieve fast iteration and maximize cost, effectiveness, accelerate product from prototype to mass production. |

Key Takeaways:

- Selecting a supplier mainly involves checking their equipment capability and quality system, as a CNC turning center manufacturer, rather than just comparing the prices.

- Using a real-time CNC turning online quote system enables instantaneous cost assessment of designs, this tool is very efficient in redesigning factors (DFM) and budget controlling.

- The consistency of precision CNC turning parts results from the combination of the latest machinery, expertise in the production process, and the implementation of strict quality control at every stage.

- High speed CNC turning plays a major role in increasing the productivity and lowering the prices per unit, however, it is necessary to have a special technology that can reduce the effects of vibration and secure the precision.

How Are Complex Parts Machined? JS Precision's CNC Turning Solutions

CNC turning is the primary process for manufacturing complicated rotating parts. JS Precision has focused on this area for quite a long time and thus has mature full, process service capabilities from prototyping to mass production.

In the capacity of a professional CNC turning parts manufacturer, we have DMG MORI and Mazak multi, axis milling and turning centers at our disposal, which allow us to complete complex processes such as drilling, tapping, and milling in an efficient manner, thus enabling us to achieve precise forming of complex parts in a single setup.

Our process team is capable of accurately designing and fabricating dedicated anti, deformation fixtures as well as toolpath optimization of easily deformable structures, such as thin walled and deep hole parts, thus always achieving stringent tolerance control of 0.005mm.

JS Precision is certified to ISO 9001:2015 and AS9100D, which guarantees that the process is compliant.

According to the data, 98% of our order deliveries are on time, and 95% of our precision parts projects continually reach tolerances of 0.005mm, thus allowing customers to cut their total manufacturing costs by an average of 20%.

For complex parts in highly regulated industries like aerospace and medical, we issue full traceability reports, which record material procurement, production, and inspection of the final product.

Want to verify JS Precision's capabilities as a CNC turning parts manufacturer? Submit your complex part drawings to receive a free customized process plan and feasibility analysis, dispelling any concerns about high-end manufacturing collaborations.

What Is CNC Turning Services? How Can It Achieve The Manufacturing Of Complex Parts?

This chapter will simply explain the CNC turning services core function so that you can get a basic understanding.It can rightly be used for the manufacture of various rotating CNC turning parts, accurately measuring and effectively balancing the works, and changing for customized requirements in different industries.

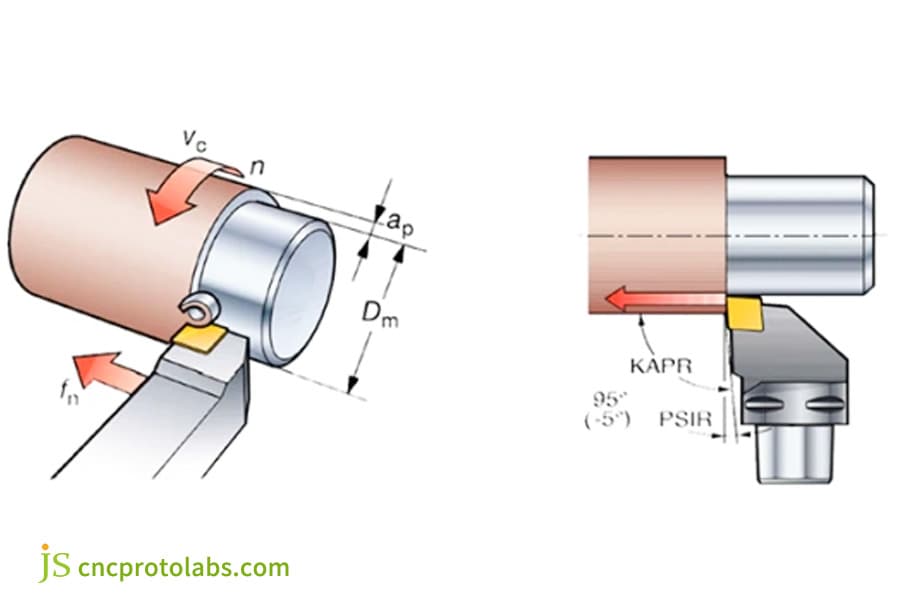

Basic Principles and Core Advantages of CNC Turning

CNC turning is essentially a method of machining where a CNC code is used to operate a lathe, which results in a rotating workpiece moving relative to a stationary cutting tool and thus the cutting tool getting the surface of the workpiece and removing material.

Its main features are: large precision (tolerances can go as low as 0.005mm), amazing repeatability, and high output, which makes it a perfect choice for the mass production of cylindrical, conical, and other rotating CNC turning parts.

Standardized Process from 3D Model to Precision Machine

- Upload CAD File: Supports multiple formats such as STEP and STL. JS Precision engineers will carry out a DFM analysis.

- Select Materials and Processes: Choose the metal or plastic materials, and the subsequent steps such as surface treatment.

- Get Quote Confirmation: Receive a clear quote via the CNC turning online platform.

- Production and Inspection: Implementation of end-to-end quality control, including first piece inspection and batch sampling.

- Delivery: Deliver the finished product on time.

Typical Application Scenarios: Shafts, Sleeves, Flanges, and Complex Assemblies

CNC turning services cover a wide range of parts, including automotive crankshafts, aerospace hydraulic fittings, and medical bone screws. These parts all fall under the category of CNC turning parts.

Want to learn more about the process details of CNC turning services? Submit your part requirements and receive a free feasibility report for precision CNC turning parts to proactively avoid design flaws.

Figure 1: Technical diagram illustrating key CNC turning parameters like cutting speed, feed rate, depth of cut, and tool angles.

How To Quickly Obtain Accurate And Competitive CNC Turning Parts Quotes?

Quotations for complex parts are frequently a source of confusion for customers. This section explains the different elements of a quote so that you can get accurate CNC turning parts quotes quickly. Say goodbye to hidden costs and enjoy complete transparency and more streamlined accounting via the CNC turning online platform.

Breaking Down Quotation Components: Materials, Tolerances, Batch, and Post-Processing

The core components of a quote include four items, with specific percentages shown in the table below:

| Cost Item | Calculation Method | Percentage (Taking 50 aluminum bushings as an example) | Influencing Factors |

| Machine Time | Labor hours × Equipment rate | 30.4% | Part complexity |

| Clamping and Programming Fee | Single charge | 17.9% | Material type and grade |

| Material Cost | Raw material cost + 25% markup | 26.8% | Material type and grade |

| Post-Processing Fee | Deburring/electroplating, etc | 15.9% | Surface requirements |

| Tool Wear Fee | Consumables such as cutting tools | 8.9% | Part hardness |

How Does Real-Time Quotation Work? Save You Time and Costs

JS Precision's CNC turning online platform can automatically extract step details from the drawings uploaded and come up with a preliminary quote within one hour, which is 80% of the time saved compared to the traditional manual way of quoting. Besides, the quotes are upfront, and there are no hidden charges.

Providing Clear Drawings and Technical Requirements: The First Step to Getting Accurate Quotes

Unambiguous CAD files must contain data like tolerances, materials, surface finishes. It is essential to get accurate CNC turning parts quotes, therefore, unclear drawings or diagrams can make the quotes go astray even by 30%.

Want to quickly obtain accurate CNC turning parts quotes? Upload your drawings now using the CNC turning online platform, and the system will automatically generate a quote, helping you efficiently control costs.

Why Are Precision CNC Turning Parts Crucial To The Success Of Your Project?

Stable part operation requires high precision as the basic foundation. This chapter will discuss the main value of high precision CNC turning parts. Being a CNC turning parts manufacturer, we know very well how it influences the success of the project, so we strictly control the precision and quality of the entire production process.

Understanding Key Precision Indicators: Tolerances, Surface Finish, and Roundness

The core indicators for precision CNC turning parts include dimensional tolerances, surface finish, and roundness. Different indicators correspond to different application scenarios:

| Tolerance Grade | Surface Finish (Ra) | Roundness Error | Applicable Industry | Typical Parts |

| ±0.005mm | 0.4μm | ≤0.003mm | Aerospace | Satellite Structural Components |

| ±0.01mm | 0.8μm | ≤0.005mm | Medical | Surgical Instruments |

| ±0.025mm | 1.6μm | ≤0.01mm | Automotive | Engine Bushings |

| ±0.05mm | 3.2μm | ≤0.02mm | Industrial Equipment | Pump Body Parts |

| ±0.1mm | 8μm | ≤0.05mm | General Machinery | Fasteners |

Ensuring Micron-Level Precision: Advanced Equipment and Process Control

JS Precision, a CNC turning parts manufacturer, has a 5 axis milling and turning center. On top of that, they use first, piece inspection and online measurement to guarantee every precision CNC turning part is exactly as per the drawing.

The Cost of Insufficient Precision: Assembly Failure, Performance Degradation, and Rework Costs

If parts are not made to precision, they may not fit together, or they may result in a noisy and short-lived assembly. The rework cost is commonly 2-3 times the original production cost.

How To Effectively Control The Vibration In High Speed CNC Turning To Ensure Quality?

Though high speed CNC turning can significantly increase the throughput, it is evident that vibration can impair the quality of the parts. This chapter will deliver precise solutions that exploit the benefits of high speed machining and at the same time, avoid accuracy drift and tool wear caused by vibration.

Where Does Vibration Come From? Negative Impacts on Machining Quality

The main causes of vibration are the lack of sufficient tool stiffness, unstable workpiece clamping and cutting parameters that are not suitable. It may result in the formation of ripples on the surface of the part and the tool, life may be reduced by over 50%.

Process Optimization Strategy: Matching Spindle Speed, Feed Rate, and Depth of Cut

- Change the spindle speed so that it doesn't hit the resonating frequency between the tool and the workpiece.

- Lower feed rate to reduce the variation in cutting force.

- Decrease the depth of cut to reduce the load on the tool.

Hardware Support: Using Vibration, Damping Tools and Dynamic Balancing Fixtures

JS Precision initially implemented vibration damping boring bars and hydraulic fixtures to effectively control the vibration during high speed CNC turning and thereby, achieving the part surface finish of Ra below 0.8m.

What Key Factors Will Affect The Final Price Of CNC Turning Online Quotes?

CNC turning online quotes are affected by many factors. This chapter will be your guide to cost optimization at the design stage. If you get to know the main factors, then you will be able to get better quotes without sacrificing performance.

- Material Cost Fluctuations: The price per unit of standard aluminum (for example 6061) is about $30/lb, with the material costs vary a lot.

- The Trade-off Between Precision and Cost: By tightening tolerance from 0.1mm to 0.025mm, the machining time would be increased by 50% and the quote will go up by 30% approximately.

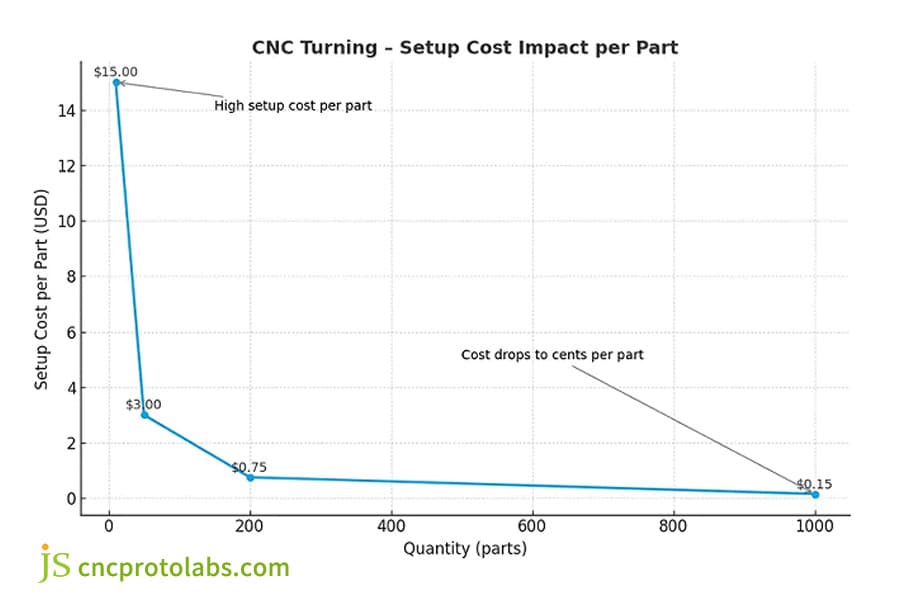

- Batch Effect: Thus, the unit cost decreases as the batch size increases. As an illustration, the unit price of a 6061 aluminum bushing is $4.2 for one piece.

Figure 2: Line graph showing how the setup cost per part for CNC turning decreases significantly as production quantity increases.

How To Identify Reliable CNC Turning Center Manufacturers And Service Providers?

Making the right choice of supplier is very important. This section offers a method to analyze the situation. Working with a top-tier CNC turning center manufacturer can not only prevent quality issues and delays in delivery but also they will be able to give you a great amount of help in your project which consequently means lower costs.

- Assess Core Strengths: The first thing to look for in a trustworthy CNC turning center manufacturer is that they have at their disposal multi, axis milling and turning centers like those from DMG MORI and Mazak.

- Verify Quality System: Look for certifications like ISO 9001 and IATF 16949 as well as parts test reports that will guarantee quality being kept under control.

- One-Stop Service Value: One-stop service means less intermediaries and therefore the delivery time will be shorter. JS Precision is offering a full-process service, from machining to surface finishing.

Want to verify the capabilities of a CNC turning center manufacturer? Check JS Precision's equipment list, schedule an on-site visit, and gain a direct understanding of our production capacity.

Case Study: JS Precision Delivers High-Precision Stainless Steel Sensor Housing Urgent Order In Three Days

Challenge

An industrial sensor manufacturer had an emergency requirement of 50 stainless steel housings made of 316 material with an internal cavity dimension tolerance of 0.01 mm.

The delay in the delivery from the original supplier has put the production line at a shutdown risk. As the parts are thin walled which makes them highly prone to deformation during the machining process, they are the typical high, precision CNC turning parts.

JS Precision Solution

1.Hour Online Response:

Upon submission of their urgent requirements together with 2D/3D drawings via the CNC turning online platform, the platform executes drawing analysis and process assessment for production within 30 minutes.

Within 1 hour, a senior process engineer releases a formal quotation with the earliest time schedule outlining the exact time limit for each stage to meet the expedited request.

2.Quick Process Optimization:

To help the process team meet the challenge of easily deformable 0.8mm thin walled stainless steel housings they created a special mandrel fixture (positioning accuracy 0.003mm) in 1.5 hours.

8000r/min high speed CNC turning process together with customized PCD tools and layered cutting paths were used so that the part's machining deformation was limited to 0.008mm which is in perfect compliance with the 0.01mm internal cavity tolerance requirement.

3. Embedded End-to-End Quality Control:

Online laser inspection (accuracy 0.002mm) is performed every 10 parts during production. A CMM report for the full size of the parts is prepared within 30 minutes after the first batch of 5 parts and this includes 28 key dimensional inspection data. All precision CNC turning parts have passed customer technical standards 100%.

Results

The total time from order confirmation to the shipment of finished products was 72 hours. Part accuracy fully met the specifications, unit cost was $28. This helped the customer successfully avoid production interruptions and the two parties established a long, term supply relationship.

Need urgent parts machining? Submit your order information, and JS Precision will customize a high speed CNC turning expedited solution, delivering in as little as 3 days to avoid production line downtime losses.

Figure 3: Assortment of high-precision metal CNC turned parts, including various threaded components, displayed with a pen for scale.

FAQs

Q1: What's the usual accuracy you can get with CNC turning?

Normally, our CNC turning accuracy can get to 0.013mm. For precision CNC turning parts, if using a high-end CNC turning center, the dimensional tolerances can be very reliably kept within 0.005mm.

Q2: Can the price change after getting an online quote?

Provided that the drawings and technical specifications you give us are not changed, the CNC turning parts quotes we give you will be the final price. There are no extra charges during the whole process, so your cost control is guaranteed.

Q3: What materials can you handle?

We can handle most materials, such as different aluminum alloys, stainless steel, carbon steel, brass, titanium alloys, and engineering plastics like PEEK and nylon, thus fulfilling the requirements of various sectors.

Q4: What is the minimum order quantity (MOQ)?

We cater to the entire spectrum of requirements, from single piece prototype to mass production, without setting any hard minimum order quantity, thus providing you with maximum flexibility for your R&D and small, batch trial production.

Q5: Can you handle composite parts with features such as milling and drilling?

Yes, our multi, axis milling and turning center is equipped to manufacture complex CNC turning parts with rotating bodies as the main component and additional features such as milling and drilling in a one-stop process, thus saving us from clamping the work, piece several times and therefore minimizing errors.

Q6: What level of surface roughness can you typically achieve?

The surface roughness of CNC turning during our normal process is typically Ra 1.6m. A mirror finish with a surface roughness of Ra 0.4m or better can be obtained by further processing such as finish turning or grinding.

Q7: How long is the production cycle usually?

The lead time of simple prototype production is about 3 to 5 business days. In case of mass production, the lead time will be adjusted according to the quantity. Besides, we provide rush services to satisfy your urgent demand.

Q8: How do you ensure consistency in mass production?

We guarantee the same high quality of every batch of precision CNC turning parts by adhering to standardized operating procedures, conducting regular sampling inspections during the production process, carrying out the final full inspection before shipment, and providing statistical reports.

Summary

Choosing the right CNC turning service provider in precision manufacturing can be a way of ensuring both efficiency and quality.

JS Precision is a professional CNC turning parts manufacturer and CNC turning center manufacturer who breaks down barriers for you throughout the whole process from design to delivery by utilizing high, speed CNC turning technology and an online CNC turning platform.

Take the plunge and get in touch with the professional, dependable manufacturing services.

Simply upload your 2D/3D part drawings onto the JS Precision online platform and get an instant quote for CNC turning parts based on real, time process analysis and professional DFM feedback. Let's help you convert your precision designs into market, successful products productively.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com