Within 5 axis CNC parts machining scenarios, a three-axis machining setup will no longer work when designing sensor brackets with complex organic curved surfaces in the aerospace industry or developing precision components needing geometric tolerances of ±0.005mm in medical devices.

In these scenarios, 5-axis CNC machining becomes the core technology to breach the manufacturing barrier. It's not just an upgrade from an upgraded machine tool with two more rotary axes, it is a whole system that includes precision programming, the implementation of GD&T engineering, and end-to-end material traceability.

The article will outline the core value of professional five-axis machining services, showing how JS Precision meets the cost advantages of CNC milling services in providing precise manufacturing solutions to global customers at values beyond their expectations.

Core Answer Summary

| Core Challenges | Common Risks | Integrated Assurance of JS Precision |

| Achieving Complex Geometry and Stringent GD&T | Multiple clamping results in datum destruction and cumulative deviations of tolerance, while software post-processing bias causes toolpath error. | Five-axis single-clamping process + advanced CAM simulation enables loss-free distribution of GD&T. |

| Ensuring Material Properties and Traceability | There may be fluctuations in processing stability because of the discrepancy between the characteristics stated in the materials’ certificates and the actual characteristics of the batches. | Use of certified suppliers worldwide, spectral analysis of incoming materials, and ability to trace the entire processing batch. |

| Controlling Overall Manufacturing Costs | Inaccurate perceptions of the relatively high unit cost of five-axis machining and the lack of consideration of the total cost benefits of process integration. | Process integration + DFM Optimization, emphasizing the key cost benefits of five-axis machining. |

Key Takeaways

- The heart of five-axis machining is the presence of “angle” in the machining process, which allows the tool to always cut in its optimal position, thus providing better surface finish (Ra ≤ 0.8μm), increasing tool life by more than 30%, and also providing better deep machining capabilities.

- GD&T is the "design language" for five axis machining. Its presence is essential to be able to identify the precision potential of the machine tool.

- Material certification is the key to reliability: in the aerospace and medical industries, documentation of material traceability is as critical as the documentation of machining operations.

- Cost optimization comes through process integration: combining multiple three-axis processes and minimizing the need for special tooling are important to optimize the cost of complex parts.

Why Choose JS Precision? We Specialize In The Professional Machining Of 5 Axis CNC Parts

Being an organization with 15 years of experience in precision manufacturing, JS Precision has the use of 5 axis CNC machining as its core competency to establish customer trust through three trust-building principles.

Equipped with 20 state-of-the-art DMG Mori and Mazak five-axis machines, with the RTCP tool tip follow function, allowing rotary axis positioning with ±2 arc-second accuracy, which can then precisely machine complex parts with tolerance requirements of ≤±0.003mm.

We are also certified in the aerospace quality system standard AS9100 and the medical device standard ISO13485. Solutions for our computer-assisted manufacturing software range from high-end tools like Siemens NX and Hypermill to CMM inspection machines of high precision, which ensure that all our products comply with the requirements of GD&T.

For the past 15 years, we have been offering personalized 5 axis manufacturing to over 500 customers globally with a yield rate of 99.7% in the aviation segment and an on-time delivery percentage of 100% in the medical segment.

A car spare parts client had been facing a 12% scrap rate attributed to multi-stage clamping in 3-axis machining techniques. However, with the new 5-axis single clamping technology, the scrap rate fell to 0.8%, with total costs down by 22%.

If you are looking for a partner to resolve the conflict between precision and cost for complex parts, submit your part drawings, and we will provide you with a free "5 axis CNC machining GD&T implementation feasibility analysis," allowing professional solutions to safeguard your projects.

What Really Changes When You Move From 3 Axis To 5 Axis CNC Milling Services?

The upgrade from three-axis to five-axis machining is more than the increase in the number of axes, but it represents an overall change in machining strategy. The overall strategy for the upgrade of CNC milling services to high-end purposes revolves around these developments.

5 axis CNC machining surpasses the spatial limitation of three-axis machining to efficiently manufacture complex parts.

Moving onwards from "Segmented Machining" to "Continuous"

In the three-axis machining of complex curved surfaces, using a ball end mill to “crawl” and mill with a short step distance of less than 0.1mm, the efficiency is low, and the machined surface has a coarse texture.

On the five-axis machining, by adjusting the lead/lag angle of the cutting tool, the side edge can take part in cutting, and thus the step distance increases to 0.5-1mm, and the efficiency increases by 3-5 times, while getting a smooth texture on the machined surface.

Core Benefits: Compact Tool, Improved Stiffness, Ability to Enter Cavities

Five-axis machining, by varying the workpiece position, is capable of using machining tools that have a length 40% shorter and diameter 25% larger in machining deep cavities or sidewalls, thus reducing tool chatter.

This advantage is particularly crucial in CNC milling for large parts, effectively avoiding dimensional deviations caused by oscillation and ensuring a stable surface finish of Ra 0.8μm for deep cavity parts.

Intelligent Tooling: 5 axis workholding solutions

We use modular electronically controlled fixtures as well as versatile support arrays to provide a stable clutch force independently of tool interference, enabling machining of over 90% of component features within a single setup. This intelligent tooling system enhances the accuracy of machining of 5-axis CNC parts by 40%.

Why Is Gd&T Not Just a Note On The Drawing For 5-Axis Machined Parts?

GD&T (Geometric Dimensions and Tolerances) is the core communication language for 5 axis CNC machining GD&T. GD&T goes beyond being a notation in the drawing, being instead a "process design blueprint" that governs the whole 5-axis machining operation, defining the precision of the CNC mill service.

DRF: The "Command Center" of 5-Axis Machining

Design datums need to be translated in turn into machining and inspection datums on the machine tool. This is termed datum system establishment. A one-shot 5-axis clamping procedure accurately retains this datum system in addition to preventing errors in the datum transfer during multi-clamping, as all the features are machined with one datum.

Geometric Tolerances are the Reflection of 5-Axis Value

The positioning, profile, and tilting tolerances are the primary indicators in the assessment of the spatial accuracy of a 5-axis machine.For instance, if the drawing calls for a positional accuracy of φ0.05mm, it is a challenge to achieve this through three-axis machining because of the offset of the datum. However, through five-axis machining, the positional error is within ±0.005mm.

Has your drawing’s GD&T annotations been reviewed for five-axis machining? Upload your 3D model and drawings, and JS Precision’s team of GD&T experts will have your annotations checked for you at no cost where you can be provided suggestions for improvement in order for your 5 axis machining services to be in line with your design requirements.

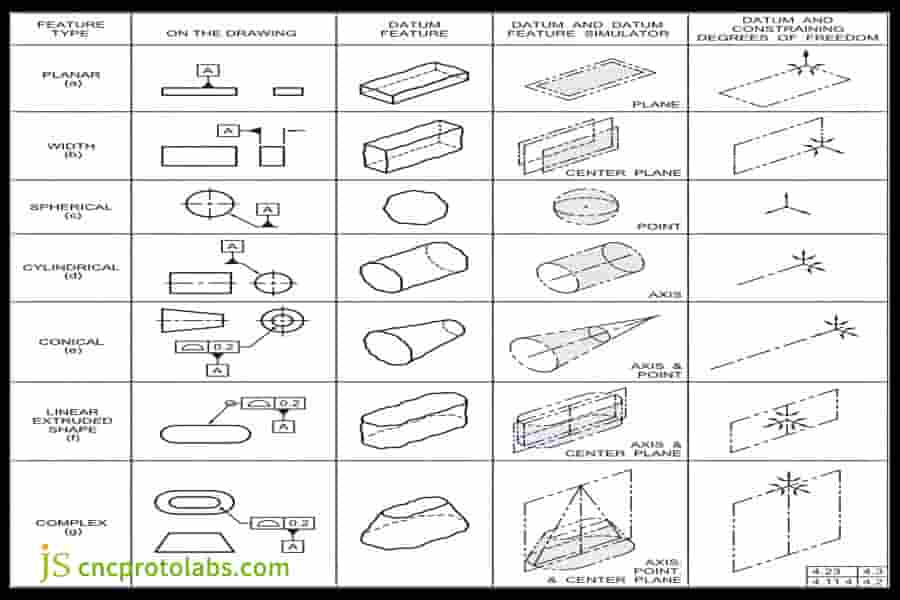

Figure 1 This table lists different benchmark features, how they limit degrees of freedom, and how benchmark feature annotations are displayed on technical drawings.

Figure 1 This table lists different benchmark features, how they limit degrees of freedom, and how benchmark feature annotations are displayed on technical drawings.

What Are The Hidden Hurdles In Implementing Gd&T For Complex Geometry?

Transforming GD&T symbols on drawings into qualified 5 axis cnc parts requires engineers to overcome two core challenges, which is also the key difference between professional five-axis service providers and ordinary machining companies.

The implementation challenges and corresponding costs of GD&T at different difficulty levels are shown in the table below:

| GD&T Difficulty Level | Typical Characteristics | Main Challenges | Applicable Tolerance Grade | Inspection Equipment | Conventional Response Cost (USD/piece) | JS Precision Optimization Cost (USD/piece) | Delivery Cycle Reduction Percentage |

| Beginner | Basic Position, Parallelism | Datum Alignment Deviation | IT7-IT8 | Ordinary Coordinate Measuring Machine | 80-120 | 60-90 | 15%-20% |

| Intermediate | Complex Profile, Tilt | Insufficient Measurement Accessibility | IT5-IT6 | High-Precision CMM (Hexagon GLOBAL S) | 200-300 | 150-220 | 25%-30% |

| Advanced | Spatial Position, Composite Tolerance | Data Flow Error | IT3-IT4 | CMM + Laser Scan (Leica T-Scan) | 400-600 | 300-450 | 30%-35% |

Measurement Accessibility: Can your CMM probe access the target area?

Difficult-to-access internal features in circular surfaces are common and create measurement obstacles. Without adequate planning, it would be difficult to check the tolerance in machining the part. The assessment of inspection tools takes place during the Design for Manufacturing process, where we set up tailored inspection tools, such as the use of lasers when needed.

Model-Based Definition (MBD) and Data Transfer

Model-based definition (MBD) has also emerged as a trend within high-end manufacturing, requiring 3D PMI models that can directly transmit GD&T information.

This requires smart compatibility between CAM programming systems and the inspection software. In this case, we provide zero-error data transfer between the Siemens NX system and Hexagon inspection software to ensure this characteristic of expert cnc machining 5 axis services.

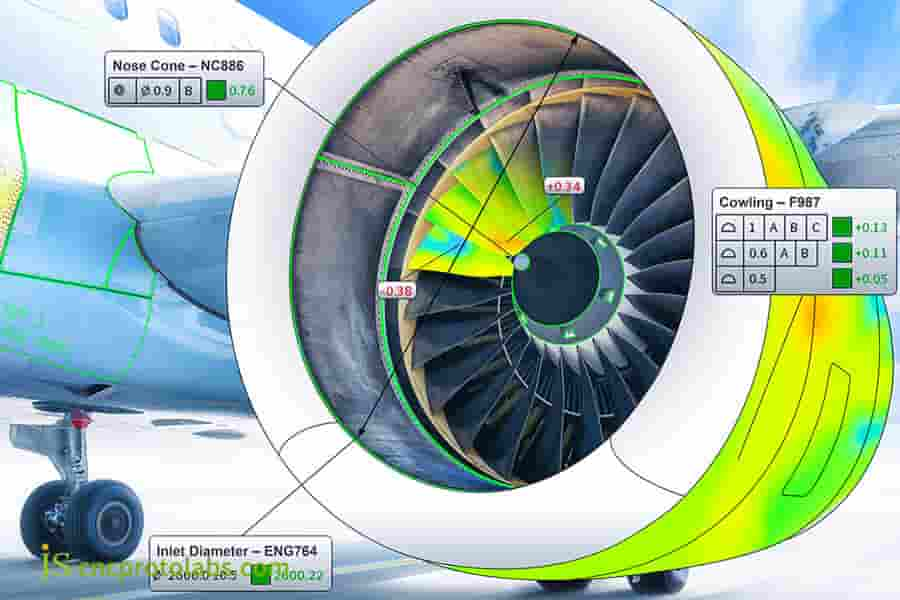

Figure 2 GD&T can embed CAD models, and when conducting inspections and measurements, with the correct software, GD&T will automatically evaluate them for you.

Figure 2 GD&T can embed CAD models, and when conducting inspections and measurements, with the correct software, GD&T will automatically evaluate them for you.

How Does Full Material Traceability Build Trust In Every Custom 5 Axis Machined Part?

In high-end fields like aerospace and medical, the reliability of material directly decides the safety of products. The completeness of a material traceability system is indispensable in 5 axis machining services and constitutes one of the key factors whereby JS Precision has been successful in gaining customer trust.

Material certification is important for what reasons?

Material properties are the very base of part functionality: strength, hardness, resistance to corrosion, among others.

Material certification, like MTC/MTR, serves as the "identity card" for materials to ensure conformance to international standards such as ASTM and ASME. It also prevents the use of any inferior material lots and makes sure that each lot of material meets the design requirements.

From Furnace Number to Finished Product: Full-Process Traceability

- Procurement from internationally certified suppliers, obtaining original material certificates.

- Rapid chemical composition analysis using a spectrometer upon warehousing, to verify conformity with the certificates.

- Batch management of inventory, recording material batch numbers during processing.

- The final delivery shall be supported by a complete material file comprising furnace number, chemical composition, and mechanical properties.

How does material consistency affect processing stability?

The certified material has a more stable heat treatment process and mechanical properties, enabling the cutting parameters to be more aggressive, thus providing over 20% improvement in the efficiency of CNC machining and preventing tool damage because of the soft spots in the material.

Need to find a service provider with complete material traceability for high demand projects? Please inform us of your material grade (such as 7075-T7351, titanium alloy Ti-6Al-4V), and JS Precision will provide you with corresponding material certification samples and traceability process instructions, so that the reliability of custom 5 axis machined parts can be traced.

From Design To Delivery: What’s The Journey Of a Custom 5 Axis Machined Part?

Excellent custom 5 axis machined parts begins with a standardized and team-working manufacturing process. There are three steps to this by JS Precision to ensure accuracy throughout the process from design to delivery.

Step 1: DFM Collaboration and GD&T Confirmation

Conduct manufacturability analysis based on the 3D models and requirements of GD&T, together with our clients, to validate the initial solutions, rationalization of tolerances, and test strategies because it helps prevent any design-manufacturing contradictions.

Step 2: Virtual Manufacturing and Program Verification

With the use of the Vericut software, the full process motion of the machine tool is simulated, and there is the verification of material removal and optimization of the tool path. This virtual manufacturing technique allows for the early detection of 99% of all potential problems that can occur, thus ensuring that the process is done in a safe and efficient manner.

Step 3: First Article Closed-Loop Verification and Mass Production

The first article is machined, and then a CMM inspection is performed to verify the part fully dimensional with respect to the GD&T requirements, producing a FAIR report. The process parameters and programming data, now confirmed, are then locked for mass production.

Would you like to know the exact process from design to delivery of your part with our 5 axis manufacturing capabilities? Simply provide your part requirement, and JS Precision will develop a production plan for you with our progress tracking services so you can see our 5-axis machining process.

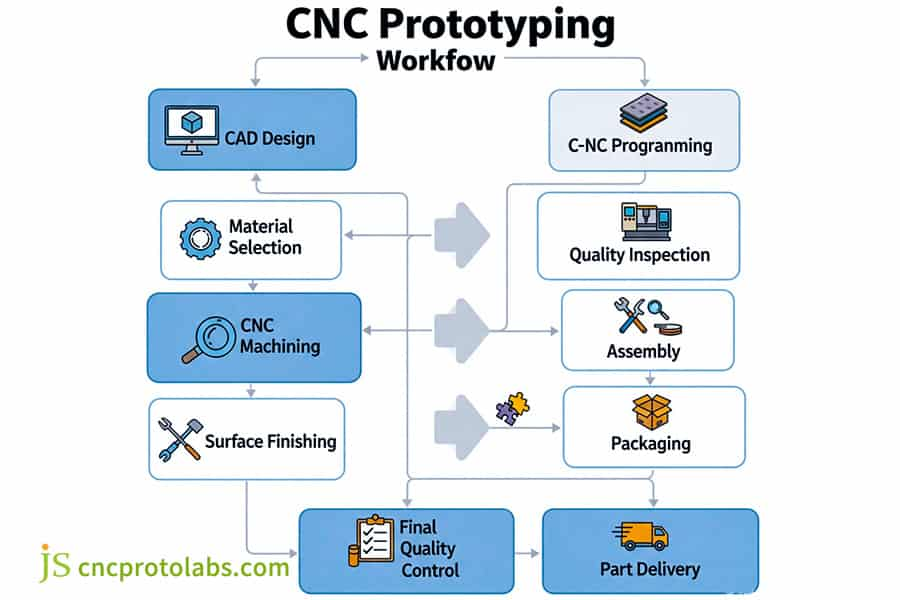

Figure 3 The CNC prototyping process can be decomposed into a series of logical steps from the initial idea to the moment of obtaining the final product.

Figure 3 The CNC prototyping process can be decomposed into a series of logical steps from the initial idea to the moment of obtaining the final product.

Can Advanced 5 Axis Machining Services Actually Lower Your Total Cost?

Many customers believe that 5 axis manufacturing has a high unit price, but in reality, 5-axis CNC machining can significantly reduce overall costs through process integration, which is the core logic of CNC milling machine cost optimization.

The cost comparison data for three-axis and five-axis machining of different types of parts is shown in the table below:

| Part Type | Machining Characteristics | Machining Material | Key Tolerance Requirements | Three-axis Machining Cost (USD/piece) | Five-axis Machining Cost (USD/piece) | Cost Reduction | Production Cycle Reduction Percentage |

| Aerospace Bracket | Multi-angle mounting surface, deep cavity (depth-to-diameter ratio 8:1) | Titanium alloy Ti-6Al-4V | Position accuracy φ0.05mm, flatness 0.02mm/m | 1200-1500 | 900-1100 | 20%-25% | 30%-35% |

| Medical Connector | Complex curved surface, precision hole system (hole diameter φ3mm±0.005mm) | Stainless steel 316L | Contour accuracy 0.03mm, perpendicularity 0.01mm | 800-1000 | 600-750 | 18%-25% | 25%-30% |

| Automotive Precision Parts | Multi-directional tilting hole, positioning groove | Aluminum alloy 6061-T6 | Position accuracy φ0.1mm, parallelism 0.05mm | 600-800 | 450-600 | 15%-22% | 20%-28% |

Saving the cost of special fixtures

If a workpiece needs to process several inclined holes, three-axis requires designing and manufacturing three sets of special angle fixtures, with the cost as high as $8,000, and the time it takes for debugging is long, five-axis only needs a standard vise. Directly save the cost of fixture and reduce the time used in designing fixtures. Price differences can be offset by fewer numbers of productions.

Process combination

Large-part three-axis machining involves transferring the parts three times on three machine tools, with an approximate handling and realignment time of 8 hours, and there's a risk of collision, five-axis machining can accomplish surface machining all in one setup, saves more than 60% of the handling time, reduces the risk of collision to zero, and reduces scrap rates resulting in an overall cost reduction of 15%-25%.

How To Vet a Professional 5 Axis CNC Machining Partner: A Technical Checklist

Choosing a reliable 5 axis machining services and 5 axis workholding solutions partner requires focusing on technical and management depth. The following checklist helps you accurately assess their capabilities:

Machine Tool Brand and Configuration

| Check Items | Professional Standards | JS Precision Configuration | Performance Parameters | Industry Average |

| Machine Tool Brand | Top-tier brands such as DMG, Mazak, and Haas | DMG DMU 50, Mazak INTEGREX i-400, DMG DMU 65 | Service life ≤ 5 years, failure rate ≤ 1% | Service life ≤ 8 years, failure rate ≤ 3% |

| Core Functions | RTCP tool tip tracking, 5-axis linkage function | All series of equipment support RTCP, 5-axis linkage response speed ≤ 0.001s | RTCP compensation accuracy ≤ 0.002mm, linkage smoothness ≥ 99.5% | RTCP compensation accuracy ≤ 0.005mm, linkage smoothness ≥ 98% |

| Rotary Axis Accuracy | Within ±3 arc-sec | ±2 Arc-sec, repeatability ≤0.002mm | Positioning accuracy stability ≥99.8%, annual drift ≤0.001mm | Positioning accuracy stability ≥99%, annual drift ≤0.003mm |

| Auxiliary Configuration | In-line probe + tool magazine + cooling and filtration system. | Renishaw SP25 in-line probe, tool magazine capacity 24-40 tools, high-precision cooling and filtration system (filtration accuracy 5μm). | Probe repeatability ≤0.001mm, tool change time ≤2s, coolant cleanliness ≥NAS 8. | Probe repeatability ≤0.003mm, tool change time ≤3s, coolant cleanliness ≥NAS 10. |

Quality System and Software Ecosystem

- Does it have AS9100/ISO13485 certification?

- What CAM software is used? (Professional grade: Siemens NX, Hypermill)

- Can you provide complete GD&T measurement reports and material traceability documents?

Case Study: Cost Reduction Of 25%: How 5 Axis Integrated Machining Reshapes Aviation Sensor Brackets

Challenge

The aerospace customer’s sensor mount is made from titanium alloy Ti-6Al-4V and contains three multi-angle-mounting interfaces and a lightweight cavity with dimensions of 120mm depth.

The conventional three-axis process consisted of four parts that had to be machined and subsequently welded together. The welding process introduced large errors in terms of flatness and positioning accuracy of critical mounting surfaces (only 0.2mm), which directly affected the production output of only 75%. The correction process had a cost of $500 per piece.

JS Precision Solution: Design Integration

Design integration: Redesign the welded components as a single integral part, optimize the internal ribs through topology design, and reduce weight by 10% while retaining strength.

Process Innovation: The Feature machining was carried out on a 5-axis titanium alloy dedicated machining center from Mazak. All feature machining was done in one operation. The high-efficiency roughing operation (cutting speed of 150m/min) can be achieved through 5-axis simultaneous-side milling, and finally, there is contour finishing.

5 axis CNC machining GD&T Control: The φ0.05mm positional accuracy specification requirement has strictly been adhered to in the drawings. Dimensional inspection with GD&T has been done by Hexagon CMM, and the FAIR report has been produced after the machining process.

Outcome

The positional accuracy of critical mounting points remains within a constant deviation of 0.05mm, enhancing accuracy by 300%, removing welding and alignment operations, thereby reducing the production cycle from 12 hours to 7.8 hours (a reduction of 35%), and decreasing the total cost of manufacturing by 25%, increasing yield to 99.7%, and supplying the certified processing history of the raw material.

If you too are experiencing issues of a lack of accuracy and high costs involved in machining complicated parts, share your project issues. JS Precision will personalize a similar solution for you so that 5 axis cnc parts will become accurate as well as economical for you.

Figure 4 CNC machining of aviation titanium alloy bracket

Figure 4 CNC machining of aviation titanium alloy bracket

FAQs

Q1: What is the smallest batch size that should be machined by 5-axis machining? Can it be used for prototypes?

Five axis machining is fully suitable for prototype production, with a minimum batch size of as low as 1 piece. Its flexibility can reduce the need for specialized tooling, allowing complex prototypes to land faster. At the same time, the accuracy of the prototype is consistent with that of mass-produced parts, and can be directly used for assembly testing.

Q2: What is your five-axis machining surface finish (Ra) capability?

The surface finish of Ra 0.8µm can be achieved by optimizing tool paths and cutting conditions in aluminum alloys, whereas Ra 1.6µm can be achieved in difficult-to-cut materials like titanium alloys by modifying variables based on material characteristics.

Q3: How do you deal with tool vibration when machining?

We adopt the dynamical milling programming algorithm alongside the Real-Time Spindle Vibration Analyzer. By adjusting the cutting speed, feed rate, and overhang, we eliminate the chatter vibration. This makes our machines very stable and delivers precise surfaces.

Q4: What kind of certification documents regarding materials do you offer?

The test report formats that can be provided include material test reports (MTR/CMTR) that comply with AMS, ASTM, and/or GB standards, which include essential details such as furnace number, chemical composition, mechanical properties, and heat treatment status.

Q5: If my design doesn't have any annotations related to GD&T, can you help me add those?

Yes. Professional suggestions for GD&T annotations will be made by our engineering team regarding the part assembly function and use case. The team will examine the manufacturability at the same time to ensure the annotations made are logical and manufacturable.

Q6: How can you avoid any kind of technical misunderstandings in remote communication?

We incorporate the review process using 3D PDF or Teamcenter collaboration platforms. All the technical requirements as well as the proposals made with regard to modifications are marked on the 3D model, and both parties confirm synchronization with regard to design as well as manufacturing on their part.

Q7: How would you support clients in the event of issues during part assembly?

Firstly, we would immediately begin a root cause analysis, obtain the process records, GD & T inspection results, and material certifications for this production batch of parts, as well as send engineers to work together with the customer to analyze the issue, so that the project can continue smoothly.

Q8: Compared to local 5-axis providers in Europe and America, what are your advantages?

We have equally sophisticated machine tools, engineering technology, and quality systems, but by taking advantage of the supply chain efficiency of China’s manufacturing, we can cut the cost of CNC milling machines by 20%-30% with shorter production cycles.

Summary

5-axis CNC machining and inspection is not merely technology enhancement in machines but a philosophy of manufacturing that ensures the accurate execution of complex designs.

JS Precision’s strong base in top-class 5-axis machines, bridging the communication divide in design and manufacturing through the use of GD&T, and the reliability platform established through material traceability in the manufacturing process, bring together the ideal harmony of precision, speed, and cost.

Your complex parts deserve matching professional manufacturing capabilities.

Please send us your key component designs. You will receive not only a CNC milling service quote, but also a "Five-Axis Manufacturing Feasibility and GD&T Implementation Analysis Report" prepared by our senior process engineers, clearly demonstrating the best path and potential optimization space to achieve your design intent.

Let us work together to transform precision into a definite advantage for your products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com