What is CNC machining? It is much more than just replacing human labor with machines. As the core of modern precision manufacturing, today's CNC machining is far more than just simple automated processing, it is complex digital design translated directly into extremely consistent physical parts.

This article will introduce, in a scientific way, the essence of precision CNC machining and reveal the key points of the whole process from choosing a CNC machining center to managing CNC machining tools, and directly introduce how to design to optimize and control CNC machining cost. Choosing a global manufacturing partner who is well versed in this field will be the key to the success of your project.

Core Answer Table

| Core Issues | Common Misconceptions/Challenges | JS Precision's Solutions |

| Boundaries of Definition and Capability | Looking at CNC as just ordinary automation sells its potential for precision and flexibility short. | Scientific Definition: CNC is a method of precision subtractive manufacturing based on digital directions that represent the very basics of accomplishing complex designs. |

| Precise Achievement Core | Note that accuracy only can depend on the brand of machine tool, and the systematic control of process is ignored. | Full-chain precision management: thermal stability, intelligent tool management, and closed-loop compensation have established a traceable precision assurance system. |

| Cost Optimisation & Design | Focus on quotation prices alone ignores the basic impact of design on total cost. | DFM Collaboration and TCO Analysis: Early Intervention in design optimisation with fully transparent cost analysis to achieve real cost reduction. |

| Equipment and Process Selection | Inefficient investment arises when the chosen equipment selected has too much or too little functionality. | Demand Matching and Technical Consulting: Recommend the most suitable CNC machining center and process chain according to your part matrix and objectives. |

| Industry-Specific Requirements Answer | Industries like medical and aerospace have very specific requirements that general suppliers cannot fulfill. | Industry-Specific Solutions: Having relevant certifications and experience, provision of materials, processes, and documentation support to comply with specific industries. |

Key Takeaways:

- CNC is the foundation of today's precision manufacturing. The value of CNC rests in the ability to take a digitally designed part and translate that into a highly complex physical part.

- The objective of ultra-high precision is of a systemic project that needs very good equipment, a severe process, and the circle of quality control.

- Design is responsible for most of the manufacturing costs. DFM is the shortest and best road to cost reduction and efficiency enhancement through an early collaboration with manufacturing experts.

- In choosing JS Precision, based in China, you'll get the exact quality of precision CNC machining that international standards would provide, combined with superior supply chain efficiency and cost advantages.

CNC Machining Guide: JS Precision Helps You Make Decisions

I'm a senior mechanical engineer at JS Precision. Our firm has been deeply involved in precision CNC machining for 15 years, targeting the most demanding machining service jobs and delivering quality parts to customers worldwide.

In the last 15 years, we have served over 5,000 clients from core industries: aerospace, medical, semi-conductor, and have completed close to 100,000 precision parts machining projects.ISO 13485:2016 stipulates explicitly the norm of quality control in the precision machining of medical parts, and we have already acquired this certificate.

We have produced implants of biocompatibility for an American medical device company and met the rigorous standards that the medical industry put forward, for a European aerospace company, we machined structural parts made of titanium alloy and met ultra-high tolerance requirements of ±0.005mm with a pass rate consistency of 99.8%.

We are familiar with the performance difference of all kinds of CNC machining center and can find the right matching of tool-materials precisely for CNC machining tools, having accumulated plenty of successful cases about optimization of CNC machining cost.

This guide is a conclusion of practical experiences, every suggestion has been validated in the production, so you can refer to it with confidence.

Want a precision machining solution for your industry in the shortest time? Submit your part machining requirements now for free, and get a preliminary feasibility analysis report from JS Precision. By using our internationally standardized machining capability, we help you avoid risks in early decision-making.

What Is CNC Machining: Beyond Simple Automation

Understanding "what is CNC machining" is the foundation for starting precision manufacturing, and it is not simply machine automation processing. It is a kind of digital manufacturing technology with the core of computer programs, the key link from digital design to physical parts, and it can turn your innovative ideas into tangible products.

From Code to Metal: Demystifying the Core Working Principle

The essence of CNC machining lies in its program drive. We transform the three-dimensional drawing of a part into G-code and M-code. These codes explicitly determine the trajectory of motion, the parameters of cutting, among other things, of the CNC machining center.

After the machine tool starts, the control system interprets the code in driving the movement of components harmoniously and accomplishes machining through milling, turning, and other processes. All the processes are controlled by a computer, hence eliminating human error.

Unique Advantages of CNC: Why it's the Mainstream Choice in Modern Manufacturing

The most outstanding features of CNC machining, in comparison with traditional machining, are the following:

- Adaptability to complex machining: It can easily finish the machining of complex surfaces, deep cavities, and other features which cannot be easily realized with traditional machine tools.

- Extreme high consistency: The parts produced in batches are with consistent dimensional precision, whose qualification rate is far beyond the traditional machining.

- High efficiency: it allows to carry out machining in continuum and with the possibility of increasing the production capacity by integrating the automation.

- Flexibility in production: Since the changeover needs only program changes, responses to multi-variety and small-batch demands are quick.

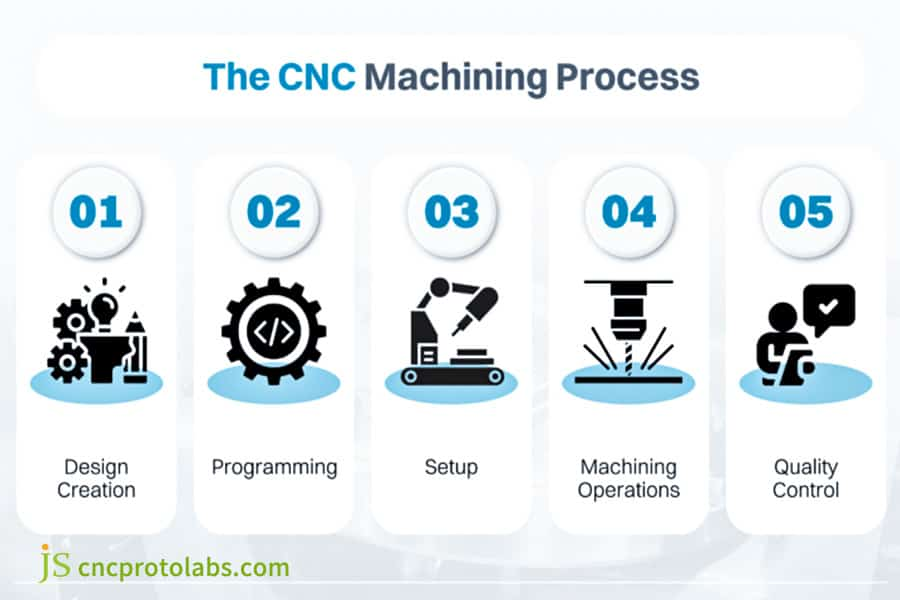

Figure 1 The CNC machining process consists of a few important steps, from initial design to quality control.

What Factors Affect The Accuracy Of Precision CNC Machining?

Precision CNC machining accuracy is derived from a series of mechanical components, environment, and process interactions. The definitions for tolerances are well-defined within ASME Y14.5-2009, Dimensioning and Tolerances. We have broken down the core influencing factors below based on this standard.

Machinery and Environmental Stability

- The accuracy and rigidity of machine tools: The geometric and positioning accuracy of the CNC machining center lays the foundation. JS Precision uses high-rigidity machine tools to solidify this foundation, ensuring that the accuracy can meet ±0.001mm tolerance.

- Thermal Deformation Control: The dimensional deviation caused by the heat of the spindle and the difference in the ambient temperature is avoided-a 20±2℃ constant-temperature workshop and thermal compensation technology.

- Tooling System: The dynamic balance and wear of CNC machining tools directly affect accuracy. We adapt the tools according to the material and monitor them in real time.

- Fixtures and Clamping: Some custom-designed fixtures and optimized clamping method are performed in order to prevent from deformation and to guarantee datum stability.

- Tooling System Performance: Dynamic balance, clamping rigidity, and the wear condition of the CNC machining tools are very important. Poor dynamic balance causes vibration, while wear decreases surface finish. We apply tools adapted to the workpiece material and provide real-time wear monitoring.

- Fixture Design and Clamping: Improperly designed fixtures might result in clamping deformation and misalignment of the datums. We design special fixtures for each part, optimizing the clamping force and methods of positioning to ensure consistent and stable datum alignment.

Full Performance of the Tooling System

CNC machining tools are the "teeth" that will be in direct contact with the material. Therefore, dynamic balance, clamping rigidity, and wear conditions are very important.

Poor dynamic balance causes cutting vibration, loose clamping affects the positioning accuracy, and tool wear will reduce the surface finish and dimensional consistency. We select suitable tools according to the workpiece material and perform real-time monitoring of tool wear.

The "Art" of Fixture Design and Workpiece Clamping

The function of a fixture is to fix the workpiece. Its inappropriateness leads to deformation during clamping, which results in machining datum misalignment. We design different kinds of dedicated fixtures for optimizing clamping force and positioning methods to ensure consistent and stable machining alignment of datum.

| Influencing Dimensions | Key Factors | JS Precision Solutions |

| Mechanische Stabilitt | Precision and rigidity of machine tools | ± 0.001mm high rigidity machine tool |

| Environmental Control | Temperature Fluctuation | Constant Temperature Workshop + Thermal Compensation Technology |

| Tooling System | Dynamic Balancing, Wear | Dedicated Matching + Real-time Monitoring |

| Clamping Process | Fixture Design, Clamping Deformation | Customized fixtures & optimization solutions |

Demystifying Tools For High-Performance CNC Machining

CNC machining tools are the core composition of CNC machining center. It directly influences efficiency, quality and CNC machining cost to choose and manage them. The following are scientific selection and management methods.

Scientific Selection of Tool Materials

- Material Matching: PCD tool adoption is done to prevent sticking of tools on aluminum alloys. CBN is used for hardened steel due to a loss in hardness, and cemented carbide due to its high cost-effectiveness for ordinary steel.

- Optimizing Parameters: The rake angle and clearance angle, among others, are adjusted in relation to the material and procedure for balancing cutting force, chip removal effect, and surface quality.

Intelligent Tool Lifecycle Management

- Wear Prediction and Compensation: Models are built using the cutting force data in order to plan in advance the tool change and make compensation with the machine tool to offset the deviations.

- Standardized Management: Through an enterprise-level tool database, solutions for various situations can be accessed in a click to reduce the preparation time.

| Tool Materials | Workable Workpiece Materials | Central Benefits |

| hard metal | Ordinary steel, cast iron | High cost-effectiveness, versatile |

| PCD | Aluminum alloy, copper alloy | Sharp, non stick knife |

| CBN | Hardened steel, high-temp alloy | High hardness, wear-resistant |

Want to find the best tooling solution for your parts? Please submit your workpiece material and machining requirements, JS Precision will provide you with free tool selection suggestions for the best reducing CNC Machining cost and improving precision CNC machining efficiency.

Figure 2 In CNC machining, choosing the appropriate cutting tools is crucial for obtaining precise and efficient machining results.

How To Choose The Right CNC Machining Center For Your Needs

Choosing a suitable CNC machining center is very crucial in precision CNC machining. The result of blind selection will be either waste in investment or inefficiency. Herein is a clear selection strategy:

Define Your Technical Needs Matrix

- Determine Technical Requirements: Choose machinery depending on part sizes, tolerance levels required, and geometry involved-for example, five-axis capability.

- Consider Materials and Batch Size: Hard material machining requires high-rigidity equipment, mass production requires equipment compatible with automation integration.

Beyond the Specification: Evaluate the "Soft Power"

- Digital Capabilities: Equipment shall be fitted with data interfaces and status monitoring functions, and shall also allow for smart manufacturing upgrades.

- Supplier Strength: Preference shall be given to the supplier who has an in-depth process support capability rather than merely sale of hardware.

Not sure which CNC machining center is suitable for you? Provide your part requirements and production plan, and let JS Precision offer you a tailored equipment selection solution to avoid waste investment and make more efficient precision CNC machining.

Design For Economy: Which Factors Inflate Your CNC Machining Cost?

Few customers realize that more than 70% of the CNC machining cost is fixed in the design stage. Some designs which sound reasonable turn out to be "cost amplifiers." Let me explain in detail what the main cost factors are.

Hidden Taxes from Geometric Complexity

- Excessively Tight Tolerances and Surface Finishes: Shallow raising in the levels of tolerance and mirror finishes below Ra 0.4 result in exponential increases in machining and inspection costs.

- Complex features: Deep cavities, micro-holes, etc., need special tools and multi-stage clamping, which cause a significant increase in machining time.

Explicit Effects of Materials and Logistic

- Material Use: Nonstandard sizes command high premiums, while unreasonable designs increase waste of materials.

- Anodizing, Heat Treatment: These subsequent processes raise costs and prolong delivery times.

| Cost Driving Factors | Percentage | Essential Effect |

| Tolerances and Surface Finish | 30%-40% | The higher the requirements, the more cost increases. |

| Geometric Complexity | 25%-35% | Increases machining difficulty and time. |

| Utilization of Raw Material | 15%-20% | Non-standard material and high waste increase the cost. |

| Post-processing | 10%-15% | Additional processes increase labor consumption. |

Saving Strategies: Proactively Reducing CNC Machining Expenses

Reducing the CNC machining cost requires scientific design optimization and production management, rather than simply lowering prices. The following are practical cost reduction strategies.

Design-Driven Optimization: DFM in the Design Phase

- Standardization of Design: Standard drill bits and equal fillets reduce complex surfaces, avoiding custom-made tools.

- Optimized Clamping Structure: Implement the process bosses, which help in maintaining uniform wall thickness for achieving the machining in one clamping.

Lean Management at the Production Level

- Process and Batch Optimization: Centralize the production of similar parts to distribute programming and tool change costs.

- Total Cost of Ownership Perspective: Comprehensively consider yield rate and on-time delivery rate to avoid rework and delay losses.

Would you like to systematically reduce the CNC machining cost? Please enquire with JS Precision's cost optimization consultants. We work out cost-reduction solutions for you at every step, from design and process right through to production, it helps customers save an average of over 20% on manufacturing costs, making precision CNC machining more cost-effective.

Figure 3 Engineer Performing Design For Manufacturability (dfm) Analysis In Cad Software To Reduce Cnc Machining Costs.

Key Industries Transformed By Precision CNC Machining

Precision CNC machining has become an indispensable manufacturing technology with high precision, consistency, and complexity for a majority of core industries. The application characteristics of these industries can allow you to better align quality requirements. The following are some key application industries:

- Aerospace & Defense: Requires lightweight, high-strength parts, tolerances of ±0.005mm for the structure parts made of titanium alloy.

- Medical & Life Sciences Implants require biocompatible materials, surgical instruments require a mirror-like finish. Our pass rate has exceeded 99.5% for five consecutive years.

- Semiconductor & Optoelectronics: Dimensional stability is so high in vacuum chambers and other parts that specialized processes and cleanrooms are needed.

Case Study: From 14 Days To 72 Hours: Medical Endoscope Component Development Accelerates By 85%

The following case study from the medical industry vividly demonstrates how we solve our clients' pain points of long R&D cycles and high costs with precision CNC machining.

Challenge: Iteration Speed Cannot Keep Up with Clinical Feedback

A medical device company was developing a new generation of orthopedic endoscopes. Its main structural parts are made from 6-series aluminum alloy and consist of many thin-wall features with a tolerance requirement of ±0.015mm.

The company previously followed a conventional outsourcing model. Every verification took 14 days, and during mass production, some serious problems such as poor sealing performance and clamping deformation happened, which delay the project schedule seriously. CNC machining cost also overshot the budget by 30%.

The Integrated Solution at JS Precision

Our engineers were heavily involved in the design of the prototypes. From the DFM analysis, they found out that three of the original sheet metal welded parts had assembly gaps, which meant poor sealing.

We recommended switching to an integral, single-part aluminum component for precision CNC machining. This greatly improved part rigidity and sealing performance while reducing assembly steps.

Simultaneously, one small-batch and fast response process was adopted, using a standardized library to avoid customization time. This allowed programming, material preparation, and equipment debugging to be done simultaneously while the processed videos and inspection data were shared with the customer in real-time.

We also prepared a detailed cost breakdown report: while the total cost of the aluminum material increased by 10%, the final product assembly reduced its cost by 35%, and the sealing test cost by 50%.

Quantifiable Outstanding Results:

After optimization, this single iteration time was reduced from 14 days to 72 hours, accelerating development by 85%, overall CNC machining cost by 22%, and the pass rate of the part sealing from 88% to 99.9%, the last product entered clinical testing 5 months ahead of time, successfully seizing market advantage.

This case also represents how high-quality, precision CNC machining services can be used to create immense business value for customers.

Would you like to efficiently accelerate your development and precisely reduce costs for your precision parts? Now send us your request for quotation of the parts, and JS Precision will tailor a dedicated CNC machining solution to replicate the outstanding results in this successful case for you.

Figure 4 Aluminum alloy orthopedic endoscope parts

JS Precision: Your Global, Highly Responsive Partner For Precision CNC Machining Solutions

It describes them as a globally trusted precision CNC machining partner, whose core strengths lie in its comprehensive advantages of technology, cost, and service.

We are equipped with the most advanced CNC machining center with high-speed milling and five-axis CNC machining functions, with a positioning accuracy as high as ±0.001mm.

Our professional team realizes intelligent selection and monitoring of CNC machining tools. We provide detailed CNC machining cost optimization and DFM reports to customers, controlling the cost from its very source.

Based in the manufacturing hub of China, we offer standard prototypes within 3-5 business days. Our quality standard is certified according to ISO9001 and ISO13485 standards for the medical industry. Whether serving prototypes or mass production, whether for the aerospace, medical, or semiconductor industries, we can offer customized solutions.

FAQs

Q1: What is a typical lead time for prototyping with CNC machining?

If the CNC machining prototype is of a simple structure and with common materials, the normal delivery time is 3-5 business days. In cases of a complex part structure, when special materials are needed, or when high-precision machining is involved, the delivery time will extend from 5-10 business days. For urgent project processing, JS Precision will offer expedited processing.

Q2: What is the smallest feature size you can machine?

Based on our advanced CNC machining center and professional CNC machining tools, we are able to machine reliable micro-holes with a diameter of 0.5mm and narrow grooves with a width of 0.3mm. As in specific machining, the ability depends on the depth ratio of materials, hardness, and actual running condition of the machine tool.

Q3: What file formats do you require for a quotation?

First, we prefer a 3D STEP or IGES format file, while at the same time needing 2D PDF drawings. Drawings shall clearly state requirements such as tolerance, material, surface treatment, and other important information. Our system supports the uploading of drawings online and their real-time analysis and evaluation.

Q4: How do you ensure the confidentiality of my design?

For confidentiality, we sign strict NDA with our client, and an encrypted secure file transfer system for file transfer. Regarding special confidentiality requirements in projects, we may involve them even in a completely isolated production and management process to comprehensively protect your design intellectual property.

Q5: What surface finishes can you achieve?

By conventional milling, we are able to achieve a surface finish of Ra 0.8μm. With finishing and polishing processes, we can achieve a mirror finish to Ra 0.1μm. We will recommend the best surface treatment solution based on the actual functional requirements of the part.

Q6: Do you provide assembly and post-processing services?

Yes, we have one-stop service, including but not limited to different post-processing techniques: anodizing, sandblasting, heat treatment, laser engraving. We can also do simple assembly work on parts to ensure that you have a ready-to-use finished product without any intermediate steps.

Q7: Are you able to work with my existing design, or do you offer design assistance?

Both. You can provide us with mature design drawings for strict manufacturing, you can also invite us to join at the stage of design, letting our professional DFM analysis service optimize your design for cost reduction.

Q8: What are some of the advantages of sourcing with a China-based CNC shop such as JS Precision?

The core advantages are threefold: first, obtaining precision CNC machining quality that meets international standards, second, enjoying large CNC machining cost advantages, shrinking overall manufacturing costs, and third, counting on a mature supply chain for rapid delivery and flexibility.

Summary

From skill to precision science, a whole new world is unfolding in the area of CNC machining. In 2025, choosing the right manufacturing partner will be the name of the game-one that can deeply integrate advanced equipment, a closed-loop process, and an agile response.

With its advanced CNC machining center, professional CNC machining tools management, scientific cost control, and rich industry experience, JS Precision could offer you a full turnkey solution from the design optimization to mass production.

Make precision manufacturing your source of differentiation.

→ Upload your drawings now and get instant quotes with suggestions for process optimization, created by in-depth DFM analysis.

→ Set up a consultation with a specialist to get answers to industry particular needs and cost reduction/efficiency improvement solutions from our application engineers.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com